Professional Documents

Culture Documents

Photo Voltaic Solar Energy

Photo Voltaic Solar Energy

Uploaded by

Philip Donovan BradleyCopyright:

Available Formats

You might also like

- Alberto Villoldo Book PDFDocument120 pagesAlberto Villoldo Book PDFtito1628100% (4)

- Florida International University College of Engineering and Computing Department of Electrical and Computer EngineeringDocument9 pagesFlorida International University College of Engineering and Computing Department of Electrical and Computer EngineeringAneelaMalikNo ratings yet

- Solar PV Project ReportDocument19 pagesSolar PV Project Reportpriyanka chaudhary70% (20)

- Materials Science and Engineering Notes 091110Document12 pagesMaterials Science and Engineering Notes 091110Mete MetelanNo ratings yet

- Motor Modutrol Honeywell PDFDocument24 pagesMotor Modutrol Honeywell PDFGustavo Casillas0% (1)

- Applications of Solar Energy PDFDocument42 pagesApplications of Solar Energy PDFpallav guptaNo ratings yet

- Sensors and TransducersDocument27 pagesSensors and TransducersKRISHNAVINODNo ratings yet

- 414 - B.a.textile Dyeing & PrintingDocument9 pages414 - B.a.textile Dyeing & PrintingJyoti JaatNo ratings yet

- AUTOMATIC GATE ALARM WITH LIGHT WorkdoneDocument21 pagesAUTOMATIC GATE ALARM WITH LIGHT WorkdoneMainuddin M JamadarNo ratings yet

- Solar Light and FanDocument59 pagesSolar Light and FanMohamed SaleemNo ratings yet

- Solar Power PlantDocument65 pagesSolar Power PlantHil GloriosoNo ratings yet

- Report On Automated BlindsDocument58 pagesReport On Automated BlindsGowthami100% (1)

- GS P&D Archsd 2012Document127 pagesGS P&D Archsd 2012Andy Lee100% (1)

- Lecture Notes Chapter 4 PDFDocument50 pagesLecture Notes Chapter 4 PDFHui ShanNo ratings yet

- The Manufacturing Processes of StaplerSDocument9 pagesThe Manufacturing Processes of StaplerSMahendra DahiyaNo ratings yet

- Cooling Tower Efficiency and ApproachDocument8 pagesCooling Tower Efficiency and Approachjeevitha jeeviNo ratings yet

- ES195 Lab Tensile Testing PDFDocument12 pagesES195 Lab Tensile Testing PDFtopbanana09No ratings yet

- Experiment # 3: Part Manufacturing Using 3D PrintingDocument12 pagesExperiment # 3: Part Manufacturing Using 3D PrintingMuhammad FarhanNo ratings yet

- DC DC ConvertersDocument26 pagesDC DC ConvertersJuan Francisco ValenzuelaNo ratings yet

- Sunglow SG1212 2424Document16 pagesSunglow SG1212 2424ibrargrt100% (1)

- Electromagnetic Shearing MachineDocument31 pagesElectromagnetic Shearing MachineANAND KRISHNANNo ratings yet

- Assignment Non Conventional MachiningDocument5 pagesAssignment Non Conventional Machiningkapun kumar nayak100% (1)

- Lecture Thermography PresentationDocument30 pagesLecture Thermography PresentationDhruv SahniNo ratings yet

- Types of ControllersDocument13 pagesTypes of Controllerscssp115No ratings yet

- CHAPTER 3-Solar EditDocument19 pagesCHAPTER 3-Solar EditIlyana ZakariahNo ratings yet

- Fabrication of Slider Crank MechanismDocument23 pagesFabrication of Slider Crank Mechanismsanjay leela bhansaliNo ratings yet

- Clipper and Climper Circit PDFDocument6 pagesClipper and Climper Circit PDFOmar Said Abu RabieNo ratings yet

- Taylor's PrincipleDocument16 pagesTaylor's PrincipleSivaNo ratings yet

- Solar Energy Fact SheetDocument4 pagesSolar Energy Fact SheetHossam Al-Dein Mostafa HelmyNo ratings yet

- TransducerDocument87 pagesTransducerBobeth TubigNo ratings yet

- Green - Book - Chapter Cold Chain EnglandDocument20 pagesGreen - Book - Chapter Cold Chain EnglandMario Vazquez BNo ratings yet

