Professional Documents

Culture Documents

MANGUITO ETA 17 0081 - Assessment

MANGUITO ETA 17 0081 - Assessment

Uploaded by

Javier Gómez CorreaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MANGUITO ETA 17 0081 - Assessment

MANGUITO ETA 17 0081 - Assessment

Uploaded by

Javier Gómez CorreaCopyright:

Available Formats

Member of

www.eota.eu

UL INTERNATIONAL (UK) LTD

Wonersh House, Building C,

The Guildway,

Old Portsmouth Road,

Guildford. GU3 1LR.

United Kingdom.

designated according to Article 29 of the Regulation (EU) No 305/2011 and member of

EOTA (European Organisation for Technical Assessment, www.eota.eu)

European Technical ETA 17/0081

Assessment of 21/06/2017

Technical Assessment Body issuing the ETA and designated according to Article 29 of the

Regulation (EU) No 305/2011: UL International (UK) Ltd

Trade name of the construction product Hilti Firestop Sleeve CFS-SL GA

Product family to which the construction Fire Stopping and Sealing Product:

product belongs • Penetration Seals

Manufacturer Hilti AG,

Feldkircherstrasse 100

FL-9494 Schaan

Liechtenstein

Internet: www.hilti.com

Manufacturing plant(s) HILTI plant 14

This European Technical Assessment contains 23 Pages including 3 Annexes which form an

integral part of this Assessment.

This European Technical Assessment is issued ETAG 026-2, edition 2011, used as European

in accordance with regulation (EU) No Assessment Document (EAD).

305/2011, on the basis of

Translations of this European Technical Assessment in other languages shall fully correspond to the original issued document and should

be identified as such.

Communication of this European Technical Assessment, including transmission by electronic means, shall be in full. However, partial

reproduction may be made, with the written consent of the issuing Technical Assessment Body. Any partial reproduction has to be

identified as such.

ETA 17/0081 of 21/06/2017

I. SPECIFIC PARTS OF THE EUROPEAN TECHNICAL ASSESSMENT

1 Technical description of the product

1.1 CFS-SL GA

1. A detailed specification of the products listed below is given in document

“Identification_CFS-SL GA” relating to the European Technical Assessment ETA-17/0081 - Hilti

Firestop Sleeve which is a non-public part of this ETA.

2. The Hilti Firestop Sleeve CFS-SL is a maintenance free cable management firestop device

(cable box), intended to form a seal to reinstate the fire resistance performance of flexible

wall, rigid wall, sandwich panel and floor constructions, where they have been provided with

openings for the penetration of services. Related acronyms following “CFS-SL” are listed

below:

GA – rubber Gasket (CFS-SL GA)

S – Small diameter device variant (CFS-SL GA S)

M – Medium diameter device variant (CFS-SL GA M)

L – Long length device variant with same diameter as CFS-SL GA M (CFS-SL GA L)

3. The CFS-SL “sleeve” portion consists of a corrugated steel tube that houses a pair of plastic

parts ("tabs") at each end, intumescent wrap strips, and a twistable inner fabric smoke seal.

Pressing the tabs allows twisting the fabric smoke seal to close the seal.

4. Two rubber gaskets composed of EPDM, are provided with each sleeve, and are placed on

both sides of sleeve - flush to wall/floor surface - to seal the annular gap between edge of

opening and perimeter of sleeve. The rubber gaskets are positioned after the sleeve is

installed, and pressed against wall/floor by flanges.

5. The two flanges made from steel - also provided with each sleeve - are used to mount the

sleeve to the wall or floor (one flange on each side). Flanges are turned clockwise on the

threading of the metal housing till tight against rubber gasket and wall/floor surface.

6. For installation details, see Seal Type 1 in Annex A.3. For Fire Resistance Classifications, see

Annex B.

The Control Plan is defined in document "Control Plan_CFS-SL GA” relating to the European

Technical Assessment ETA-17/0081 – Hilti Firestop Sleeve, which is a non-public part of this

ETA.

ETA 17/0081 of 21/06/2017 – Page 2 of 23

1.2 Ancillary products

Acronyms used for ancillary products also follow “CFS-SL” and are listed below:

GP 40 – The 40 centimeter Gangplate with 3 openings (CFS-SL GP 40)

GP 60 – The 60 centimeter Gangplate with 4 openings (CFS-SL GP 60)

GP CAP - The Gangplate CAP for “blank” Gangplate openings (CFS-SL GP CAP)

1.2.1 Hilti Firestop Gangplate CFS-SL GP 40 and CFS-SL GP 60

Both Gangplate variants consist of a sandwich type construction of steel plates, ceramic

paper, EPDM rubber seal and EPDM foam sealing strips. Gangplates are used only with the

Medium and Long diameter Sleeve variants - CFS-SL GA M/L (flanges and rubber gaskets not

required.) Gangplates are surface mounted over pre-formed openings, direct to surface of

flexible/rigid wall or sandwich panel by twelve screws (CFS-SL GP 40) or fourteen screws

(CFS-SL GP 60).

For installation details - see Seal Type 2 in Annex A.3.

1.2.2 Hilti Firestop Gangplate CAP CFS-SL GP CAP

The Gangplate CAP consists of a zinc coated, steel plate. It allows for the option of having

“blank” openings in a Gangplate (openings without sleeves installed.) The CAPs are installed

both sides of wall, in Gangplate openings, each by removing four hexagonal nuts and a flange

plate, then by inserting the CAP, and reinstalling the flange plate and nuts.

For installation details, see Seal Type 2a in Annex A.4.

Further ancillary products - used as needed - for annular space filling or additional insulation:

1.2.3 Hilti Firestop Acrylic Sealant CFS-S ACR

For Specification, see relevant ETA. For installation details, see Seal Type 1a in Annex A.4.

1.2.4 Hilti Firestop Plug CFS-PL 132

For Specification, see relevant ETA. For installation details, see Seal Type 2a in Annex A.4.

1.2.5 Hilti Firestop Putty Roll CP 619 T

For Specification, see relevant ETA. For installation details, see Seal Type 1b in Annex A.4.

