Professional Documents

Culture Documents

HSE-RA-040 Marble Fixing Rev 0

HSE-RA-040 Marble Fixing Rev 0

Uploaded by

عمروCopyright:

Available Formats

You might also like

- 2318-RA 18.03.2023-REV 0A Cutting The Leg Bracing - RIG Rig LovansingDocument9 pages2318-RA 18.03.2023-REV 0A Cutting The Leg Bracing - RIG Rig LovansingHafeez AliNo ratings yet

- Health Safety and Environment Policy Corporate About AGLDocument2 pagesHealth Safety and Environment Policy Corporate About AGLShashi Shekhar100% (1)

- Chung, Kevin C. - Essentials of Hand Surgery-JP Medical Publishers (2015)Document815 pagesChung, Kevin C. - Essentials of Hand Surgery-JP Medical Publishers (2015)normNo ratings yet

- Disney Safety PlanDocument55 pagesDisney Safety Planapi-505775092No ratings yet

- Subcontractor Production Report: Job SafetyDocument2 pagesSubcontractor Production Report: Job Safetyzubair nawazNo ratings yet

- HSE-RA-029 Straight and Cut Operation - Rev 0Document8 pagesHSE-RA-029 Straight and Cut Operation - Rev 0عمروNo ratings yet

- HSE-RA-024 Civil Store - Rev 0Document15 pagesHSE-RA-024 Civil Store - Rev 0عمروNo ratings yet

- HSE-RA-061 Table and Bench Saw - Rev 0Document14 pagesHSE-RA-061 Table and Bench Saw - Rev 0عمروNo ratings yet

- HSE-RA-030 Bulk Excavation With Excavator - Rev 0Document9 pagesHSE-RA-030 Bulk Excavation With Excavator - Rev 0عمروNo ratings yet

- HSE-RA-013 Deshuttering - Rev 0.Document16 pagesHSE-RA-013 Deshuttering - Rev 0.عمروNo ratings yet

- Elephant Project - Sayakha GujaratDocument8 pagesElephant Project - Sayakha Gujaratalla malikNo ratings yet

- Risk Assessment TemplateDocument183 pagesRisk Assessment TemplateAkeem RodriguezNo ratings yet

- 11 Construction of Kill LineDocument9 pages11 Construction of Kill LinePangky AbasoloNo ratings yet

- Electrical Safety ChecklistDocument2 pagesElectrical Safety ChecklistMohamad ShariinNo ratings yet

- Concrete Risk AssessmentDocument1 pageConcrete Risk AssessmentTariq saifiNo ratings yet

- HSE MOMENT On April 2023 Theme R1 PDFDocument2 pagesHSE MOMENT On April 2023 Theme R1 PDFKulakarni AdusumilliNo ratings yet

- Procter Risk Assessment CalculatorDocument241 pagesProcter Risk Assessment CalculatorFormosa SysNo ratings yet

- Trizac Automation - Presentation - BG - 08.07.2016Document29 pagesTrizac Automation - Presentation - BG - 08.07.2016Atemp-mail.orgInboxNo ratings yet

- Emergency Cooling Severe Heat Related Illnesses: National Centre For Disease ControlDocument40 pagesEmergency Cooling Severe Heat Related Illnesses: National Centre For Disease Controllakshminivas PingaliNo ratings yet

- PSJV Duqm Refinery Project Hsse Observations Tracking RegisterDocument3 pagesPSJV Duqm Refinery Project Hsse Observations Tracking RegisterbalasubramaniamNo ratings yet

- Process Flow ChartDocument6 pagesProcess Flow ChartMahayu Mohd IsaNo ratings yet

- Issue-Based Risk Assessment Sub-Contractor ITS Filters CleaningDocument5 pagesIssue-Based Risk Assessment Sub-Contractor ITS Filters CleaningAhmed AbdulmajeedNo ratings yet

- Attachment 1 Risk AssessmentDocument9 pagesAttachment 1 Risk Assessmentjaouad id boubkerNo ratings yet

- SAM-HSE-F-003-03 Safety Induction Checklist (Project)Document2 pagesSAM-HSE-F-003-03 Safety Induction Checklist (Project)Azman.jpamNo ratings yet

- Risk Assessment:: Corresponding Permit To Work NoDocument4 pagesRisk Assessment:: Corresponding Permit To Work NoNaseemandson TeamNo ratings yet

- Risk AssessmentDocument55 pagesRisk Assessmentmohamed ibrahimNo ratings yet

- Tele HandlerDocument30 pagesTele HandlerArturNo ratings yet

- HSE Organization ChartDocument1 pageHSE Organization ChartMohammad MasihullahNo ratings yet

- Reinforcement Cutting Bending JSA HSE ProfessionalsDocument1 pageReinforcement Cutting Bending JSA HSE ProfessionalsNoval FebriNo ratings yet

- RMR-HSMS-P-001 Hazard Identification Risk Assessment and Risk ManagementDocument14 pagesRMR-HSMS-P-001 Hazard Identification Risk Assessment and Risk ManagementkamranNo ratings yet

- Toolbox Talk Slips Trips and FallsDocument2 pagesToolbox Talk Slips Trips and FallsrajNo ratings yet

- Risk Assessment For Dismantling of Formwork Supporting Steel Strcuture - FOB - BRT Station.Document2 pagesRisk Assessment For Dismantling of Formwork Supporting Steel Strcuture - FOB - BRT Station.salauddin0mohammedNo ratings yet

- Whs Hazard and Risk Management: Doc Id DOC Owner Active Date Review DateDocument17 pagesWhs Hazard and Risk Management: Doc Id DOC Owner Active Date Review DateRamanpreet KaurNo ratings yet

- Building Materials Risk AssessmentDocument3 pagesBuilding Materials Risk AssessmentAhmed El-sherpiniNo ratings yet

- Risk Assessment For SLAB ON GRADE Work: Initial Risk Score Control Measure Residual Risk Score Action VerifiedDocument2 pagesRisk Assessment For SLAB ON GRADE Work: Initial Risk Score Control Measure Residual Risk Score Action Verifiedeng mohamad husamNo ratings yet

- Monthly HSE Report - Oktober2019 - Aneka CoffeeDocument57 pagesMonthly HSE Report - Oktober2019 - Aneka CoffeeKikie KieeNo ratings yet

- 15 Driving Safety and Training ProcedureDocument6 pages15 Driving Safety and Training Procedureihajar9100% (1)

- 04weekly Statistics Report (July) : Técnicas Reunidas Petrokemya Abs ProjectDocument5 pages04weekly Statistics Report (July) : Técnicas Reunidas Petrokemya Abs ProjectAviects Avie JaroNo ratings yet

