Professional Documents

Culture Documents

AMA Instruments Datasheet HG500 160 ML Min

AMA Instruments Datasheet HG500 160 ML Min

Uploaded by

certificat energeticOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AMA Instruments Datasheet HG500 160 ML Min

AMA Instruments Datasheet HG500 160 ML Min

Uploaded by

certificat energeticCopyright:

Available Formats

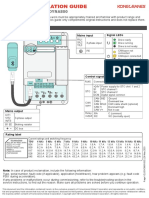

UHP Hydrogen Generator – HG 500

04.08.2016, page 1 of 2

AMA Instruments GmbH

Science Park II

Lise-Meitner-Str. 8

89081 Ulm, Germany

Tel +49 731 850774-0

Fax +49 731 850774-10

info@ama-instruments.com

www.ama-instruments.com

Safe hydrogen supply at

ultra high purity levels

UHP Hydrogen Generator – HG 500

The HG 500 series of ultra high purity hydrogen generators offers high performance and reliable ope-

ration even under harsh operating conditions such as in industrial installations. Utilising field proven

PEM cell technology, hydrogen is produced from deionised water on demand only. Using a

HG 500 instead of high pressure hydrogen cylinders saves money and results in a high level of safety.

The HG 500 ideally complements online GC systems and other type of analyzers to be used for

process, emissions and environmental monitoring applications. Due to the ultra high purity grade of

hydrogen being generated, the HG 500 allows to operate any type of combustion detectors and even

to supply hydrogen as carrier gas for GC applications.

The menu driven user interface and the innovative control software ensures easy setup of the HG 500

as well as operational safety and reliability. Operation of the hydrogen generator can be controlled and

monitored remotely using field bus communication via Modbus RTU protocol. Different versions of

the HG 500 operate at maximum flow rates between 160 ml/min to 1000 ml/min.

Automatic refill of the internal water tank from an external canister or deionised water system allows

unattended operation over long periods of time.

Unique SMARTdry™ technology

Instead of using a desiccant cartridge to be replaced frequently, our premium model of hydrogen

generators features unique SMARTdry™ technology for efficient water removal.

This allows the HG 500 series of gas generators to supply hydrogen at consistently high purity levels

and provides maintenance free operation and low cost of ownership.

UHP Hydrogen Generator – HG 500

04.08.2016, page 2 of 2

TECHNICAL DATA

AMA Instruments GmbH

General

Science Park II

Lise-Meitner-Str. 8

Enclosure 19“ plug-in case

89081 Ulm, Germany

Height 4 height units Tel +49 731 850774-0

Depth 460 mm Fax +49 731 850774-10

Weight 15 kg to 24 kg, depending on version / flow rate

Mounting designed for cabinet/rack mounting info@ama-instruments.com

www.ama-instruments.com

Ambient temperature 5°C to 35°C

Humidity 5% to 80% relative humidity, non-condensing

EMC CE-marking, conformity with EMC-guidelines 2004/108/EC

Electrolysis cell PEM electrolysis cell, does not require caustic solutions to operate

(PEM = Polymer Electrolyte Membrane)

Internal water tank water capacity 1.2 liter

Water removal SMARTdry™ technology for efficient water removal

Hydrogen specifications

Flow rate / versions max. 160 / 250 / 400 / 650 / 800 / 1000 ml/min

Outlet pressure 2.0 barg to 10.0 barg

Hydrogen purity 99.9999 % (gas quality grade 6.0)

Instrument supply

Power supply 100 – 240 VAC

Line frequency 50 to 60 Hz

Power consumption 200 W to 800 W, depending on version / maximum flow rate

Water supply deionised water, ASTM II, >1MΩ, <1μs, filtered to <100μm

automatic water refill from external canister or deionised water system

Water consumption 800 ml/week (24h/7d at hydrogen flow rate of 100 ml/min)

Connections

Hydrogen outlet port 1/8” bulkhead union

Water hose Quick release push in fitting

Ion exchange cartridge 2 dual connection ports with quick release push in fittings for ion exchange cartridge

(allows to replace ion exchange cartridge without operating interruption)

