Professional Documents

Culture Documents

HSD Unloading Sop

HSD Unloading Sop

Uploaded by

Vikas KumarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HSD Unloading Sop

HSD Unloading Sop

Uploaded by

Vikas KumarCopyright:

Available Formats

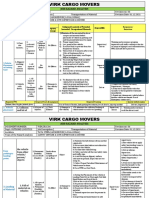

STANDARD OPERATING PROCEDURE FOR RECEIVING DIESEL AT RIGS.

CHECKS BEFORE TANK TRUCK UNLOADING

1. CHECK TANKER TRUCK AND VERIFY THE SAME WITH CALIBRATION AVAILABLE WITH TANKER

TRUCK.

2. CHECK WHETHER SEAL/LOCK IS AVAILABLE AND PROPERLY PLACED.

3. RECORD TIME AT WHICH TANK TRUCK LEFT THE SUPPLY POINT AND TIME AT WHICH IT

REACHED RIG SITE. ALSO RECORD TOTAL TIME IN TRANSIT IT MUST REACH DRILL SITE WITHIN 03

HRS. INORDINATE DELAY IN TRANSIT MUST BE RECORDED AND REPORTED TO CONCERNED

AUTHORITY.

4. RECORD DENSITY AT AMBIENT TEMPERATURE.

5. CONVERT DENSITY AT AMBIENT TEMPERATURE TO DENSITY AT 15° C WITH THE HELP OF ASTM

TABLE 53B.

6. COMPARE ASTM DENSITY AT 15° C WITH THE DENSITY GIVEN IN INVOICE AT 15° C. THIS SHOULD

BE RANGE OF +- 3 ONLY.

7. ALLOW TRANK TRUCK TO REMAIN PARKED ON LEVEL SURFACE FOR 30 MINUTES.

8. SEAL/ LOCKS TO BE CHECKED AT ALL POINTS INCLUDE DOME COVERS.

9. MASTER VALVE TO BE RELEASED TO FILL DIESEL IN OUTLET PIPES.

10. CHECK CALIBRATION CERTIFICATE FOR DIP LEVEL AND PROOF LEVEL DETAILS AND VERIFY THE

SAME WITH THE MEASUREMENT RECORDED IN THE INVOICE.

11. CHECK AND VERIFY THAT DIP STICK IS NOT TAMPERED WITH AND CROSSCHECK THE READINGS

OF CALIBRATION CERTIFICATE FOR DIPLEVEL AND PROOF LEVEL DETAILS BY ACTUALLY

MEASURING IT.

12. CHECK FOR WEIGHTS AND MEASURE DEPARTMENT MARKING ON THE DIP ROD USED FOR

CHECKING DIESEL LEVEL IN COMPARTMENTS.

PROCEDURE DURING TANK TRUCK UNLOADING

1. CHECK PROOF LEVEL AND THE DIP LEVEL IN EACH COMPARTMENT.

2. TAKE SAMPLE FROM BOTTOM AFTER ALLOWING IT TO BE SETTLED ABOUT 30 LITRES OF DIESEL

TO BE COLLECTED IN A BUCKET FOR EACH COMPARTMENT.

3. CHECK WHETHER DIP LEVEL COMES DOWN TO THE EXTENT OF QUANTITY COLLECTED IN LITRES.

THIS ELIMINATES THE POSSIBILITY OF FAKE DIP TUBE.

4. CHECK FOR APPEARANCE, MEASURE DENSITY AND TEMPERATURE.

5. COMPARE DENSITY MENTIONED IN INVOICE @ 15° C WITH DENSITY MENTIONED IN ASTM

TABLE 53B @15° C.

6. USE WATER FINDING PASTE TO DETECT PRESENCE OF WATER.

7. UNLOAD THE TANK TRUCK IF ALL PARAMETERS ARE AS PER SPECIFICATION.

8. AFTER UNLOADING ENSURE TANK TRUCK IS COMPLETELY EMPTY AND INSIST DRIVER TO

MANOEUVRE THE TRUCK IN MOTION SO AS TO BE ABLE TO REMOVE RESIDUAL DIESEL.