1.2.6 Hilti Firestop Putty Pad CP 617

For Specification, see relevant ETA. For installation details, see Seal Type 1b in Annex A.4.

1.2.7 Hilti Firestop Putty Bandage CFS-P BA

For Specification, see relevant ETA. For installation details, see Seal Type 1b in Annex A.4.

For Fire Resistance Classifications, see Annex B.

Technical product literature

Technical Data Sheet Hilti Firestop Sleeve CFS-SL GA including all ancillary products.

ETA 17/0081 of 21/06/2017 – Page 3 of 23

2 Specification of the intended uses of the product in accordance with the applicable

European Assessment Document (Hereinafter EAD): ETAG 026-2

Detailed information and data is given in Annex A and Annex B.

The intended use of Hilti Firestop Sleeve CFS-SL GA (and ancillary products) is to reinstate the

fire resistance performance of flexible or rigid wall, sandwich panel and floor constructions

where they are penetrated by services.

1. Construction elements for use of CFS-SL GA to provide a penetration seal in, are detailed in

Annex A.1.

2. The provisions made in this European Technical Assessment are based on an assumed

working life of the Hilti Firestop Sleeve of 10 years, provided that the conditions laid down in

the manufacturer’s datasheet and instructions for the packaging / transport / storage /

installation / use / repair are met. The indications given on the working life cannot be

interpreted as a guarantee given by the producer, but are to be regarded only as a means

for choosing the right products in relation to the expected economically reasonable working

life of the works.

3. Intention for use

Type Z2: intended for uses at internal conditions with humidity classes other than Z1,

excluding temperatures below 0° C.

ETA 17/0081 of 21/06/2017 – Page 4 of 23

3 Performance of the product and references to the methods used for its assessment

Product-type:mixed seal Intended use: Penetration Seal

Basic requirement for

Basic Requirement Performance

construction work

BWR 1 Mechanical resistance and stability

- None Not relevant

BWR 2 Safety in case of fire

EN 13501-1 Reaction to fire Class E

EN 13501-2 Resistance to fire Annex B

BWR 3 Hygiene, health and environment

Pressure Leakage

10 Pa 0.24 m3/(h)

50 Pa 0.83 m3/(h)

100 Pa 1.38 m3/(h)

Air permeability (Device 0% Filled) 150 Pa 1.83 m3/(h)

EN 1026:2000

(CFS-SL GA M/L) 200 Pa 2.21 m3/(h)

250 Pa 2.59 m3/(h)

300 Pa 2.95 m3/(h)

450 Pa 3.94 m3/(h)

600 Pa 4.79 m3/(h)

Water permeability (material

ETAG 026-2, Annex C No performance determined

property)

Declaration of

Release of dangerous substances Declaration of manufacturer

manufacturer

BWR 4 Safety in use

EOTA TR 001:2003 Mechanical resistance and stability No performance determined

EOTA TR 001:2003 Resistance to impact/movement No performance determined

EOTA TR 001:2003 Adhesion No performance determined

BWR 5 Protection against noise

EN 10140-2/EN ISO 717-1 Airborne sound insulation No performance determined

BWR 6 Energy economy and heat retention

EN 12664, EN 12667 or

Thermal properties No performance determined

EN 12939

EN ISO 12572

Water vapour permeability No performance determined

EN 12086

General aspects relating to fitness for use

EOTA TR 024:2009, clause Z2

Durability and serviceability

3.1.11 & 3.1.12

BWR 7 Sustainable use of natural resources

- - No performance determined

ETA 17/0081 of 21/06/2017 – Page 5 of 23

1. The applicant has submitted a written declaration that the product and/or constituents of

the product contains no substances which have been classified as dangerous according to

Directive 67/548/EEC and Regulation (EC) No. 1272/2008 and listed in the ‘indicative list on

dangerous substances’ of the EGDS – taking into account the installation conditions of the

construction product and the release scenarios resulting from there.

2. In addition to the specific clauses relating to dangerous substances contained in this

European Technical Assessment, there may be other requirements applicable to the products

falling within its scope (e.g. transposed European legislation and national laws, regulations

and administrative provisions). In order to meet the provisions of the Construction Products

Regulation, these requirements need also to be complied with, when and where they apply.

4 Assessment and verification of constancy of performance (hereinafter AVCP) system applied,

with reference to its legal base

According to the decision 1999/454/EC – Commission Decision of date 22nd June 1999 on the

procedure for attesting the conformity of construction products pursuant to Article 20(2) of

Council Directive 89/106/EEC as regards fire stopping, fire sealing and fire protective products,

published in the Official Journal of the European Union (OJEU) L178/52 of 14/07/1999, see

http://eur-lex.europa.eu/JOIndex.do) of the European Commission1, as amended, the system(s)

of assessment and verification of constancy of performance (see Annex V to Regulation (EU)

No 305/2011) given in the following table(s) applies (apply).

Product(s) Intended use(s) Level(s) or class(es) System(s)

Fire stopping and Fire For fire Any 1

Sealing Products compartmentation

and/or fire protection

or fire performance

5 Technical details necessary for the implementation of the AVCP system, as provided for in the

applicable EAD

Tasks of the manufacturer:

Factory production control:

The manufacturer shall exercise permanent internal control of production. All the elements,

requirements and provisions adopted by the manufacturer shall be documented in a

systematic manner in the form of written policies and procedures, including records of

results performed. This production control system shall ensure that the product is in

conformity with this European Technical Assessment.

The manufacturer may only use initial / raw / constituent materials stated in the technical

documentation of this European Technical Assessment.

1

Official Journal of the European Communities L178/52 of 14/7/1999

ETA 17/0081 of 21/06/2017 – Page 6 of 23

The factory production control shall be in accordance with the Control Plan dated 18.05.2017

relating to the European Technical Assessment ETA 17/0081 issued on 21.0.2017 which is

part of the technical documentation of this European Technical Assessment. The "Control

Plan" is laid down in the context of the factory production control system operated by the

manufacturer and deposited at UL International (UK) Ltd.