Operation

Setup Menu driven user interface for manual setup and operation

Display Large and back-lighted LCD display to indicate generator status, outlet pressure,

hydrogen flow rate and operation mode

Data entry Capacitive touch keys

Operation modes Local control or remote control via Modbus RTU

Communication

Communication ports 2 x RS-485 for field bus communication via Modbus RTU

You might also like

- Optima SecurityDocument28 pagesOptima SecurityNaveed Shaheen0% (1)

- Silenta Premium BrochureDocument32 pagesSilenta Premium Brochurejagadeeshkumar116No ratings yet

- 2 SdsillerDocument21 pages2 SdsillerBagas Maulana SNo ratings yet

- Product Bulletin PulsFOG TurbofoggerDocument1 pageProduct Bulletin PulsFOG TurbofoggerSiyad SiddiqueNo ratings yet

- FOB Series TSDocument4 pagesFOB Series TSjellali houcemeddineNo ratings yet

- Maximum Adaptability: Electromagnetic Dosing PumpsDocument6 pagesMaximum Adaptability: Electromagnetic Dosing PumpsÁrpád VassNo ratings yet

- Brochure Ind HighTechDocument7 pagesBrochure Ind HighTechFarid HafezNo ratings yet

- Sebf-I: The Art of Powerful Cleaning..Document3 pagesSebf-I: The Art of Powerful Cleaning..Pn ThanhNo ratings yet

- Jupiter: High Throughput Closed Microwave Digestion/Extraction WorkstationDocument6 pagesJupiter: High Throughput Closed Microwave Digestion/Extraction WorkstationwidyawatiNo ratings yet

- Industrial Air CleanersDocument4 pagesIndustrial Air CleanerssalgoraNo ratings yet

- Sebf-Iii: The Art of Powerful Cleaning..Document3 pagesSebf-Iii: The Art of Powerful Cleaning..Pn ThanhNo ratings yet

- Analytical MeasurementDocument262 pagesAnalytical Measurementaco1970100% (1)

- AutoclaveDocument2 pagesAutoclaveSaif AliNo ratings yet

- Packing Machine - Selgron - BrasilDocument2 pagesPacking Machine - Selgron - BrasilEnriqueMiguelPriceNo ratings yet

- Building Automation Cable PDFDocument28 pagesBuilding Automation Cable PDFmelgarcia829No ratings yet

- Side Entry Agitator: ES 2000 For BiofuelsDocument2 pagesSide Entry Agitator: ES 2000 For BiofuelsFahd Bin RiasatNo ratings yet

- Mobile X Ray Polymobil Plus Product BrochureDocument8 pagesMobile X Ray Polymobil Plus Product BrochureWilly Charly Chirilla VacaflorNo ratings yet

- Alat Lab Tambahan 1Document38 pagesAlat Lab Tambahan 1plazawebsiteNo ratings yet

- Flyer LaborPilot eDocument4 pagesFlyer LaborPilot eMarcos Daniel Paez MoreraNo ratings yet

- PP Elmasonic TI-H10 enDocument1 pagePP Elmasonic TI-H10 enBarbara AvanciniNo ratings yet

- FG ECU 15kDocument7 pagesFG ECU 15kriyazNo ratings yet

- Putzmaus BrochureDocument2 pagesPutzmaus BrochureJeffrey ChooNo ratings yet

- Use of HFCDocument10 pagesUse of HFCYamral WubetuNo ratings yet

- PDF Produkte 2010 10 VACUREMA Inline Strapping EDocument4 pagesPDF Produkte 2010 10 VACUREMA Inline Strapping EHatem RayaNo ratings yet

- Stalam Textile Dryers Eng 2011Document16 pagesStalam Textile Dryers Eng 2011Saif RahmanNo ratings yet

- Ecocota 1100 Life Pearl by Shahid FDCDocument5 pagesEcocota 1100 Life Pearl by Shahid FDCMohammed ZubairNo ratings yet

- Maallgem-024 1TDocument24 pagesMaallgem-024 1TAngeles Sendon GonzalezNo ratings yet

- Offer 8656 Ø80 PET Strap Extrusion LineDocument9 pagesOffer 8656 Ø80 PET Strap Extrusion Linevoronwe5No ratings yet