- Norton TheoremDocument11 pagesNorton TheoremRacknarockNo ratings yet

- Phase DiagramsDocument48 pagesPhase DiagramszanretNo ratings yet

- Economic Analysis of Bread Baking Enterprises in Kaduna and Zaria Metropolis of Kaduna State, Nigeria.Document78 pagesEconomic Analysis of Bread Baking Enterprises in Kaduna and Zaria Metropolis of Kaduna State, Nigeria.omoyegunNo ratings yet

- Assignment On Nuclear Power PlantADocument13 pagesAssignment On Nuclear Power PlantAtheunsung tale100% (1)

- FEU Institute of Technology Project Design RubricDocument2 pagesFEU Institute of Technology Project Design RubricBryan CustodioNo ratings yet

- U11Document32 pagesU11Kapildev KumarNo ratings yet

- Solar Energy: This Article Is About All Uses of Solar Energy. For The Journal, SeeDocument38 pagesSolar Energy: This Article Is About All Uses of Solar Energy. For The Journal, Seefriends_isNo ratings yet

- QB Ieq Me6i (22657) Ut 1 13022020Document5 pagesQB Ieq Me6i (22657) Ut 1 13022020Ashvin PawaraNo ratings yet

- Cold Chain ManagementDocument37 pagesCold Chain Managementcallmedump1No ratings yet

- Motor EfficiencyDocument28 pagesMotor EfficiencyMani KandanNo ratings yet

- Hot Working Cold WorkingDocument2 pagesHot Working Cold WorkingBivas Panigrahi100% (1)

- Development of An Advanced Servo Manipulator For Remote Handling in Nuclear InstallationsDocument8 pagesDevelopment of An Advanced Servo Manipulator For Remote Handling in Nuclear InstallationsK. JayarajanNo ratings yet

- Lab Report ExampleDocument5 pagesLab Report ExampleSaeed AhmadNo ratings yet

- Chemical SafetyDocument20 pagesChemical SafetyRocky MeetNo ratings yet

- Electronics IndustrialDocument6 pagesElectronics IndustrialhongNo ratings yet

- ME8595-Thermal Engineering-II Valliammai PDFDocument19 pagesME8595-Thermal Engineering-II Valliammai PDFSiva SubramaniamNo ratings yet

- Lecture 3Document53 pagesLecture 3Akarshan AvinashNo ratings yet

- Guidelines To Electrical Wiring Around Your HomeDocument38 pagesGuidelines To Electrical Wiring Around Your HomevozoscribdNo ratings yet

- Laser Dismantling of PHWR Spent Fuel Bundles and De-Cladding of Fuel Pins in The Highly Radioactive Hot CellsDocument6 pagesLaser Dismantling of PHWR Spent Fuel Bundles and De-Cladding of Fuel Pins in The Highly Radioactive Hot CellsK. JayarajanNo ratings yet

- Learning Outcome - 1 - Three Phase Circuit (003) - 2020Document55 pagesLearning Outcome - 1 - Three Phase Circuit (003) - 2020Sara AlnuaimiNo ratings yet

- JJ104 Workshop Technology CHAPTER9 Arc WeldingDocument14 pagesJJ104 Workshop Technology CHAPTER9 Arc WeldingAh Tiang50% (4)

- IEM ProductivityDocument15 pagesIEM ProductivityThe Bhavuk's ChannelNo ratings yet

- Maximum Power Transfer Theorem - GATE Study Material in PDFDocument10 pagesMaximum Power Transfer Theorem - GATE Study Material in PDFNarendra AgrawalNo ratings yet

- 3 Phase Lab ReportDocument2 pages3 Phase Lab ReportSheikh BajunaidNo ratings yet

- Power StationDocument10 pagesPower Stationletter_ashish4444No ratings yet

- Intrinsic & Extrinsic SemiconductorsDocument20 pagesIntrinsic & Extrinsic SemiconductorsmaharjansumirNo ratings yet

- Project Design and Log FrameDocument17 pagesProject Design and Log FrameDrGajendraSinghNo ratings yet

- 3D Printing Report PDFDocument33 pages3D Printing Report PDFvivek patelNo ratings yet

- CV Hari Wahyudi EL ITB 86Document13 pagesCV Hari Wahyudi EL ITB 86agungNo ratings yet

- HOSPITALDocument23 pagesHOSPITALsanika shindeNo ratings yet

- IJSDR1902043Document8 pagesIJSDR1902043Boutaina BoujradaNo ratings yet

- StirfryDocument2 pagesStirfryPhilip Donovan BradleyNo ratings yet

- Week 8 Playbook Illustrative ResponsesDocument20 pagesWeek 8 Playbook Illustrative ResponsesPhilip Donovan BradleyNo ratings yet