The results of factory production control shall be recorded and evaluated in accordance with

the provisions of the Control Plan.

Other tasks of the manufacturer

Additional information

The manufacturer shall provide a technical data sheet and an installation instruction with the

following minimum information:

(a) Technical data sheet:

Field of application

Building elements for which the penetration seal is suitable, type and

properties of the building elements like minimum thickness, density, and - in

case of lightweight constructions – the construction requirements.

Limits in size, minimum thickness etc. of the penetration seal

Construction of the penetration seal including the necessary components

and additional products (e.g. backfilling material) with clear indication

whether they are generic or specific.

(b) Installation instruction:

Steps to be followed

Procedure in case of retrofitting

Stipulations on maintenance, repair and replacement

6 Issued on:

21.06.2017

Report by: Reviewed by:

C. Johnson C. W. Miles

Staff Engineer Business Manager – Europe & Latin America

Building and Life Safety Technologies Building and Life Safety Technologies

For and on behalf of UL International (UK) Ltd.

ETA 17/0081 of 21/06/2017 – Page 7 of 23

ANNEX A – Manufacturer Detailed Installation Information

A.1 Supporting Constructions for CFS-SL GA S/M/L:

Flexible and Flexible Walls:

Rigid walls Minimum thickness 100mm & maximum thickness 200mm (CFS-SL GA S/M)

Minimum thickness 200mm & maximum thickness 300mm (CFS-SL GA L)

Comprise timber or steel studs lined on both faces to a thickness of 25mm

according to EN 520 type F.

For timber stud walls - minimum distance of 100mm of the seal to any stud,

the cavity between stud and seal must be closed, and a minimum of 100mm

insulation of Class A1 or A2 (in accordance with EN 13501-1) is required in

the cavity between stud and seal.

Rigid Walls:

Minimum thickness 100mm & maximum thickness 200mm (CFS-SL GA S/M)

Minimum thickness 200mm & maximum thickness 300mm (CFS-SL GA L)

Comprise of: concrete, aerated concrete or masonry, with a minimum

density of 550 kg/m³.

Sandwich Tested with 100mm Paroc line 200 AST F 100/99 and 150mm Paroc line 200 AST F.

panels:

Field of application, based on tested Specimens (in accordance with Standard

EN 14509:2013):

Minimum thickness 100mm & maximum thickness 200mm (CFS-SL GA S/M)

Minimum thickness 200mm & maximum thickness 300mm (CFS-SL GA L)

Shall comprise Euroclass A1 structural stone wool core of density between:

100 kg/m3 and 150kg/m3, and Reaction to Fire: Euroclass A2-s1,d0

Steel faced with exposed and unexposed sides between 0.50mm and 1mm

Flat or light profile type

Polyurethane based adhesive

Valid for vertically and horizontally installed panels

PVDF (external) and SP (Internal) steel coating

1.2m width of panel. Unlimited decrease in width, and increase up to 1.44m

Floors: Minimum thickness 150mm & maximum thickness 200mm (CFS-SL GA S/M)

Minimum thickness 200mm & maximum thickness 300mm (CFS-SL GA L)

Aerated concrete or concrete with a minimum density of 550kg/m³.

The walls / floors must be classified in accordance with EN 13501-2 for the required fire resistance

period or fulfil the requirements of the relevant Eurocode.

For supporting constructions for ancillary products – see A.4.

ETA 17/0081 of 21/06/2017 – Page 8 of 23

A.2 Illustration Abbreviations:

A Hilti Firestop Sleeve CFS-SL GA

A1 Rubber Gasket

B Hilti Firestop Gangplate: CFS-SL GP 40 or 60

B1 Hilti Firestop Gangplate CAP: CFS-SL GP CAP

B1a Hilti Firestop Plug: CFS-PL 132

A1a Hilti Firestop Acrylic Sealant CFS-S ACR

A1b Hilti Firestop Putty Roll CP 619 T

A1c Hilti Firestop Putty Pad CP 617 – cut to 25mm width

A1d Hilti Firestop Putty Bandage CFS-P BA

C Cables/Conduits

E1 Building Element Flexible/Rigid Wall

E2 Building Element Sandwich Panel

E3 Building Element Floor

tE Thickness of Building Element – refer to A.1

A.3 Seal Type Details and Installation:

There are two primary Seal Types:

Device/s

Seal Type Seal Detail

Wall (incl. Sandwich panel) Floor

1 Single Devices CFS-SL GA S/M/L CFS-SL GA S/M/L

CFS-SL GA M/L &

2 Ganged Devices N/A

CFS-SL GP 40 or 60

A.3.1 Seal Type 1 Details:

Section –

CFS-SL GA S/M/L

in Flexible or Rigid

Wall

ETA 17/0081 of 21/06/2017 – Page 9 of 23

Section –

CFS-SL GA S/M/L

in Sandwich Panel

Section –

CFS-SL GA S/M/L

in Floor

A.3.2 Seal Type 2 Detail:

Section –

CFS-SL GA M/L and

CFS-SL GP 40 or 60

in Flexible or Rigid

Wall or Sandwich

Panel

ETA 17/0081 of 21/06/2017 – Page 10 of 23

A.3.3 Seal Type 1 Application Information (CFS-SL GA S/M/L)

Walls and Sandwich Panels:

Floors:

A.3.4 Seal Type 2 Application Information (CFS-SL GP 40 or 60)

Walls and Sandwich Panels:

ETA 17/0081 of 21/06/2017 – Page 11 of 23

A.4 Variations on Seal Type

As variations to Seal Type 1 and 2, further ancillary products can be installed to provide:

- Higher Fire Classification ratings in specific flexible or rigid wall applications: Hilti Firestop Acrylic

Sealant CFS-S ACR can be applied to seal annular gaps in place of Rubber Gaskets. (See Seal Type 1a

for installation)

- Higher Fire Classifications for CFS-SL GA M/L in 150mm thick Sandwich Panels: Hilti Firestop Putty is

pressed around opening - CP 619 T or CP 617 (cut to 25mm width) before installing rubber gasket,

and CFS-P BA used to wrap first 100mm of cables as they project from tabs of sleeve.

