Professional Documents

Culture Documents

1 Office of Highway Safety Combined Group Chairman Factual Report Final-Rel

1 Office of Highway Safety Combined Group Chairman Factual Report Final-Rel

Uploaded by

JENNIFER WEISERCopyright:

Available Formats

You might also like

- Phy 102 Lecture 8 - Electrical Energy and Capacitance (B)Document72 pagesPhy 102 Lecture 8 - Electrical Energy and Capacitance (B)chipango lungoweNo ratings yet

- Lto PlateDocument95 pagesLto PlateInchan AbreganaNo ratings yet

- TOR Form UP DilimanDocument1 pageTOR Form UP DilimanKevin CordovizNo ratings yet

- Wftda Statsbook Full Us LetterDocument58 pagesWftda Statsbook Full Us Lettermariana jaquelineNo ratings yet

- LB! - Walkthrough - TLWikiDocument7 pagesLB! - Walkthrough - TLWikiM.K. SyahmiNo ratings yet

- TDT 172718DEI 65Fv05Document1 pageTDT 172718DEI 65Fv05Дмитрий100% (1)

- Circular No. 444 - Amendments To Pag-IBIG Fund Circular No. 388Document3 pagesCircular No. 444 - Amendments To Pag-IBIG Fund Circular No. 388Attorney III DOH CHDNo ratings yet

- No Dues Certificate: Date: Loan Account No: 37M0Cdhi631670 Customer Name: Bikash DebnathDocument1 pageNo Dues Certificate: Date: Loan Account No: 37M0Cdhi631670 Customer Name: Bikash Debnathsja shawnNo ratings yet

- Jeep AutocheckDocument6 pagesJeep AutocheckLindsey HudsonNo ratings yet

- Republic of The PhilippinesDocument2 pagesRepublic of The PhilippinesNFRDI BAC SecretariatNo ratings yet

- Travel ItineraryDocument4 pagesTravel Itineraryapi-653571771No ratings yet

- Current: Current Shots 365 Yearly MagazineDocument112 pagesCurrent: Current Shots 365 Yearly MagazineShourya GautamNo ratings yet

- Gmail - Booking Confirmation On IRCTC, Train - 14008, 25-Nov-2021, 2S, ANVT - SLNDocument1 pageGmail - Booking Confirmation On IRCTC, Train - 14008, 25-Nov-2021, 2S, ANVT - SLNchandan tiwariNo ratings yet

- Ticket TK281710054m45Document2 pagesTicket TK281710054m45gandi harikrishnaNo ratings yet

- RDO No. 55 - San Pablo City, East LagunaDocument522 pagesRDO No. 55 - San Pablo City, East LagunaMiko Jim Paulo PanganibanNo ratings yet

- BL + CO + Inv + Pack 113477877Document11 pagesBL + CO + Inv + Pack 113477877Đàn NguyễnNo ratings yet

- Customs Power of Attorney-Company-2021Document1 pageCustoms Power of Attorney-Company-2021shahwaizNo ratings yet

- Trips Flight DownloadETicket-2Document3 pagesTrips Flight DownloadETicket-2Harshith20No ratings yet

- Internship ReportDocument29 pagesInternship ReportARPIT SONINo ratings yet

- Essai Mozhi - CMTDocument30 pagesEssai Mozhi - CMTSHYAM SUNDARNo ratings yet

- SUPPLY UNDER GST-Unit 2Document56 pagesSUPPLY UNDER GST-Unit 2niveditaNo ratings yet

- BL + CO + Inv + Pack 113485709Document10 pagesBL + CO + Inv + Pack 113485709Đàn NguyễnNo ratings yet

- Enerplus 05 May 2022 PSDocument92 pagesEnerplus 05 May 2022 PSShubham RaulNo ratings yet

- Fund TechDocument2 pagesFund TechBina ShahNo ratings yet

- BCO 11 Block 03Document70 pagesBCO 11 Block 03Al OkNo ratings yet

- Babawande Afolabi List of Acknowledgments GAADocument5 pagesBabawande Afolabi List of Acknowledgments GAADavid HundeyinNo ratings yet

- Language - Register bsn1cDocument27 pagesLanguage - Register bsn1cMonica JoyceNo ratings yet

- Cta 00 CV 04340 D 1993sep10 AssDocument11 pagesCta 00 CV 04340 D 1993sep10 AsscyeeeNo ratings yet

- Application For Registration of New Ecozone EnterprisesDocument4 pagesApplication For Registration of New Ecozone EnterprisesMark Kevin SamsonNo ratings yet

- Terms and Conditions 27 06 PDFDocument4 pagesTerms and Conditions 27 06 PDFShreyash NaikwadiNo ratings yet

- Arguments Against Condonation ApplicationDocument2 pagesArguments Against Condonation ApplicationKartikey singhNo ratings yet

- Foi Request FormDocument2 pagesFoi Request FormLeo De ocampoNo ratings yet

- CountryTerritory Report - TurkeyDocument65 pagesCountryTerritory Report - TurkeyBatuhan ParlakNo ratings yet

- HP+New+Year+Offer+2022 V4Document9 pagesHP+New+Year+Offer+2022 V4bijendra83No ratings yet

- Format of Undertaking by Foreign DirectorDocument1 pageFormat of Undertaking by Foreign DirectorsamNo ratings yet

- Main Admission Form Bachelors 2022-26Document8 pagesMain Admission Form Bachelors 2022-26Isra ShahidNo ratings yet

- List of Cases Phasea 3-2022Document8 pagesList of Cases Phasea 3-2022SAFI ULLAH KHANNo ratings yet

- 1673 00T3s00002oE1AjEAKDocument6 pages1673 00T3s00002oE1AjEAKJonas GonzalesNo ratings yet

- Appnd Anf Eng Part1Document476 pagesAppnd Anf Eng Part1Sam Hunt100% (1)

- PDS Geotech Iec CertificateDocument1 pagePDS Geotech Iec Certificaterohit ghorpadeNo ratings yet

- Complaint - Mississippi State Conference of The Naacp v. State Board of Election CommissionersDocument95 pagesComplaint - Mississippi State Conference of The Naacp v. State Board of Election CommissionersRuss LatinoNo ratings yet

- JEE Main-2023 Session 2 - RegistrationDocument2 pagesJEE Main-2023 Session 2 - RegistrationTaaha BaigNo ratings yet

- Jurisprudence Insurance Law 2021-4Document11 pagesJurisprudence Insurance Law 2021-4dyosaNo ratings yet

- MA and Equity Offerings Market Report 2022Document21 pagesMA and Equity Offerings Market Report 2022thinh thaiNo ratings yet

- Travel ItineraryDocument4 pagesTravel ItineraryKamal HassanNo ratings yet

- Nagarro - Receipt For Claiming Drivers SalaryDocument1 pageNagarro - Receipt For Claiming Drivers SalaryNitin YadavNo ratings yet

- СV Be Free 2020 (Нужно написать ваше имя и фамилию на английском) (3) - копияDocument3 pagesСV Be Free 2020 (Нужно написать ваше имя и фамилию на английском) (3) - копия5 к CompanyNo ratings yet

- CertificateDocument1 pageCertificateShamsurahman ShamsiNo ratings yet

- Sofi Digital Assets LLC Customer AgreementDocument34 pagesSofi Digital Assets LLC Customer AgreementJohn SmithNo ratings yet

- Presentation Super BowlDocument8 pagesPresentation Super BowlAdeelSiddiqueNo ratings yet

- Yahoo Mail - Trent University Offer of AdmissionDocument2 pagesYahoo Mail - Trent University Offer of Admissionapi-641119081No ratings yet

- AirtelDocument4 pagesAirtelkartikNo ratings yet

- Exam Time Table PDFDocument3 pagesExam Time Table PDFShreyash NaikwadiNo ratings yet

- Sensors 23 06430Document18 pagesSensors 23 06430r.shekara22No ratings yet

- Print - Udyam Registration CertificateDocument2 pagesPrint - Udyam Registration CertificatePankaj PandeyNo ratings yet

- Adobe Scan Mar 5 2022Document19 pagesAdobe Scan Mar 5 2022PAULA MENDITANo ratings yet

- Track Shipment Status - Consignment Status - DTDC IndiaDocument1 pageTrack Shipment Status - Consignment Status - DTDC IndiaAjay Chowdary Ajay ChowdaryNo ratings yet

- Literatures CitedDocument4 pagesLiteratures CitedCyrus CorpuzNo ratings yet

- Comprehensive Tender Documents 83370976 PDFDocument19 pagesComprehensive Tender Documents 83370976 PDFBogale WorkuNo ratings yet

- USW NTSB Crash ReportDocument15 pagesUSW NTSB Crash ReportNewsWest 9No ratings yet

- NTSB Safety Recommendation Amtrak Crash Cayce, SCDocument4 pagesNTSB Safety Recommendation Amtrak Crash Cayce, SCWLTXNo ratings yet

- The Effect of Crosswalk Markings On Vehicle Speeds in Maryland, Virginia, and ArizonaDocument11 pagesThe Effect of Crosswalk Markings On Vehicle Speeds in Maryland, Virginia, and ArizonaRobert OrtizNo ratings yet

- Opinion ED110491Document5 pagesOpinion ED110491JENNIFER WEISERNo ratings yet

- Donald Eugene Fields IIDocument1 pageDonald Eugene Fields IIJillian SmithNo ratings yet

