Professional Documents

Culture Documents

Rel - Valve 46,47,48,49 - Rev1

Rel - Valve 46,47,48,49 - Rev1

Uploaded by

IRAQ iiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rel - Valve 46,47,48,49 - Rev1

Rel - Valve 46,47,48,49 - Rev1

Uploaded by

IRAQ iiCopyright:

Available Formats

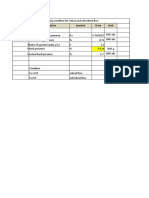

RELIEF VALVES

Item N°: PSV 46 PSV 47 PSV 48 PSV 49

1 Protected Equipment P-15A P-15B P-16A P-16B

EQUIPMENT INFORMATION

2 777-ZD 777-ZD 783-ZC 783-ZC

Reference P&I

3 PID 009 PID 009 PID 009 PID 009

4 Fluid Name Deemulsifier Agent Deemulsifier Agent Caustic Soln´5% Caustic Soln´5%

5 Phase (liquid/vapour) liquid liquid liquid liquid

6 Corrosion. Yes No Yes No Yes No Yes No

7 Operating / Design Temperature °C 55/80 55/80 55/80 55/80

8 Operating / Design Pressure kg/cm2 (g) 10/12 10/12 12/15 12/15

9

Reliefing to back to suction back to suction back to suction back to suction

10

11 Accumulation % 10 10 10 10

12 Reliefing Quantity kg/h

13 Temperature (in/out) °C 50 50 50 50

CHARACTERISTICS

14 Amount Flashing % wt.

15 Molecular Weight FORMTEXT

FLUIDS

16 Vapour Cp/Cv

17 Compressibility Factor Z

18 Density (at. P.T.) kg/m3 1190 1190 1046 1046

19 Liquid Viscosity cSt 600 600 0.8 0.8

20 Latent Heat kcal/kg

21 Type of Relief Valve (Conv./Balanced) Conv. Conv. Conv. Conv.

CHARACT.

22 Number of Relief Valves 1 1 1 1

RELIEF

VALVE

23 Size of Relieving area (Calc.) mm2

24

Line Specification

25

26 Set Pressure (Pset) kg/cm2 (g) 12 12 15 15

FLARE SYSTEM

27 Inlet All. Lead Line ∆P (%Pset)kg/cm2 (g)

RELIEF AND

28 Actual Lead Line ∆P kg/cm2 (g)

DATA

29 Variable Back Press. kg/cm2 (g)

30 Superimp. Back Press. kg/cm2 (g)

Outlet

31 Allowable Back Press. kg/cm2 (g) 0 0 0 0

32 Built-Up Back Pressure kg/cm2 (g)

33 Power Failure

34 Utility Failure

RELIEF CONDITIONS

35 Reflux Failure

36 Aircooler Failure

37 Closed Outlet

38 Vapour in Exchanger/Heater

39 Liquid Expansion

40 Refrigerant Failure

41 Overfilling

42 Fire

43 Other Failure

44 Connection Size (inlet/outlet) 1/2" / 1/2" 1/2" / 1/2" 1/2" / 1/2" 1/2" / 1/2"

45 Flange Facing 150RF / 150RF 150RF / 150RF 150RF / 150RF 150RF / 150RF

MATERIALS AND

CONSTRUCTION

46 Pipping class NOAA/NOAA NOAA/NOAA NOAA/NOAA NOAA/NOAA

47 Test Lever Yes No Yes No Yes No Yes No

48 Open

Type of

49 Closed

Constr.

50 Bellows

1 1

51 Body SS316 1 SS316 1 SS316 SS316

Materials

52 Trim SS316 SS316 SS316 SS316

53 Notes: with spare springs and bellows (if aplicable)

54 Supply of Pumps

55

56

Project New Crude Distillation Unit, Basrah, Iraq

3 Customer South Refineries Co.

2 Order N°

1 VOD SKR PKP 09/2009 for Construction Page

0 VOD SKR PKP 05/2009 for Construction

R. Des. Chd. Ap. Date Description 17/24

Property of P.E. can be used only in reference to contract or proposals of this company. Reproduction of this print disclosed is prohibited.