In all cases, putty is installed in 2 layers with minimum 5mm overlap. (See Seal Type 1b for

installation)

- Blank openings (no sleeve) in Gangplates: Hilti CFS-SL GP CAP & CFS-PL 132 are required.

(See Seal Type 2a for installation)

Ancillary product

Seal Type

Seal Detail 100mm Sandwich 150mm Sandwich

Variation Wall

Panel Panel

1a Single Devices CFS-S ACR - -

CP 619 T or

1b Single Devices - - CP 617. And

CFS-P BA

CFS-SL GP 40 or 60, CFS-SL GP CAP &

2a Ganged Devices

CFS-PL 132

A.4.1 Seal Type 1a Detail:

Section –

CFS-SL GA S/M/L

and CFS-S ACR

in Flexible or Rigid

Wall

Recommended A1a

(CFS-S ACR) installed

to 25mm depth into

wall

ETA 17/0081 of 21/06/2017 – Page 12 of 23

A.4.2 Seal Type 1b Detail:

Section –

CFS-SL GA M/L with

CP 619 T or CP 617

behind flanges and

CFS-P BA around

Cables - in

150mm Sandwich

Panel

A.4.3 Seal Type 2a Detail:

Section –

CFS-SL GA M/L and

CFS-SL GP 40 or 60

with CFS-SL GP CAP

and CFS-PL 132

in Flexible or Rigid

Wall or Sandwich

Panel

A.4.4 Seal Type 1a Application Information (CFS-SL GA S/M/L and CFS-S ACR)

Flexible and Rigid Walls

ETA 17/0081 of 21/06/2017 – Page 13 of 23

A.4.5 Seal Type 1b Application Information (CFS-SL GA M/L & CP 619 T/CP 617 and

CFS-P BA)

Flexible and Rigid Walls

A.4.6 Seal Type 2a Application Information (CFS-SL GA M/L, CFS-SL GP 40 or 60,

CFS-SL GP CAP & CFS-PL 132)

Flexible and Rigid Walls and Sandwich Panels

A.5 Seal Type Opening Sizes:

Seal Type Seal Detail Device Opening Ø

CFS-SL GA S 63 – 73mm

1, 1a & 1b Single Devices

CFS-SL GA M/L 113 - 122mm

2 & 2a Ganged Devices CFS-SL GP 40 or 60 113 - 122mm

ETA 17/0081 of 21/06/2017 – Page 14 of 23

A.6. Distances between openings

A.6.1 Seal Type 1 including 1a and 1b

Depending on Fire Classification and space requirements, the Hilti Firestop Sleeve CFS-SL GA

can be installed with:

- ≥ 200mm distance between openings, or

- flanges touching (zero distance between devices)

200mm (horizontal/vertical distance between openings linear or cluster)

Zero distance (horizontal/vertical distance between flanges linear or cluster)

Note: dimensions above relate to Ø122mm (CFS-SL GA M/L) – using smaller diameters will

alter the distances between opening centres.

(For CFS-SL GA S – use diameter Ø63-73mm as in Section A.5.)

ETA 17/0081 of 21/06/2017 – Page 15 of 23

A.6.2 Seal Type 2 including 2a

Depending on Fire Classification and space requirements, the Hilti Firestop Sleeve CFS-SL GP

can be installed with:

- ≥ 200mm distance between openings, or

- Gangplates touching or slight overlap (zero distance)

200mm from Opening to nearest Opening - For Single to any number of installations:

(Lower, dashed Gangplate illustrates correct placement of 200mm distance)

Zero Distance between Devices - For Double Gangplate installation:

(Outside of Double Constellation, 200mm to next Gangplate/Constellation /Device opening)

Zero Distance between Devices - For Triple Gangplates to any number of installations:

ETA 17/0081 of 21/06/2017 – Page 16 of 23

A.6.3 Guideline for Gangplate fixing elements

Aerated

Sandwich

Anchoring solution Anchor Indication Drywall Concrete

Panel

wall

Diameter: 3.5mm

Drywall Screws: x x

Length: ≥ 35mm

Diameter: 3.5mm

Self-drilling Screws: x

Length: ≥ 19mm

CFS-SL GP 40 CFS-SL GP 60

Total Number of fixations 12 14

A.7 Penetrating services

A.7.1 Cables

Penetrating services Description

Small Cables Ø ≤ 21mm: All cable types currently and commonly used in building practice in

(CFS-SL GA S/M/L) Europe (e.g. power, control, signal, telecommunication, data, optical

fibre cables, with or without cable supports) with a diameter Ø ≤21mm.

Medium and Large Cables All cable types currently and commonly used in building practice in

(CFS-SL GA M/L) Europe (e.g. power, control, signal, telecommunication, data, optical

fibre cables, with or without cable supports) with a diameter up to

Ø ≤ 80mm.

Cable Fills: All Fire Classifications in Annex B allow sleeves to be left blank or filled

with cables to up to 60% of the total sleeve cross section/area.

For fills higher than 60%, there are classifications with:

- 36mm bundles (CFS-SL GA S) and 86mm bundles (CFS-SL GA M/L) or,

- 100% fills (CFS-SL GA S/M/L) Note that all cables with Ø ≤21mm are

covered, and in cases cables up to Ø ≤80mm.

ETA 17/0081 of 21/06/2017 – Page 17 of 23

A.7.2 Conduits

Penetrating services Description

Single conduits Ø ≤ 25mm: Rigid, flexible and pliable plastic conduits and metal conduits with a

(CFS-SL GA S): diameter Ø ≤ 25mm with or without cables.

Single conduits Ø ≤ 63mm Rigid, flexible and pliable plastic conduits and metal conduits with a

(CFS-SL GA M/L): diameter Ø ≤ 63mm with or without cables.

Conduit bundle Conduits with a max. single conduit diameter Ø ≤ 25mm with or

(CFS-SL GA S): without cables can be bundled to a diameter Ø ≤ 48mm.