- Trump IndictmentDocument45 pagesTrump IndictmentJENNIFER WEISERNo ratings yet

- JC Ward PrecDocument1 pageJC Ward PrecJENNIFER WEISERNo ratings yet

- 2023 Spring Turkey Hunting RegsDocument24 pages2023 Spring Turkey Hunting RegsJENNIFER WEISERNo ratings yet

- Route GuideDocument2 pagesRoute GuideJENNIFER WEISERNo ratings yet

- Covid 19 Recovery March 2022Document14 pagesCovid 19 Recovery March 2022JENNIFER WEISERNo ratings yet

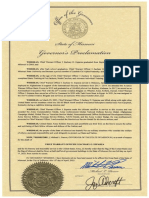

- March 29 2023 Chief Warrant Officer 3 Zachary Esparza DECEASED SOLDIER - KILLED ProclamationDocument1 pageMarch 29 2023 Chief Warrant Officer 3 Zachary Esparza DECEASED SOLDIER - KILLED ProclamationJENNIFER WEISERNo ratings yet

- 2022 Spring Clean Up AdDocument1 page2022 Spring Clean Up AdJENNIFER WEISERNo ratings yet

- 2022-06-06 Boone County Mourns Passing of PA Dan KnightDocument1 page2022-06-06 Boone County Mourns Passing of PA Dan KnightJENNIFER WEISERNo ratings yet

- HB2704IDocument6 pagesHB2704IJENNIFER WEISERNo ratings yet

- LODD Assistant Chief Boone County Fire Protection - Bryant GladneyDocument1 pageLODD Assistant Chief Boone County Fire Protection - Bryant GladneyJENNIFER WEISERNo ratings yet

- Hernandez - Statement of FactsDocument7 pagesHernandez - Statement of FactsJENNIFER WEISERNo ratings yet

- Cps PetitionDocument16 pagesCps PetitionJENNIFER WEISERNo ratings yet

- 2021 22 COVID 19 Protocols Revised 011222Document6 pages2021 22 COVID 19 Protocols Revised 011222JENNIFER WEISERNo ratings yet

- To-2022-Xxxx Motion To Open Docket and Motion For Expedited TreatmentDocument11 pagesTo-2022-Xxxx Motion To Open Docket and Motion For Expedited TreatmentJENNIFER WEISERNo ratings yet

- House Bill No. 2117: 101St General AssemblyDocument139 pagesHouse Bill No. 2117: 101St General AssemblyJENNIFER WEISERNo ratings yet

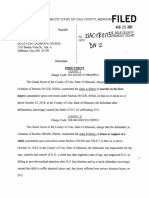

- Givens IndictmentDocument4 pagesGivens IndictmentJENNIFER WEISERNo ratings yet

- Aligning,: 5. One Member From The Missouri General AssemblyDocument2 pagesAligning,: 5. One Member From The Missouri General AssemblyJENNIFER WEISERNo ratings yet

- Chapter 02 Radio Frequency & Antenna FundamentalsDocument46 pagesChapter 02 Radio Frequency & Antenna FundamentalsSenthilathiban Thevarasa50% (2)

- Acoustics: - "A Science That Deals With The Production, Control, Transmission, Reception, and Effects of Sound."Document42 pagesAcoustics: - "A Science That Deals With The Production, Control, Transmission, Reception, and Effects of Sound."Amit JainNo ratings yet

- Noise CalculatorDocument6 pagesNoise CalculatorngockhoapsNo ratings yet

- Volte: Sensitivity: InternalDocument32 pagesVolte: Sensitivity: InternalHabib MohammedNo ratings yet

- As 062Document6 pagesAs 062mukeshkumarjNo ratings yet

- Noise Exposure Ready-Reckoner (Weekly Exposure)Document1 pageNoise Exposure Ready-Reckoner (Weekly Exposure)igor_239934024No ratings yet

- RF Transceiver Architectures For W-CDMADocument10 pagesRF Transceiver Architectures For W-CDMABình PhạmNo ratings yet

- DX 1710 2170 65 18i 2F - Complementares - Re2 - 05 08 09Document1 pageDX 1710 2170 65 18i 2F - Complementares - Re2 - 05 08 09MackamNo ratings yet

- Audison Bit One - Sheet TechnicalDocument2 pagesAudison Bit One - Sheet TechnicalVlad GrigoreNo ratings yet

- Hewlett-Packard - AN150-10 - Spectrum Analysis - Field Strenght MeasurementDocument2 pagesHewlett-Packard - AN150-10 - Spectrum Analysis - Field Strenght Measurementgbr123No ratings yet

- Re200ge 140909Document8 pagesRe200ge 140909ErstebabaJiiNo ratings yet

- Noise CalculatorDocument9 pagesNoise CalculatormukeshkumarjNo ratings yet

- JVC KDS 48 J Service ManualDocument20 pagesJVC KDS 48 J Service ManualAlejandro CastilloNo ratings yet

- Odp-065r18kv 18KV PDFDocument1 pageOdp-065r18kv 18KV PDFAlberto LinaresNo ratings yet

- Outdoor Directional Dual-Band Antenna: ODP-065R09M12J-G (2J)Document2 pagesOutdoor Directional Dual-Band Antenna: ODP-065R09M12J-G (2J)SandroTrigoValdivia100% (1)

- KR MV5 R410A 380V, 5060Hz HP SA MFL67474050 0CVV0-01H Jan.2020Document453 pagesKR MV5 R410A 380V, 5060Hz HP SA MFL67474050 0CVV0-01H Jan.2020CARLOS AUGUSTUS PAGLIOSANo ratings yet

- Oscilla PDFDocument24 pagesOscilla PDFCabrito VeleñoNo ratings yet

- Terrestial Communications ECE 530 2nd Sem 2016Document68 pagesTerrestial Communications ECE 530 2nd Sem 2016Clark Jones Edgar CastilloNo ratings yet

- Module 2 Noise-1Document3 pagesModule 2 Noise-1CydelMarie PerezNo ratings yet

- TG PG Test Procedure PDFDocument129 pagesTG PG Test Procedure PDFHari Prasad100% (2)

- JIS Z 3062 2009 Method and Acceptance Criteria of Ultrasonic ExaminationDocument20 pagesJIS Z 3062 2009 Method and Acceptance Criteria of Ultrasonic ExaminationLe Anh DuyNo ratings yet

- ATH201Series-User - Manual Eone Et 310aDocument26 pagesATH201Series-User - Manual Eone Et 310aSérgio Henrique da SilvaNo ratings yet

- K742226V01Document3 pagesK742226V01Witto PereNo ratings yet

- AttenuatorsDocument6 pagesAttenuatorsenglandbroNo ratings yet

- Dx-690-960-65-16.5I-M-R Easyret 2-Port Antenna With 1 Integrated Rcu - 2.0M Model: A704516R0V06Document2 pagesDx-690-960-65-16.5I-M-R Easyret 2-Port Antenna With 1 Integrated Rcu - 2.0M Model: A704516R0V06юрий ермошенкоNo ratings yet

- Noise Emissions: Technical Information No. 1Document8 pagesNoise Emissions: Technical Information No. 1EdilsonNo ratings yet

- TECHNICAL NOTE 013 Steel Sheet Piling - Drivability Vs SPT-N Values - Vibrations and Noise LevelDocument3 pagesTECHNICAL NOTE 013 Steel Sheet Piling - Drivability Vs SPT-N Values - Vibrations and Noise LevelRaed Naim Khammash100% (1)

- Service Manual: KD-A805J, KD-R800J, KD-R801E, KD-R801EX, KD-R801EY, KD-R801EU, KD-R805U, KD-R805UT, KD-R807EEDocument57 pagesService Manual: KD-A805J, KD-R800J, KD-R801E, KD-R801EX, KD-R801EY, KD-R801EU, KD-R805U, KD-R805UT, KD-R807EEMe Ego100% (1)

1 Office of Highway Safety Combined Group Chairman Factual Report Final-Rel

1 Office of Highway Safety Combined Group Chairman Factual Report Final-Rel

Uploaded by

JENNIFER WEISEROriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 Office of Highway Safety Combined Group Chairman Factual Report Final-Rel

1 Office of Highway Safety Combined Group Chairman Factual Report Final-Rel

Uploaded by

JENNIFER WEISERCopyright:

Available Formats

National Transportation Safety Board

Office of Highway Safety

Washington, DC 20594

RRD22MR010

HIGHWAY SAFETY

Group Chair's Factual Report

August 22, 2022

HIGHWAY SAFETY RRD22MR010

GROUP CHAIR'S FACTUAL REPORT PG 1 OF 31

A. CRASH

Location: BNSF Railroad Milepost 363.8 US DOT Crossing 005284Y at Porche

Prairie Ave., Mendon, MO

Date: June 27, 2022

Time: 12:42 Central Daylight Time CDT

Vehicle 1: 2007 Kenworth W900B Loaded Dump Truck

Train 1: Amtrak Train #4 with two locomotives and 8 passenger cars

B. HIGHWAY SAFETY GROUP

Group Co-Chair Eric Gregson

National Transportation Safety Board (NTSB)

Washington, DC

Group Co-Chair David Rayburn

NTSB

Group Co-Chair Shawn Currie

NTSB

Group Member Troy E. Hughes P.E.