SAFETY ASPECTS

1. ENSURE TO PLACE FIRE EXTINGUISHER NEARBY TANKER.

2. ALWAYS USE BRAIDED RUBBER HOSE (BONDED WITH COPPER WIRE) FOR UNLOADING. STRICTLY

DO NOT USE PLASTIC HOSE FOR UNLOADING.

3. ALWAYS ENSURE PROPER EARTHING OF THE TANK TRUCK TO DISSIPATE STATIC ELECTRICITY VIA

EARTH PIT.

4. DO NOT ALLOW ANY MATCH STICKS, CIGARS, ANY BURNING ELEMENT NEAR UNLOADING OR

STOARGE PLACE.

5. KEEP SAND BUCKETS READY IN ORDER TO COVER UP AND ABSORB SPILLAGE.

SOP FOR MONITORING INTERNAL CONSUMPTION

1. DIP LEVEL IN MAIN STORAGE TANK TO BE CHECKED/ RECORDED AT FIXED INTERVALS ON DAILY

BASIS TO ASSESS THE CONSUMPTION OF DIESEL.

2. BEFORE ANY DIESEL ISSUE (ABOVE 1000 LITRES), DIP LEVEL SHALL BE RECORDED BEFORE AND

AFTER THE ISSUE.

3. AUTHORIZATION/ APPROVAL FROM COMPETENT AUTHORITY SHALL BE TAKEN BEFORE ISSUE OF

DIESEL FROM THE MAIN STORAGE TANK AT SITES. SIMULTANEOUSLY, THE NAME AND

SIGNATURE OF RECEIVING OFFICERS/ PERSONNEL SHALL ALSO BE KEPT AS A RECORD.

SOP FOR MAIN STORAGE TANK

1. MAIN STORAGE TANK SHOULD EQUIPPED WITH DIP TUBE AND SUITABLE DIP STICK. DIP STICK

SHOULD HAVE PROOF LEVEL MARKING FOR BOTH STORAGE AND ACTIVE TANK.

2. RECORD DIP LEVEL IN MAIN STORAGE TANK BEFORE AND AFTER UNLOADING. COMPARE THE

SAME WITH TANK TABLE AND CHECK THAT AMOUNT OF DIESEL RECEIVED IS CORRECT.

3. WEEKLY DRAINING OF WATER FROM TANK BOTTOM.

4. PERIODIC IN HOUSE TESTING OF HSD SAMPLE FROM STORAGE TANK FOR DENSITY @15° C AND

WATER PRESENCE.

5. ANY ABNORMAL CHANGE IN TANK LEVEL TO BE MONITORED AND ANALYSED FOR PROBABLE

LEAKAGES.

You might also like

- SOP For Operation and Cleaning of Conveyer BeltDocument2 pagesSOP For Operation and Cleaning of Conveyer BeltSudheer Nair100% (1)

- Method Statement For ACC TAMDEM SHIFTINGDocument7 pagesMethod Statement For ACC TAMDEM SHIFTINGHsebepl NkNo ratings yet

- Checklist For Internal Safety Audit - OISD-145Document4 pagesChecklist For Internal Safety Audit - OISD-145jai-shriram100% (1)

- 4-JSA - Unloading Under Inert - F9030 B NewDocument6 pages4-JSA - Unloading Under Inert - F9030 B NewAde RahmadiNo ratings yet

- Method Statement For Flue Gas DuctDocument7 pagesMethod Statement For Flue Gas DuctWASIM MAKANDARNo ratings yet

- Indian Oil Corporation Limited (Marketing Division) : Pre Refuelling (Visual)Document8 pagesIndian Oil Corporation Limited (Marketing Division) : Pre Refuelling (Visual)Jahnavi Vijaykumar0% (1)