- Bending (Ch-6) - 2010Document19 pagesBending (Ch-6) - 2010Philip Donovan BradleyNo ratings yet

- Why Is Collective Bargaining Fa - Geoffry HealdDocument301 pagesWhy Is Collective Bargaining Fa - Geoffry HealdPhilip Donovan BradleyNo ratings yet

- GeothermalDocument5 pagesGeothermalPhilip Donovan BradleyNo ratings yet

- Detail Spesifikasi Teknis Dan Gambar ABF Dan Walk in Freezer 1Document1 pageDetail Spesifikasi Teknis Dan Gambar ABF Dan Walk in Freezer 1akhmad arifinNo ratings yet

- Journal of Aerospace Technology and Management 02v 01Document136 pagesJournal of Aerospace Technology and Management 02v 01Álvaro Conti FilhoNo ratings yet

- Engine Cooling ColumnDocument2 pagesEngine Cooling ColumnHari NugrohoNo ratings yet

- Wavelength and How It Compares To A SlinkyDocument3 pagesWavelength and How It Compares To A Slinkyapi-262586446100% (1)

- Automotive Electronics System: GaugesDocument8 pagesAutomotive Electronics System: Gaugeshadush gebreNo ratings yet

- OscarII Manual PartsBook ElectricalDocument84 pagesOscarII Manual PartsBook ElectricalPablo SchinkeNo ratings yet

- Heat Treatment Manual Part IIDocument21 pagesHeat Treatment Manual Part IIAnonymous lmCR3SkPrK100% (3)

- CIV3703 Transport Engineering (USQ)Document32 pagesCIV3703 Transport Engineering (USQ)hao baiNo ratings yet

- Electric CircuitDocument15 pagesElectric CircuittitinadiyantiNo ratings yet

- Manual Ut EspañolDocument52 pagesManual Ut EspañolEugenioNo ratings yet

- Bab 7 Diagram Alir ProsesDocument2 pagesBab 7 Diagram Alir ProsesWisnu Center'zNo ratings yet

- Unit 4.3Document44 pagesUnit 4.3syed1188No ratings yet

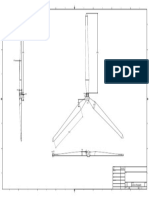

- Wind Turbine Blade Drawing GADocument1 pageWind Turbine Blade Drawing GAjonahNo ratings yet

- Regen SWDocument92 pagesRegen SWSubibechanaShawNo ratings yet

- Exam 2 Review Questions PHY 2425 - Exam 2Document46 pagesExam 2 Review Questions PHY 2425 - Exam 2Ashish VermaNo ratings yet

- Uses of The Components of Crude Oil As FuelsDocument6 pagesUses of The Components of Crude Oil As FuelsPearl LawrenceNo ratings yet

- Reviewer Organic Chemistry LectureDocument9 pagesReviewer Organic Chemistry LectureAlyanna Elisse Vergara100% (1)

- ICE 160 230 0296 HammerDocument119 pagesICE 160 230 0296 HammerRıfat BingülNo ratings yet

- P43x DIST Application Guide en E2Document45 pagesP43x DIST Application Guide en E2Antonio Solís MurilloNo ratings yet

- Ranger Pro Wireless Condition Monitoring Datasheet - 125M5237Document11 pagesRanger Pro Wireless Condition Monitoring Datasheet - 125M5237Nurdin MubarokNo ratings yet

- MaxDNA Based EHTC Calibration ProcedureDocument3 pagesMaxDNA Based EHTC Calibration ProcedureSanjay Chakraborty100% (1)

- Transfermachines - IADocument18 pagesTransfermachines - IADivyeshNo ratings yet

- Lec 7 Gender Issues in IWRM Bangladesh Experiences IPSWAMPDocument24 pagesLec 7 Gender Issues in IWRM Bangladesh Experiences IPSWAMPsuchisharmin1No ratings yet

- Business+Problem +Stora+EnsoDocument4 pagesBusiness+Problem +Stora+Ensoadnan ansariNo ratings yet

- IEA Renewables Information 2011Document498 pagesIEA Renewables Information 2011aksharchandraNo ratings yet

- Nr6 P0089 P1169Document2 pagesNr6 P0089 P1169Yuting NgNo ratings yet

- Presentation - Gate FixingDocument11 pagesPresentation - Gate FixingAshutosh DubeyNo ratings yet

- Yaskawa 1000Document269 pagesYaskawa 1000mahh1234No ratings yet

Photo Voltaic Solar Energy

Photo Voltaic Solar Energy

Uploaded by

Philip Donovan BradleyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Photo Voltaic Solar Energy