Administrator of Railroads

Missouri Department of Transportation (MODOT)

Jefferson City, MO

Group Member Howard J. Gillespie

District Specialist Grade Crossing Division

Federal Railroad Administration

Washington, DC

Group Member Joe Lair

Senior Railroad Safety Inspector

Missouri Division of Railroad Safety

Jefferson City, MO

Group Member Aaron Ratledge

Director of Transportation Safety

BNSF Railroad

Fort Worth, TX

HIGHWAY SAFETY RRD22MR010

GROUP CHAIR'S FACTUAL REPORT PG 2 OF 31

Group Member Detective Robert N. Hanson

Amtrak Police Department

New Haven, CT

Group Member Sergeant Glen Ward

Missouri State Highway Patrol

Mendon, MO

C. SUMMARY

On Monday, June 27th, 2022, about 12:42 p.m. central daylight time, an

eastbound Amtrak passenger train struck a northbound 2007 Kenworth dump truck

(Kenworth) loaded with aggregate, at a grade crossing in Mendon, Chariton County,

Missouri. The Amtrak train was on Burlington Northern Santa Fe (BNSF) railway tracks

and struck the left rear of the Kenworth dump truck.

The highway portion of the grade crossing, Porche Prairie Avenue consisted of

a northbound and southbound lane.

The highway-railroad grade crossing was controlled by a passive warning

system with a single crossbuck in conjunction with a stop sign. The highway intersected

with the grade crossing at approximately 45 degrees.

As a result of the collision one (1) locomotive and eight (8) railcars derailed.

Three (3) passengers on the train and the driver of the Kenworth were fatally injured.

D. HIGHWAY FACTORS

1.0 Introduction

On Monday, June 27th, 2022, the NTSB initiated an investigation of a highway-

railroad grade crossing (rail crossing) collision that occurred on Porche Prairie Ave.,

Mendon, MO. 1 A 2007 Kenworth dump truck, loaded with aggregate, had been

travelling northbound on Porche Prairie Avenue attempting to traverse the crossing.

The rail crossing was controlled by a passive warning system. 2 The passive

warning at the crossing consisted of a single crossbuck in conjunction with a stop

sign.

1

The grade crossing is owned and operated by the Burlington Northern and Santa Fe Railway (BNSF)

and is identified by the DOT grade crossing inventory #005284Y, at BNSF milepost 363.8.

2

According to the Highway-Rail Crossing Handbook, 3rd Edition, a passive crossing is where warnings

and traffic control is provided by passive devices such as signs and pavement markings where no

Active Grade Crossing Warning System is present.

HIGHWAY SAFETY RRD22MR010

GROUP CHAIR'S FACTUAL REPORT PG 3 OF 31

As the Kenworth entered the rail crossing, Amtrak Train 4 (Southwest Chief)

consisting of two locomotives and seven passenger carrying cars, and one baggage

car was approaching from the southwest. The train engineer sounded the horn and

placed the train into emergency braking. The front of the lead locomotive collided

with the left side rear of the Kenworth.

The impact propelled the Kenworth into a counterclockwise rotation. Due to

the collision the dump bed and the cab portion of the Kenworth were torn from the

chassis.

The Highway Safety group for this investigation was convened for the purpose

of obtaining information related to the design, maintenance, and operation of the

highway environment to establish a foundation for evaluation whether the condition,

design, or operation of the highway facility contributed to the collision. In support,

the on-scene documentation of the crash location consisted of ground based

terrestrial photography of the scene and Kenworth coupled with aerial photographs

of the scene. Documentation of the damage to the Kenworth and train was also

obtained.

The Highway group further obtained information about the design of the

railroad/highway grade crossing including location, geometric design, traffic metrics,

accident history, and traffic control devices. Focus areas included examining previous

crossing studies by the Missouri Department of Transportation establishing the need

for the stop sign at the crossing and examining the decision-making process to

determine if improvements are needed at the crossing. Further documentation and

information were obtained from MS Contracting LLC., the motor carrier involved in

the collision.

Factual reports prepared by other NTSB investigative groups should be

consulted for information related to other aspects of the investigation, including

information used within this report.

HIGHWAY SAFETY RRD22MR010

GROUP CHAIR'S FACTUAL REPORT PG 4 OF 31

2.0 Collision Site and Geometric Design

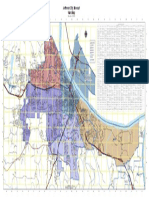

Figure 1 is a crash map that depicts the crash location which was

approximately 3.2 miles southwest of the city of Mendon, MO.

Figure 1. Crash map (Source: Google Maps revised).

Figure 2 is a site map of the Porche Prairie Avenue and BNSF double grade

crossing #005284Y. The collision occurred on Track #2.

HIGHWAY SAFETY RRD22MR010

GROUP CHAIR'S FACTUAL REPORT PG 5 OF 31

Figure 2. Site map of the Porche Prairie Avenue and BNSF double grade

crossing showing geometry and signage. (Source: Google Earth revised).

2.1 Collision Site

The highway-railroad grade crossing is in the Burlington Northern Santa Fe

(BNSF) railroad Chicago division and Marceline subdivision. The Federal Railroad

Administration (FRA) Grade Crossing Inventory form submitted by BNSF on 9/3/2020

shows the railroad measured the Global Positioning Satellite coordinates (GPS) at

39.5605810 degrees latitude and -93.181186 degrees longitude. BNSF indicated

crossing 005284Y was located on their railroad tracks at milepost 363.876. The

highway location is on Porche Prairie Avenue about .7 miles north of Missouri

supplemental route BB. The inventory form also lists Porche Prairie Avenue as

Chariton County Road 113 (CR113).

Porche Prairie Avenue intersected the grade crossing at a 45° angle and was

oriented in a north-south direction with the rail line running northeast to southwest.

The roadway was constructed of gravel and had a varying width of 17-20 feet. The

surface had humps and potholes on the approach to the crossing.

HIGHWAY SAFETY RRD22MR010

GROUP CHAIR'S FACTUAL REPORT PG 6 OF 31

2.2 Horizontal Geometry

The crossing is on a right skew angle of approximately 45 degrees. A skew

angle is any angle less than 90 degrees. 3 The text describes skewed intersections as

undesirable because they can result in a driver having to turn their head at larger

angles to see, and interior components of the vehicle can restrict or obstruct a drivers

view. Earlier version of the American Association of State Highway and

Transportation Officials (AASHTO) manual recommended intersection angles no less

than 60 degrees, but the 2018 version recommends intersection angles be as close

to 90 degrees as practicable and no less than 75 degrees for new construction or

realignment. The AASHTO text also suggests several ways to realign roadways so that

they can intersect closer to 90 degrees. Figure 3 is a photograph of a NTSB

investigator, in an exemplar truck, at this crossing leaning well forward and looking

over his left shoulder to overcome the restriction of the skewed crossing angle and

vehicle “B” pillar sight obstruction.

Figure 3. View of NTSB investigator leaning forward almost to the steering wheel to see around the

"B" pillar sight obstruction caused by the skew angle of the crossing. Using this strategy, the

investigator was able to see the following view in figure 4.

3

American Association of State Highway and Transportation Officials (AASHTO) “A Policy on

Geometric Design of Highway and Streets”, 2018, 7th Edition.

HIGHWAY SAFETY RRD22MR010

GROUP CHAIR'S FACTUAL REPORT PG 7 OF 31

Figure 4 depicts the view seen by the above investigator after leaning forward.

Figure 4. View of a freight train approaching from approximately the whistle post located 1,328 feet

from the crossing.

2.3 Vertical Alignment

The vertical profile at this crossing exceeded the roadway approach grade

found in the current American Association of Railroad Engineering and Maintenance

of Way Association’s (AREMA) Railway Engineering Manual (REM 2020). In earlier

versions of the AASHTO geometric design policy The American Railway Engineering

Association (AREA), which later became The AREMA standards and guidelines were

adopted by AASHTO. These guidelines apply to new construction and

reconstruction. The elevations standards adopted in the 1990 AASHTO geometric

design policy indicated that from the nearside rail the elevation could slope down no

more than 6 inches in 30 feet from the rail. The current AASHTO policy and REM

2020 recommends the approach roadway surface not slope down more than 3 inches

in 30 feet from the nearside rail. The maintenance of grade outside the railroad right-

of-way was the responsibility of Chariton County. The Burlington Northern Santa Re

Railroad (BNSF) right-of-way extended 50 feet south of the center of rail #2. Research

into whether the operating railroad or the public road authority was responsible for

maintain the approach grade to the crossing even though it was on the railroad right-

HIGHWAY SAFETY RRD22MR010

GROUP CHAIR'S FACTUAL REPORT PG 8 OF 31

of-way indicated the following: There are no existing federal regulations requiring in-

service improvement to maintain approach grades to current design standards. And

the practice of the highway authority funding horizontal and vertical alignment

improvements as well as funding crossing replacements themselves has evolved or

the decades with the states formally and informally entering into agreements to fund

approach grade improvements. 4 MoDOT safety rules indicate the roadway authority

is responsible for maintenance of the approach grade. At this site, the railroad was

constructed approximately 1910-1920 by the Atchison Topeka Santa Fe Railroad

(ATSF) and the County Constructed County Road 113 or Porche Prairie Avenue. The

construction date was not available through Chariton County. The crossing and

approach grades were constructed where the gravel roadway was constructed. In

summary, the earliest guideline for approach grades to crossings was published by

AREA in 1971and by AASHTO in 1990. Currently, Missouri has regulations in its’ Code

of State Regulations (CSR 265-8.130) governing construction/reconstruction and

maintenance of grade crossings. The regulations mirror the guidelines found in the

AREMA REM Part 8 (2013) which is adopted by reference. 5

Article 8.1.0 of the REM provides the following text regarding the scope of

recommended guidelines: “The fact that design values and practices for new

construction or for the reconstruction of highway/railroad at-grade crossings are

presented in this Part does not imply that existing non-conforming crossings are

unsafe, nor does it mandate the initiation of improvement projects. For projects

involving rehabilitation, restoration, replacement, renewal, resurfacing or

maintenance of existing tracks through crossings, crossing surfaces, or roadway

approaches to crossings, where major revisions to alignment, elevation, or profile are

deemed impractical or beyond the scope of the work being undertaken, existing

design values may be retained, particularly if a site investigation indicates the existing

site design features are performing in a satisfactory manner for the normally

anticipated traffic exercising due care. Absent other compelling factors, the cost of

full reconstruction of these facilities solely to conform to the recommended practices

contained herein, particularly on lower volume roadways, will often not be justified.”