- Information:: YellowDocument6 pagesInformation:: YellowSHRISH SHUKLANo ratings yet

- Chaliyama Steel Plant-Rungta Mines Limited Hazard Identification & Risk AssessmentDocument3 pagesChaliyama Steel Plant-Rungta Mines Limited Hazard Identification & Risk AssessmentCPP EI DSpNo ratings yet

- Changing Hydroulic Pump An Equipment (WS)Document6 pagesChanging Hydroulic Pump An Equipment (WS)John KalvinNo ratings yet

- Annex 10 - ODS Training Matrix 23.2.22Document1 pageAnnex 10 - ODS Training Matrix 23.2.22Fahmi AbdullahNo ratings yet

- Hard Land Scape Risk AssessmentDocument4 pagesHard Land Scape Risk AssessmentvivekanandhanNo ratings yet

- Risk Assessment IIIDocument1 pageRisk Assessment IIIJosh Booth100% (2)

- 8) SWP-08 Working at HeightsDocument3 pages8) SWP-08 Working at HeightsRachel NoraNo ratings yet

- Deshuttering EPC10 RA15 R1Document3 pagesDeshuttering EPC10 RA15 R1salauddin0mohammedNo ratings yet

- RA - EIA Neon LampsDocument2 pagesRA - EIA Neon Lampsعمرو100% (1)

- Drivers Safe InductionDocument1 pageDrivers Safe Inductionortega yawa100% (1)

- Risk Assessment Carpentry Works For Dismantling Wooden BoxesDocument10 pagesRisk Assessment Carpentry Works For Dismantling Wooden BoxesSinaNo ratings yet

- RA - 15 - For Production Delivery Installation of Precast Pre-Stressed ElementsDocument30 pagesRA - 15 - For Production Delivery Installation of Precast Pre-Stressed ElementsIbrahim EsmatNo ratings yet

- Risk Assessment CalculatorDocument244 pagesRisk Assessment CalculatorJoséAntonioBarbosaNo ratings yet

- RA - Fire Alarm SystemDocument12 pagesRA - Fire Alarm Systemvelangi rajuNo ratings yet

- Risk Assesment Project VimalDocument7 pagesRisk Assesment Project VimalHASHIM TKNo ratings yet

- Working at Same Levels (High Risk Areas) RA-R9-01-001-02Document1 pageWorking at Same Levels (High Risk Areas) RA-R9-01-001-02cmrig74No ratings yet

- Templates Package 1 ContentDocument1 pageTemplates Package 1 ContentM IqbalNo ratings yet

- Risk / Impact Assessment Control Sheet: MatrixDocument4 pagesRisk / Impact Assessment Control Sheet: MatrixSaim AliNo ratings yet

- GC3 ObservationDocument16 pagesGC3 ObservationjithinNo ratings yet

- Concrete Works Sub StructureDocument5 pagesConcrete Works Sub StructureRaja NasirNo ratings yet

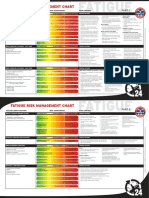

- DDAAFS Fatigue Risk Management Chart - Nov 2015Document2 pagesDDAAFS Fatigue Risk Management Chart - Nov 2015Ghulam MustafaNo ratings yet

- HSE-RA-016 Waste Materials - Rev 0Document12 pagesHSE-RA-016 Waste Materials - Rev 0عمروNo ratings yet

- HSE-RA-041 Water Proofing - Activities - Rev 0Document11 pagesHSE-RA-041 Water Proofing - Activities - Rev 0عمروNo ratings yet

- HSE-RA-028 Straight and Cut Machine - Rev 0Document10 pagesHSE-RA-028 Straight and Cut Machine - Rev 0عمروNo ratings yet

- HSE-RA-037Bending and Cutting Machine - Rev 0Document13 pagesHSE-RA-037Bending and Cutting Machine - Rev 0عمروNo ratings yet

- HSE-RA-065 Confined Space Entry - Rev 0Document15 pagesHSE-RA-065 Confined Space Entry - Rev 0عمروNo ratings yet

- HSE-RA-060 Using A Personnel Bucket - Rev 0Document11 pagesHSE-RA-060 Using A Personnel Bucket - Rev 0عمروNo ratings yet

- HSE-RA-062 Erecting and Dismantling of Passenger, Material Hoist - Rev - 0Document11 pagesHSE-RA-062 Erecting and Dismantling of Passenger, Material Hoist - Rev - 0عمروNo ratings yet

- HSE-RA-008 Scaffold Erection and Dismantling - Rev 0Document20 pagesHSE-RA-008 Scaffold Erection and Dismantling - Rev 0عمرو100% (1)

- HSE-RA-038 Cut and Bend Operations - Rev 0Document8 pagesHSE-RA-038 Cut and Bend Operations - Rev 0عمروNo ratings yet

- HSE-RA-047 Distribution Board - Rev 0Document11 pagesHSE-RA-047 Distribution Board - Rev 0عمروNo ratings yet

- HSE-RA-021 Blockwork - Rev 0Document10 pagesHSE-RA-021 Blockwork - Rev 0عمروNo ratings yet

- HSE-RA-046 Open Shaft Works and Scaffolding in Shafts - Rev 0Document12 pagesHSE-RA-046 Open Shaft Works and Scaffolding in Shafts - Rev 0عمروNo ratings yet

- HSE-RA-015 Fire Fighting and Prevention - Rev 0Document10 pagesHSE-RA-015 Fire Fighting and Prevention - Rev 0عمروNo ratings yet

- HSE-RA-051 Grade Slabs, Column, Wall and Beam Casting - Rev 0Document30 pagesHSE-RA-051 Grade Slabs, Column, Wall and Beam Casting - Rev 0عمروNo ratings yet

- HSE-RA-049 Loading Platforms - Rev 0Document11 pagesHSE-RA-049 Loading Platforms - Rev 0عمروNo ratings yet

- HSE-RA-066 Using of Cutting Torch - Rev 0Document16 pagesHSE-RA-066 Using of Cutting Torch - Rev 0عمروNo ratings yet

- HSE-RA-035 Gas Welding and Brazing - Rev 0Document12 pagesHSE-RA-035 Gas Welding and Brazing - Rev 0عمروNo ratings yet

- HSE-RA-026 Overhead Work - Rev 0Document9 pagesHSE-RA-026 Overhead Work - Rev 0عمروNo ratings yet

- HSE-RA-043 Heat Stress - Rev 0Document9 pagesHSE-RA-043 Heat Stress - Rev 0عمروNo ratings yet