Photo Voltaic Solar Energy

Uploaded by

Philip Donovan BradleyCopyright:

Available Formats

Photovoltaic Solar Energy

Solar energy is a vital building block for our future global sustainable energy scheme. Its potential is almost unlimited and it can be applied in sunny regions as well as in less favourable conditions. Photovoltaic conversion is very versatile as it can be used from a MW to a GW scale. It can be used for consumer products, solar home systems, rural use, building integrated systems and large-scale power plants. Photovoltaics is a field of technology and research in which devices directly convert sunlight into DC electricity. Solar cells are the basic building blocks of photovoltaic technology. Solar cells are made of semiconductor materials, such as silicon, which are presently the most common. An important property of such semiconductors which makes them very useful is that their conductivity may be easily altered by introducing impurities into their crystal lattice structures.

Figure ##1: Basic Photovoltaic Cell [##1]

When sunlight strikes the solar cell, the semiconductor material absorbs some of the light, photons. This energy triggers the release of electrons, allowing them to flow freely. As previously stated, by introducing impurities (doping) such as phosphorus and boron atoms into the solar cell, the conductivity can be altered. Therefore the one side of the cell contains phosphorous atoms, with five valence electrons (one more than pure silicon), and the other side contains boron, with three valence electrons (one less than pure silicon). The phosphorous atoms donate their valence electrons to the silicon thus creating negatively charged carriers, N-type. The boron atoms on the other side of the silicon have a greater affinity to attract electrons than the silicon material, Ptype. Electrons diffuse from a region of high concentration, phosphorous, to a region of low concentration, boron. When the electrons diffuse across the silicon, they combine again with free holes on the boron side of the silicon. This imbalance of charges on either side of the silicon creates an electric field which acts as a diode. This electric field encourages current to flow in a certain direction. Metal contacts are made to both sides of the solar cell, thus allowing the current to flow to an external load. So in summary, photons from the sunlight strike the solar cells transferring their energy to the charge carriers. The electric field across the solar cell separates the positively charged carriers from the negatively charged electrons, thus forming an electric current when the circuit is closed and the field provides the voltage, thus power is produced. An anti-

reflective coating covers the silicon because silicon is shiny material thus reflecting some of the photons from the sun light [##13].

Figure ##2: Wafer based crystalline silicon [##4]

There are several different types of solar cells, but the most common consist of wafer-based silicon cells, as seen in figure 3. These types of solar cells can either be cut from a single crystal rod, mono-crystalline, or from a block composing of many crystals, multi-crystalline. Singlecrystal wafer cells are generally more expensive because they are cut from cylindrical ingots and thus do not completely cover a solar cell module without space being wasted. Multi-crystalline cells are less expensive to produce than single crystal silicon cells but are less efficient. The thicknesses of the wafer-based silicon solar cells vary between 100 m and 200 m thick [##1]. Solar modules made from wafers of crystalline silicon have been the dominant technology in land based photovoltaics for many years due to the massive resources and expertise available from the micro-electronics industry. Wafer-based silicon cells also have a record of being very reliable and the cost is consistently dropping. Even though silicon is an extremely abundant raw material, the processing required to achieve the necessary purity of the silicon is very expensive. Significant effort and money has been invested into reducing silicon consumption and developing new, less energy-intensive techniques for silicon solar cells. Crystalline silicon devices are now approaching the theoretical limiting efficiency of 29% [##9].

Figure ##3: Thin Film Technology [##5]

Another type of solar cell technology is based on thin-films, figure 2, which range between 1 m and 2 m in thickness and therefore require significantly less semiconducting material [##5]. Thin-film solar cells can be manufactured at a lower cost and in larger quantities and hence their market for them will likely increase in the future. However, they provide lower efficiencies than wafer-based silicon solar cells, which means that a greater surface area is required and hence

more material for the installation is required for a similar performance. Thin-film solar modules are produced by depositing thin films directly onto large glass panels or long foils. Although efficiencies of thin-film materials are presently lower than those of crystalline silicon, thin-film technology offers lower cost per watt and is thus growing rapidly and is expected to account for 31 percent of the global installed power by 2013 [##2]. In conjunction with the efforts to decrease the price of present day solar modules, more essential research is being carried out with the aim of developing drastically lower cost or higher efficient modules in the long term. Radical concepts incorporating and enabling technologies such as nanotechnology, (which aim to modify the active layer to better match the solar spectrum, or to modify the incoming solar radiation before it strikes the active layer), are being researched . Closer to todays market are the technologies of organic solar cells or even more so, concentrator photovoltaics with have significant advances in recent years. This technology works by concentrating direct sunlight onto a small but efficient material. Concentrator photovoltaics have the possibility of reaching efficiencies of over 30 %, which have not been achieved by any other photovoltaic system [##6].