See figure 5 for a view of the severe approach grade. Figure 6 is a diagram

displaying the current AASHTO recommendation in relation to the measurements

recorded at the scene for the grade crossing approach.

4

For more information see Highway-Rail Crossing Surfaces, Washington, D.C. National Cooperative

Research Program Report Synthesis of Practice 250 (1997) Washington D.C. NCHRP.

5

MO CSR accessed on January 22, 2023.

HIGHWAY SAFETY RRD22MR010

GROUP CHAIR'S FACTUAL REPORT PG 9 OF 31

Figure 5. View of exemplar truck on approach to the railroad tracks.

Table 1 below shows elevation measurements that were taken by the highway group

from the nearside rail on Wednesday, two days after the crash.

Table 1. Lists the elevation drop as measured from the near side rail.

Distance from crossing (near side Elevation

rail) drops

30 feet 39 inches

40 feet 44 inches

50 feet 57 inches

80 feet 70 inches

On the day of the crash the Missouri State Highway Patrol (MSHP) crash

reconstruction team documented the grade via drone measurements and smart level

before the surface changed from all the heavy vehicle activity associated with rescue

and recovery. The MSHP measurements indicated the slope near the top of the grade

was 15.8 percent and near the bottom of the grade before it leveled out was 4.3

percent. See figure7 below for MSHP Grade measurements.

HIGHWAY SAFETY RRD22MR010

GROUP CHAIR'S FACTUAL REPORT PG 10 OF 31

Figure 6. Diagram showing the AASHTO standard related to

the actual grade crossing approach measurement.

This area intentionally left blank.

HIGHWAY SAFETY RRD22MR010

GROUP CHAIR'S FACTUAL REPORT PG 11 OF 31

Figure 7. Image of slope calculations completed by MSHP.

HIGHWAY SAFETY RRD22MR010

GROUP CHAIR'S FACTUAL REPORT PG 12 OF 31

2.4 Traffic Control Devices

There were no advance warning signs on either side of the crossing as

required by the Manual on Uniform Traffic Control Devices (MUTCD). The placement

of advance warning signs was the responsibility of the roadway owner, Chariton

County. The dimensions, lateral placement and mounting height of the passive traffic

control devices were documented. The stop sign and crossbuck were on the same

Figure 8. View of stop sign and crossbucks at the crossing. (Source: MSHP)

mast which was located laterally approximately 14 feet from the roadway edge. The

MUTCD designation for the stop sign was R-1 and the crossbuck designation was R-

15-1. The crossbuck also had the 2-track designation and mast had retroreflective

tape. The center of the 36-inch stop sign was approximately 7 feet high and the

crossbuck mounting height was approximately 9 feet high. Both signs had the

correct dimensions, lateral placement, and mounting height. The MUTCD requires

an engineering study be performed before a stop sign can be used at a passive

grade crossing. 6 The decision to upgrade highway/railroad grade crossing warning

devices requires public governing body approval. See figure 8 above for a view of

the Stop sign and crossbucks with 2 tracks plaque.

6

MoDOT is searching for the study documenting the reasons a stop sign was used at this crossing. As

of August 1, 2022, they have been unable to locate the study.

HIGHWAY SAFETY RRD22MR010

GROUP CHAIR'S FACTUAL REPORT PG 13 OF 31

2.4.1 Special Stops Required

The Motor Vehicle Revised Statutes of Missouri Sec. 304.035

specifies the following duties of a driver approaching a railroad

/highway grade crossing: “When any person driving a vehicle

approaches a railroad grade crossing, the driver of the vehicle shall

operate the vehicle in a manner so he will be able to stop, and he shall

stop the vehicle not less than 15 feet and not more than 50 feet from

the nearest rail of the railroad track and shall not proceed until he can

safely do so if:

(1.) A clearly visible electric or mechanical signal device warns of

the approach of a railroad train; or

(2.) A crossing gate is lowered or when a human flagman gives or

continues to give a signal or warning of the approach or

passage of a railroad train; or

(3.) An approaching railroad train is visible and is in hazardous

proximity to such crossing; or

(4.) Any other traffic sign, device or any other act, rule, regulation,

or statute requires a vehicle to stop at a railroad grade crossing.

2. No person shall drive any vehicle through, around or under any

crossing gate or barrier at a railroad crossing when a train is approaching

while such gate or barrier is closed or is being opened or closed.

3. No person shall drive a vehicle through a railroad crossing when

there is not sufficient space to driver completely through the crossing.

4. No person shall drive a vehicle through a railroad crossing

unless such vehicle has sufficient undercarriage clearance necessary to

prevent the undercarriage of the vehicle from contacting the railroad

crossing.

5. Every commercial motor vehicle as defined in section 302.700

shall, upon approaching a railroad grade crossing, be driven at a rate of

speed which will permit said commercial motor vehicle to be stopped

before reaching the nearest rail of such crossing and shall not be driven

upon or over such crossing until due caution has been taken to ascertain

that the course is clear. This section does not apply to vehicles which are

required to stop at railroad crossings pursuant to section 304.030.

6. Any person in violation of the provisions of this section is guilty

HIGHWAY SAFETY RRD22MR010

GROUP CHAIR'S FACTUAL REPORT PG 14 OF 31

of a class C misdemeanor.

2.4.2 Track Safety Standards and FRA Highway-Rail Grade Crossing

Guidelines for High-Speed Passenger Rail

49 CFR Part 213.347 requires FRA approved barriers at crossing where train

speeds of 110 mph are permitted, and where train speeds of 125 mph or greater a

grade separation is required. In guidance provided through the 1990s, the DOT

advocated for a minimum of active warning systems with gates, controlled by

constant warning time circuitry, on rail lines with speeds of 80 mph and greater. 7

Gates provide an unequivocal indication to the motorist regarding the behavior

expected. This continues to be a good foundation for crossing safety on HSR lines,

but developments since that time point the way to additional strategies. 8 Sealed

corridor programs where passive crossing elimination has been the most recent focus

on high-speed passenger trains.

2.5 Traffic Metrics

The Missouri Department of Transportation records indicated the Average

Daily Traffic (ADT) for the crossing was 8 vehicles per day. Truck traffic was

approximately one truck per day. The BNSF data on the grade crossing inventory

showed that approximately 58 freight trains and two passenger trains came through

the crossing each day. The speed limit for the track was 90 mph. The speed limit on

a gravel road when not otherwise posted was 50 mph. 9

2.6 Crash History

There was no record of any other crashes at this crossing. Information provided

by MoDOT showed that there are 1,703 grade crossings in Missouri with active

warning devices and 1,450 crossings with passive devices (either crossbucks, stop

signs, or both). In the five-year-period 2017-2021 there were 22 fatalities at public

railroad/highway grade crossing in Missouri.

2.7 Design Clearing Sight Distance

Design clearing sight distance is the distance a vehicle operator needs to see

an approaching train to be able to start forward from a stopped position 15 feet from

the nearside rail and clear the tracks and dynamic envelope before the arrival of the

train even if the train comes into view when the vehicle starts forward. The following

7

FRA Highway-Rail Grade Crossing Guidelines for High-Speed Passenger Rail 2009

8

8 Constant warning time circuitries may not be practical on electrified rail lines under some

conditions (including the nature of the legacy train control system). If that is the case, special care

should be given to ensuring that warning system traffic control at the crossing is observed.

9

Revised Statutes of Missouri RSMO Section 304.010.

HIGHWAY SAFETY RRD22MR010

GROUP CHAIR'S FACTUAL REPORT PG 15 OF 31

Figure 9. Basic Calculation Values for Design Clearing Sight Distance.

equations provide the designer with procedures to estimate this distance on a

level surface at a near 90-degree crossing. Modifications to the calculation

procedures need to be made for skewed crossing angles, steep grades, and multiple

tracks:

In this accident the nearside track was track number 2 and the far sidetrack was

track number one. Since multiple tracks had to be crossed on a skewed angle

crossing with a severe grade, adjustments were made by conducting an acceleration

HIGHWAY SAFETY RRD22MR010

GROUP CHAIR'S FACTUAL REPORT PG 16 OF 31

test with a similar vehicle. The accident truck weighed 76,120 pounds. The exemplar

truck weighed approximately 71,600 pounds. An acceleration test was performed to

find the design clearing sight distance required for the accident driver. The exemplar

truck was accelerated in the same gear from the stopping point 15 feet from the

nearside rail; it required 20.3 seconds to clear track 2, 27.3 seconds to clear track 1

and 33.53 seconds for the rear of the truck to clear the dynamic envelope, which was

6 feet past the far side rail. Using the train speed limit of 90 mph or 132.3 feet per

second shows the driver would need to be able to see the train from 4,366 feet away

to start forward from a stopped position and clear the tracks before the train arrived.