You might also like

- 10 0893 01 MS 7RP AFP tcm143-701176Document18 pages10 0893 01 MS 7RP AFP tcm143-701176Yusuf Jemal91% (11)

- Grade 6 Weekly Spelling WordsDocument6 pagesGrade 6 Weekly Spelling WordsJessie OcadoNo ratings yet

- Green Wedge Urbanism History, Theory and Contemporary PracticeDocument302 pagesGreen Wedge Urbanism History, Theory and Contemporary PracticeTeodora FlrNo ratings yet

- Semi Detailed Lesson Plan DIASS (Humss) (Demo)Document5 pagesSemi Detailed Lesson Plan DIASS (Humss) (Demo)Nildy Ponteras100% (4)

- Data Sheet For PSVDocument1 pageData Sheet For PSVBABILIN VNo ratings yet

- Choke Valve DatasheetDocument1 pageChoke Valve DatasheetMuhammad Rizqi SiregarNo ratings yet

- Log ChillerDocument4 pagesLog ChillerJoe JordisonNo ratings yet

- Process Data Sheet For Fired HeaterDocument8 pagesProcess Data Sheet For Fired HeaterBangkiyak LanangNo ratings yet

- CVL Consent PDFDocument5 pagesCVL Consent PDFGolam SarwarNo ratings yet

- SUMMATIVE TEST IN SCIENCE 6 (Fourth Quarter)Document3 pagesSUMMATIVE TEST IN SCIENCE 6 (Fourth Quarter)Cindy Mae Macamay100% (2)

- Data Sheet For PSVDocument9 pagesData Sheet For PSVashams492No ratings yet

- 077154C - 1813 PDS 1543 001 A Technip India LTD.: Client MRPL Location Mangalore, Karnata Unit New LPG AtuDocument1 page077154C - 1813 PDS 1543 001 A Technip India LTD.: Client MRPL Location Mangalore, Karnata Unit New LPG AtuChakravarthy BharathNo ratings yet

- FEA-Inlet Separator & Scrubber Process Data Sheet ADA Rev. B0Document14 pagesFEA-Inlet Separator & Scrubber Process Data Sheet ADA Rev. B0ddaalayamoct313024No ratings yet

- GeneralDocument1 pageGeneralamirNo ratings yet

- GeneralDocument1 pageGeneralamirNo ratings yet

- Documents For Approval Rev-1 - ApprovedDocument42 pagesDocuments For Approval Rev-1 - ApprovedAbhijeet WayaseNo ratings yet

- Pzem 33H224 3 Pumps 10 HPDocument4 pagesPzem 33H224 3 Pumps 10 HPRutchelle BrunoNo ratings yet

- Booster Pump, 5 HP, 80 GPM X 180 FTDocument4 pagesBooster Pump, 5 HP, 80 GPM X 180 FTRutchelle BrunoNo ratings yet

- General: CRUDE OIL / Liquid 313.9 / 313.9Document1 pageGeneral: CRUDE OIL / Liquid 313.9 / 313.9amirNo ratings yet

- GeneralDocument1 pageGeneralamirNo ratings yet

- 20G12-MF-0010 - RA Heat & Mass Balance Diagram-2 PDFDocument7 pages20G12-MF-0010 - RA Heat & Mass Balance Diagram-2 PDFahmedNo ratings yet

- 3Ph Vert Sep 2010 Weir VerA FPS PDFDocument5 pages3Ph Vert Sep 2010 Weir VerA FPS PDFhaiderNo ratings yet

- Abb-02-Ics-Das-Enf-000-00001-00 Z-03Document2 pagesAbb-02-Ics-Das-Enf-000-00001-00 Z-03mvdeole7056No ratings yet

