Professional Documents

Culture Documents

HSE-RA-022 Environmental Management - Rev 0

HSE-RA-022 Environmental Management - Rev 0

Uploaded by

عمروOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HSE-RA-022 Environmental Management - Rev 0

HSE-RA-022 Environmental Management - Rev 0

Uploaded by

عمروCopyright:

Available Formats

DOC No DS/CA006P02/00022

PAGE No 1 of 22

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 022

Job Description: Environmental Management

Index:

Form 1 Task Analysis Initiation

Form 2 Risk Assessment Process As per Risk Assessment Procedure.

Form 3 Written Safe Work Procedure Result

Compiled by the following team:

NAME DESIGNATION SIGNATURE

Project Manager

Construction Manager

Site Engineer

Safety Officer

Risk Assessment Review 1 Review 2 Review 3 Review 4

Review Date: Date : Date : Date:

Name and Signature

of person reviewing :

AUTHORISATION

Prepared by: Approved by

Signature Date Signature Date

HSE Manager Project Manager

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 2 of 22

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 022

Job Description: Environmental Management

TASK ANALYSIS - FORM 1

Impact

SEQUENCE OF TASK STEPS POTENTIAL INJURIES OR HAZARDS RECOMMENDED CONTROLS

H, S, E

1. Pre-use inspection and use of all Failure of equipment will cause injuries to Faulty equipment to be repaired/maintained or replaced.

equipment persons and / or property damage. Guards to be on all Machinery and appropriate PPE to be

worn.

Faulty hand tools and power tools. Fuel/oil leaks could cause environmental H, S, E Engine ran machinery to have fire extinguishers available

concerns. locally.

Drip trays/heavy gauge plastic to be provided in case of leaks

and spill kit to be within the project for accidental spills.

2. Wear appropriate Personal Protective Failure to use Personal Protective Equipment

Equipment. will cause injuries to employees.

Gloves.

Safety boots. Enforce the use of Personal Protective Equipment AT ALL

H

Overalls. times

Hard hat.

Hearing protection.

Eye protection

3. Use trained employees only All Enforce the use of competent persons only

Lack of knowledge All employees assigned to this task must be Safety Inducted

also they will have to attend a safety meeting, which will

Failure may result in injuries to persons and include the Standard Operating Procedures, types of potential

property damage. hazards, and actual hazards present and controls for those

H, S

hazards.

Workers should be legally appointed & having their Id’s.

Ensure that the operatives are physically and mentally fit to do

the activity.

4. Competent supervision Failure will cause injuries to employees and H, S Competent supervisor should be appointed for every activity to

or property damage monitor the workers. Work task instruction should be provided

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 3 of 22

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 022

Job Description: Environmental Management

for every activity.

5. Solid waste A separate waste collection area should be made for collection and

Access system, concreting, storage of waste for final disposal.

demolition, hot works, drainage, Re-usable and recyclable material should be collected separately in

electrical equipment, fixture and separate collection skips.

fittings, ground work, heating system, Ensure that no useable material goes into discard waste skips.

masonry, mobile plant, office furniture, Proper identification of all skips regarding the type of waste.

Depletion of natural resources (Human, Land,

pipe and duct work, site E,H Proper housekeeping of the area and segregation of the waste

Water, Birds, Animals)

establishment, structural framing according to their type.

system, surface finishing, wall lining The hazardous materials skip should be covered.

and waterproofing. The empty hazardous waste materials containing containers, drums

and tins should not be thrown on site after their utilization.

Compile and maintain all types of waste data.

Minimise the waste through design and proper planning.

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 4 of 22

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 022

Job Description: Environmental Management

TASK ANALYSIS - FORM 1 (continued)

SEQUENCE OF TASK STEPS POTENTIAL INJURIES OR HAZARDS RECOMMENDED CONTROLS

7. Noise Pollution Place or install all noisy machinery at such a place where there is less

concreting, cutting and grinding, demolition, exposure of human to high noise.

ground work, electrical equipment, masonry, Provide ear protection and other personal protection equipment to worker

mobile plant directly exposed to high noise and ensure the proper PPE utilization.

Schedule noisy construction activities during day time.

Switch off generators, air compressors and noise generating machinery when

Human, Birds and Animals E,H

not in use.

Restrict the movement of unconcerned person in or near high noise

generating source.

Using the quietest machinery available.

Replace worn, loose or unbalanced machine parts that cause vibration.

Tool box training to employees regarding their protection against high noise.

8. Air Pollution Vehicles should be driven slowly in unpaved areas.

Access system, administration, air Display of traffic and speed limit sign along the roads.

conditioning, concreting, cutting and Vehicle and machinery should be maintained properly.

grinding, demolition, drainage, fuel storage, E,H Masks should be provided to workers working in high dusty or air polluted

fixture and fittings, ground work, lighting, Depletion of natural resources areas.

masonry, mobile plant, electrical system, (Human, Land, Water, Birds, Ensure the proper ventilation while working in building or confined spaces.

fuel storage, heating system, pipe and duct Animals) Placed generators and air compressor as much as possible away from

work, site surface finishing, wall lining, working area.

waterproofing, welding and cutting. New hiring vehicles and emission generating machinery should be checked

by a safety personnel regarding emission and ensure its fitness.

Vehicles and machinery should be turned off when not in use.

Do not burn anything within the project premises.

Vehicles carrying dusty materials should be sheeted.

CFC leakages from ACs should be checked on bi-annual basis.