From the stopped position 15 feet from the nearside rail the only vision restrictions or

obstructions were the vehicle “B” pillar. However, it is permissible to stop no closer

than 15 feet and no farther than 50 feet from the nearside rail. If a driver stops farther

back at this crossing, vegetation could restrict the view of an approaching train.

2.7.1 External Sight Restrictions at the Crossing

The following vegetation growth was documented:

1. A Maple tree was located 959 feet from the crossing and laterally it was

located 32 feet south of the center of track #2

2. A Crepe Myrtle tree was located 1226 feet from the crossing and 29 feet 6

inches from the center of track #2.

3. An approximate 20-foot-tall pecan tree was located 1247 feet west of the

crossing and 31 feet 6 inches south of the center of track #2.

All the vegetation growth listed above could restrict a driver’s view if they

chose to stop 50 feet from the crossing instead of 15 feet from the crossing. See

figures 10 and 11 for views of the vegetation.

HIGHWAY SAFETY RRD22MR010

GROUP CHAIR'S FACTUAL REPORT PG 17 OF 31

Figure 10. View of vegetation on the south side of track #2 that could restrict a driver's view. This view

shows the Amtrack's eastbound approach.

This area intentionally left blank.

HIGHWAY SAFETY RRD22MR010

GROUP CHAIR'S FACTUAL REPORT PG 18 OF 31

Figure 11. View of vegetation from 50 feet south of the nearside rail looking to the west. (Source:

MSHP).

3.0 MoDOT Railroad/Highway Grade Crossing Improvement Program

Since 2017 MoDOT has been partnering with Railroads and Local Public

Agencies (LPA’s) to identify and address crossing improvement needs. The

Department has been awarded two Consolidated Rail Infrastructure and Safety

Improvement Grants (CRSI) and is working to address the identified needs on two

southwest Missouri corridors which do not include this location. Missouri’s

constitution requires MoDOT to spend the dedicated State Road Fund (SRF) on the

State Highway System. MoDOT’s crossing improvement program is funded 7.5

million annually by 6 million from Section130 funds and 1.5 million from the Grade

Crossing Safety Account (GCSA). These funds may be spent on public crossings

located on the State Highway System and local road systems.

Table 2. Rail crossings in Missouri.

Owner Total Active Passive Upgrade Costs 10

State Highway 496 471 25 $10 Million

Local Roads 2,658 1,208 1,425 $570 Million

Private 2,183

10

Estimated costs to install active warning devices at the passive crossings.

HIGHWAY SAFETY RRD22MR010

GROUP CHAIR'S FACTUAL REPORT PG 19 OF 31

The Department administers the grade crossing program with the assistance of

local communities helping to identify rail crossings for improvement. While MoDOT is

responsible for administering this process, nothing prevents any entity, including

railroads and LPAs, from approaching MoDOT to improve safety at a particular rail

crossing. In fact, MoDOT encourages communities to engage in this process by

identifying crossings for closure and those most in need of safety improvements. This

mix of closures and safety improvements has always been the Department’s

approach to rail crossing safety. Using this collaborative approach, the Department

has worked with local communities and roadway authorities to upgrade or close

more than half of the previously identified rail crossings.

The Department has worked to improve safety at rail crossings on the State

Highway System (SHS) by closing some crossings and installing active warning

systems or grade separations on other rail crossings. The result of this effort is that

95% of the nearly 500 rail crossings on the SHS have been closed, separated, or

improved with active warning devices. MoDOT's other primary focus has been

improving the safety of the state sponsored intercity passenger rail service, Amtrak's

Missouri River Runner route that crosses the state from Kansas City to St. Louis. Rail

crossings along this corridor have been improved with grade separations, active

warnings, closures, leaving only I passive public crossing on the corridor. The

Department has also worked with all railroads operating within the state to

implement recent revisions required by the Manual on Uniform Traffic Control

Devices (MUTCD). Finally, MoDOT is seeking to upgrade the rail crossings along the

corridor of the other two passenger rail routes in the state, The Southwest Chief and

The Texas Eagle.

Railroads and LPAs have contributed their own money with in-kind services on

many of the rail safety improvement projects. Since 2017, railroads have used more

than four million dollars to partner with MoDOT and the communities to make safety

improvements. Federal CRSI grants, coupled with state, railroad, and local funding

for improvements along rail corridors in the southwest region of Missouri will result in

closing 13 crossings, placing active crossing protection at 4 crossings, construction of

I railroad overpass, enhancing pedestrian safety, and a myriad of other safety

improvements, all focused on saving lives and preventing injuries.

4.0 Grade Crossing Maintenance Requests by Chariton County

Commissioner’s Court

The following notes by the Presiding Commissioner of Chariton County reflect

maintenance complaints received and requests by the County Commissioners to the

BNSF Railroad and MODOT for maintenance.

Timeline of information from my personal notes concerning the Porche Prairie

Avenue rail crossing.

HIGHWAY SAFETY RRD22MR010

GROUP CHAIR'S FACTUAL REPORT PG 20 OF 31

Chariton County Presiding Commissioner

• December 2, 2019

o The Commission spoke to Mike Spencer about his concerns at the

Porche Prairie Ave rail crossing.

o He said the approach is very steep and needs addressed.

o He has been in contact with the railroad but said they were not being

very cooperative.

o We gave him the contact information for MoDOT railroad safety.

• December 9, 2019

o The Commission spoke to Jack Wright, MoDOT Railroad Safety, about

the Porche Prairie Ave crossing.

o They told us they were aware of the issues at the crossing, and it is on

their plans to repair.

o They said they would start talking to landowners to get dirt to fix the

approach.

• March 3, 2021

o The Commission met at the Porche Prairie Ave rail crossing with Jack

Wright of MoDOT Railroad Safety, Mike Spencer, and Jon Dwigging of

Howe Company.

o The approach to the crossing is very steep and needs to be addressed.

o Since the gravel road and railroad intersect at an angle, it can make it

difficult to see.

o The crossing is used by a lot of farm equipment which would make it

especially difficult to navigate.

o Mo DOT still has the crossing on their list to repair but no timeline was

given to us.

• May 23, 2022

o Commissioner Milford was contacted by residents about brush

obstructing the view at the Porche Prairie Ave rail crossing.

o The Commission contacted Jack Wright of MoDOT Railroad Safety by

email about the visibility issues but never received a response.

• May 31, 2022

o The Commission called the Mariano Rodriguez, Roadmaster with BNSF,

to express our concerns with the visibility issues at the Porche Prairie

Ave rail crossing.

5.0 Audibility of Train Horns at Passive Grade Crossings

Due to recovery operations and Amtrak locomotive availability actual audibility

testing was not performed at the site. However, research and testing by the NTSB in

other cases provided a foundation for assessing the audibility of the train horn in this

investigation. The Federal Railroad Administration’s (FRA) regulation for audible

HIGHWAY SAFETY RRD22MR010

GROUP CHAIR'S FACTUAL REPORT PG 21 OF 31

warning devices states that locomotives shall be provided with an audible warning

device that produces a minimum sound level of 96 dB(A) at 100 feet forward of the

locomotive in its direction of travel. 11 Typical test values of Amtrak locomotive horns

indicate they can produce a 100-105 decibel sound pressure level at the 100-foot

distance. FRA test records for ATK 133, the accident lead locomotive showed that the

certification test for the locomotive horn was performed in 2010. The horn could emit

a sound pressure level of 101.4 dB(A).

Audibility testing of outdoor sounds show that the sound pressure levels

typically reduce in intensity by 6 decibels for each doubling of distance from the

sound source. 12 The Amtrak locomotive began sounding its horn near the Whistle

post which was 1,328 feet from the crossing. At this distance from the crossing the

sound pressure level would be reduced by approximately 24 decibels.

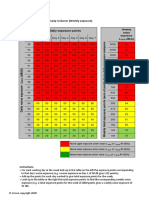

Table 3. Reduction in decibels at certain distances.

Distance Reduction in Sound

Density

200 feet 6 dB

400 feet 12 dB

800 feet 18 dB

1600 feet 24 dB

Also, the wind conditions could have lessened the sound pressure levels; the

wind was blowing 3-7 mph from 3 to 87 degrees or carrying the sound to the south

and west of the crossing.

Sound pressure testing in a previous NTSB investigation in a conventional cab

straight truck on a gravel surface indicated the ambient noise levels varied between

80-85 decibels. 13 Audibility research indicates that the sound pressure level needs to

be 3-8 decibels higher than the ambient noise level to detect sound and 10 decibels

greater for the detected sound to be alerting. 14 In this investigation insertion loss did

not have to be accounted for because the post-crash inspection showed that the

dump truck windows were down when the crash occurred. 15

11

49 CFR Part 229.212a

12

Acoustical Society of America 1994. Procedures for outdoor measurement of sound pressure level.

American National Standard Institute (ANSI) ANSI Standard S12.18-1994. New York, NY ANSI S-12.18

Page 4.

13

Blum, Texas investigation HAB02-10 HWY98Sh007.

14

Lipscomb, David M. 1982. Audibility and the Law. In: Kramer, M.B.; Armbruster, J.M., eds. Forensic

Audiology. Baltimore, MD. University Park Press: 191-222. Chapter 11. “The alerting level is the sound

level at which a person is aware of a sound and recognizes its source.