Conduit bundle Conduits with a max. single conduit diameter Ø ≤ 63mm with or

(CFS-SL GA M/L): without cables can be bundled to a diameter Ø ≤ 92mm.

A.8 Distances for all cable support constructions

The distances from the surface of the separating element to the first supporting construction:

a) Wall (distance from the face of the wall on both sides): ≤ 250mm

b) Floor (distance from upper side of floor): ≤ 250mm

ETA 17/0081 of 21/06/2017 – Page 18 of 23

ANNEX B – Resistance to Fire Classifications

B.1 Seal Type 1 (Including 1a and 1b)

B.1.1 200mm between openings (See A.6.1):

Description (CFS-SL GA S) (CFS-SL GA M/L)

Blank Device EI 120 EI 120

All sheathed cables ≤ 21mm EI 90 EI 90 1)

All sheathed cables ≤ 50mm - EI 90

All sheathed cables ≤ 80mm - EI 60

Cable bundles ≤ 36mm

EI 90 -

All sheathed cables ≤ 21mm

Flexible & Cable bundles ≤ 86mm

- EI 90

All sheathed cables ≤ 21mm

Rigid wall

100% filled device with cables ≤ 21mm EI 60 2) EI 90

Conduits ≤ 25mm (CFS-SL GA S) EI 120 -

Conduits ≤ 63mm (CFS-SL GA M/L) - EI 90 3)

For higher Fire Classifications – follow Seal Type 1a (ACR) installation:

1)

All sheathed cables ≤ 21mm - EI 120

2)

100% filled device with cables ≤ 21mm EI 90 -

3)

Conduits ≤ 63mm (CFS-SL GA M/L) - EI 120

Blank Device EI 90 EI 90 4)

All sheathed cables ≤ 21mm EI 60 EI 90 4)

All sheathed cables ≤ 50mm - EI 90

Sandwich

Panel 100% filled device with cables ≤ 21mm EI 60 -

150mm 100% filled device with cables ≤ 50mm - EI 60 4)

thickness

For higher Fire Classifications – follow Seal Type 1b (Putty) installation:

4)

100% filled device with cables ≤ 21mm

- EI 120

(CFS-SL GA M/L)

ETA 17/0081 of 21/06/2017 – Page 19 of 23

B.1.2 Zero distance between flanges (See A.6.1):

Description (CFS-SL GA S) (CFS-SL GA M/L)

Blank Device EI 120 EI 90

All sheathed cables ≤ 21mm EI 60 EI 90

All sheathed cables ≤ 50mm - EI 60

All sheathed cables ≤ 80mm - EI 60

Flexible & Cable bundles ≤ 36mm

EI 90 -

Rigid wall All sheathed cables ≤ 21mm

Cable bundles ≤ 86mm

- EI 60

All sheathed cables ≤ 21mm

100% filled device with cables ≤ 21mm EI 60 EI 60

100% filled device with cables ≤ 80mm - EI 60

Conduits ≤ 25mm (CFS-SL GA S) EI 90 -

Conduits ≤ 63mm (CFS-SL GA M/L) - EI 60

Blank Seal EI 45 EI 90

Sandwich

Panel

All sheathed cables ≤ 21mm EI 45 EI 90

100mm

thickness All sheathed cables ≤ 50mm - EI 60

100% filled device with cables ≤ 21mm EI 45 EI 60

100% filled device with cables ≤ 50mm - EI 60

ETA 17/0081 of 21/06/2017 – Page 20 of 23

Description (CFS-SL GA S) (CFS-SL GA M/L)

Blank Device EI 180 EI 180

All sheathed cables ≤ 21mm EI 180 EI 180

All sheathed cables ≤ 50mm - EI 120 5)

All sheathed cables ≤ 80mm - EI 60

Cable bundles ≤ 36mm

EI 180 -

All sheathed cables ≤ 21mm

Floors Cable bundles ≤ 86mm

- EI 120

All sheathed cables ≤ 21mm

100% filled device with cables ≤ 21mm EI 120 -

100% filled device with cables ≤ 50mm - EI 120

Conduits ≤ 25mm (CFS-SL GA S) EI 120 -

Conduits ≤ 63mm (CFS-SL GA M/L) - EI 60 6)

For higher Fire Classifications – increase distances between openings - 200mm:

5)

All sheathed cables ≤ 50mm - EI 180

6)

Conduits ≤ 63mm (CFS-SL GA M/L) - EI 120

ETA 17/0081 of 21/06/2017 – Page 21 of 23

B.2 Seal Type 2 (Multiple/Ganged devices)

B.2.1 Flexible/Rigid Walls:

B.2.1.1 ≥ 200mm Distance between Openings (See A.6.2):

Blank Device to 100% filled

Flexible & Cables ≤ 21mm

EI120

Rigid wall

Blank Seal (CAP and Plug)

B.2.1.2 Double Gangplate Zero Distance between Devices (See A.6.2):

Blank Device to 100% filled

Flexible & Cables ≤ 21mm

EI90

Rigid wall

Blank Seal (CAP and Plug)

B.2.1.3 Triple Gangplate (or more) Zero Distance between Devices (See A.6.2):

Blank Device to 100% filled

Flexible & Cables ≤ 21mm

EI60

Rigid wall

Blank Seal (CAP and Plug)

B.2.2 Sandwich Panel – 100mm thick:

B.2.2.1 Double Gangplate Zero Distance between Devices (See A.6.2):

Sandwich Blank Device to 100% filled

Panel Cables ≤ 21mm

EI60

100mm

thickness Blank Seal (CAP and Plug)

B.2.3 Sandwich Panel – 150mm thick:

B.2.3.1 ≥ 200mm Distance between Openings (See A.6.2):

Sandwich Blank Device to 100% filled

Panel Cables ≤ 21mm

EI120

150mm

thickness Blank Seal (CAP and Plug)

ETA 17/0081 of 21/06/2017 – Page 22 of 23

ANNEX C – Abbreviations and referenced documents

C.1 References to standards mentioned in the ETA

Norm Description

EN 1366-3 Fire resistance tests for service installations - Part 3: Penetration seals