- OISD 225 TT Decantation Procedure - Check ListDocument5 pagesOISD 225 TT Decantation Procedure - Check Listtaranakgec100% (1)

- Start Up Airline Dossier-Creation of A Low Cost Domestic Airline in The Polish MarketDocument63 pagesStart Up Airline Dossier-Creation of A Low Cost Domestic Airline in The Polish Marketntongo58% (12)

- Quiz For TT DriverDocument8 pagesQuiz For TT DriverGulbarga DepotNo ratings yet

- SOP of HydraDocument9 pagesSOP of HydraGyanendra Narayan NayakNo ratings yet

- Jsa For Roof Air LiftDocument2 pagesJsa For Roof Air LiftKoshy Thankachen100% (1)

- Jha 2022Document8 pagesJha 2022Sandeep KumarNo ratings yet

- Ocp-01 DG Set OperationDocument2 pagesOcp-01 DG Set OperationShankar SanyalNo ratings yet

- HSD Unloading Standard Operating ProcedureDocument4 pagesHSD Unloading Standard Operating ProcedureMD Shahadat Hossan100% (1)

- Rim SealDocument6 pagesRim SealVasant Kumar VarmaNo ratings yet

- Apcosil 605Document1 pageApcosil 605rihtak123No ratings yet

- Water Treatment Plant Weekly Log SheetDocument1 pageWater Treatment Plant Weekly Log SheetShashank Saxena100% (1)

- 113 - Check List For Air Washer & Ventillation SystemDocument1 page113 - Check List For Air Washer & Ventillation SystemR MathirajNo ratings yet

- Standard Operating Procedure (SOP) Compressed Gas Cylinders (Original SOP From Eastern Washington University)Document10 pagesStandard Operating Procedure (SOP) Compressed Gas Cylinders (Original SOP From Eastern Washington University)Sandeep ShettyNo ratings yet

- Checklist Boiler and TurbineDocument17 pagesChecklist Boiler and Turbinekeerthi dayarathna50% (2)

- Diesel Generator (DG) Inspection Checklist: AfconsDocument1 pageDiesel Generator (DG) Inspection Checklist: Afconsprabu lingamNo ratings yet

- Jha - de Spading Activities For N2 PurgingDocument4 pagesJha - de Spading Activities For N2 PurgingNasrullah100% (1)

- Zincanode 620 Voc v1 Jan 2018Document2 pagesZincanode 620 Voc v1 Jan 2018Moin AltafNo ratings yet

- Ppe MatrixDocument1 pagePpe Matrixizzah100% (1)

- Process Instrumentation and Interlock ListDocument1 pageProcess Instrumentation and Interlock ListSafrin SangiaNo ratings yet

- EEEPL - JSA EARTH FLAT LAYING New 123Document7 pagesEEEPL - JSA EARTH FLAT LAYING New 123nishanthNo ratings yet

- HIRA Grain Distillary ProcessesDocument22 pagesHIRA Grain Distillary Processesjithu_1986No ratings yet

- Calorific Value of FuelsDocument2 pagesCalorific Value of FuelsParinita DevadigaNo ratings yet

- Tank TruckDocument80 pagesTank Truckjacobpm2010No ratings yet

- Jsa n2 Purging PDF FreeDocument1 pageJsa n2 Purging PDF FreeSKH CultureNo ratings yet

- Control System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Document8 pagesControl System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Jayson EscamillanNo ratings yet

- OIL FILTERATION - TRA - RevDocument21 pagesOIL FILTERATION - TRA - RevBenasher IbrahimNo ratings yet

- Checklist For Separator Cum Storage TankDocument5 pagesChecklist For Separator Cum Storage TankRamalingam PrabhakaranNo ratings yet