15

Insertion loss is the difference between the measured values of a sound from an exterior sound

source taken outside the vehicle and inside the vehicle.

HIGHWAY SAFETY RRD22MR010

GROUP CHAIR'S FACTUAL REPORT PG 22 OF 31

6.0 Enforcement Activity

A five-year historical search of traffic enforcement records was performed by

the Missouri State Highway Patrol and Chariton County Sheriff’s Office. No crashes or

enforcement records for the crossing were located.

E. TECHNICAL RECONSTRUCTION

7.0 Vehicle Documentation

7.1 Locomotive

Upon arrival of NTSB investigators, the lead locomotive, identified as ATK 133,

was derailed and still attached to the remainder of the train. The locomotive was

examined by investigators on June 28th, 2022. Additional examination and

photography occurred on June 30th, 2022, at a location northeast of the rail crossing.

The lead locomotive, ATK 133, was identified as a General Electric model

P42DC and was 69 feet in length, and 14’9” tall. The locomotive was photographed

utilizing a small Unmanned Aircraft System (sUAS). Figure 12 depicts the damage

sustained by the lead locomotive from the collision.

Figure 12. Photograph depicting the damage to the front of the locomotive.

HIGHWAY SAFETY RRD22MR010

GROUP CHAIR'S FACTUAL REPORT PG 23 OF 31

Direct impact occurred on the front and left side of the locomotive. The

damage to the front extended inboard an approximate distance of 6.45 feet and

upward to the top of the left windshield. The coupling device was damaged. The

fiberglass covering on the front was cracked in several locations. The main impact

was located on in the area around the left light and left front corner of the locomotive.

7.2 Commercial Motor Vehicle

The involved commercial motor vehicle was identified as a 2007 Kenworth

W900 dump truck. The dump truck had been removed from the scene and secured

indoors at a storage facility. On June 30th, 2022, NTSB investigators attended an

examination/inspection of the dump truck conducted by MSHP investigators. The

vehicle was photographed during the examination. Post-collision the cab, dump bed,

and rear drive axle, axle #5, had been torn away from the frame of the dump truck.

Figure 13 is a photograph of the dump truck frame.

Figure 13. Photograph showing the damage to the rear of the dump truck.

HIGHWAY SAFETY RRD22MR010

GROUP CHAIR'S FACTUAL REPORT PG 24 OF 31

Figure 14. Photograph depicting the damage to the 5th axle sustained during the collision.

Figure 14 is a photograph of the 5th axle showing the damage described

above. The frame rails at the rear of the dump truck at about the 4th axle were bent

towards the right (passenger) side at about a 30° angle. Both right tires on the 4th axle

had separated from their respective wheels. The 5th axle left (drivers’ side) outer steel

wheel was torn and the pieces that were torn away were bent. The tire had

completely separated from the wheel. The inner steel wheel was also bent, and the

inner sidewall of the tire had torn open. The left side of the axle had been

compressed inwards toward the differential, decreasing the track width. The left

brake chamber was bent inwards towards the center of the axle, and the left side

outer cover of the differential was dented inward.

The cab suffered extensive overall damage. All the glass had been broken out

and the roof was torn away. The steering column was bent forward, toward the

dashboard, and the upper rim of the steering wheel was bent forward. The seatbelt

and belt buckle were observed retracted and against the “B” pillar. During the

inspection of the cab MSHP investigators removed the instrument gauge clusters

from inside the cab. Figure 15 is a photograph of the one of the clusters removed.

The pictured cluster housed two gauges, speedometer, and revolutions per minute

HIGHWAY SAFETY RRD22MR010

GROUP CHAIR'S FACTUAL REPORT PG 25 OF 31

(RPM). Of note, the speedometer needle was stopped at approximately 5 mph and

the RPM was displaying 1100 rpm.

Figure 15. Image of instrument gauge cluster from the 2007 dump truck.

Contact damage to the left rear corner was observed. The left rear corner was

pushed upward, with the side wall being pushed inward. The upper steel rail, left

side, and the tailgate had been torn off. The front wall of the dump bed separated

from the left side at the corner seam, and the front wall was pulled forward away from

the left wall.

7.3 Electronic Event Data

The commercial motor vehicle involved was powered by a diesel engine

manufactured by Caterpillar. The engine is controlled by several controllers which are

generally referred to as electronic control modules (ECMs). The ECMs may be

capable of recording and storing engine data relating to parameters and event data.

Depending on engine and vehicle setup the data may be recorded and stored on a

single module or multiple modules. The modules can be accessed through

commercially available software or require manufacturer assistance where the data is

proprietary.

HIGHWAY SAFETY RRD22MR010

GROUP CHAIR'S FACTUAL REPORT PG 26 OF 31

The Kenworth was equipped with a 14.6-liter Caterpillar six-cylinder diesel

engine, and a 10-speed Eaton Fuller transmission. MSHP investigators were able to

locate and remove the ECM from the vehicle. Due to damage the ECM was

photographed and shipped to the NTSB Office of Research and Engineering for

examination and imaging. Figure 16 is a photograph of the damaged ECM.

Figure 16. Photograph of damaged ECM removed from the Kenworth. (Photograph courtesy of

MSHP).

Caterpillar uses proprietary software that is not commercially available. The

software program is Electronic Technician. The software will report calibration

information, trip data, fault codes, and critical event snapshots. There are three

scenarios in which data records to the ECM.

1. Critical event snapshot: i.e., low oil pressure, low engine coolant

2. Driver triggered snapshot

3. Quick stop

Investigators from the Office of Research and Engineering located a Caterpillar

representative whose services were engaged to conduct an image of the ECM. The

ECM was hand carried to Carter Machinery for the imaging by a Research and

Engineering recorder specialist and Office of Highway Safety investigator. Refer to

HIGHWAY SAFETY RRD22MR010

GROUP CHAIR'S FACTUAL REPORT PG 27 OF 31

the NTSB Electronic Control Module Specialist’s Factual Report for details about the

imaging.

The Electronic Technician software provides a multiple page report that

includes ECM Summary, Critical Events, Configuration, Logged Event Codes, as well

as data regarding Total Time vs. Vehicle Speed and Engine Speed. 16

The ECM Summary reported the Engine Serial Number as MXS85820 and the

ECM Serial Number as 10266994JX. The record reported one critical event for very

low coolant level, reported on June 21, 2022, at approximately 8:43 pm. The ECM

reported the event codes along with the diagnostic codes in relation to the internal

diagnostic clock which was at 6,236 hours. Table 4 shows the logged event codes

that were recorded by the ECM. The occurrence is the number of times the event had

been logged. The first and last are the first time (diagnostic clock), and the last time

the code was logged.

Table 4. Logged event codes from the truck ECM.

Code Description Occurrence First Last

J1939 Device Not

231-12 1 6236 6236

Responding

Low Coolant Level

111-1 11 6121 6214

Warning

Very Low Coolant

111-11 10 6121 6214

Level

Eight current diagnostic codes were also reported. Each had only one occurrence

and the first and last reported time was 6236, which as mentioned above was the

current diagnostic clock count.

As mentioned above the third scenario for triggering a critical event is with a

quick stop. Within the ECM configuration the quick stop rate is a setting that can be

activated by the vehicle owner through the Caterpillar software. According to the

configuration of the truck the quick stop rate was set to 0.0 miles per hour per

second.

8.0 Video Study

The lead locomotive was equipped with a forward-facing camera that captured

the collision and the movement of the truck prior to impact. The truck was visible

within the camera frame along with a dust cloud that trailed the truck as it traveled

northbound on Porche Prairie Ave. Refer to the NTSB Office of Research and

Engineering Video Study for further details.

The Caterpillar Electronic Technician Product Status Report can be found with the Electronic Control

16

Module Specialists Factual Report.

HIGHWAY SAFETY RRD22MR010

GROUP CHAIR'S FACTUAL REPORT PG 28 OF 31

F. MOTOR CARRIER HISTORY AND OPERATIONS

The motor carrier involved in this crash was MS Contracting LLC. (MS).

According to the Federal Motor Carrier Safety Administration (FMCSA) Motor Carrier

Management Information System (MCMIS), the carrier was issued USDOT number

3383523. The carrier is registered as an Intrastate for hire carrier of large objects,

gravel and sand and is domiciled in Brookfield, Missouri. Per the carrier’s latest MCS-

150, the carrier utilized 14 trucks and employed M9 drivers. 17 18

9.0 History of MS Contracting LLC.

MS was established on May 27, 2015, through a filing with the state of

Missouri. 19 They were primarily in the business moving aggregates and equipment.

MS was subject to an off-site New Entrant audit by state investigators. MS

exited the new entrant audit on January 8, 2021. The state of Missouri investigators

completed an on-site comprehensive compliance review (CR) because of this crash.

A comprehensive CR may be used if the carrier was involved in a crash or there has

been a complaint made. A comprehensive CR addresses all aspects of the carrier’s

operation and may result a safety rating. The review was completed on August 4,

2022 and was not rated. 20

The following violations were noted on the post-crash review:

• Using a driver before the carrier has received a negative pre-

employment-controlled substance test (49CFR382.301(a))

• Using a commercial vehicle not periodically inspected (49CFR396.17(a))

• Failing to ensure that each driver subject to random alcohol and

controlled substances testing has an equal chance of being selected

each time selections are made (49CFR382.305(i)(2))

• Failing to ensure person designated to determine that drivers undergo

reasonable suspicion testing receive 60 minutes training for alcohol

and/or 60 minutes of training for controlled substances (49CFR382.603)

• Failing to conduct an annual query (49CFR382.701(b)(1))

• Failing to conduct a pre-employment query (49 CFR382.701(a))

• Failing to register in the Clearinghouse (49CFR382.711(b))

• Using a driver who has not completed and furnished an employment

application (49CFR391.21(a))

17

Form MCS-150 and Instructions - Motor Carrier Identification Report | FMCSA (dot.gov)

18

Motor Carrier Attachment - MCS – 150 dated August 25, 2022.