EN ISO 717-1 Acoustics – Rating of sound insulation of buildings and of building

elements – Part 1: Airborne sound insulation

EN 10140-2 Acoustics - Laboratory measurement of sound insulation of building

elements - Part 2: Measurement of airborne sound insulation

EN 1026 Windows and doors - Air permeability - Test method

EN 12086 Thermal insulating products for building applications - Determination of

water vapour transmission properties

EN ISO 12572 Hygrothermal performance of building materials and products -

Determination of water vapour transmission properties (ISO 12572:2001);

EN 12664 Thermal performance of building materials and products - Determination

of thermal resistance by means of guarded hot plate and heat flow meter

methods - Dry and moist products with medium and low thermal

resistance

EN 12667 Thermal performance of building materials and products – Determination

of thermal resistance by means of guarded hot plate and heat flow meter

methods – Products of high and medium thermal resistance

EN 12939 Thermal performance of building materials and products - Determination

of thermal resistance by means of guarded hot plate and heat flow meter

methods - Thick products of high and medium thermal resistance;

EN 13501-1 Fire classification of construction products and building elements – Part 1:

Classification using test data from reaction to fire tests

EN 13501-2 Fire classification of construction products and building elements – Part 2:

Classification using test data from fire resistance tests

EN 14509 Self-supporting double skin metal faced insulating panels -

Factory made products

EN 520 Gypsum plasterboards - Definitions, requirements and test methods;

EOTA TR 001 Determination of impact resistance of panels and panel assemblies

EOTA TR 024 Characterization, Aspects of Durability and Factory Production Control for

Reactive Materials, Components and Products

ETAG 026 Fire Stopping and Fire Sealing Products

ETA 17/0081 of 21/06/2017 – Page 23 of 23

You might also like

- Lean To PlanDocument7 pagesLean To PlandimfoNo ratings yet

- 4 - Walls, Doors, Windows - CeilingsDocument19 pages4 - Walls, Doors, Windows - CeilingsAnderson GuerraNo ratings yet

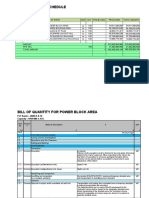

- Boq Working Pearls 100214Document5 pagesBoq Working Pearls 100214Santosh ThakurNo ratings yet

- Protastructure 2018 Whats New PDFDocument57 pagesProtastructure 2018 Whats New PDFDokan groupNo ratings yet

- Hilti 2022 TA-12-0101-CFS-M-RG-Approval-document-ASSET-DOC-APPROVAL-0512Document35 pagesHilti 2022 TA-12-0101-CFS-M-RG-Approval-document-ASSET-DOC-APPROVAL-0512aldea catalinNo ratings yet

- ETA 19 0556 HSL 4 11 2022 Approval Document ASSET DOC 11738371Document59 pagesETA 19 0556 HSL 4 11 2022 Approval Document ASSET DOC 11738371mekrishnababucNo ratings yet

- ETA 20 0541 HIT RE 500 V4 Anchor EC2 100yearsDocument247 pagesETA 20 0541 HIT RE 500 V4 Anchor EC2 100yearsעמי עמרניNo ratings yet

- Hit-Re-500-V3 - Eta 2019Document100 pagesHit-Re-500-V3 - Eta 2019pate84No ratings yet

- Noted ETA RE500v3 AnchorDocument49 pagesNoted ETA RE500v3 AnchorĐỗ Hữu LinhNo ratings yet

- ETA 20 0539 HIT RE 500 V4 07 022 Approval Document ASSET DOC 13313220Document47 pagesETA 20 0539 HIT RE 500 V4 07 022 Approval Document ASSET DOC 13313220Essam Nabih YacoubNo ratings yet

- ETA 20 0540 HIT RE 500 V4 Rebar EC2 100years 112020 Approval Document ASSET DOC 13313367 1Document135 pagesETA 20 0540 HIT RE 500 V4 Rebar EC2 100years 112020 Approval Document ASSET DOC 13313367 1eng.msc.pnNo ratings yet

- European Technical Assessment ET A - 1 9 / 0 5 5 6 o F 0 3 / 0 6 / 2 0 2 1Document29 pagesEuropean Technical Assessment ET A - 1 9 / 0 5 5 6 o F 0 3 / 0 6 / 2 0 2 1Li Juen GamNo ratings yet

- ZD Etab F 20-1066 Sen Aip V1Document18 pagesZD Etab F 20-1066 Sen Aip V1HOANG KHANH SONNo ratings yet

- Hilti HIT-RE 500 V4 Injection Mortar: English 2-53 French 54-123 124-177 PolishDocument177 pagesHilti HIT-RE 500 V4 Injection Mortar: English 2-53 French 54-123 124-177 PolishAli KayaNo ratings yet

- CT1 CSTB ETA-11 0390 RebarDocument22 pagesCT1 CSTB ETA-11 0390 RebarsaidNo ratings yet

- CT1 CSTB Eta-11 0354Document19 pagesCT1 CSTB Eta-11 0354Alden CayagaNo ratings yet

- Dsi Dywidag z32!1!9 Gewi Piles 63 5mm enDocument19 pagesDsi Dywidag z32!1!9 Gewi Piles 63 5mm enTato Del AguilaNo ratings yet

- Sandwich Panel Declaration-of-performance-Hilti-SF-DoP-009-EN-Declaration-of-performanceDocument17 pagesSandwich Panel Declaration-of-performance-Hilti-SF-DoP-009-EN-Declaration-of-performancegraziella njeimNo ratings yet

- HY200R V3 DIBt ETA-19 0601Document44 pagesHY200R V3 DIBt ETA-19 0601deepesh sethNo ratings yet

- Agrement Mastic Acrilic Antifoc CFS-S - ACR - J RosturiDocument18 pagesAgrement Mastic Acrilic Antifoc CFS-S - ACR - J RosturiOvidiu NeaguNo ratings yet

- ETA 19 0601 HIT HY 200 A R V3 Anchoring Jun 2023 Approval Document ASSET DOC 11504013Document213 pagesETA 19 0601 HIT HY 200 A R V3 Anchoring Jun 2023 Approval Document ASSET DOC 11504013gundeskNo ratings yet