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 5 of 22

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 022

Job Description: Environmental Management

9. Dust Emission Regular watering of unpaved roads or exposed soils / grounds is the best

Cutting, demolition, ground work, masonry, option of minimizing the dust generation.

mobile plant, transportation, site Hauling trucks should cover their loads with canvass or any equivalent

establishment materials.

Soil, Human, Birds, Animals

E,H REDUCE SPEED. Sign boards should be displayed at prominent places

and Plants

along dust generating area.

Proper compaction of the unpaved roads.

Use defined roads for movement and minimize off road vehicle movement.

Tool box training to drivers regarding reducing speed on unpaved roads.

10. Land Contamination Check the vehicle and machinery regarding oil leakages on a regular basis.

Concreting, demolition, fuel storage, ground Use collection and dip trays for the collection of oil spillages / leakages from

work, mobile plant, masonry, site machines / generators.

establishment wash rooms Remove the oil containment soil from the point of spillages and dispose off

according to legal requirements.

Land, Water and Human E,H All oils, fluid fuels and chemical drums should be placed in a bounded area.

Make a separate paved area for the washing of concrete mixing vehicles to

contain washout material.

Remove and prevent the water leakages / spillages from wash rooms and

other water using activities.

Regular collection of sewerage waste water to prevent overflow.

11. Material Wastage Do not throw usable material in waste skip.

Ground work, concreting, demolition, pipe After the completion of activity, collect all excess usable material separately.

and duct work, structural framing, wall Handle pipes and other breakable materials properly to minimize their

finishing and lining, grinding, fabrication, Depletion of natural resources wastage factor.

E,H

office and street furniture, cutting, masonry, (Land and Humans) Plan properly before the start up of work regarding the material section,

fixture and finishing, electrical and handling and transportation on site.

mechanical maintenance work Material waste reduction plan should be made for the reduction of materials

used in the project.

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 6 of 22

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 022

Job Description: Environmental Management

12. Flora Plant indigenous tree species and ornamental plants within the project

Concreting, demolition, ground work, premises.

Plants E

transportation Use of markers and fences to direct heavy equipment traffic in the

construction site and avoid damage to plants.

13. Fauna Identify some areas within or outside the project premises and provides food

Concreting, demolition, ground work, mobile Animals and Birds E and water to existing birds.

plant, site establishment Do not kill or injure any birds or animal within the project premises.

14. Soil Erosion Soil erosion could be minimised by proper sloping of the banks.

Ground work, transportation, storage of Land Prevent and restrict the vehicle construction machinery movement close to

materials the bank.

15. Fuel Switch off vehicles and machinery when not in use.

Access system, office furniture, ground work Proper maintenance of vehicles and machines.

administration, concreting, demolition, site Depletion of natural resources Manage task smarter by planning routes.

E,H,S

establishment , structural framing system, (Air, Human and Land) Change air and oil filters according to schedule.

fuel storage, grinding and cutting, surface

finishing, transportation, wall lining

16. Energy Wastage Purchase of energy efficient appliances.

Turn off lights, air conditioners and other electrical equipment while leaving

the office or when not needed.

Depletion of natural resources,

E Usage of daylight as much as possible.

air pollution

Usage of energy saver bulbs.

Cleaning of air conditioning unit filter on a regular basis to increase efficiency.

Switch off unnecessary lights.

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 7 of 22

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 022

Job Description: Environmental Management

17. Chemical Storage and Handling Ensure availability and utilization of Personal Protection Equipment during

Concreting, ground work, fixture and fittings, handling and using of chemicals.

surface finishing, paint work, waterproofing, Proper ventilation and availability of fresh air while working in closed building.

wall lining Availability of fire fighting equipment while handling and using flammable

Air, Water, Land and Human E chemicals.

Giving tool box training to the person using chemicals regarding the safe

handling before the start up of activity.

Prepare and maintained list of all stored chemicals with their expiry and

review on monthly basis to minimize the chemical wastage due to expiry.

18. Water Wastage Use dewater for soil compaction rather than sweet water

Concreting, ground work, site establishment Don’t use drinking water for washing purposes.

Depletion of natural resources

washing, masonry, mobile plant Clean the vehicles with cloth rather than frequent washing.

(Land, Human and Water E

Avoid unnecessary flushing and water wastage in toilets.

Pollution)

Raise employee awareness regarding the importance of water conservation

through tool box training and through awareness brochures.

19. Office Waste Make double-sided copies whenever possible. This can dramatically reduce

Papers, cartridges, folders, used pens, your paper usage.

cardboards, envelopes, office furniture Print draft on used paper rather than new one.

Review text on computer screens to limit mistake on drafts.

Instead of making individual copies for everyone, use a routing slip when

Depletion of natural resources circulating information to staff, or post notices on a bulletin board.

E

(Land and Human) If possible, use electronic mail instead of making hard copies of all

communications.

Use a single space format for the text of final reports.

Try to re-use folders and envelopes.

Minimise the paper photocopying.

All the printer cartridges should be collected and sent for re-using.

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 8 of 22

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 022

Job Description: Environmental Management

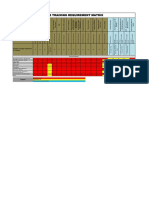

RISK ASSESSMENT – FORM 2

Risk Rating Calculation

Risk Rating = A + B + C + D.