- HSE-RA-057 Hydro Test Rev 0Document15 pagesHSE-RA-057 Hydro Test Rev 0عمروNo ratings yet

- HSE-RA-025 Erecting, Dismantling and Maintanance of Tower Crane - Rev 0Document16 pagesHSE-RA-025 Erecting, Dismantling and Maintanance of Tower Crane - Rev 0عمروNo ratings yet

- HSE-RA-039 Plastering Activities - Rev 0Document9 pagesHSE-RA-039 Plastering Activities - Rev 0عمروNo ratings yet

- HSE-RA-042 Gas Cylinder Storage - Rev 0Document10 pagesHSE-RA-042 Gas Cylinder Storage - Rev 0عمروNo ratings yet

- HSE-RA-022 Environmental Management - Rev 0Document22 pagesHSE-RA-022 Environmental Management - Rev 0عمروNo ratings yet

- HSE-RA-011 Manual Handling - Rev 0Document11 pagesHSE-RA-011 Manual Handling - Rev 0عمروNo ratings yet

- HSE-RA-053 Floor Screed - Rev 0Document9 pagesHSE-RA-053 Floor Screed - Rev 0عمروNo ratings yet

- HSE-RA-063 Erecting and Dismantling of Placing Boom - Rev 0Document15 pagesHSE-RA-063 Erecting and Dismantling of Placing Boom - Rev 0عمروNo ratings yet

- HSE-RA-024 Civil Store - Rev 0Document15 pagesHSE-RA-024 Civil Store - Rev 0عمروNo ratings yet

- HSE-RA-058Testing and Comminssioning of Electrical Line Rev 0.Document18 pagesHSE-RA-058Testing and Comminssioning of Electrical Line Rev 0.عمروNo ratings yet

- HSE-RA-018 Use of An Angle Grinder - Rev 0Document15 pagesHSE-RA-018 Use of An Angle Grinder - Rev 0عمروNo ratings yet

- HSE-RA-019 Steel Fixing - Rev 0Document15 pagesHSE-RA-019 Steel Fixing - Rev 0عمروNo ratings yet

- Grade 6 DLL Mapeh q4 Week 6Document4 pagesGrade 6 DLL Mapeh q4 Week 6Ivy PacateNo ratings yet

- NSS-14 Triple SuperphosphateDocument1 pageNSS-14 Triple SuperphosphateNuraini RahmaNo ratings yet

- Bomba Hidráulica FestoDocument8 pagesBomba Hidráulica FestoAlex TamayoNo ratings yet

- Chemistry in Context 6th Edition American Chemical Society Acs Test BankDocument17 pagesChemistry in Context 6th Edition American Chemical Society Acs Test Bankjenniferrichardsonjrwfpzsdim100% (32)

- Geothermal Case Study CompetitionDocument16 pagesGeothermal Case Study CompetitionTimSenator TERRANo ratings yet

- CNCEC Saudi - IMS Manual (Issue 01, April 2011)Document41 pagesCNCEC Saudi - IMS Manual (Issue 01, April 2011)chao gaoNo ratings yet

- dsmc0020 en Medc hd1 Heat DetectorDocument2 pagesdsmc0020 en Medc hd1 Heat DetectorAbdul Hakeem MohammedNo ratings yet

- Watts Zone Controls and Valves - 2Document16 pagesWatts Zone Controls and Valves - 2Sid KherNo ratings yet

- Compressed Air System Design, Operating and MaintenanceDocument29 pagesCompressed Air System Design, Operating and Maintenanceibrahim1961No ratings yet

- CAEPIPE Presentation - v11.00Document17 pagesCAEPIPE Presentation - v11.00Johan ConradieNo ratings yet

- Jipmer Overall 2Document2,787 pagesJipmer Overall 2Balaji Ganesan0% (1)

- Non-Ferrous Extractive Metallurgy Prof. H. S. Ray Department of Metallurgical and Materials Engineering Indian Institute of Technology, KharagpurDocument22 pagesNon-Ferrous Extractive Metallurgy Prof. H. S. Ray Department of Metallurgical and Materials Engineering Indian Institute of Technology, Kharagpursubrat754No ratings yet

- Peek Optima Reinforced 4Document7 pagesPeek Optima Reinforced 4Davis LarrubiaNo ratings yet

- McDonald & Dominos Entry in IndiaDocument24 pagesMcDonald & Dominos Entry in IndiaRaj Paroha83% (6)

- SF20 - OKL04 Risk Assessment WeldingDocument2 pagesSF20 - OKL04 Risk Assessment WeldingMike BoyesNo ratings yet

- Ilovepdf MergedDocument95 pagesIlovepdf MergedYoussef El bahiNo ratings yet

- Work Immersion Portfolio: Jhon Carlo Cera CatindoyDocument22 pagesWork Immersion Portfolio: Jhon Carlo Cera CatindoyJoel DufaleNo ratings yet

- ?CCS Template Guide Attachment 3 V2?Document32 pages?CCS Template Guide Attachment 3 V2?Umair HussainNo ratings yet

- Research Projects JiitDocument14 pagesResearch Projects JiitSAMAIRA SINGHNo ratings yet

- Functional Safety Embedded Systems: Integration of in The Development Process ofDocument34 pagesFunctional Safety Embedded Systems: Integration of in The Development Process ofAleksandar MilinkovicNo ratings yet

- PARCO Pakistan HRMDocument38 pagesPARCO Pakistan HRMfujimukazu100% (1)

- D5462 PDFDocument6 pagesD5462 PDFZamir Danilo Morera ForeroNo ratings yet

- Aspects of Pharmacology in The Neonatal FoalDocument26 pagesAspects of Pharmacology in The Neonatal FoalAristoteles Esteban Cine VelazquezNo ratings yet

- Samsung 2009 VRF DVMDocument60 pagesSamsung 2009 VRF DVMe_mumcik100% (2)

- Geotechnical Factual ReportDocument89 pagesGeotechnical Factual ReportMohamed RusfanNo ratings yet

- VD UM DOSIMAX Plus A HV 001 - NDDocument31 pagesVD UM DOSIMAX Plus A HV 001 - NDPaweł KopyśćNo ratings yet

- Grant AwardDocument15 pagesGrant AwardRay StillNo ratings yet

- Quest Circular Motion 1 KeyDocument5 pagesQuest Circular Motion 1 KeyCarlos Ortiz100% (1)

- Tank Loss EstimateDocument123 pagesTank Loss EstimateAndreea AntohiNo ratings yet

HSE-RA-040 Marble Fixing Rev 0

HSE-RA-040 Marble Fixing Rev 0

Uploaded by

عمروOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HSE-RA-040 Marble Fixing Rev 0

HSE-RA-040 Marble Fixing Rev 0

Uploaded by

عمروCopyright:

Available Formats

DOC No DS/CA006P02/00022

PAGE No 1 of 12

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 040

Job Description: Marble Fixing

Index:

Form 1 Task Analysis Initiation

Form 2 Risk Assessment Process As per Risk Assessment Procedure.