- Wonder® RGR: Retractable Bypass Conductor For Floating Roof TanksDocument9 pagesWonder® RGR: Retractable Bypass Conductor For Floating Roof TanksrazmirarazakNo ratings yet

- Boiler Safety ChecklistDocument2 pagesBoiler Safety ChecklistAnand Pal Singh100% (1)

- 27k Crane Lifting PermitDocument1 page27k Crane Lifting Permitsafety86No ratings yet

- Fire Water TankDocument1 pageFire Water TankAnonymous yCpjZF1rF100% (1)

- Job Safety Analysis (Jsa) : Title of Activity / Work: DG OperationDocument2 pagesJob Safety Analysis (Jsa) : Title of Activity / Work: DG Operationba ratnaparkheNo ratings yet

- Tank Lorry Filling GantryDocument21 pagesTank Lorry Filling GantrySiddharth BarmanNo ratings yet

- PTW PresentationDocument13 pagesPTW Presentationkevin kishoreNo ratings yet

- EOT Crane PermitDocument1 pageEOT Crane PermitHimanshu KumarNo ratings yet

- Form 13Document4 pagesForm 13Jayendra NaiduNo ratings yet

- Compressive Testing Machine Check List - TPLIPMSSAFETYCTMCL048 Rev00 Dt.22.10.2019Document2 pagesCompressive Testing Machine Check List - TPLIPMSSAFETYCTMCL048 Rev00 Dt.22.10.2019MOHAMMEDNo ratings yet

- Mobile Crane Set Up Ckeck List: PROJECT TITLE: OG119-Design & Construction of KIZAD Gas Network DateDocument3 pagesMobile Crane Set Up Ckeck List: PROJECT TITLE: OG119-Design & Construction of KIZAD Gas Network DateImran KhanNo ratings yet

- Sop HiteshDocument152 pagesSop HiteshManju TripathiNo ratings yet

- JSA For Flue Gas Duct Height WorkDocument4 pagesJSA For Flue Gas Duct Height Worksubhadipmanna8No ratings yet

- Static and Mobile Pressure Vessels Rules 1981Document40 pagesStatic and Mobile Pressure Vessels Rules 1981mahendran50% (2)

- Jsa Bearing Replacement-OverhaulingDocument2 pagesJsa Bearing Replacement-Overhaulingashish engineeringNo ratings yet

- Lifting Plan Loading and Unloading of Structural MaterialDocument9 pagesLifting Plan Loading and Unloading of Structural Materialjallouli mohamed omar100% (1)

- Discharge Rod 11kv 3phaseDocument1 pageDischarge Rod 11kv 3phasewaytobhushan100% (1)

- Checklist - LDO-UnLoading PumpDocument12 pagesChecklist - LDO-UnLoading PumpBandi Suryakanthareddy V G0% (1)

- JSA Tank Modification and Repair Work 1683009539 PDFDocument12 pagesJSA Tank Modification and Repair Work 1683009539 PDFLabroratoirNo ratings yet

- JSA For Cleaning Boiler, SCR & ESP InternalDocument18 pagesJSA For Cleaning Boiler, SCR & ESP InternalThái Đạo Phạm LêNo ratings yet

- Chemicals Zetag MSDS Powder Magnafloc 1011 - 0810Document6 pagesChemicals Zetag MSDS Powder Magnafloc 1011 - 0810PromagEnviro.comNo ratings yet

- Positive IsolationDocument10 pagesPositive IsolationArunava Basak0% (1)

- Colour Codes For Pipe LineDocument3 pagesColour Codes For Pipe LinemahaveenNo ratings yet

- DG SET-Technical Specs PDFDocument26 pagesDG SET-Technical Specs PDFankur yadavNo ratings yet

- Ast Jsa - Piping FabricationDocument3 pagesAst Jsa - Piping Fabricationmd_rehan_2No ratings yet