A + B + C + D

Injury Severity Potential Damage / Loss Frequency or Likelihood Environmental Impact

0 No injury 0 No damage 0 Never happened before 0 No effect

1 Minor – (FAC) 1 Minor < 500 AED, No delay 1 Happened somewhere 1 Minor Effect - Short term < less 1 month

2 Major – (MTC) 2 Major > 500 AED, No delay 2 Happens occasionally 2 Major Effect - Long term > Greater 1 month

3 LTI 3 Major > 10 000 AED, one day delay 3 Happened before

4 Disabling Injuries 4 Serious > 100, 000 AED, >1 day delay 4 Happens regularly

Risk Rating Matrix

5 Fatality 5 Severe > 1, 000, 000 AED, Weeks delay. 5 Daily occurrence

Result Classification:

Risk Rating

Critical = 17►15 High = 14►11 Medium = 10►7 Low = 6►0 16

Immediate action. Action in 24 hours. Action in a week. ASAP. 14

12

10

8

6

Risk Reduction Hierarchy: 4

1. Engineering to reduce risk. 2

0

2. Replacement with lower risk. 1

5

2 4

3. Isolation of risk – Barricading or Guarding. 3

4 3

5 Probability

4. Reduction of exposure to risk. Potential Impact 6

7 2 (C)

(A / B / D) 8

5. PPE and Training 9 1

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 9 of 22

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 022

Job Description: Environmental Management

RISK ASSESSMENT – FORM 2 (continued)

Impact HOW IS HAZARD TO BE BY Result

No HAZARD IDENTIFIED RISK ASSOCIATED WITH HAZARD H, S, E RR BY WHOM RR

DEALT WITH WHEN

1 Faulty hand tools Bruises, cuts. Gloves, trowels in good Supervisor Before &

condition. during

Mechanical guards not Entanglement, Skeletal Damage. the use

in place Guards in place and equipment of

H,S,E 13 regularly maintained. equipme 6

nt

Unwanted Fuel/Oil Contamination of the soil, atmospheric Care to be taken refuelling and

Spillages pollution, risk of fire. drip trays/heavy gauge plastic to

be in place as required.

2 Injury to project Potential Death, Major/Minor Skeletal Following PPE to be worn Supervisor Before &

employees damage, cuts and bruises to all parts of appropriately to the task – during

the body, asthma. Gloves. work

Safety boots.

H,S 10 5

Overalls.

Hard hat.

Hearing protection.

Eye protection

3 Un trained employees Poor quality of work, chance for Provided trained/competent PE/FM Always

H,S 7 5

accident /incident or property lost/damage worker and supervision

4 Poor Supervision Poor quality of work, chance for Ensure the availability of PE/FM Always

accident /incident or property lost/damage competent supervisor at work

place.

H,S 10 3

Work task instruction should be

provided to the workers prior to

the commencement of activity

5 Solid waste Depletion of natural resources (Human, H,E 8 Ensure a nominated individual to Project Always 6

Land, Water, Birds, Animals) have the responsibility of waste Engineer/

management FM

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 10 of 22

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 022

Job Description: Environmental Management

Impact HOW IS HAZARD TO BE BY Result

No HAZARD IDENTIFIED RISK ASSOCIATED WITH HAZARD H, S, E RR BY WHOM RR

DEALT WITH WHEN

Store different waste types

separately to avoid confusion

Never store incompatible wastes

together

Select appropriate container for the

waste and ensure it is in good

condition

Keep quantities of waste and storage

times to a minimum

Protect the waste from sunlight, rain

and wind if necessary

Do not dispose of unusual wastes in

a general waste skip

Declare the whole site as “No

Burning” zone for all type of waste

materials

Never discharge waste into air, earth

without prior approval of concerned

authorities

Allocate adequate resources for

continuous house keeping

Train employees on house keeping

Allocate an adequate number of

dumpsters and trash bins

Ensure instant and regular waste

removal from site

Separate food waste from

construction waste

6 Noise Pollution Environmental contamination, Hearing Assign competent person for the Project Always

loss. Nuisance work Engineer/

H,E 9 Appropriate training to the workers FM 6

about noise hazards

Provide appropriate hearing

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 11 of 22

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 022

Job Description: Environmental Management

Impact HOW IS HAZARD TO BE BY Result

No HAZARD IDENTIFIED RISK ASSOCIATED WITH HAZARD H, S, E RR BY WHOM RR

DEALT WITH WHEN

protection

Reduce exposure to the noise

Isolate and post warning signs to the

noise area

Locate noise source at a distance

from people

Place a sound proof cover over the

noise sourcet

7 Air Pollution Depletion of natural resources, Smoke, Vehicles should be driven slowly Project Always

Smog, Fog, Dust, Carbon monoxide. in unpaved areas. Engineer/

Display of traffic and speed limit FM

sign along the roads.

Vehicle and machinery should

be maintained properly.

Masks should be provided to

workers working in high dusty or

air polluted areas.

Ensure the proper ventilation

while working in building or

H,E 7 confined spaces. 6

Placed generators and air

compressor as much as

possible away from working

area.

New hiring vehicles and

emission generating machinery

should be checked by a safety

personnel regarding emission

and ensure its fitness.

Vehicles and machinery should

be turned off when not in use.

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 12 of 22

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 022

Job Description: Environmental Management

Impact HOW IS HAZARD TO BE BY Result

No HAZARD IDENTIFIED RISK ASSOCIATED WITH HAZARD H, S, E RR BY WHOM RR

DEALT WITH WHEN

Do not burn anything within the

project premises.

Vehicles carrying dusty

materials should be sheeted.

CFC leakages from ACs should

be checked on bi-annual basis.