Form 3 Written Safe Work Procedure Result

Compiled by the following team:

NAME DESIGNATION SIGNATURE

Project Manager

Construction Manager

Site Engineer

Safety Officer

Risk Assessment Review 1 Review 2 Review 3 Review 4

Review Date: Date : Date : Date:

Name and Signature

of person reviewing :

AUTHORISATION

Prepared by: Approved by

Signature Date Signature Date

HSE Manager Project Manager

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 2 of 12

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 040

Job Description: Marble Fixing

TASK ANALYSIS - FORM 1

Impact

SEQUENCE OF TASK STEPS POTENTIAL INJURIES OR HAZARDS RECOMMENDED CONTROLS

H, S, E

Pre-use inspection and use of all equipment Failure of equipment will cause injuries to Faulty equipment to be repaired/maintained or replaced.

persons and / or property damage. Guards to be on all Machinery and appropriate PPE to be

Faulty hand tools and power tools. worn.

Fuel/oil leaks could cause environmental Engine ran machinery to have fire extinguishers available

1. concerns. H, S, E

locally.

Drip trays/heavy gauge plastic to be provided in case of

leaks and spill kit to be within the project for accidental

spills.

Wear appropriate Personal Protective Failure to use Personal Protective

Equipment. Equipment will cause injuries to employees.

Gloves.

Safety boots. Enforce the use of Personal Protective Equipment AT

2. H

Overalls. ALL times

Hard hat.

Hearing protection.

Eye protection

All Enforce the use of competent persons only

Lack of knowledge All employees assigned to this task must be Safety

Inducted also they will have to attend a safety meeting,

Failure may result in injuries to persons and which will include the Standard Operating Procedures,

Use trained employees only property damage. types of potential hazards, and actual hazards present

3. H, S

and controls for those hazards.

Workers should be legally appointed & having their Id’s.

Ensure that the operatives are physically and mentally fit

to do the activity.

Competent supervision Failure will cause injuries to employees and Competent supervisor should be appointed for every

4. H, S

or property damage activity to monitor the workers. Work task instruction

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 3 of 12

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 040

Job Description: Marble Fixing

should be provided for every activity.

All the tools must be inspected before use.

Any or all faulty tools must be removed from the

workplace.

Ensure cable management system is applied

Special tools should be certified as safe for use and also

must be inspected before use.

Defective tools

All type of power tools must be colour coded and tagged

Extension cords with worn

as safe for use also must be entered in register.

insulations

Permit to work system should be in place.

Tripping hazards

5. Using Hand & Power Tools H, S Ensure that the machine guarding system is

Use of tools not intended for the job

implemented.

Use of improper PPE

Failure will result in injuries to persons and /

Safety officer must be ensure that the workplace is

or property damage properly secured and comply with the minimum

environmental requirements.

PPE should be worn by all operators as per the job

nature.

Avoid any unnecessary and unwanted materials in the

workplace that can cause tripping hazard

.

Ensure that the Chain block is not defective and safe to

Defective lifting devise use

Equipment failure for lifting Chain block must be inspected and certified by third

Lack of trained operatives party.

Using Lifting devise Failure to adopt lifting plan and Use trained person that intended to do the lifting

6. H,S,E

(Chain Block) procedures operation.

Failure will result in injuries to persons and / Permit to work system should be in place.

or property damage PPE should be worn by all operators as per the job

nature.

Avoid any unnecessary and unwanted materials in the

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 4 of 12

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 040

Job Description: Marble Fixing

workplace that can cause tripping hazard.

Lifting area must be cordoned off and assigned

watchman to control the peoples movement.

Full time supervision is much required.

Ensure proper scaffolding / working platform is properly

Failure to provide proper working erected and safe to use.

platform The scaffolding must be comply with the minimum

Presence of unsafe scaffold due to standard requirements

insufficient minimum requirements (Edge protection, Landing platform and proper access)

Failure to assign competent Scaffolding must be erected by competent scaffolding

scaffolding erectors. erectors only.

Failure will allow employees to climb Ensure that the scaffolding is inspected and tagging

onto incomplete or unsafe scaffolds system is in place.

7. Using of Scaffolding / Working Platform resulting in injury to persons Permit to work procedure must be issued prior to climb

Overloading can cause collapsing of H,S up the scaffolding.

scaffold causing injuries and or Ensure only the required material to be loaded on top of

property damage the platform.

Lack of training and knowledge for Materials to be kept on the top of scaffolding must be

working in the scaffolding procedure properly stacked and secured.

Falling equipment / material can Supervision of work should be done under the competent

cause injuries and or property supervision such as, an Engineer or Competent

damage Supervisor only.

Signage and notification warning signs should be fixed.

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 5 of 12

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 040

Job Description: Marble Fixing

Failure to cordoned off the area and Area must be barricaded to stop unauthorized entry in the

not secured similar area.

Unauthorized entry / Lack of Supervision of work should be done under the competent

supervision supervision such as, an Engineer or Competent

Barricading

Failure to provide signage / noticed Supervisor only.

8. & H, S

Work supervision board Signage and notification warning signs should be fixed in

the workplace to avoid unauthorized entry and to

Failure of all above stated will cause injuries determine the potential and actual hazard.

to person and/or property damage

Failure to adopt the correct Toolbox talk and training must be conducted to all

procedure operatives together with the supervisor prior to start the

Non-observance of personnel on work.

proper fixing procedure Marble fixing procedures must be properly discussed by

Lack of supervision the supervisor to the operatives.

Failure of all above stated will cause injuries Safety officer must be ensure that the workplace is

to person and/or property damage properly secured and comply with the minimum

environmental requirements.

9. Installation procedure H, S The installation must be done by trained person only.

Competent supervisor must be present all the time during

the installation.

Tools and equipment must be inspected and ensure it is

in good condition and safe to use.

Scaffolding platform must be properly erected and fitted

on the required height and the platform is sufficient.

Unsure that the marble is fixed and properly secured

before leaving the area and shifted from one place to

another.