- Herzog HP m100pDocument4 pagesHerzog HP m100pAs Wandy0% (1)

- Strip Preparation and Accumulation TechnologyDocument3 pagesStrip Preparation and Accumulation Technologygoran120771No ratings yet

- Asoma Model 682t HPDocument2 pagesAsoma Model 682t HPJairo SotomayorNo ratings yet

- SRI SensorDocument7 pagesSRI SensorArun GuptaNo ratings yet

- Rovemavvi200 UnileverDocument16 pagesRovemavvi200 UnileverAhmad عfiaNo ratings yet

- Ote Fp-S Filter Press Eng Web PDFDocument8 pagesOte Fp-S Filter Press Eng Web PDFRegina Choque HuallpaNo ratings yet

- AMPRO CatalogueDocument23 pagesAMPRO Cataloguedrmallikarjun19No ratings yet

- Tuttnauer - Intl - Narrow T-Max - Medical - CAT2007 - Ver 1.7Document9 pagesTuttnauer - Intl - Narrow T-Max - Medical - CAT2007 - Ver 1.7Leonel Losada CardozoNo ratings yet

- FOB4 Series TSDocument4 pagesFOB4 Series TSegomfricomNo ratings yet

- SafeFast Top 4Document6 pagesSafeFast Top 4Anonymous 5RhHmNmgJNo ratings yet

- 8000 Process I/O: Intelligent PlatformsDocument8 pages8000 Process I/O: Intelligent PlatformspablogoncNo ratings yet

- Greenhouse Fans Fe2owletDocument2 pagesGreenhouse Fans Fe2owletandhikaNo ratings yet

- Fronius OhmpilotDocument2 pagesFronius OhmpilotMihai RaduNo ratings yet

- MFA-4P Motion Failure Alarm 1Document6 pagesMFA-4P Motion Failure Alarm 1Kirk WaterworthNo ratings yet

- Clean Agent SystemDocument8 pagesClean Agent Systemstanjack99No ratings yet

- Vacuum Cast Coil Catalogue EngDocument18 pagesVacuum Cast Coil Catalogue EngDante FilhoNo ratings yet

- Fotemp DatasheetDocument4 pagesFotemp DatasheetSaravanan MathiNo ratings yet

- Spectro 2000 RS SpectrophotometerDocument4 pagesSpectro 2000 RS Spectrophotometerkkpig26No ratings yet

- Riopipeline2019 1008 201906030844ibp1008 19 Acousti PDFDocument5 pagesRiopipeline2019 1008 201906030844ibp1008 19 Acousti PDFMarcelo Varejão CasarinNo ratings yet

- Ds100-4-Eng (Mut2200el+mut2500el)Document14 pagesDs100-4-Eng (Mut2200el+mut2500el)sar_tpgitNo ratings yet

- SP - RingsDocument17 pagesSP - Ringsprasanna kumarNo ratings yet

- Altecnic Tagus Class D Pulsed Volumetric Cold Water Meter 3-4inch MBSPDocument1 pageAltecnic Tagus Class D Pulsed Volumetric Cold Water Meter 3-4inch MBSPAdvancedWaterCoNo ratings yet

- 570-T With DiagramDocument2 pages570-T With DiagramEzzat Sev100% (2)

- Labnet International 2011 European CatalogeDocument60 pagesLabnet International 2011 European CatalogelabnetinternationalNo ratings yet

- Sauermann Si82 Pack2Document2 pagesSauermann Si82 Pack2Farhaan SajjadNo ratings yet

- Cellulose Insulation Technology Fibretec Production LinesDocument5 pagesCellulose Insulation Technology Fibretec Production LinesMAKRONNo ratings yet

- 08.9-Dukungan Fire AlarmDocument23 pages08.9-Dukungan Fire AlarmDaffaBahirNo ratings yet

- Pilodist: Petrodist 400 CCDocument7 pagesPilodist: Petrodist 400 CCWaheed ZebNo ratings yet