8 Dust Emission Dust, Visibility. Adequate dust suppression by Project Always

watering Engineer/

Provision of personal protective FM

equipments

Effective supervision of the

employees

Provide adequate washing facility

Cleaning of hands before

consuming food

H,E 8 Use of barrier creams 4

Identify materials and substances

before use

Correct disposal procedures of

materials and containers

Adequate training to the employees

about dust hazards

Manufactures or Suppliers

instructions available and observed

Hygienic eating area

9 Land Contamination Depletion of natural resources, Waste. Machineries must be well Project Always

maintained Engineer/

H,E 6 Lubrication and refueling only in FM 4

designated locations

Do not carry out repairs on roads

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 13 of 22

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 022

Job Description: Environmental Management

Impact HOW IS HAZARD TO BE BY Result

No HAZARD IDENTIFIED RISK ASSOCIATED WITH HAZARD H, S, E RR BY WHOM RR

DEALT WITH WHEN

or open ground

Do not use vehicle which emits

excessive noise / smoke

Clean up spills instantly

Do not leave tools scattered

around the work place

Regular maintenance and check

up must be conducted

Oil leaks must be rectified

immediately to avoid oil spillage

Washing / cleaning of machinery

only in designated locations

Provide drip trays for all

generators

Concrete mixers / truck washing

must be done only in the washing

bay.

10 Material Wastage Depletion of natural resources (Land and Material should be stored only in Store man Always

Humans) an approved locations

Material should be protected with

barriers

Ensure storage area is of

sufficient size and is suitably

H,E 9 4

located

Clearly label the storage

containers and storage area

Ensure the storage area is

secure and protected from

accidental or malicious damage

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 14 of 22

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 022

Job Description: Environmental Management

Impact HOW IS HAZARD TO BE BY Result

No HAZARD IDENTIFIED RISK ASSOCIATED WITH HAZARD H, S, E RR BY WHOM RR

DEALT WITH WHEN

Provide bunds for all diesel / oil

containers

Never store incompatible material

together

11 Flora Loss of Environment, Ecological Effects Plant indigenous tree species Project Always

and ornamental plants within the Engineer/

project premises. FM

H,E 9 Use of markers and fences to 3

direct heavy equipment traffic in

the construction site and avoid

damage to plants.

12 Fauna Loss of Environment, Ecological Effects Identify some areas within or Project Always

outside the project premises and Engineer/

provides food and water to FM

H,E 9 existing birds. 3

Do not kill or injure any birds or

animal within the project

premises.

13 Soil Erosion Landscaping loss of land, ecological Soil erosion could be minimised Project Always

damage by proper sloping of the banks. Engineer/

H,E 6 Prevent and restrict the vehicle FM 3

construction machinery

movement close to the bank.

14 Fuel Depletion of natural resources (Air, Switch off vehicles and Workshop, Always

Human and Land) machinery when not in use. Store man.

Proper maintenance of vehicles

H,E 7 4

and machines.

Manage task smarter by

planning routes.

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 15 of 22

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 022

Job Description: Environmental Management

Impact HOW IS HAZARD TO BE BY Result

No HAZARD IDENTIFIED RISK ASSOCIATED WITH HAZARD H, S, E RR BY WHOM RR

DEALT WITH WHEN

Change air and oil filters

according to schedule.

15 Energy Wastage Depletion of natural resources, air Purchase of energy efficient Project Always

pollution appliances. Engineer/

Turn off lights, air conditioners FM

and other electrical equipment

while leaving the office or when

not needed.

H,E 8 Usage of daylight as much as 5

possible.

Usage of energy saver bulbs.

Cleaning of air conditioning unit

filter on a regular basis to

increase efficiency.

Switch off unnecessary lights.

16 Chemical Storage Air, Water, Land and Human. Chemical Ensure proper transportation, use Project Always

Hazards, burns, fires, permanent and handling Engineer/

ecological damage. Disposal of hazardous FM

substances must be observed

H,E 8 4

strictly

Ensure hazardous materials are

stored in a designated place

17 Office waste Depletion of natural resources (Land, Use dewater for soil compaction Project Always

Human and Water Pollution) rather than sweet water Engineer/

Don’t use drinking water for FM

H,E 8 washing purposes. 4

Clean the vehicles with cloth

rather than frequent washing.

Avoid unnecessary flushing and

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 16 of 22

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 022

Job Description: Environmental Management

Impact HOW IS HAZARD TO BE BY Result

No HAZARD IDENTIFIED RISK ASSOCIATED WITH HAZARD H, S, E RR BY WHOM RR

DEALT WITH WHEN

water wastage in toilets.

Raise employee awareness

regarding the importance of

water conservation through tool

box training and through

awareness brochures.

18 Water Waste Depletion of natural resources (Land and Make double-sided copies Project Always

Human) - whenever possible. This can Engineer/

dramatically reduce your paper FM

usage.

Print draft on used paper rather

than new one.

Review text on computer

screens to limit mistake on

drafts.

Instead of making individual

copies for everyone, use a

routing slip when circulating

H,E 7 4

information to staff, or post

notices on a bulletin board.

If possible, use electronic mail

instead of making hard copies of

all communications.

Use a single space format for

the text of final reports.

Try to re-use folders and

envelopes.

Minimise the paper

photocopying.

All the printer cartridges should

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 17 of 22

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 022

Job Description: Environmental Management

Impact HOW IS HAZARD TO BE BY Result

No HAZARD IDENTIFIED RISK ASSOCIATED WITH HAZARD H, S, E RR BY WHOM RR

DEALT WITH WHEN

be collected and sent for re-

using.