RISK ASSESSMENT – FORM 2

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 6 of 12

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 040

Job Description: Marble Fixing

Risk Rating Calculation

Risk Rating = A + B + C + D.

A + B + C + D

Injury Severity Potential Damage / Loss Frequency or Likelihood Environmental Impact

0 No injury 0 No damage 0 Never happened before 0 No effect

1 Minor – (FAC) 1 Minor < 500 AED, No delay 1 Happened somewhere 1 Minor Effect - Short term < less 1 month

2 Major – (MTC) 2 Major > 500 AED, No delay 2 Happens occasionally 2 Major Effect - Long term > Greater 1 month

3 LTI 3 Major > 10 000 AED, one day delay 3 Happened before

4 Disabling Injuries 4 Serious > 100, 000 AED, >1 day delay 4 Happens regularly

Risk Rating Matrix

5 Fatality 5 Severe > 1, 000, 000 AED, Weeks delay. 5 Daily occurrence

Result Classification:

Risk Rating

Critical = 17►15 High = 14►11 Medium = 10►7 Low = 6►0 16

Immediate action. Action in 24 hours. Action in a week. ASAP. 14

12

10

Risk Reduction Hierarchy: 8

6

1. Engineering to reduce risk. 4

2. Replacement with lower risk. 2

0

3. Isolation of risk – Barricading or Guarding. 1

5

2 4

4. Reduction of exposure to risk. 3

4 3

5 Probability

5. PPE and Training Potential Impact 6

7 2 (C)

(A / B / D) 8

9 1

RISK ASSESSMENT – FORM 2 (continued)

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 7 of 12

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 040

Job Description: Marble Fixing

RISK ASSOCIATED WITH Impact HOW IS HAZARD TO BE BY Result

No HAZARD IDENTIFIED H, S, E RR BY WHOM RR

HAZARD DEALT WITH WHEN

Faulty hand tools Bruises, cuts. Gloves, trowels in good Supervisor Before &

condition. during

Mechanical guards not in Entanglement, Skeletal Damage. the use

place Guards in place and equipment of

1 H,S,E 13 regularly maintained. equipme 6

nt

Unwanted Fuel/Oil Contamination of the soil, Care to be taken refuelling and

Spillages atmospheric pollution, risk of fire. drip trays/heavy gauge plastic to

be in place as required.

Injury to project employees Potential Death, Major/Minor Following PPE to be worn Supervisor Before &

Skeletal damage, cuts and bruises to appropriately to the task – during

all parts of the body, asthma. Gloves. work

Safety boots.

2 H,S 10 5

Overalls.

Hard hat.

Hearing protection.

Eye protection

Un trained employees Poor quality of work, chance for Provided trained/competent PE/FM Always

3 accident /incident or property H,S 7 worker and supervision 5

lost/damage

Poor Supervision Poor quality of work, chance for Ensure the availability of PE/FM Always

accident /incident or property competent supervisor at work

lost/damage place.

4 H,S 10 3

Work task instruction should be

provided to the workers prior to

the commencement of activity

Appropriate Personal protective Before

Injuries to person and / or property Supervisor

5 Handling Marbles and material H, S, 12 equipments must be wear at all starting 3

damage. Operator

time work.

All the equipments must be Supervisor

Injuries to person and / or property

6 Equipment failure H, S 12 inspected by third party and safe Plant Dept. Always 4

damage.

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 8 of 12

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 040

Job Description: Marble Fixing

* RR = Risk Rating

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 9 of 12

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 040

Job Description: Marble Fixing

WRITTEN SAFE WORK PROCEDURE

1. OBJECTIVE

1. To prevent injuries to employees and / or property damage incidents.

2. PROCEDURE

1. Do pre-use inspection of all equipment to be used and replace or repair faulty items.

2. Use trained competent employees only.

3. Use appropriate Personal Protective Equipment i.e.:

3.1. Hardhat.

3.2. Safety boots.

3.3. Overalls.

3.4. Ear Plugs

3.5. Masks

3.6. Safety Glasses

3.7. Hand gloves

Prior to work commencement

1. Must have PPE – safety footwear, gloves, hardhat, goggles, foul weather clothing etc.

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 10 of 12

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 040

Job Description: Marble Fixing

2. Must have appropriate tools and equipment in good condition.

3. Must have weatherproof covers for materials and equipment, waste containers, warning tape.

4. Consider risks and hazards in work area. Refer any concerns to supervisor. Are relevant permits in place?

5. Check if it is necessary to secure area adjacent to work. Refer to supervisor if appropriate.

6. Arrange for transport of materials and equipment to site via supervisor.

7. Ensure materials and equipment are secure or removed when site unattended, eg overnight or during breaks.

Hazards

1. Manual handling of materials and equipment – LITE to be considered at all times.

2. Slips and trips from untidy work area.

3. Falling materials, eg bricks and blocks, mortar, lintels etc.

4. Contact with cement and adhesive. (see COSSH sheet and materials packaging).

5. Collapse of existing structures, eg wall.

6. Hazards associated with equipment used for mixing machine etc, eg. Electric shock, water storage, entanglement etc.

7. Contact with sharp edges, eg. Tile cutting with grinder.

8. Consideration of weather and ground conditions must be made.

Harm

Potential Death, Minor/major cuts and contusions, loss of limbs, fractures, concussion, to fatality, electric shock.

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 11 of 12

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 040

Job Description: Marble Fixing

Persons in danger

1. Masons and Labour.

2. Other workers/visitors in vicinity, eg. Passers-by in corridors etc.

Control measures

No lone working

Work involving in the marble fixing activity

2.1. Appropriate PPE must be worn by all workers on site & special PPE should be provided for those who are directly

involved in this activity.

2.2. Site Induction and tool box talks should be given prior to start job.

2.3. Equipment to be used in transporting marbles should be inspected and must be safe for use.

2.4. Marbles shall be properly secured while being transported.

2.5. Marble stand and racks capable of carrying the load. Load capacity clearly visual on every unit.

2.6. Employees shall be educated in keeping out of possible crush on marbles turn into pieces

2.7. Permit to work system should be followed by all supervisors and engineers.

2.8. Daily, weekly and monthly inspection to be done regularly any defect found must be reported immediately.

2.9. Physical barricade to installed and maintained with entry and exit points.

2.10. Only personnel involve in the marble fixing activities are allowed inside the barricaded area. Enforce the use of competent

persons only.