- 150FV054-IFT-Data SheetDocument1 page150FV054-IFT-Data SheetgerardoNo ratings yet

- Series RHC Characteristics: Check Valve, Hydraulically Pilot-OperatedDocument4 pagesSeries RHC Characteristics: Check Valve, Hydraulically Pilot-OperatedLLNo ratings yet

- PCV-2013 DatasheetDocument1 pagePCV-2013 DatasheetraufyNo ratings yet

- Data Sheet & Sizing SheetDocument3 pagesData Sheet & Sizing SheetazitaggNo ratings yet

- Behind JNTUK - MOPUDocument10 pagesBehind JNTUK - MOPUfrAnkEnstEin liveNo ratings yet

- Ed0581b-1639e 01 Ap1Document5 pagesEd0581b-1639e 01 Ap1Erol DAĞNo ratings yet

- Final End User Data Sheets 15 Valves Tor Deshy Rev1Document15 pagesFinal End User Data Sheets 15 Valves Tor Deshy Rev1Ghofrane HNo ratings yet

- Comp 10 6 X 7 Phe7 Ba2Document2 pagesComp 10 6 X 7 Phe7 Ba2Ravi KantNo ratings yet

- Ps 138 Ma Data SheetDocument4 pagesPs 138 Ma Data SheetRutchelle BrunoNo ratings yet

- KSB MIL Controls Limited Valve Specification SheetDocument2 pagesKSB MIL Controls Limited Valve Specification SheetPablo TorresNo ratings yet

- 2 Phase Separator Sizing: Vertical Horizontal OrientationDocument2 pages2 Phase Separator Sizing: Vertical Horizontal Orientationmohideenaliyarjafeer.shanawazNo ratings yet

- Planilla Calculo PSVDocument66 pagesPlanilla Calculo PSVPROCESOS PROCESOSNo ratings yet

- ALIVIATORDocument14 pagesALIVIATORPROCESOS PROCESOSNo ratings yet

- Simulation of Single Stage Flash VaporizationDocument16 pagesSimulation of Single Stage Flash VaporizationSridhar KattaNo ratings yet

- Pressure Safety Valve-Preliminary Sizing: Input DataDocument6 pagesPressure Safety Valve-Preliminary Sizing: Input DataPIDNo ratings yet

- BTÑ HTDS - H 10Document1 pageBTÑ HTDS - H 10Juan Pablo Sanchez MelgarejoNo ratings yet

- Damper DS - 1196DPR-430Document2 pagesDamper DS - 1196DPR-430harishcsharmaNo ratings yet

- ANEXO 3.1 - Hoja de Datos PSV-110A - Version 2 - Rta 6Document1 pageANEXO 3.1 - Hoja de Datos PSV-110A - Version 2 - Rta 6Annie De WildeNo ratings yet

- General: Crude Oil - 219 Crude Oil - 219 1.117 82.6Document1 pageGeneral: Crude Oil - 219 Crude Oil - 219 1.117 82.6amirNo ratings yet

- ECP Jo Colombia 3102124385 Quote Number:: Pressure Relief Valve Sizing & Selection ReportDocument6 pagesECP Jo Colombia 3102124385 Quote Number:: Pressure Relief Valve Sizing & Selection ReportJorge LemusNo ratings yet

- Cam 200-390-110kwDocument4 pagesCam 200-390-110kwbocahjeblogNo ratings yet

- Hojas de Datos Ejercicio ExtraDocument1 pageHojas de Datos Ejercicio ExtraJohnny Ramos DíazNo ratings yet

- 150FV104-IFT-Data SheetDocument1 page150FV104-IFT-Data SheetgerardoNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument3 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Solvent Recovery Bottoms Pumps (09P007A/B) : Data SheetDocument6 pagesSolvent Recovery Bottoms Pumps (09P007A/B) : Data SheetAthiphap SrisupareerathNo ratings yet