- Declaration of Performance CFS 0761 CPD 0210 EN Declaration of Performance IBD WWI 00000000000003746527 000Document1 pageDeclaration of Performance CFS 0761 CPD 0210 EN Declaration of Performance IBD WWI 00000000000003746527 000G GNo ratings yet

- ZD Etab F 21-0678 SenDocument19 pagesZD Etab F 21-0678 SenHOANG KHANH SONNo ratings yet

- ETA 12 0084 HIT HY 200 R Anchor EC2 TR055 50years 082019 Approval Document ASSET DOC APPROVAL 0197Document89 pagesETA 12 0084 HIT HY 200 R Anchor EC2 TR055 50years 082019 Approval Document ASSET DOC APPROVAL 0197inunezNo ratings yet

- HY200 V3 DIBt ETA-19 0601Document53 pagesHY200 V3 DIBt ETA-19 0601opulitheNo ratings yet

- Note ETA RE500v3 RebarDocument31 pagesNote ETA RE500v3 RebarĐỗ Hữu LinhNo ratings yet

- ETA-19/0665 HIT-HY-200-R-V3-Rebar-TR069-100yearsDocument58 pagesETA-19/0665 HIT-HY-200-R-V3-Rebar-TR069-100yearsFranco CapelliNo ratings yet

- Declaration of Performance No. 0012 - ENDocument34 pagesDeclaration of Performance No. 0012 - ENALEXEICALERONo ratings yet

- Eta Guardia UkDocument9 pagesEta Guardia UkTunisianoCANo ratings yet

- ETA 16 0142 HIT-RE 500 V3 Injection Mortar Rebar en Approval Document ASSET DOC 6065380Document28 pagesETA 16 0142 HIT-RE 500 V3 Injection Mortar Rebar en Approval Document ASSET DOC 6065380migusagoNo ratings yet

- Eta - 02-0042 - 2017-22-11Document37 pagesEta - 02-0042 - 2017-22-11Alden CayagaNo ratings yet

- ETA 16-0142 Hilti RE 500 V3 Rebar enDocument29 pagesETA 16-0142 Hilti RE 500 V3 Rebar enzilaNo ratings yet

- European Technical Assessment - ETA 14/0108Document20 pagesEuropean Technical Assessment - ETA 14/0108Alexa AlexaNo ratings yet

- Eta 11-0190 Wurth AssyDocument112 pagesEta 11-0190 Wurth Assymrc8327No ratings yet

- DSI DYWIDAG Z 34.11 225 Permanent Bar Anchors enDocument20 pagesDSI DYWIDAG Z 34.11 225 Permanent Bar Anchors enjeff_56No ratings yet

- HIT - HY 100 Eta-14-0009-2019-09-06-EnDocument21 pagesHIT - HY 100 Eta-14-0009-2019-09-06-Enעמי עמרניNo ratings yet

- ETA 98 0001 HST3 HST Metal Expansion Anchor Approval Document ASSET DOC 5422375Document269 pagesETA 98 0001 HST3 HST Metal Expansion Anchor Approval Document ASSET DOC 5422375Deitie ArkelvNo ratings yet

- Ball-Valves ISO17292 EN1983515 530 Series PDFDocument21 pagesBall-Valves ISO17292 EN1983515 530 Series PDFGeorge_Wabag_2014No ratings yet

- ETA 98 0001 HST3 HST Metal Expansion Anchor Approval Document ASSET DOC 5422375Document254 pagesETA 98 0001 HST3 HST Metal Expansion Anchor Approval Document ASSET DOC 5422375Murat AcarNo ratings yet

- ETA 14 0378 FISCHER FiAM Intumescent Acoustic Matic Pen Seal 3Document15 pagesETA 14 0378 FISCHER FiAM Intumescent Acoustic Matic Pen Seal 3ibrahimNo ratings yet

- ETA 11 0374 HSA Stud Anchor ETAG 001 02 Option 7 Approval Document ASSET DOC APPROVAL 0201Document57 pagesETA 11 0374 HSA Stud Anchor ETAG 001 02 Option 7 Approval Document ASSET DOC APPROVAL 0201dokumentasistudioNo ratings yet

- Hilti HIT-RE 500-SD - 8915492798494 PDFDocument9 pagesHilti HIT-RE 500-SD - 8915492798494 PDFAnonymous ELujOV3No ratings yet

- FM753 Crack - ETA 09-0056 - EN - Op1 Seismic - 2017-07-18Document18 pagesFM753 Crack - ETA 09-0056 - EN - Op1 Seismic - 2017-07-18Kareem HelalNo ratings yet

- HOMOLOGACIÓN PANELES PRE PINTADOS ETA-11-0429-for-CFS-CT-CFS-CTDocument209 pagesHOMOLOGACIÓN PANELES PRE PINTADOS ETA-11-0429-for-CFS-CT-CFS-CTJavier Gómez CorreaNo ratings yet

- Halfen Cast-In Channels: T - HK5-W 12/17 Z - HZA - 08/18-EDocument18 pagesHalfen Cast-In Channels: T - HK5-W 12/17 Z - HZA - 08/18-EAnrStukNo ratings yet

- SA Equip SAF35 ITS SA CYCLONE EX ATEX CertificateDocument3 pagesSA Equip SAF35 ITS SA CYCLONE EX ATEX CertificateMuhammad ImanNo ratings yet

- Eta 11 - 0284Document68 pagesEta 11 - 0284Anonymous f3uZJugqvNo ratings yet

- ETA 02 - 0027 Final-2017-09 ENDocument16 pagesETA 02 - 0027 Final-2017-09 ENAlden CayagaNo ratings yet

- FM753 - ETA 01-0014 - EN - Op7 - 2017-05-29Document13 pagesFM753 - ETA 01-0014 - EN - Op7 - 2017-05-29Kareem HelalNo ratings yet

- PERI UP T 72 Scaffold System Approval US1 enDocument18 pagesPERI UP T 72 Scaffold System Approval US1 enHugoVargasLijeronNo ratings yet