19 Sewage waste Contamination of ground water Utility services only in an Project Always

Infection, odour, air, water pollution. approved locations Engineer/

All sewerage / drainage waste FM

shall be collected in a tank and

disposed off to an approved

H,E 6 locations 4

All washing facility should have

proper waste collection tank

Ensure the sewerage tank and

drainage tanks are not over flown

* RR = Risk Rating

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 18 of 22

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 022

Job Description: Environmental Management

WRITTEN SAFE WORK PROCEDURE

1. OBJECTIVE

1. To prevent injuries to employees and / or property damage incidents.

2. PROCEDURE

1. Do pre-use inspection of all equipment to be used and replace or repair faulty items.

2. Use trained competent employees only.

3. Use appropriate Personal Protective Equipment i.e.:

3.1. Hardhat.

3.2. Safety boots.

3.3. Overalls.

3.4. Hand protection

3.5. Eye protection.

Prior to work commencement

1. Must have PPE – safety footwear, gloves, hardhat, goggles, foul weather clothing etc.

2. Must have appropriate tools and equipment in good condition.

3. Must have weatherproof covers for materials and equipment, waste containers, warning tape.

4. Consider risks and hazards in work area. Refer any concerns to supervisor. Are relevant permits in place?

5. Check if it is necessary to secure area adjacent to work. Refer to supervisor if appropriate.

6. Arrange for transport of materials and equipment to site via supervisor.

7. Ensure materials and equipment are secure or removed when site unattended, eg overnight or during breaks.

Hazards

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 19 of 22

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 022

Job Description: Environmental Management

1. Slips and trips from untidy work area.

2. Falling materials

3. Environmental damage

Harm

All work force, Land, water, air and public

Control measures

1. A separate waste collection area should be made for collection and storage of waste for final disposal.

2. Re-usable and recyclable material should be collected separately in separate collection skips.

3. Ensure that no useable material goes into discard waste skips.

4. Proper identification of all skips regarding the type of waste.

5. Proper housekeeping of the area and segregation of the waste according to their type.

6. The hazardous materials skip should be covered.

7. The empty hazardous waste materials containing containers, drums and tins should not be thrown on site after their utilization.

8. Compile and maintain all types of waste data.

9. Minimise the waste through design and proper planning.

10. Place or install all noisy machinery at such a place where there is less exposure of human to high noise.

11. Provide ear protection and other personal protection equipment to worker directly exposed to high noise and ensure the proper

PPE utilization.

12. Schedule noisy construction activities during day time.

13. Switch off generators, air compressors and noise generating machinery when not in use.

14. Restrict the movement of unconcerned person in or near high noise generating source.

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 20 of 22

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 022

Job Description: Environmental Management

15. Using the quietest machinery available.

16. Replace worn, loose or unbalanced machine parts that cause vibration.

17. Tool box training to employees regarding their protection against high noise.

18. Vehicles should be driven slowly in unpaved areas.

19. Display of traffic and speed limit sign along the roads.

20. Vehicle and machinery should be maintained properly.

21. Masks should be provided to workers working in high dusty or air polluted areas.

22. Ensure the proper ventilation while working in building or confined spaces.

23. Placed generators and air compressor as much as possible away from working area.

24. New hiring vehicles and emission generating machinery should be checked by a safety personnel regarding emission and ensure

its fitness.