19

Motor Carrier Attachment – Articles of Organization

20

Motor Carrier Attachment – Post crash compliance review

HIGHWAY SAFETY RRD22MR010

GROUP CHAIR'S FACTUAL REPORT PG 29 OF 31

Approximately June 7, 2022, MS Contracting entered into a verbal

agreement with Better by Design and the US Army Corps of Engineers to haul

rock to the Garden of Eve levee in the local area to repair flood damage to the

levee. MS Contracting had hauled approximately 56 loads of shot road to this

designated area between June 7th and the date of this crash across the

highway/rail at-grade crossing on Porche Prairie Avenue. MS Contracting had

reportedly received verbal instructions to use the route that traversed the

passive grade crossing at this location because it was determined that another

route, that would lead to a crossing protected by signals, was not feasible

because the loaded trucks could not safely turn into an access road off County

Road 122 and Porche Prairie Avenue. The corner was too tight to make the

turn. MS Contracting also confirmed on the day of the Pre-job meeting the

Corps of Engineers gave verbal instructions to use the route where this crash

occurred. 21

10.0 Commercial Motor Vehicle Driver

According to the MSHP a records check conducted on the driver identified that

he was exempt under Missouri law from possessing a medical certificate. 22

G. LIST OF ATTACHMENTS

1. Highway Attachment – Letter from MODOT Director to NTSB Chair

Homendy.

2. Highway Attachment – Police Accident Report.

3. Highway Attachment – FRA Grade Crossing Inventory Report.

4. Motor Carrier Attachment – MCS – 150 dated August 25, 2022.

5. Motor Carrier Attachment – Articles of Organization.

6. Motor Carrier Attachment – Post crash compliance review.

7. Motor Carrier Attachment – Email from MS Contracting providing

information on construction contract route.

21

See email from MS Contracting to NTSB dated January 24, 2023.

22

MoDOT.org/mcs. The driver possessed a Chauffeurs license prior to May 13, 1988, which exempted

him from the need to have a DOT medical card.

HIGHWAY SAFETY RRD22MR010

GROUP CHAIR'S FACTUAL REPORT PG 30 OF 31

Submitted by:

Eric Gregson

Technical Reconstructionist

David S. Rayburn

Senior Highway Factors Investigator

Shawn Currie

Senior Motor Carrier Factors Investigator

HIGHWAY SAFETY RRD22MR010

GROUP CHAIR'S FACTUAL REPORT PG 31 OF 31

You might also like

- Phy 102 Lecture 8 - Electrical Energy and Capacitance (B)Document72 pagesPhy 102 Lecture 8 - Electrical Energy and Capacitance (B)chipango lungoweNo ratings yet

- Lto PlateDocument95 pagesLto PlateInchan AbreganaNo ratings yet

- TOR Form UP DilimanDocument1 pageTOR Form UP DilimanKevin CordovizNo ratings yet

- Wftda Statsbook Full Us LetterDocument58 pagesWftda Statsbook Full Us Lettermariana jaquelineNo ratings yet

- LB! - Walkthrough - TLWikiDocument7 pagesLB! - Walkthrough - TLWikiM.K. SyahmiNo ratings yet

- TDT 172718DEI 65Fv05Document1 pageTDT 172718DEI 65Fv05Дмитрий100% (1)

- Circular No. 444 - Amendments To Pag-IBIG Fund Circular No. 388Document3 pagesCircular No. 444 - Amendments To Pag-IBIG Fund Circular No. 388Attorney III DOH CHDNo ratings yet

- No Dues Certificate: Date: Loan Account No: 37M0Cdhi631670 Customer Name: Bikash DebnathDocument1 pageNo Dues Certificate: Date: Loan Account No: 37M0Cdhi631670 Customer Name: Bikash Debnathsja shawnNo ratings yet

- Jeep AutocheckDocument6 pagesJeep AutocheckLindsey HudsonNo ratings yet

- Republic of The PhilippinesDocument2 pagesRepublic of The PhilippinesNFRDI BAC SecretariatNo ratings yet

- Travel ItineraryDocument4 pagesTravel Itineraryapi-653571771No ratings yet

- Current: Current Shots 365 Yearly MagazineDocument112 pagesCurrent: Current Shots 365 Yearly MagazineShourya GautamNo ratings yet

- Gmail - Booking Confirmation On IRCTC, Train - 14008, 25-Nov-2021, 2S, ANVT - SLNDocument1 pageGmail - Booking Confirmation On IRCTC, Train - 14008, 25-Nov-2021, 2S, ANVT - SLNchandan tiwariNo ratings yet

- Ticket TK281710054m45Document2 pagesTicket TK281710054m45gandi harikrishnaNo ratings yet

- RDO No. 55 - San Pablo City, East LagunaDocument522 pagesRDO No. 55 - San Pablo City, East LagunaMiko Jim Paulo PanganibanNo ratings yet

- BL + CO + Inv + Pack 113477877Document11 pagesBL + CO + Inv + Pack 113477877Đàn NguyễnNo ratings yet

- Customs Power of Attorney-Company-2021Document1 pageCustoms Power of Attorney-Company-2021shahwaizNo ratings yet

- Trips Flight DownloadETicket-2Document3 pagesTrips Flight DownloadETicket-2Harshith20No ratings yet

- Internship ReportDocument29 pagesInternship ReportARPIT SONINo ratings yet

- Essai Mozhi - CMTDocument30 pagesEssai Mozhi - CMTSHYAM SUNDARNo ratings yet

- SUPPLY UNDER GST-Unit 2Document56 pagesSUPPLY UNDER GST-Unit 2niveditaNo ratings yet

- BL + CO + Inv + Pack 113485709Document10 pagesBL + CO + Inv + Pack 113485709Đàn NguyễnNo ratings yet

- Enerplus 05 May 2022 PSDocument92 pagesEnerplus 05 May 2022 PSShubham RaulNo ratings yet

- Fund TechDocument2 pagesFund TechBina ShahNo ratings yet

- BCO 11 Block 03Document70 pagesBCO 11 Block 03Al OkNo ratings yet

- Babawande Afolabi List of Acknowledgments GAADocument5 pagesBabawande Afolabi List of Acknowledgments GAADavid HundeyinNo ratings yet

- Language - Register bsn1cDocument27 pagesLanguage - Register bsn1cMonica JoyceNo ratings yet

- Cta 00 CV 04340 D 1993sep10 AssDocument11 pagesCta 00 CV 04340 D 1993sep10 AsscyeeeNo ratings yet

- Application For Registration of New Ecozone EnterprisesDocument4 pagesApplication For Registration of New Ecozone EnterprisesMark Kevin SamsonNo ratings yet

- Terms and Conditions 27 06 PDFDocument4 pagesTerms and Conditions 27 06 PDFShreyash NaikwadiNo ratings yet

- Arguments Against Condonation ApplicationDocument2 pagesArguments Against Condonation ApplicationKartikey singhNo ratings yet

- Foi Request FormDocument2 pagesFoi Request FormLeo De ocampoNo ratings yet

- CountryTerritory Report - TurkeyDocument65 pagesCountryTerritory Report - TurkeyBatuhan ParlakNo ratings yet

- HP+New+Year+Offer+2022 V4Document9 pagesHP+New+Year+Offer+2022 V4bijendra83No ratings yet

- Format of Undertaking by Foreign DirectorDocument1 pageFormat of Undertaking by Foreign DirectorsamNo ratings yet

- Main Admission Form Bachelors 2022-26Document8 pagesMain Admission Form Bachelors 2022-26Isra ShahidNo ratings yet

- List of Cases Phasea 3-2022Document8 pagesList of Cases Phasea 3-2022SAFI ULLAH KHANNo ratings yet

- 1673 00T3s00002oE1AjEAKDocument6 pages1673 00T3s00002oE1AjEAKJonas GonzalesNo ratings yet

- Appnd Anf Eng Part1Document476 pagesAppnd Anf Eng Part1Sam Hunt100% (1)

- PDS Geotech Iec CertificateDocument1 pagePDS Geotech Iec Certificaterohit ghorpadeNo ratings yet

- Complaint - Mississippi State Conference of The Naacp v. State Board of Election CommissionersDocument95 pagesComplaint - Mississippi State Conference of The Naacp v. State Board of Election CommissionersRuss LatinoNo ratings yet

- JEE Main-2023 Session 2 - RegistrationDocument2 pagesJEE Main-2023 Session 2 - RegistrationTaaha BaigNo ratings yet

- Jurisprudence Insurance Law 2021-4Document11 pagesJurisprudence Insurance Law 2021-4dyosaNo ratings yet

- MA and Equity Offerings Market Report 2022Document21 pagesMA and Equity Offerings Market Report 2022thinh thaiNo ratings yet

- Travel ItineraryDocument4 pagesTravel ItineraryKamal HassanNo ratings yet

- Nagarro - Receipt For Claiming Drivers SalaryDocument1 pageNagarro - Receipt For Claiming Drivers SalaryNitin YadavNo ratings yet