- Safety Check (Please Put Tick ( ) Mark in The Appropriate BoxDocument8 pagesSafety Check (Please Put Tick ( ) Mark in The Appropriate BoxAntony JebarajNo ratings yet

- Instructions - SILVER HAGUE - LANGSATDocument9 pagesInstructions - SILVER HAGUE - LANGSATZaid Al Aris Md ArisNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- 06 Clicker Questions PhysicsDocument20 pages06 Clicker Questions PhysicsVerenice Fuentes100% (1)

- ESC-MEPS FS v2nDocument8 pagesESC-MEPS FS v2nBen ChNo ratings yet

- Gjames Glass Handbook PDFDocument106 pagesGjames Glass Handbook PDFJohn Van RooyenNo ratings yet

- дачия 1304-1305-1307 пикап PDFDocument654 pagesдачия 1304-1305-1307 пикап PDFRobert IvanNo ratings yet

- ISO-4156-1981 PreviewDocument15 pagesISO-4156-1981 Previewbee1406763181No ratings yet

- Hydraulics Manual - Drainage DesignDocument690 pagesHydraulics Manual - Drainage DesignAnita100% (1)

- Global Local Analysis WhitepaperDocument3 pagesGlobal Local Analysis WhitepaperagniflameNo ratings yet

- Assignment 1 Part 1Document6 pagesAssignment 1 Part 1Aditi AgrawalNo ratings yet

- 5054 w05 QP 1Document20 pages5054 w05 QP 1mstudy123456No ratings yet

- Map Info Pro Install GuideDocument77 pagesMap Info Pro Install Guidececil tivaniNo ratings yet

- Internship Ghazi TractorDocument42 pagesInternship Ghazi Tractorkaleemshah0% (1)

- Torque SpecificationDocument20 pagesTorque SpecificationSyed Mohammad Naveed100% (1)

- ASTM-C533 - Calcium Silicate Block and Pipe Thermal InsulationDocument4 pagesASTM-C533 - Calcium Silicate Block and Pipe Thermal InsulationEspie SualogNo ratings yet

- Natural Ventilation Engineering GuideDocument40 pagesNatural Ventilation Engineering GuidePrestoneK100% (1)

- EMH Presentation - 1 0Document54 pagesEMH Presentation - 1 0Landon MitchellNo ratings yet

- Pipes and Tubes (VB)Document92 pagesPipes and Tubes (VB)Phúc nguyễnNo ratings yet

- Bougainville Technical CollegeDocument5 pagesBougainville Technical Collegeapi-241292749No ratings yet

- Parts-List: Thyssenkrupp Industrial SolutionsDocument3 pagesParts-List: Thyssenkrupp Industrial Solutionsfernando cordova zegarraNo ratings yet

- Electrical MCDocument41 pagesElectrical MCphilip00165No ratings yet

- CAREvent ALS BLS Manual Rev K Sept 08Document8 pagesCAREvent ALS BLS Manual Rev K Sept 08KennethAdrianRosaNo ratings yet

- How Much Does It Cost To Build A 1,000 BBL Per Day Oil Refinery?Document4 pagesHow Much Does It Cost To Build A 1,000 BBL Per Day Oil Refinery?manojkumarmurlidharaNo ratings yet

- IT Assignment 2Document2 pagesIT Assignment 2syed02No ratings yet

- AC DC Mixing - Case Study PDFDocument3 pagesAC DC Mixing - Case Study PDFAnonymous g0InJ4BLBNo ratings yet

- French Level 2 - Student Workbook PDFDocument100 pagesFrench Level 2 - Student Workbook PDFmetztli100% (2)

- Andrew DB878H120ESXDocument2 pagesAndrew DB878H120ESXGindo FerialNo ratings yet

- Checklist King Air 350Document7 pagesChecklist King Air 350Alejo Giraldo VélezNo ratings yet

- Prestige XT-W Installation InstructionsDocument2 pagesPrestige XT-W Installation Instructionstatiana_370273750No ratings yet