25. Vehicles and machinery should be turned off when not in use.

26. Do not burn anything within the project premises.

27. Vehicles carrying dusty materials should be sheeted.

28. CFC leakages from AC units should be checked on bi-annual basis.

29. Regular watering of unpaved roads or exposed soils / grounds is the best option of minimizing the dust generation.

30. Hauling trucks should cover their loads with canvass or any equivalent materials.

31. REDUCE SPEED. Sign boards should be displayed at prominent places along dust generating area.

32. Proper compaction of the unpaved roads.

33. Use defined roads for movement and minimize off road vehicle movement.

34. Tool box training to drivers regarding reducing speed on unpaved roads.

35. Check the vehicle and machinery regarding oil leakages on a regular basis.

36. Use collection and dip trays for the collection of oil spillages / leakages from machines / generators.

37. Remove the oil containment soil from the point of spillages and dispose off according to legal requirements.

38. All oils, fluid fuels and chemical drums should be placed in a bounded area.

39. Make a separate paved area for the washing of concrete mixing vehicles to contain washout material.

40. Remove and prevent the water leakages / spillages from wash rooms and other water using activities.

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 21 of 22

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 022

Job Description: Environmental Management

41. Regular collection of sewerage waste water to prevent overflow.

42. Do not throw usable material in waste skip.

43. After the completion of activity, collect all excess usable material separately.

44. Handle pipes and other breakable materials properly to minimize their wastage factor.

45. Plan properly before the start up of work regarding the material section, handling and transportation on site.

46. Material waste reduction plan should be made for the reduction of materials used in the project.

47. Plant indigenous tree species and ornamental plants within the project premises.

48. Use of markers and fences to direct heavy equipment traffic in the construction site and avoid damage to plants.

49. Identify some areas within or outside the project premises and provides food and water to existing birds.

50. Do not kill or injure any birds or animal within the project premises.

51. Soil erosion could be minimised by proper sloping of the banks.

52. Prevent and restrict the vehicle construction machinery movement close to the bank.

4. Switch off vehicles and machinery when not in use.

5. Proper maintenance of vehicles and machines.

6. Manage task smarter by planning routes.

7. Change air and oil filters according to schedule.

8. Purchase of energy efficient appliances.

9. Turn off lights, air conditioners and other electrical equipment while leaving the office or when not needed.

10. Usage of daylight as much as possible.

11. Usage of energy saver bulbs.

12. Cleaning of air conditioning unit filter on a regular basis to increase efficiency.

13. Switch off unnecessary lights.

14. Ensure availability and utilization of Personal Protection Equipment during handling and using of chemicals.

15. Proper ventilation and availability of fresh air while working in closed building.

16. Availability of fire fighting equipment while handling and using flammable chemicals.

17. Giving tool box training to the person using chemicals regarding the safe handling before the start up of activity.

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 22 of 22

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 022

Job Description: Environmental Management

18. Prepare and maintained list of all stored chemicals with their expiry and review on monthly basis to minimize the chemical wastage

due to expiry.

19. Use dewater for soil compaction rather than sweet water

20. Don’t use drinking water for washing purposes.

21. Clean the vehicles with cloth rather than frequent washing.

22. Avoid unnecessary flushing and water wastage in toilets.

23. Raise employee awareness regarding the importance of water conservation through tool box training and through awareness

brochures.

24. Make double-sided copies whenever possible. This can dramatically reduce your paper usage.

25. Print draft on used paper rather than new one.

26. Review text on computer screens to limit mistake on drafts.

27. Instead of making individual copies for everyone, use a routing slip when circulating information to staff, or post notices on a

bulletin board.

28. If possible, use electronic mail instead of making hard copies of all communications.

29. Use a single space format for the text of final reports.

30. Try to re-use folders and envelopes.

31. Minimise the paper photocopying.

32. All the printer cartridges should be collected and sent for re-using.

HSE/QUALITY SYSTEM DOCUMENTATION

You might also like

- PM22-Lone Working Policy and ProcedureDocument13 pagesPM22-Lone Working Policy and ProcedurehdbundoNo ratings yet

- SDS Powerweld S12Document6 pagesSDS Powerweld S12azreen96.worksNo ratings yet

- BTME HSE PlanDocument122 pagesBTME HSE PlanNibu P ShajiNo ratings yet

- Food Poisoning Investigation Form Version 3 - 0 - 0Document10 pagesFood Poisoning Investigation Form Version 3 - 0 - 0shahanaa AR100% (1)

- Clearing Brush With Weed Trimmer: Job Safety AnalysisDocument2 pagesClearing Brush With Weed Trimmer: Job Safety AnalysisRetselisitsoe100% (1)

- HSE-RA-030 Bulk Excavation With Excavator - Rev 0Document9 pagesHSE-RA-030 Bulk Excavation With Excavator - Rev 0عمروNo ratings yet

- HSE-RA-016 Waste Materials - Rev 0Document12 pagesHSE-RA-016 Waste Materials - Rev 0عمروNo ratings yet

- HSE-RA-013 Deshuttering - Rev 0.Document16 pagesHSE-RA-013 Deshuttering - Rev 0.عمروNo ratings yet

- HSE-RA-031 Back Filling of - Excavation - Rev 0Document9 pagesHSE-RA-031 Back Filling of - Excavation - Rev 0عمروNo ratings yet

- HSE-RA-064 Control of Hazardous - Substances - Rev 0Document13 pagesHSE-RA-064 Control of Hazardous - Substances - Rev 0عمروNo ratings yet

- HSE-RA-063 Erecting and Dismantling of Placing Boom - Rev 0Document15 pagesHSE-RA-063 Erecting and Dismantling of Placing Boom - Rev 0عمروNo ratings yet

- HSE-RA-005 Working at Heights - Rev - 0Document8 pagesHSE-RA-005 Working at Heights - Rev - 0عمروNo ratings yet

- HSE RA 032 Diesel Storage Rev 0Document11 pagesHSE RA 032 Diesel Storage Rev 0عمروNo ratings yet

- Office Area S. N. Inspection Item Yes No Score NA RemarksDocument5 pagesOffice Area S. N. Inspection Item Yes No Score NA RemarksRavi BhatraNo ratings yet

- Hazards and Risk Identification and ManagementDocument2 pagesHazards and Risk Identification and Managementsai ramNo ratings yet

- CMHL - HSE Department KPI Template - 2019 (Apr - Sep)Document4 pagesCMHL - HSE Department KPI Template - 2019 (Apr - Sep)Htoo Htoo KyawNo ratings yet

- Contractor Accountability ProcedureDocument15 pagesContractor Accountability ProcedureAmir M. ShaikhNo ratings yet

- FSSC 22000 Part III CI To CIVDocument14 pagesFSSC 22000 Part III CI To CIVMelek Derya ÖztoprakNo ratings yet

- HIRARC Update - HR CanteenDocument6 pagesHIRARC Update - HR CanteenDon McleanNo ratings yet

- Updated-MARC ARBOUR CITY HOTEL-COSHH Assessment 2 - Paint Thinner PlusDocument2 pagesUpdated-MARC ARBOUR CITY HOTEL-COSHH Assessment 2 - Paint Thinner PlusPaul McGahanNo ratings yet

- Cilt Desember 2018 Surabaya-1Document82 pagesCilt Desember 2018 Surabaya-1Diky RiansyahNo ratings yet