2.11. All hand and power tools must be inspected before use

2.12. All hand and power tools must be safe for use

2.13. All type of power tools must be colour coded and tagged as safe for use also must be entered in register.

2.14. Permit to work system should be in place.

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 12 of 12

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 040

Job Description: Marble Fixing

2.15. PPE should be worn by all operators as per the job nature.

2.16. Maintain work area isolated with means of barricade and appropriate signage should be in place.

2.17. Remind personnel through toolbox talk to observe proper positioning when working

2.18. All the work should be done under the competent supervision.

HSE/QUALITY SYSTEM DOCUMENTATION

You might also like

- 2318-RA 18.03.2023-REV 0A Cutting The Leg Bracing - RIG Rig LovansingDocument9 pages2318-RA 18.03.2023-REV 0A Cutting The Leg Bracing - RIG Rig LovansingHafeez AliNo ratings yet

- Health Safety and Environment Policy Corporate About AGLDocument2 pagesHealth Safety and Environment Policy Corporate About AGLShashi Shekhar100% (1)

- Chung, Kevin C. - Essentials of Hand Surgery-JP Medical Publishers (2015)Document815 pagesChung, Kevin C. - Essentials of Hand Surgery-JP Medical Publishers (2015)normNo ratings yet

- Disney Safety PlanDocument55 pagesDisney Safety Planapi-505775092No ratings yet

- Subcontractor Production Report: Job SafetyDocument2 pagesSubcontractor Production Report: Job Safetyzubair nawazNo ratings yet

- HSE-RA-029 Straight and Cut Operation - Rev 0Document8 pagesHSE-RA-029 Straight and Cut Operation - Rev 0عمروNo ratings yet

- HSE-RA-024 Civil Store - Rev 0Document15 pagesHSE-RA-024 Civil Store - Rev 0عمروNo ratings yet

- HSE-RA-061 Table and Bench Saw - Rev 0Document14 pagesHSE-RA-061 Table and Bench Saw - Rev 0عمروNo ratings yet

- HSE-RA-030 Bulk Excavation With Excavator - Rev 0Document9 pagesHSE-RA-030 Bulk Excavation With Excavator - Rev 0عمروNo ratings yet

- HSE-RA-013 Deshuttering - Rev 0.Document16 pagesHSE-RA-013 Deshuttering - Rev 0.عمروNo ratings yet

- Elephant Project - Sayakha GujaratDocument8 pagesElephant Project - Sayakha Gujaratalla malikNo ratings yet

- Risk Assessment TemplateDocument183 pagesRisk Assessment TemplateAkeem RodriguezNo ratings yet

- 11 Construction of Kill LineDocument9 pages11 Construction of Kill LinePangky AbasoloNo ratings yet

- Electrical Safety ChecklistDocument2 pagesElectrical Safety ChecklistMohamad ShariinNo ratings yet

- Concrete Risk AssessmentDocument1 pageConcrete Risk AssessmentTariq saifiNo ratings yet

- HSE MOMENT On April 2023 Theme R1 PDFDocument2 pagesHSE MOMENT On April 2023 Theme R1 PDFKulakarni AdusumilliNo ratings yet

- Procter Risk Assessment CalculatorDocument241 pagesProcter Risk Assessment CalculatorFormosa SysNo ratings yet

- Trizac Automation - Presentation - BG - 08.07.2016Document29 pagesTrizac Automation - Presentation - BG - 08.07.2016Atemp-mail.orgInboxNo ratings yet

- Emergency Cooling Severe Heat Related Illnesses: National Centre For Disease ControlDocument40 pagesEmergency Cooling Severe Heat Related Illnesses: National Centre For Disease Controllakshminivas PingaliNo ratings yet

- PSJV Duqm Refinery Project Hsse Observations Tracking RegisterDocument3 pagesPSJV Duqm Refinery Project Hsse Observations Tracking RegisterbalasubramaniamNo ratings yet

- Process Flow ChartDocument6 pagesProcess Flow ChartMahayu Mohd IsaNo ratings yet

- Issue-Based Risk Assessment Sub-Contractor ITS Filters CleaningDocument5 pagesIssue-Based Risk Assessment Sub-Contractor ITS Filters CleaningAhmed AbdulmajeedNo ratings yet

- Attachment 1 Risk AssessmentDocument9 pagesAttachment 1 Risk Assessmentjaouad id boubkerNo ratings yet

- SAM-HSE-F-003-03 Safety Induction Checklist (Project)Document2 pagesSAM-HSE-F-003-03 Safety Induction Checklist (Project)Azman.jpamNo ratings yet

- Risk Assessment:: Corresponding Permit To Work NoDocument4 pagesRisk Assessment:: Corresponding Permit To Work NoNaseemandson TeamNo ratings yet

- Risk AssessmentDocument55 pagesRisk Assessmentmohamed ibrahimNo ratings yet

- Tele HandlerDocument30 pagesTele HandlerArturNo ratings yet

- HSE Organization ChartDocument1 pageHSE Organization ChartMohammad MasihullahNo ratings yet

- Reinforcement Cutting Bending JSA HSE ProfessionalsDocument1 pageReinforcement Cutting Bending JSA HSE ProfessionalsNoval FebriNo ratings yet

- RMR-HSMS-P-001 Hazard Identification Risk Assessment and Risk ManagementDocument14 pagesRMR-HSMS-P-001 Hazard Identification Risk Assessment and Risk ManagementkamranNo ratings yet

- Toolbox Talk Slips Trips and FallsDocument2 pagesToolbox Talk Slips Trips and FallsrajNo ratings yet

- Risk Assessment For Dismantling of Formwork Supporting Steel Strcuture - FOB - BRT Station.Document2 pagesRisk Assessment For Dismantling of Formwork Supporting Steel Strcuture - FOB - BRT Station.salauddin0mohammedNo ratings yet

- Whs Hazard and Risk Management: Doc Id DOC Owner Active Date Review DateDocument17 pagesWhs Hazard and Risk Management: Doc Id DOC Owner Active Date Review DateRamanpreet KaurNo ratings yet

- Building Materials Risk AssessmentDocument3 pagesBuilding Materials Risk AssessmentAhmed El-sherpiniNo ratings yet

- Risk Assessment For SLAB ON GRADE Work: Initial Risk Score Control Measure Residual Risk Score Action VerifiedDocument2 pagesRisk Assessment For SLAB ON GRADE Work: Initial Risk Score Control Measure Residual Risk Score Action Verifiedeng mohamad husamNo ratings yet

- Monthly HSE Report - Oktober2019 - Aneka CoffeeDocument57 pagesMonthly HSE Report - Oktober2019 - Aneka CoffeeKikie KieeNo ratings yet

- 15 Driving Safety and Training ProcedureDocument6 pages15 Driving Safety and Training Procedureihajar9100% (1)