- Sa Sar ActuatorDocument56 pagesSa Sar ActuatorJoel CatubayNo ratings yet

- Alp General ACCESORIESDocument74 pagesAlp General ACCESORIESsas_uu100% (1)

- Catálogo - Capacitivos - S1683 04Document96 pagesCatálogo - Capacitivos - S1683 04alsdoomNo ratings yet

- Privacy-Preserving and Truthful DetectionDocument11 pagesPrivacy-Preserving and Truthful DetectionKumara SNo ratings yet

- Iub Data Configuration ATM (BSC6900V900R012)Document53 pagesIub Data Configuration ATM (BSC6900V900R012)tienpq150987No ratings yet

- Calzoni Hydraulic Motor Seal Kits 2022Document4 pagesCalzoni Hydraulic Motor Seal Kits 2022Sidney Pereira JuniorNo ratings yet

- Apps DownloaddDocument15 pagesApps DownloaddManik JainNo ratings yet

- Improving Feasibility of Robot MillingDocument9 pagesImproving Feasibility of Robot MillingChristos PAPAIOANNOUNo ratings yet

- ME-6501Computer Aided Design (CAD) WITH QB - BY Civildatas - Com 1Document85 pagesME-6501Computer Aided Design (CAD) WITH QB - BY Civildatas - Com 1Nathar ShaNo ratings yet

- CRO Olympiad Book For Class 3Document11 pagesCRO Olympiad Book For Class 3hiral shethNo ratings yet

- Academic Advising Via Facebook Examining Student Help SeekingDocument8 pagesAcademic Advising Via Facebook Examining Student Help Seekingdwi handayaniNo ratings yet

- Genichi TaguchiDocument5 pagesGenichi TaguchiCyriac Antony50% (2)

- Google's Chief Executive in Need of A Change Leadership StyleDocument12 pagesGoogle's Chief Executive in Need of A Change Leadership Stylebagadbilla1612No ratings yet

- Computer Notes PDFDocument69 pagesComputer Notes PDFAyush SharmaNo ratings yet

- Lesson 2 - E-CommerceDocument2 pagesLesson 2 - E-CommerceMarvin Glenn Arevalo CanayNo ratings yet

- Oracle Data Guard PresentationDocument52 pagesOracle Data Guard PresentationleemyyNo ratings yet

- P343 Report For R1Document23 pagesP343 Report For R1rohitctpp100% (1)

- Thesis On FPGADocument79 pagesThesis On FPGAAshish BabuNo ratings yet

- Photoshop Watermark Step-by-StepDocument13 pagesPhotoshop Watermark Step-by-StepSlavkoRosulNo ratings yet

- Hsieh 2015Document16 pagesHsieh 2015Monal RajNo ratings yet

- Lecture 2 Data GovernanceDocument44 pagesLecture 2 Data GovernanceMecheal ThomasNo ratings yet

- Difference BDocument2 pagesDifference BgeethuuuuNo ratings yet

- RTK TIDES For HYPACK 2013Document6 pagesRTK TIDES For HYPACK 2013Juliana Jacomini MenegucciNo ratings yet

- E600 User Manual v1.04 enDocument4 pagesE600 User Manual v1.04 enluisNo ratings yet

- GST Issues and ChallengesDocument31 pagesGST Issues and ChallengesSiva Sankari100% (1)

- 5G Light KPI Formulas v1.00Document27 pages5G Light KPI Formulas v1.00ehsan souryNo ratings yet

- ALTA - Translation Services OverviewDocument10 pagesALTA - Translation Services OverviewJon WoodroofNo ratings yet

- BB Anual Report 2010Document127 pagesBB Anual Report 2010Shakeel AhmedNo ratings yet

- The Assumptions Underlying The Method of Least Squares (CLRM)Document11 pagesThe Assumptions Underlying The Method of Least Squares (CLRM)Giri PrasadNo ratings yet

- READMEDocument2 pagesREADMERyn DonnNo ratings yet

- Romney Ch05Document169 pagesRomney Ch05Rabbumaa KabbadaaNo ratings yet

- DOC665105Document2 pagesDOC665105DeivisNo ratings yet

- Color RefinementDocument22 pagesColor RefinementDino BENITO MONZONo ratings yet