Figure ##4: Solar Module [##7]

The problem with using a single solar cell is that it does not provide a lot of electricity, so by connecting a number of solar cells together and mounting them in a single frame to form a photovoltaic module, a higher more usable amount of electricity can be extracted, as seen in figure 4. These modules have been designed to supply a set amount of voltage such as 12V. The current on the other hand is directly proportional to the intensity of the light striking the cells. To produce even more electricity, these modules can be wired together to form an array which can be connected in both parallel and series depending on the required voltage and current combination. The solar cells in the modules and arrays produce direct current electricity which can be used directly to charge a battery or run certain equipment, but this is not necessarily a good thing because the integrated grids of many countries supply the public with AC electricity. There are two main types of photovoltaic systems namely Grid-connected systems and autonomous systems. Grid-connected systems are connected to the grid and provide electricity straight into the grid and thus the direct current produced by the solar modules has to be converted into AC. Solar inverters are used to change the DC electricity produced by the cells into AC current which can the be used by the public once passed into the integrated grid system. Autonomous systems on the other hand can be operated without the need of the integrated grid system. The majority of photovoltaic systems worldwide are currently implemented as grid-connected systems. Trackers and sensors are used to optimise the performance of solar cells. Tracking systems can increase feasible output by up to 100% [##8].

Figure ##5: Solar Panels on a Satellite [##5]

Advantages of harnessing solar power in the form of photovoltaic systems are as follows; solar power is pollution free and safe, photovoltaic installations can operate for a long time with little maintenance (ideal for satellites, figure 5), isolated locations do not need power from grid systems therefore saving money on power lines, solar power is near limitless and of high density in most places around the world, there is very little research done on this technology which means that there is room for improvement in the near future. Disadvantages of this technology include; photovoltaics are expensive to install (roughly $10 per Watt in the U.S.)[##4], unless programs such as feed-in tariffs[##3] are implemented it becomes very expensive, solar energy is not produced at night and is reduced with cloudy conditions, cells produce DC which needs to be converted into AC which incurs a small amount of energy loss. In Conclusion, in order for photovoltaic to be employed on a significant scale, the cost of solar electricity needs to be reduced. This cost is mainly derived from the raw material, (high purity crystalline silicon), and the low density of energy gained from the photovoltaic collectors. The only way forward is by creating thinner and more efficient silicon wafers or by introducing new technologies which are more efficient. The newer thin film cells are cheaper but less efficient than the wafer type cells therefore more material is required to achieve similar efficiencies. However solar array power plants have been successful and can produce 40-60kW of power at $5/W at efficiencies as high as 27%, but the area required for such power plants is very large [##7]. Photovoltaic concentrators are commonly used to produce energy for stand alone geysers. By considering the amount of solar radiation hitting the earth in a certain region and the concentrator yield, a formula can be used to calculate the area required of photovoltaic material. Cy = Sr c sys; [##11]

Cy is the concentrator yield in kWh/m Sr is Solar radiation in kWh/m.day c is the concentrator efficiency sys is the system efficiency

The formula used to calculate the amount of energy produced by photovoltaic cells is as follows; E = Gd Apv [##12]

E is the energy produced in kWh/day Gd is the global radiation per day in kWh/m.day Apv is the area of the photovoltaic cell is the efficiency of the solar cell material used

References: 1. http://ec.europa.eu/energy/publications/doc/2009_report-solar-energy.pdf, retrieved on 03/03/11 2. http://www.renewableenergyworld.com/rea/news/article/2009/11/thin-filmsshare-of- solar-panel-market-to-double-by-2013, retrieved on 03/03/11 3. http://www.evoenergy.co.uk/evoenergy-news/helping-our-customers-makeinformed-decisions-on-pv-finance-our-mds-thoughts/, retrieved on 03/03/11 4. http://www.nrel.gov/docs/fy09osti/43844.pdf pg 11, retrieved on 03/03/11 5. http://www.zoomers.ca/profiles/blogs/solar-people-become, retrieved on 03/03/11 6. "A New Invention To Harness The Sun" Popular Science, retrieved on 03/03/11 7. http://www.concentrix-solar.de/power-plants/?L=1 , retrieved on 03/03/11 8. "Small Photovoltaic Arrays". Research Institute for Sustainable Energy (RISE), Murdoch University. http://www.rise.org.au/info/Applic/Array/index.html , retrieved on 03/03/11 9. "Photovoltaics: Thin-film technology about to make its breakthrough". http://www.solarserver.de/solarmagazin/index-e.html, retrieved on 03/03/11 10. PHOTOVOLTAIC SOLAR ENERGY: Development and current research, 2009, ISBN

978-92-79-10644-6. 11. Concen 12. PV

13. University of the Witwatersrand, School of Electrical and Information Engineering,

Johannesburg. Elen2000 Electrical Engineering Course Notes.