- 04weekly Statistics Report (July) : Técnicas Reunidas Petrokemya Abs ProjectDocument5 pages04weekly Statistics Report (July) : Técnicas Reunidas Petrokemya Abs ProjectAviects Avie JaroNo ratings yet

- Information:: YellowDocument6 pagesInformation:: YellowSHRISH SHUKLANo ratings yet

- Chaliyama Steel Plant-Rungta Mines Limited Hazard Identification & Risk AssessmentDocument3 pagesChaliyama Steel Plant-Rungta Mines Limited Hazard Identification & Risk AssessmentCPP EI DSpNo ratings yet

- Changing Hydroulic Pump An Equipment (WS)Document6 pagesChanging Hydroulic Pump An Equipment (WS)John KalvinNo ratings yet

- Annex 10 - ODS Training Matrix 23.2.22Document1 pageAnnex 10 - ODS Training Matrix 23.2.22Fahmi AbdullahNo ratings yet

- Hard Land Scape Risk AssessmentDocument4 pagesHard Land Scape Risk AssessmentvivekanandhanNo ratings yet

- Risk Assessment IIIDocument1 pageRisk Assessment IIIJosh Booth100% (2)

- 8) SWP-08 Working at HeightsDocument3 pages8) SWP-08 Working at HeightsRachel NoraNo ratings yet

- Deshuttering EPC10 RA15 R1Document3 pagesDeshuttering EPC10 RA15 R1salauddin0mohammedNo ratings yet

- RA - EIA Neon LampsDocument2 pagesRA - EIA Neon Lampsعمرو100% (1)

- Drivers Safe InductionDocument1 pageDrivers Safe Inductionortega yawa100% (1)

- Risk Assessment Carpentry Works For Dismantling Wooden BoxesDocument10 pagesRisk Assessment Carpentry Works For Dismantling Wooden BoxesSinaNo ratings yet

- RA - 15 - For Production Delivery Installation of Precast Pre-Stressed ElementsDocument30 pagesRA - 15 - For Production Delivery Installation of Precast Pre-Stressed ElementsIbrahim EsmatNo ratings yet

- Risk Assessment CalculatorDocument244 pagesRisk Assessment CalculatorJoséAntonioBarbosaNo ratings yet

- RA - Fire Alarm SystemDocument12 pagesRA - Fire Alarm Systemvelangi rajuNo ratings yet

- Risk Assesment Project VimalDocument7 pagesRisk Assesment Project VimalHASHIM TKNo ratings yet

- Working at Same Levels (High Risk Areas) RA-R9-01-001-02Document1 pageWorking at Same Levels (High Risk Areas) RA-R9-01-001-02cmrig74No ratings yet

- Templates Package 1 ContentDocument1 pageTemplates Package 1 ContentM IqbalNo ratings yet

- Risk / Impact Assessment Control Sheet: MatrixDocument4 pagesRisk / Impact Assessment Control Sheet: MatrixSaim AliNo ratings yet

- GC3 ObservationDocument16 pagesGC3 ObservationjithinNo ratings yet

- Concrete Works Sub StructureDocument5 pagesConcrete Works Sub StructureRaja NasirNo ratings yet

- DDAAFS Fatigue Risk Management Chart - Nov 2015Document2 pagesDDAAFS Fatigue Risk Management Chart - Nov 2015Ghulam MustafaNo ratings yet

- HSE-RA-016 Waste Materials - Rev 0Document12 pagesHSE-RA-016 Waste Materials - Rev 0عمروNo ratings yet

- HSE-RA-041 Water Proofing - Activities - Rev 0Document11 pagesHSE-RA-041 Water Proofing - Activities - Rev 0عمروNo ratings yet

- HSE-RA-028 Straight and Cut Machine - Rev 0Document10 pagesHSE-RA-028 Straight and Cut Machine - Rev 0عمروNo ratings yet

- HSE-RA-037Bending and Cutting Machine - Rev 0Document13 pagesHSE-RA-037Bending and Cutting Machine - Rev 0عمروNo ratings yet

- HSE-RA-065 Confined Space Entry - Rev 0Document15 pagesHSE-RA-065 Confined Space Entry - Rev 0عمروNo ratings yet

- HSE-RA-060 Using A Personnel Bucket - Rev 0Document11 pagesHSE-RA-060 Using A Personnel Bucket - Rev 0عمروNo ratings yet

- HSE-RA-062 Erecting and Dismantling of Passenger, Material Hoist - Rev - 0Document11 pagesHSE-RA-062 Erecting and Dismantling of Passenger, Material Hoist - Rev - 0عمروNo ratings yet

- HSE-RA-008 Scaffold Erection and Dismantling - Rev 0Document20 pagesHSE-RA-008 Scaffold Erection and Dismantling - Rev 0عمرو100% (1)

- HSE-RA-038 Cut and Bend Operations - Rev 0Document8 pagesHSE-RA-038 Cut and Bend Operations - Rev 0عمروNo ratings yet

- HSE-RA-047 Distribution Board - Rev 0Document11 pagesHSE-RA-047 Distribution Board - Rev 0عمروNo ratings yet

- HSE-RA-021 Blockwork - Rev 0Document10 pagesHSE-RA-021 Blockwork - Rev 0عمروNo ratings yet

- HSE-RA-046 Open Shaft Works and Scaffolding in Shafts - Rev 0Document12 pagesHSE-RA-046 Open Shaft Works and Scaffolding in Shafts - Rev 0عمروNo ratings yet

- HSE-RA-015 Fire Fighting and Prevention - Rev 0Document10 pagesHSE-RA-015 Fire Fighting and Prevention - Rev 0عمروNo ratings yet

- HSE-RA-051 Grade Slabs, Column, Wall and Beam Casting - Rev 0Document30 pagesHSE-RA-051 Grade Slabs, Column, Wall and Beam Casting - Rev 0عمروNo ratings yet

- HSE-RA-049 Loading Platforms - Rev 0Document11 pagesHSE-RA-049 Loading Platforms - Rev 0عمروNo ratings yet

- HSE-RA-066 Using of Cutting Torch - Rev 0Document16 pagesHSE-RA-066 Using of Cutting Torch - Rev 0عمروNo ratings yet

- HSE-RA-035 Gas Welding and Brazing - Rev 0Document12 pagesHSE-RA-035 Gas Welding and Brazing - Rev 0عمروNo ratings yet

- HSE-RA-026 Overhead Work - Rev 0Document9 pagesHSE-RA-026 Overhead Work - Rev 0عمروNo ratings yet