- Visitor EntryDocument4 pagesVisitor Entryhanshul sisodiyaNo ratings yet

- FD Self AssessmentDocument7 pagesFD Self Assessmentapi-277257927No ratings yet

- 4.3 - B - 10 - Procedure For Hazard Identification and ControlDocument5 pages4.3 - B - 10 - Procedure For Hazard Identification and ControlSASIKUMAR SNo ratings yet

- Cleaning Schedule Template 28Document2 pagesCleaning Schedule Template 28Ajay ChefNo ratings yet

- Corporate Safety - Template: Job Safety & Environmental Analysis (JSEA) / Safe Work Method Statement (SWMS)Document6 pagesCorporate Safety - Template: Job Safety & Environmental Analysis (JSEA) / Safe Work Method Statement (SWMS)yyyyyuil100% (1)

- SA8000 Measures Social Performance in Eight Areas Important To Social Accountability in WorkplacesDocument21 pagesSA8000 Measures Social Performance in Eight Areas Important To Social Accountability in WorkplacesSkr SkrNo ratings yet

- Environment Health Safety Director in Huntsville AL Resume Ainsworth ThomasDocument2 pagesEnvironment Health Safety Director in Huntsville AL Resume Ainsworth ThomasAinsworthThomasNo ratings yet

- Duties & Qualities of Safety OfficersDocument21 pagesDuties & Qualities of Safety OfficersBobbit C ArninioNo ratings yet

- Risk Assessment GenericsDocument7 pagesRisk Assessment Genericsdbrocklehurst13No ratings yet

- Induction FormDocument3 pagesInduction Formnorafikatolah1992No ratings yet

- Job Safety Analysis (Jsa) N2.Document5 pagesJob Safety Analysis (Jsa) N2.Joseph Paul IlaganNo ratings yet

- Food Safety Management System ContentsDocument22 pagesFood Safety Management System ContentsRocky BisNo ratings yet

- SDSU 08 - Job Hazard Anaylsis - IncidentDocument18 pagesSDSU 08 - Job Hazard Anaylsis - IncidentkananiNo ratings yet

- MSDS Cement PDFDocument5 pagesMSDS Cement PDFHendrik SimatupangNo ratings yet

- PL EV 01 Environmental Management Plan Rev.6 PDFDocument42 pagesPL EV 01 Environmental Management Plan Rev.6 PDFKhashbaatar BadralNo ratings yet

- TRA FOR FRT - Rev.S2-2 (Recovered)Document31 pagesTRA FOR FRT - Rev.S2-2 (Recovered)rodman823No ratings yet

- Health, Safety and Environmental Considerations For Process SynthesisDocument6 pagesHealth, Safety and Environmental Considerations For Process SynthesisBramJanssen76No ratings yet

- Safe Work Method For Peb Work: Procedure Possible Hazards Control MeasuresDocument35 pagesSafe Work Method For Peb Work: Procedure Possible Hazards Control Measuressandip patilNo ratings yet

- Health, Safety & WellbeingDocument13 pagesHealth, Safety & WellbeingImran ChowdhuryNo ratings yet

- Workplace Safety Manual 17 18Document12 pagesWorkplace Safety Manual 17 18Maria Kathleen Evangelio JognoNo ratings yet

- Annex 10 - ODS Training Matrix 23.2.22Document1 pageAnnex 10 - ODS Training Matrix 23.2.22Fahmi AbdullahNo ratings yet

- Risk Assessment For Spraying PesticideDocument9 pagesRisk Assessment For Spraying PesticidearmkarthickNo ratings yet

- Accident Incident Report SampleDocument4 pagesAccident Incident Report SampleNgoua CalixNo ratings yet

- Hazard Identification (Hazid) NO YES: Checklist Analysis Hazop + Checklist AnalysisDocument7 pagesHazard Identification (Hazid) NO YES: Checklist Analysis Hazop + Checklist AnalysisZeroRecoNo ratings yet

- Risk Assessment: Kitchen - HomeDocument5 pagesRisk Assessment: Kitchen - HomesonofoddinNo ratings yet

- HSE ViolationDocument1 pageHSE ViolationBrian GiduduNo ratings yet

- Generic Risk Assessment - General Lathe Use v.1Document7 pagesGeneric Risk Assessment - General Lathe Use v.1Darus YasunNo ratings yet

- Sample Construction Risk Assessment 3.13.55 PMDocument4 pagesSample Construction Risk Assessment 3.13.55 PMEmmanuelNo ratings yet

- 5 - Contoh Risk RegisterDocument1 page5 - Contoh Risk RegisterIINNo ratings yet

- CHRC SWMS Excavation Activities PDFDocument6 pagesCHRC SWMS Excavation Activities PDFBorislav VulićNo ratings yet

- Safe Use of Chemicals: 1.0 PurposeDocument10 pagesSafe Use of Chemicals: 1.0 PurposeFuzail AyazNo ratings yet

- SpecificationDocument56 pagesSpecificationIwan Herawan100% (1)

- Machinery Equipment Repair and MaintenanceDocument18 pagesMachinery Equipment Repair and Maintenancepradeepgamage4513No ratings yet

- KPI Submission (October)Document3 pagesKPI Submission (October)Htoo Htoo KyawNo ratings yet

- First Aid Box ContentDocument1 pageFirst Aid Box ContentwaytobhushanNo ratings yet

- Daily Hse Statistics Report Jaya Proyek ServisDocument2 pagesDaily Hse Statistics Report Jaya Proyek ServisIvankaNo ratings yet

- Chemical Risk Assessment Screening Tool of A Globa PDFDocument33 pagesChemical Risk Assessment Screening Tool of A Globa PDFUlviyye ElesgerovaNo ratings yet