You might also like

- Alberto Villoldo Book PDFDocument120 pagesAlberto Villoldo Book PDFtito1628100% (4)

- Florida International University College of Engineering and Computing Department of Electrical and Computer EngineeringDocument9 pagesFlorida International University College of Engineering and Computing Department of Electrical and Computer EngineeringAneelaMalikNo ratings yet

- Solar PV Project ReportDocument19 pagesSolar PV Project Reportpriyanka chaudhary70% (20)

- Materials Science and Engineering Notes 091110Document12 pagesMaterials Science and Engineering Notes 091110Mete MetelanNo ratings yet

- Motor Modutrol Honeywell PDFDocument24 pagesMotor Modutrol Honeywell PDFGustavo Casillas0% (1)

- Applications of Solar Energy PDFDocument42 pagesApplications of Solar Energy PDFpallav guptaNo ratings yet

- Sensors and TransducersDocument27 pagesSensors and TransducersKRISHNAVINODNo ratings yet

- 414 - B.a.textile Dyeing & PrintingDocument9 pages414 - B.a.textile Dyeing & PrintingJyoti JaatNo ratings yet

- AUTOMATIC GATE ALARM WITH LIGHT WorkdoneDocument21 pagesAUTOMATIC GATE ALARM WITH LIGHT WorkdoneMainuddin M JamadarNo ratings yet

- Solar Light and FanDocument59 pagesSolar Light and FanMohamed SaleemNo ratings yet

- Solar Power PlantDocument65 pagesSolar Power PlantHil GloriosoNo ratings yet

- Report On Automated BlindsDocument58 pagesReport On Automated BlindsGowthami100% (1)

- GS P&D Archsd 2012Document127 pagesGS P&D Archsd 2012Andy Lee100% (1)

- Lecture Notes Chapter 4 PDFDocument50 pagesLecture Notes Chapter 4 PDFHui ShanNo ratings yet

- The Manufacturing Processes of StaplerSDocument9 pagesThe Manufacturing Processes of StaplerSMahendra DahiyaNo ratings yet

- Cooling Tower Efficiency and ApproachDocument8 pagesCooling Tower Efficiency and Approachjeevitha jeeviNo ratings yet

- ES195 Lab Tensile Testing PDFDocument12 pagesES195 Lab Tensile Testing PDFtopbanana09No ratings yet

- Experiment # 3: Part Manufacturing Using 3D PrintingDocument12 pagesExperiment # 3: Part Manufacturing Using 3D PrintingMuhammad FarhanNo ratings yet

- DC DC ConvertersDocument26 pagesDC DC ConvertersJuan Francisco ValenzuelaNo ratings yet

- Sunglow SG1212 2424Document16 pagesSunglow SG1212 2424ibrargrt100% (1)

- Electromagnetic Shearing MachineDocument31 pagesElectromagnetic Shearing MachineANAND KRISHNANNo ratings yet

- Assignment Non Conventional MachiningDocument5 pagesAssignment Non Conventional Machiningkapun kumar nayak100% (1)

- Lecture Thermography PresentationDocument30 pagesLecture Thermography PresentationDhruv SahniNo ratings yet

- Types of ControllersDocument13 pagesTypes of Controllerscssp115No ratings yet

- CHAPTER 3-Solar EditDocument19 pagesCHAPTER 3-Solar EditIlyana ZakariahNo ratings yet

- Fabrication of Slider Crank MechanismDocument23 pagesFabrication of Slider Crank Mechanismsanjay leela bhansaliNo ratings yet

- Clipper and Climper Circit PDFDocument6 pagesClipper and Climper Circit PDFOmar Said Abu RabieNo ratings yet

- Taylor's PrincipleDocument16 pagesTaylor's PrincipleSivaNo ratings yet

- Solar Energy Fact SheetDocument4 pagesSolar Energy Fact SheetHossam Al-Dein Mostafa HelmyNo ratings yet

- TransducerDocument87 pagesTransducerBobeth TubigNo ratings yet

- Green - Book - Chapter Cold Chain EnglandDocument20 pagesGreen - Book - Chapter Cold Chain EnglandMario Vazquez BNo ratings yet