- HSE-RA-043 Heat Stress - Rev 0Document9 pagesHSE-RA-043 Heat Stress - Rev 0عمروNo ratings yet

- HSE-RA-057 Hydro Test Rev 0Document15 pagesHSE-RA-057 Hydro Test Rev 0عمروNo ratings yet

- HSE-RA-025 Erecting, Dismantling and Maintanance of Tower Crane - Rev 0Document16 pagesHSE-RA-025 Erecting, Dismantling and Maintanance of Tower Crane - Rev 0عمروNo ratings yet

- HSE-RA-039 Plastering Activities - Rev 0Document9 pagesHSE-RA-039 Plastering Activities - Rev 0عمروNo ratings yet

- HSE-RA-042 Gas Cylinder Storage - Rev 0Document10 pagesHSE-RA-042 Gas Cylinder Storage - Rev 0عمروNo ratings yet

- HSE-RA-022 Environmental Management - Rev 0Document22 pagesHSE-RA-022 Environmental Management - Rev 0عمروNo ratings yet

- HSE-RA-011 Manual Handling - Rev 0Document11 pagesHSE-RA-011 Manual Handling - Rev 0عمروNo ratings yet

- HSE-RA-053 Floor Screed - Rev 0Document9 pagesHSE-RA-053 Floor Screed - Rev 0عمروNo ratings yet

- HSE-RA-063 Erecting and Dismantling of Placing Boom - Rev 0Document15 pagesHSE-RA-063 Erecting and Dismantling of Placing Boom - Rev 0عمروNo ratings yet

- HSE-RA-024 Civil Store - Rev 0Document15 pagesHSE-RA-024 Civil Store - Rev 0عمروNo ratings yet

- HSE-RA-058Testing and Comminssioning of Electrical Line Rev 0.Document18 pagesHSE-RA-058Testing and Comminssioning of Electrical Line Rev 0.عمروNo ratings yet

- HSE-RA-018 Use of An Angle Grinder - Rev 0Document15 pagesHSE-RA-018 Use of An Angle Grinder - Rev 0عمروNo ratings yet

- HSE-RA-019 Steel Fixing - Rev 0Document15 pagesHSE-RA-019 Steel Fixing - Rev 0عمروNo ratings yet

- Grade 6 DLL Mapeh q4 Week 6Document4 pagesGrade 6 DLL Mapeh q4 Week 6Ivy PacateNo ratings yet

- NSS-14 Triple SuperphosphateDocument1 pageNSS-14 Triple SuperphosphateNuraini RahmaNo ratings yet

- Bomba Hidráulica FestoDocument8 pagesBomba Hidráulica FestoAlex TamayoNo ratings yet

- Chemistry in Context 6th Edition American Chemical Society Acs Test BankDocument17 pagesChemistry in Context 6th Edition American Chemical Society Acs Test Bankjenniferrichardsonjrwfpzsdim100% (32)

- Geothermal Case Study CompetitionDocument16 pagesGeothermal Case Study CompetitionTimSenator TERRANo ratings yet

- CNCEC Saudi - IMS Manual (Issue 01, April 2011)Document41 pagesCNCEC Saudi - IMS Manual (Issue 01, April 2011)chao gaoNo ratings yet

- dsmc0020 en Medc hd1 Heat DetectorDocument2 pagesdsmc0020 en Medc hd1 Heat DetectorAbdul Hakeem MohammedNo ratings yet

- Watts Zone Controls and Valves - 2Document16 pagesWatts Zone Controls and Valves - 2Sid KherNo ratings yet

- Compressed Air System Design, Operating and MaintenanceDocument29 pagesCompressed Air System Design, Operating and Maintenanceibrahim1961No ratings yet

- CAEPIPE Presentation - v11.00Document17 pagesCAEPIPE Presentation - v11.00Johan ConradieNo ratings yet

- Jipmer Overall 2Document2,787 pagesJipmer Overall 2Balaji Ganesan0% (1)

- Non-Ferrous Extractive Metallurgy Prof. H. S. Ray Department of Metallurgical and Materials Engineering Indian Institute of Technology, KharagpurDocument22 pagesNon-Ferrous Extractive Metallurgy Prof. H. S. Ray Department of Metallurgical and Materials Engineering Indian Institute of Technology, Kharagpursubrat754No ratings yet

- Peek Optima Reinforced 4Document7 pagesPeek Optima Reinforced 4Davis LarrubiaNo ratings yet

- McDonald & Dominos Entry in IndiaDocument24 pagesMcDonald & Dominos Entry in IndiaRaj Paroha83% (6)

- SF20 - OKL04 Risk Assessment WeldingDocument2 pagesSF20 - OKL04 Risk Assessment WeldingMike BoyesNo ratings yet

- Ilovepdf MergedDocument95 pagesIlovepdf MergedYoussef El bahiNo ratings yet

- Work Immersion Portfolio: Jhon Carlo Cera CatindoyDocument22 pagesWork Immersion Portfolio: Jhon Carlo Cera CatindoyJoel DufaleNo ratings yet

- ?CCS Template Guide Attachment 3 V2?Document32 pages?CCS Template Guide Attachment 3 V2?Umair HussainNo ratings yet

- Research Projects JiitDocument14 pagesResearch Projects JiitSAMAIRA SINGHNo ratings yet

- Functional Safety Embedded Systems: Integration of in The Development Process ofDocument34 pagesFunctional Safety Embedded Systems: Integration of in The Development Process ofAleksandar MilinkovicNo ratings yet

- PARCO Pakistan HRMDocument38 pagesPARCO Pakistan HRMfujimukazu100% (1)

- D5462 PDFDocument6 pagesD5462 PDFZamir Danilo Morera ForeroNo ratings yet

- Aspects of Pharmacology in The Neonatal FoalDocument26 pagesAspects of Pharmacology in The Neonatal FoalAristoteles Esteban Cine VelazquezNo ratings yet

- Samsung 2009 VRF DVMDocument60 pagesSamsung 2009 VRF DVMe_mumcik100% (2)

- Geotechnical Factual ReportDocument89 pagesGeotechnical Factual ReportMohamed RusfanNo ratings yet

- VD UM DOSIMAX Plus A HV 001 - NDDocument31 pagesVD UM DOSIMAX Plus A HV 001 - NDPaweł KopyśćNo ratings yet

- Grant AwardDocument15 pagesGrant AwardRay StillNo ratings yet

- Quest Circular Motion 1 KeyDocument5 pagesQuest Circular Motion 1 KeyCarlos Ortiz100% (1)

- Tank Loss EstimateDocument123 pagesTank Loss EstimateAndreea AntohiNo ratings yet