- Risk Assessment of Trees MaintenanceDocument9 pagesRisk Assessment of Trees Maintenanceطارق رضوان100% (1)

- HSE-RA-041 Water Proofing - Activities - Rev 0Document11 pagesHSE-RA-041 Water Proofing - Activities - Rev 0عمروNo ratings yet

- HSE-RA-028 Straight and Cut Machine - Rev 0Document10 pagesHSE-RA-028 Straight and Cut Machine - Rev 0عمروNo ratings yet

- HSE-RA-037Bending and Cutting Machine - Rev 0Document13 pagesHSE-RA-037Bending and Cutting Machine - Rev 0عمروNo ratings yet

- HSE-RA-065 Confined Space Entry - Rev 0Document15 pagesHSE-RA-065 Confined Space Entry - Rev 0عمروNo ratings yet

- HSE-RA-060 Using A Personnel Bucket - Rev 0Document11 pagesHSE-RA-060 Using A Personnel Bucket - Rev 0عمروNo ratings yet

- HSE-RA-062 Erecting and Dismantling of Passenger, Material Hoist - Rev - 0Document11 pagesHSE-RA-062 Erecting and Dismantling of Passenger, Material Hoist - Rev - 0عمروNo ratings yet

- HSE-RA-008 Scaffold Erection and Dismantling - Rev 0Document20 pagesHSE-RA-008 Scaffold Erection and Dismantling - Rev 0عمرو100% (1)

- HSE-RA-038 Cut and Bend Operations - Rev 0Document8 pagesHSE-RA-038 Cut and Bend Operations - Rev 0عمروNo ratings yet

- HSE-RA-047 Distribution Board - Rev 0Document11 pagesHSE-RA-047 Distribution Board - Rev 0عمروNo ratings yet

- HSE-RA-021 Blockwork - Rev 0Document10 pagesHSE-RA-021 Blockwork - Rev 0عمروNo ratings yet

- HSE-RA-046 Open Shaft Works and Scaffolding in Shafts - Rev 0Document12 pagesHSE-RA-046 Open Shaft Works and Scaffolding in Shafts - Rev 0عمروNo ratings yet

- HSE-RA-015 Fire Fighting and Prevention - Rev 0Document10 pagesHSE-RA-015 Fire Fighting and Prevention - Rev 0عمروNo ratings yet

- HSE-RA-051 Grade Slabs, Column, Wall and Beam Casting - Rev 0Document30 pagesHSE-RA-051 Grade Slabs, Column, Wall and Beam Casting - Rev 0عمروNo ratings yet

- HSE-RA-049 Loading Platforms - Rev 0Document11 pagesHSE-RA-049 Loading Platforms - Rev 0عمروNo ratings yet

- HSE-RA-066 Using of Cutting Torch - Rev 0Document16 pagesHSE-RA-066 Using of Cutting Torch - Rev 0عمروNo ratings yet

- HSE-RA-035 Gas Welding and Brazing - Rev 0Document12 pagesHSE-RA-035 Gas Welding and Brazing - Rev 0عمروNo ratings yet

- HSE-RA-024 Civil Store - Rev 0Document15 pagesHSE-RA-024 Civil Store - Rev 0عمروNo ratings yet

- HSE-RA-043 Heat Stress - Rev 0Document9 pagesHSE-RA-043 Heat Stress - Rev 0عمروNo ratings yet

- HSE-RA-057 Hydro Test Rev 0Document15 pagesHSE-RA-057 Hydro Test Rev 0عمروNo ratings yet

- HSE-RA-025 Erecting, Dismantling and Maintanance of Tower Crane - Rev 0Document16 pagesHSE-RA-025 Erecting, Dismantling and Maintanance of Tower Crane - Rev 0عمروNo ratings yet

- HSE-RA-039 Plastering Activities - Rev 0Document9 pagesHSE-RA-039 Plastering Activities - Rev 0عمروNo ratings yet

- HSE-RA-042 Gas Cylinder Storage - Rev 0Document10 pagesHSE-RA-042 Gas Cylinder Storage - Rev 0عمروNo ratings yet

- HSE-RA-026 Overhead Work - Rev 0Document9 pagesHSE-RA-026 Overhead Work - Rev 0عمروNo ratings yet

- HSE-RA-011 Manual Handling - Rev 0Document11 pagesHSE-RA-011 Manual Handling - Rev 0عمروNo ratings yet

- HSE-RA-063 Erecting and Dismantling of Placing Boom - Rev 0Document15 pagesHSE-RA-063 Erecting and Dismantling of Placing Boom - Rev 0عمروNo ratings yet

- HSE-RA-058Testing and Comminssioning of Electrical Line Rev 0.Document18 pagesHSE-RA-058Testing and Comminssioning of Electrical Line Rev 0.عمروNo ratings yet

- HSE-RA-018 Use of An Angle Grinder - Rev 0Document15 pagesHSE-RA-018 Use of An Angle Grinder - Rev 0عمروNo ratings yet

- HSE-RA-023 Site Establishment - Rev 0Document17 pagesHSE-RA-023 Site Establishment - Rev 0عمروNo ratings yet

- HSE-RA-019 Steel Fixing - Rev 0Document15 pagesHSE-RA-019 Steel Fixing - Rev 0عمروNo ratings yet

- HSE-RA-053 Floor Screed - Rev 0Document9 pagesHSE-RA-053 Floor Screed - Rev 0عمروNo ratings yet