- 07-PSV-07 Folha de Dados ValbracDocument1 page07-PSV-07 Folha de Dados ValbracRODRIGO CARDOSONo ratings yet

- Log ChillerDocument4 pagesLog ChillerJoe JordisonNo ratings yet

- TEMA Sheet CorregidoDocument1 pageTEMA Sheet Corregidosaragineth.saNo ratings yet

- Pressure Safety Valve-Preliminary Sizing: Input DataDocument5 pagesPressure Safety Valve-Preliminary Sizing: Input DataTun Naing WinNo ratings yet

- 22-DS-R-001 Rev 1 API 617 GTCPsDocument25 pages22-DS-R-001 Rev 1 API 617 GTCPsChike Nwachukwu100% (1)

- 150FV002-IFT-Data SheetDocument1 page150FV002-IFT-Data SheetgerardoNo ratings yet

- MKI-DS-J-001-A4 - Rev A Data Sheet PCVDocument60 pagesMKI-DS-J-001-A4 - Rev A Data Sheet PCVFIRMANSYAHNo ratings yet

- HSCP-649-DAT-3101 - REV E (Compressor Data Sheet)Document10 pagesHSCP-649-DAT-3101 - REV E (Compressor Data Sheet)phantuan080213No ratings yet

- Aspen Zik PDFDocument31 pagesAspen Zik PDFAhmad ZikryNo ratings yet

- Sr. No Description Symbol Data Unit: CF 1 P V 2 2Document11 pagesSr. No Description Symbol Data Unit: CF 1 P V 2 2Dharmik PatelNo ratings yet

- Refrigeratoion TextDocument66 pagesRefrigeratoion TextPhyo Ko KoNo ratings yet

- 150HV003-IFT-Data SheetDocument1 page150HV003-IFT-Data SheetgerardoNo ratings yet

- 113 80 330 FD 202 - Rev1 19Document1 page113 80 330 FD 202 - Rev1 19Maria Eduarda AndradeNo ratings yet

- A11627SE-04 - CVDS Rev C Technical Specification 840GDocument2 pagesA11627SE-04 - CVDS Rev C Technical Specification 840GMichael Adu-boahenNo ratings yet

- Quick Coupling DatasheetDocument1 pageQuick Coupling DatasheetfaridferdiansyahNo ratings yet

- Fan-Compressor Process Duty SpecificationDocument2 pagesFan-Compressor Process Duty SpecificationZUCEL ARLLETTE MAJUS CASTANEDANo ratings yet

- امثلة الأستاذ من اليوتيوبDocument7 pagesامثلة الأستاذ من اليوتيوبIRAQ iiNo ratings yet

- 5 - Unsteady State Mass Transfer 54Document27 pages5 - Unsteady State Mass Transfer 54IRAQ iiNo ratings yet

- RELAP-7: Demonstrating Seven-Equation, Two-Phase Flow Simulation in A Single-Pipe, Two-Phase Reactor Core and Steam Separator/DryerDocument40 pagesRELAP-7: Demonstrating Seven-Equation, Two-Phase Flow Simulation in A Single-Pipe, Two-Phase Reactor Core and Steam Separator/DryerIRAQ iiNo ratings yet

- مصرف جيهانDocument3 pagesمصرف جيهانIRAQ iiNo ratings yet

- DE-11 - Lesson 34. PROBLEMS ON DRYINGDocument8 pagesDE-11 - Lesson 34. PROBLEMS ON DRYINGIRAQ iiNo ratings yet

- Chapter Four: Forced ConvectionDocument3 pagesChapter Four: Forced ConvectionIRAQ iiNo ratings yet

- حلول اسألة تنافسي جامعة بغداد 2018Document9 pagesحلول اسألة تنافسي جامعة بغداد 2018IRAQ iiNo ratings yet