- HDANPP DIBt Z-21.1-1696Document22 pagesHDANPP DIBt Z-21.1-1696Alden CayagaNo ratings yet

- F1.5 - Gas MainsDocument6 pagesF1.5 - Gas MainsKwan Chun SingNo ratings yet

- FM744 - ETA 05-0169 - EN - Op7 - 2015-01-29Document12 pagesFM744 - ETA 05-0169 - EN - Op7 - 2015-01-29Kareem HelalNo ratings yet

- Approval Z-12.5-96Document8 pagesApproval Z-12.5-96bmndevelopNo ratings yet

- La ImpDocument13 pagesLa ImplydiaNo ratings yet

- Hilti HIT HY-200 A Injection Mortar: 42-80 82-120 2-40 English Deutsch Français Polski 122-160Document160 pagesHilti HIT HY-200 A Injection Mortar: 42-80 82-120 2-40 English Deutsch Français Polski 122-160Rafał LechocińskiNo ratings yet

- HSL3 CSTB Eta-02 0042Document20 pagesHSL3 CSTB Eta-02 0042Karmen YuenNo ratings yet

- HSC CSTB Eta 02 0027Document20 pagesHSC CSTB Eta 02 0027Karmen YuenNo ratings yet

- Chemical BoltDocument36 pagesChemical BoltKiatchai IttivikulNo ratings yet

- Approval Document ASSET DOC APPROVALDocument57 pagesApproval Document ASSET DOC APPROVALmohammad alsayyidNo ratings yet

- Homologacion Z-32.1-2 GEWI Piles 20mm 25mm 28mm 32mm 40mm 50mmDocument25 pagesHomologacion Z-32.1-2 GEWI Piles 20mm 25mm 28mm 32mm 40mm 50mmVladimir Correa OportoNo ratings yet

- Guide to the IET Wiring Regulations: IET Wiring Regulations (BS 7671:2008 incorporating Amendment No 1:2011)From EverandGuide to the IET Wiring Regulations: IET Wiring Regulations (BS 7671:2008 incorporating Amendment No 1:2011)Rating: 4 out of 5 stars4/5 (2)

- Ejectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsFrom EverandEjectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsNo ratings yet

- Importance of Facade TestingDocument10 pagesImportance of Facade Testingy2kareinNo ratings yet

- Aluminium Forms SystemDocument46 pagesAluminium Forms SystemHazbullah ShajiNo ratings yet

- Earthquake Resistant Masonary BuildingsDocument26 pagesEarthquake Resistant Masonary BuildingsSourabhAdikeNo ratings yet

- E-Brochure Skypark ResidencesDocument24 pagesE-Brochure Skypark ResidencesLester Sim100% (1)

- Business Park Design Guide: City of MuskegoDocument17 pagesBusiness Park Design Guide: City of Muskegoahmedusamahashem1677No ratings yet

- Description of Tilt-Up Concrete Wall ConstructionDocument8 pagesDescription of Tilt-Up Concrete Wall ConstructionnevinkoshyNo ratings yet

- ABSTRACTDocument46 pagesABSTRACTOpensource projextsNo ratings yet

- Case Study.. 10th AprilDocument20 pagesCase Study.. 10th AprilMonika Aishwarya Bhokrey100% (4)

- Spatial OrganizationDocument14 pagesSpatial OrganizationumarulafzanNo ratings yet

- BD - K - EXPANSION JOINTSDocument18 pagesBD - K - EXPANSION JOINTSMuthusamy ArumugamNo ratings yet

- Kingspan - Architectural Wall Panel KS1000 AWP - Installation Guide - Vertically Laid - January 2020 - AU NZ - ENDocument12 pagesKingspan - Architectural Wall Panel KS1000 AWP - Installation Guide - Vertically Laid - January 2020 - AU NZ - ENBranZzZzZNo ratings yet

- Typical General Arrangement of A BuildingDocument1 pageTypical General Arrangement of A BuildingSamitha SoysaNo ratings yet

- PNAAP928Document250 pagesPNAAP928bereket woredeNo ratings yet

- DCD Material Test Standards - September - 2018Document128 pagesDCD Material Test Standards - September - 2018Ghayas JawedNo ratings yet

- BQ Civil Package Indrajaya PenawaranDocument403 pagesBQ Civil Package Indrajaya PenawaranMogul Khan100% (1)

- Detailed Accomplishment Report: Suntrust Verona Housing ProjectDocument3 pagesDetailed Accomplishment Report: Suntrust Verona Housing ProjectAllen MendozaNo ratings yet

- Estimation For Building Works - Long Wall Short Wall, Centerline MethodsDocument3 pagesEstimation For Building Works - Long Wall Short Wall, Centerline MethodswaynectwNo ratings yet

- International Primary School Design: Case StudyDocument109 pagesInternational Primary School Design: Case Studydolar buhaNo ratings yet

- INDIA PRECAST - Boundary-WallDocument2 pagesINDIA PRECAST - Boundary-WallPrateek ModyNo ratings yet

- Ubbl 1984Document196 pagesUbbl 1984IVIastergrade100% (2)

- Buckstay SystemDocument15 pagesBuckstay SystemAssistente Engenharia HNRNo ratings yet

- Installation and Maintenance Instructions: Ecotec PlusDocument48 pagesInstallation and Maintenance Instructions: Ecotec PlusSlobodan TubinNo ratings yet

- Yared Mola - RT 1028 11Document31 pagesYared Mola - RT 1028 11yared molaNo ratings yet

- Application & Construction: Simple Retaining Walls in Clay BrickworkDocument4 pagesApplication & Construction: Simple Retaining Walls in Clay BrickworkummerdNo ratings yet

- TCVN 2622-1995 Fire PreventionDocument47 pagesTCVN 2622-1995 Fire PreventiontrungjindoNo ratings yet

- Virtual Reality Technology Applied in Civil Engineering Educa-TionDocument5 pagesVirtual Reality Technology Applied in Civil Engineering Educa-TionMufeez MominNo ratings yet