- Norton TheoremDocument11 pagesNorton TheoremRacknarockNo ratings yet

- Phase DiagramsDocument48 pagesPhase DiagramszanretNo ratings yet

- Economic Analysis of Bread Baking Enterprises in Kaduna and Zaria Metropolis of Kaduna State, Nigeria.Document78 pagesEconomic Analysis of Bread Baking Enterprises in Kaduna and Zaria Metropolis of Kaduna State, Nigeria.omoyegunNo ratings yet

- Assignment On Nuclear Power PlantADocument13 pagesAssignment On Nuclear Power PlantAtheunsung tale100% (1)

- FEU Institute of Technology Project Design RubricDocument2 pagesFEU Institute of Technology Project Design RubricBryan CustodioNo ratings yet

- U11Document32 pagesU11Kapildev KumarNo ratings yet

- Solar Energy: This Article Is About All Uses of Solar Energy. For The Journal, SeeDocument38 pagesSolar Energy: This Article Is About All Uses of Solar Energy. For The Journal, Seefriends_isNo ratings yet

- QB Ieq Me6i (22657) Ut 1 13022020Document5 pagesQB Ieq Me6i (22657) Ut 1 13022020Ashvin PawaraNo ratings yet

- Cold Chain ManagementDocument37 pagesCold Chain Managementcallmedump1No ratings yet

- Motor EfficiencyDocument28 pagesMotor EfficiencyMani KandanNo ratings yet

- Hot Working Cold WorkingDocument2 pagesHot Working Cold WorkingBivas Panigrahi100% (1)

- Development of An Advanced Servo Manipulator For Remote Handling in Nuclear InstallationsDocument8 pagesDevelopment of An Advanced Servo Manipulator For Remote Handling in Nuclear InstallationsK. JayarajanNo ratings yet

- Lab Report ExampleDocument5 pagesLab Report ExampleSaeed AhmadNo ratings yet

- Chemical SafetyDocument20 pagesChemical SafetyRocky MeetNo ratings yet

- Electronics IndustrialDocument6 pagesElectronics IndustrialhongNo ratings yet

- ME8595-Thermal Engineering-II Valliammai PDFDocument19 pagesME8595-Thermal Engineering-II Valliammai PDFSiva SubramaniamNo ratings yet

- Lecture 3Document53 pagesLecture 3Akarshan AvinashNo ratings yet

- Guidelines To Electrical Wiring Around Your HomeDocument38 pagesGuidelines To Electrical Wiring Around Your HomevozoscribdNo ratings yet

- Laser Dismantling of PHWR Spent Fuel Bundles and De-Cladding of Fuel Pins in The Highly Radioactive Hot CellsDocument6 pagesLaser Dismantling of PHWR Spent Fuel Bundles and De-Cladding of Fuel Pins in The Highly Radioactive Hot CellsK. JayarajanNo ratings yet

- Learning Outcome - 1 - Three Phase Circuit (003) - 2020Document55 pagesLearning Outcome - 1 - Three Phase Circuit (003) - 2020Sara AlnuaimiNo ratings yet

- JJ104 Workshop Technology CHAPTER9 Arc WeldingDocument14 pagesJJ104 Workshop Technology CHAPTER9 Arc WeldingAh Tiang50% (4)

- IEM ProductivityDocument15 pagesIEM ProductivityThe Bhavuk's ChannelNo ratings yet

- Maximum Power Transfer Theorem - GATE Study Material in PDFDocument10 pagesMaximum Power Transfer Theorem - GATE Study Material in PDFNarendra AgrawalNo ratings yet

- 3 Phase Lab ReportDocument2 pages3 Phase Lab ReportSheikh BajunaidNo ratings yet

- Power StationDocument10 pagesPower Stationletter_ashish4444No ratings yet

- Intrinsic & Extrinsic SemiconductorsDocument20 pagesIntrinsic & Extrinsic SemiconductorsmaharjansumirNo ratings yet

- Project Design and Log FrameDocument17 pagesProject Design and Log FrameDrGajendraSinghNo ratings yet

- 3D Printing Report PDFDocument33 pages3D Printing Report PDFvivek patelNo ratings yet

- CV Hari Wahyudi EL ITB 86Document13 pagesCV Hari Wahyudi EL ITB 86agungNo ratings yet