- Rel - Valve 58 - Rev1Document1 pageRel - Valve 58 - Rev1IRAQ iiNo ratings yet

- Rel - Valve 54,55,56,57 - Rev1Document1 pageRel - Valve 54,55,56,57 - Rev1IRAQ iiNo ratings yet

- تجربة 1-مختبر انتقال الحرارة-1 - 230124 - 114342Document29 pagesتجربة 1-مختبر انتقال الحرارة-1 - 230124 - 114342IRAQ iiNo ratings yet

- Fourier SeriesDocument18 pagesFourier SeriesIRAQ iiNo ratings yet

- Viichy France and The Resistance Culture & IdeologyDocument301 pagesViichy France and The Resistance Culture & IdeologyandybgNo ratings yet

- 8 Fall of The Ottoman EmpireDocument10 pages8 Fall of The Ottoman Empireapi-303147801No ratings yet

- Chapter 75Document2 pagesChapter 75Quranic ResourcesNo ratings yet

- Optical Communication NetworksDocument4 pagesOptical Communication Networksarivurp100% (1)

- 3 Combine Wiring Diagram Pad BDocument7 pages3 Combine Wiring Diagram Pad BDimas FirmanNo ratings yet

- Capacitor Placement Replacement Control in Large-Scale Distribution Systems by A GA-Based Two-Stage AlgorithmDocument7 pagesCapacitor Placement Replacement Control in Large-Scale Distribution Systems by A GA-Based Two-Stage AlgorithmKishore Kumar ReddyNo ratings yet

- Case Study 3Document15 pagesCase Study 3kdp2203No ratings yet

- Sample 70 - 2Document7 pagesSample 70 - 2Mikhael MangopoNo ratings yet

- Homemade Chicken Nuggets - The Cozy CookDocument2 pagesHomemade Chicken Nuggets - The Cozy CookBejeweled LuigiGhostNo ratings yet

- District CalendarDocument1 pageDistrict Calendarapi-271737972No ratings yet

- Marketing Project OutlineDocument3 pagesMarketing Project OutlineRana AhmedNo ratings yet

- Slides 4tl4Document312 pagesSlides 4tl4Isac AareiasNo ratings yet

- Seminar-Quality Assurance (13-11-2013) - Copy (Repaired)Document200 pagesSeminar-Quality Assurance (13-11-2013) - Copy (Repaired)ASIR DHAYANINo ratings yet

- HP ZBOOK 17 QUICKSPECS c04111344Document45 pagesHP ZBOOK 17 QUICKSPECS c04111344hutz5000No ratings yet

- TRIAL Poultry Farm Financial Model Excel Template v2.0Document96 pagesTRIAL Poultry Farm Financial Model Excel Template v2.0Muhammad Haroon YousafNo ratings yet

- Father Absence and Self EsteemDocument40 pagesFather Absence and Self EsteemAlexandra BobeșNo ratings yet

- Course Info Sheet - NST001Document7 pagesCourse Info Sheet - NST001Ching DialomaNo ratings yet

- Prelims-Arche 4 Sy 2122-StudentsDocument3 pagesPrelims-Arche 4 Sy 2122-StudentsAaron CansinoNo ratings yet

- A Teacher's Guide To CosmosDocument45 pagesA Teacher's Guide To CosmosMSU UrbanSTEM100% (2)

- Guía Didáctica - Profesionalización Inglés A1Document60 pagesGuía Didáctica - Profesionalización Inglés A1Fernanda AndradeNo ratings yet

- This Study Resource Was: Example On Steam Pipe InsulationDocument3 pagesThis Study Resource Was: Example On Steam Pipe InsulationRamses Uriel Torres CanoNo ratings yet

- Candidate Handbook 2021Document27 pagesCandidate Handbook 2021Jose Daniel NuñezNo ratings yet

- Capstone Project ProposalDocument7 pagesCapstone Project Proposalapi-596258184No ratings yet

- HR Practices NTPCDocument16 pagesHR Practices NTPCRuchika SinhaNo ratings yet