- HOSPITALDocument23 pagesHOSPITALsanika shindeNo ratings yet

- IJSDR1902043Document8 pagesIJSDR1902043Boutaina BoujradaNo ratings yet

- StirfryDocument2 pagesStirfryPhilip Donovan BradleyNo ratings yet

- Week 8 Playbook Illustrative ResponsesDocument20 pagesWeek 8 Playbook Illustrative ResponsesPhilip Donovan BradleyNo ratings yet

- Bending (Ch-6) - 2010Document19 pagesBending (Ch-6) - 2010Philip Donovan BradleyNo ratings yet

- Why Is Collective Bargaining Fa - Geoffry HealdDocument301 pagesWhy Is Collective Bargaining Fa - Geoffry HealdPhilip Donovan BradleyNo ratings yet

- GeothermalDocument5 pagesGeothermalPhilip Donovan BradleyNo ratings yet

- Detail Spesifikasi Teknis Dan Gambar ABF Dan Walk in Freezer 1Document1 pageDetail Spesifikasi Teknis Dan Gambar ABF Dan Walk in Freezer 1akhmad arifinNo ratings yet

- Journal of Aerospace Technology and Management 02v 01Document136 pagesJournal of Aerospace Technology and Management 02v 01Álvaro Conti FilhoNo ratings yet

- Engine Cooling ColumnDocument2 pagesEngine Cooling ColumnHari NugrohoNo ratings yet

- Wavelength and How It Compares To A SlinkyDocument3 pagesWavelength and How It Compares To A Slinkyapi-262586446100% (1)

- Automotive Electronics System: GaugesDocument8 pagesAutomotive Electronics System: Gaugeshadush gebreNo ratings yet

- OscarII Manual PartsBook ElectricalDocument84 pagesOscarII Manual PartsBook ElectricalPablo SchinkeNo ratings yet

- Heat Treatment Manual Part IIDocument21 pagesHeat Treatment Manual Part IIAnonymous lmCR3SkPrK100% (3)

- CIV3703 Transport Engineering (USQ)Document32 pagesCIV3703 Transport Engineering (USQ)hao baiNo ratings yet

- Electric CircuitDocument15 pagesElectric CircuittitinadiyantiNo ratings yet

- Manual Ut EspañolDocument52 pagesManual Ut EspañolEugenioNo ratings yet

- Bab 7 Diagram Alir ProsesDocument2 pagesBab 7 Diagram Alir ProsesWisnu Center'zNo ratings yet

- Unit 4.3Document44 pagesUnit 4.3syed1188No ratings yet

- Wind Turbine Blade Drawing GADocument1 pageWind Turbine Blade Drawing GAjonahNo ratings yet

- Regen SWDocument92 pagesRegen SWSubibechanaShawNo ratings yet

- Exam 2 Review Questions PHY 2425 - Exam 2Document46 pagesExam 2 Review Questions PHY 2425 - Exam 2Ashish VermaNo ratings yet

- Uses of The Components of Crude Oil As FuelsDocument6 pagesUses of The Components of Crude Oil As FuelsPearl LawrenceNo ratings yet

- Reviewer Organic Chemistry LectureDocument9 pagesReviewer Organic Chemistry LectureAlyanna Elisse Vergara100% (1)

- ICE 160 230 0296 HammerDocument119 pagesICE 160 230 0296 HammerRıfat BingülNo ratings yet

- P43x DIST Application Guide en E2Document45 pagesP43x DIST Application Guide en E2Antonio Solís MurilloNo ratings yet

- Ranger Pro Wireless Condition Monitoring Datasheet - 125M5237Document11 pagesRanger Pro Wireless Condition Monitoring Datasheet - 125M5237Nurdin MubarokNo ratings yet

- MaxDNA Based EHTC Calibration ProcedureDocument3 pagesMaxDNA Based EHTC Calibration ProcedureSanjay Chakraborty100% (1)

- Transfermachines - IADocument18 pagesTransfermachines - IADivyeshNo ratings yet

- Lec 7 Gender Issues in IWRM Bangladesh Experiences IPSWAMPDocument24 pagesLec 7 Gender Issues in IWRM Bangladesh Experiences IPSWAMPsuchisharmin1No ratings yet

- Business+Problem +Stora+EnsoDocument4 pagesBusiness+Problem +Stora+Ensoadnan ansariNo ratings yet

- IEA Renewables Information 2011Document498 pagesIEA Renewables Information 2011aksharchandraNo ratings yet

- Nr6 P0089 P1169Document2 pagesNr6 P0089 P1169Yuting NgNo ratings yet

- Presentation - Gate FixingDocument11 pagesPresentation - Gate FixingAshutosh DubeyNo ratings yet

- Yaskawa 1000Document269 pagesYaskawa 1000mahh1234No ratings yet