- СV Be Free 2020 (Нужно написать ваше имя и фамилию на английском) (3) - копияDocument3 pagesСV Be Free 2020 (Нужно написать ваше имя и фамилию на английском) (3) - копия5 к CompanyNo ratings yet

- CertificateDocument1 pageCertificateShamsurahman ShamsiNo ratings yet

- Sofi Digital Assets LLC Customer AgreementDocument34 pagesSofi Digital Assets LLC Customer AgreementJohn SmithNo ratings yet

- Presentation Super BowlDocument8 pagesPresentation Super BowlAdeelSiddiqueNo ratings yet

- Yahoo Mail - Trent University Offer of AdmissionDocument2 pagesYahoo Mail - Trent University Offer of Admissionapi-641119081No ratings yet

- AirtelDocument4 pagesAirtelkartikNo ratings yet

- Exam Time Table PDFDocument3 pagesExam Time Table PDFShreyash NaikwadiNo ratings yet

- Sensors 23 06430Document18 pagesSensors 23 06430r.shekara22No ratings yet

- Print - Udyam Registration CertificateDocument2 pagesPrint - Udyam Registration CertificatePankaj PandeyNo ratings yet

- Adobe Scan Mar 5 2022Document19 pagesAdobe Scan Mar 5 2022PAULA MENDITANo ratings yet

- Track Shipment Status - Consignment Status - DTDC IndiaDocument1 pageTrack Shipment Status - Consignment Status - DTDC IndiaAjay Chowdary Ajay ChowdaryNo ratings yet

- Literatures CitedDocument4 pagesLiteratures CitedCyrus CorpuzNo ratings yet

- Comprehensive Tender Documents 83370976 PDFDocument19 pagesComprehensive Tender Documents 83370976 PDFBogale WorkuNo ratings yet

- USW NTSB Crash ReportDocument15 pagesUSW NTSB Crash ReportNewsWest 9No ratings yet

- NTSB Safety Recommendation Amtrak Crash Cayce, SCDocument4 pagesNTSB Safety Recommendation Amtrak Crash Cayce, SCWLTXNo ratings yet

- The Effect of Crosswalk Markings On Vehicle Speeds in Maryland, Virginia, and ArizonaDocument11 pagesThe Effect of Crosswalk Markings On Vehicle Speeds in Maryland, Virginia, and ArizonaRobert OrtizNo ratings yet

- Opinion ED110491Document5 pagesOpinion ED110491JENNIFER WEISERNo ratings yet

- Donald Eugene Fields IIDocument1 pageDonald Eugene Fields IIJillian SmithNo ratings yet

- Trump IndictmentDocument45 pagesTrump IndictmentJENNIFER WEISERNo ratings yet

- JC Ward PrecDocument1 pageJC Ward PrecJENNIFER WEISERNo ratings yet

- 2023 Spring Turkey Hunting RegsDocument24 pages2023 Spring Turkey Hunting RegsJENNIFER WEISERNo ratings yet

- Route GuideDocument2 pagesRoute GuideJENNIFER WEISERNo ratings yet

- Covid 19 Recovery March 2022Document14 pagesCovid 19 Recovery March 2022JENNIFER WEISERNo ratings yet

- March 29 2023 Chief Warrant Officer 3 Zachary Esparza DECEASED SOLDIER - KILLED ProclamationDocument1 pageMarch 29 2023 Chief Warrant Officer 3 Zachary Esparza DECEASED SOLDIER - KILLED ProclamationJENNIFER WEISERNo ratings yet

- 2022 Spring Clean Up AdDocument1 page2022 Spring Clean Up AdJENNIFER WEISERNo ratings yet

- 2022-06-06 Boone County Mourns Passing of PA Dan KnightDocument1 page2022-06-06 Boone County Mourns Passing of PA Dan KnightJENNIFER WEISERNo ratings yet

- HB2704IDocument6 pagesHB2704IJENNIFER WEISERNo ratings yet

- LODD Assistant Chief Boone County Fire Protection - Bryant GladneyDocument1 pageLODD Assistant Chief Boone County Fire Protection - Bryant GladneyJENNIFER WEISERNo ratings yet

- Hernandez - Statement of FactsDocument7 pagesHernandez - Statement of FactsJENNIFER WEISERNo ratings yet

- Cps PetitionDocument16 pagesCps PetitionJENNIFER WEISERNo ratings yet

- 2021 22 COVID 19 Protocols Revised 011222Document6 pages2021 22 COVID 19 Protocols Revised 011222JENNIFER WEISERNo ratings yet

- To-2022-Xxxx Motion To Open Docket and Motion For Expedited TreatmentDocument11 pagesTo-2022-Xxxx Motion To Open Docket and Motion For Expedited TreatmentJENNIFER WEISERNo ratings yet

- House Bill No. 2117: 101St General AssemblyDocument139 pagesHouse Bill No. 2117: 101St General AssemblyJENNIFER WEISERNo ratings yet

- Givens IndictmentDocument4 pagesGivens IndictmentJENNIFER WEISERNo ratings yet

- Aligning,: 5. One Member From The Missouri General AssemblyDocument2 pagesAligning,: 5. One Member From The Missouri General AssemblyJENNIFER WEISERNo ratings yet

- Chapter 02 Radio Frequency & Antenna FundamentalsDocument46 pagesChapter 02 Radio Frequency & Antenna FundamentalsSenthilathiban Thevarasa50% (2)

- Acoustics: - "A Science That Deals With The Production, Control, Transmission, Reception, and Effects of Sound."Document42 pagesAcoustics: - "A Science That Deals With The Production, Control, Transmission, Reception, and Effects of Sound."Amit JainNo ratings yet

- Noise CalculatorDocument6 pagesNoise CalculatorngockhoapsNo ratings yet

- Volte: Sensitivity: InternalDocument32 pagesVolte: Sensitivity: InternalHabib MohammedNo ratings yet

- As 062Document6 pagesAs 062mukeshkumarjNo ratings yet

- Noise Exposure Ready-Reckoner (Weekly Exposure)Document1 pageNoise Exposure Ready-Reckoner (Weekly Exposure)igor_239934024No ratings yet

- RF Transceiver Architectures For W-CDMADocument10 pagesRF Transceiver Architectures For W-CDMABình PhạmNo ratings yet

- DX 1710 2170 65 18i 2F - Complementares - Re2 - 05 08 09Document1 pageDX 1710 2170 65 18i 2F - Complementares - Re2 - 05 08 09MackamNo ratings yet

- Audison Bit One - Sheet TechnicalDocument2 pagesAudison Bit One - Sheet TechnicalVlad GrigoreNo ratings yet

- Hewlett-Packard - AN150-10 - Spectrum Analysis - Field Strenght MeasurementDocument2 pagesHewlett-Packard - AN150-10 - Spectrum Analysis - Field Strenght Measurementgbr123No ratings yet

- Re200ge 140909Document8 pagesRe200ge 140909ErstebabaJiiNo ratings yet

- Noise CalculatorDocument9 pagesNoise CalculatormukeshkumarjNo ratings yet

- JVC KDS 48 J Service ManualDocument20 pagesJVC KDS 48 J Service ManualAlejandro CastilloNo ratings yet

- Odp-065r18kv 18KV PDFDocument1 pageOdp-065r18kv 18KV PDFAlberto LinaresNo ratings yet

- Outdoor Directional Dual-Band Antenna: ODP-065R09M12J-G (2J)Document2 pagesOutdoor Directional Dual-Band Antenna: ODP-065R09M12J-G (2J)SandroTrigoValdivia100% (1)

- KR MV5 R410A 380V, 5060Hz HP SA MFL67474050 0CVV0-01H Jan.2020Document453 pagesKR MV5 R410A 380V, 5060Hz HP SA MFL67474050 0CVV0-01H Jan.2020CARLOS AUGUSTUS PAGLIOSANo ratings yet

- Oscilla PDFDocument24 pagesOscilla PDFCabrito VeleñoNo ratings yet

- Terrestial Communications ECE 530 2nd Sem 2016Document68 pagesTerrestial Communications ECE 530 2nd Sem 2016Clark Jones Edgar CastilloNo ratings yet

- Module 2 Noise-1Document3 pagesModule 2 Noise-1CydelMarie PerezNo ratings yet

- TG PG Test Procedure PDFDocument129 pagesTG PG Test Procedure PDFHari Prasad100% (2)

- JIS Z 3062 2009 Method and Acceptance Criteria of Ultrasonic ExaminationDocument20 pagesJIS Z 3062 2009 Method and Acceptance Criteria of Ultrasonic ExaminationLe Anh DuyNo ratings yet

- ATH201Series-User - Manual Eone Et 310aDocument26 pagesATH201Series-User - Manual Eone Et 310aSérgio Henrique da SilvaNo ratings yet

- K742226V01Document3 pagesK742226V01Witto PereNo ratings yet

- AttenuatorsDocument6 pagesAttenuatorsenglandbroNo ratings yet

- Dx-690-960-65-16.5I-M-R Easyret 2-Port Antenna With 1 Integrated Rcu - 2.0M Model: A704516R0V06Document2 pagesDx-690-960-65-16.5I-M-R Easyret 2-Port Antenna With 1 Integrated Rcu - 2.0M Model: A704516R0V06юрий ермошенкоNo ratings yet

- Noise Emissions: Technical Information No. 1Document8 pagesNoise Emissions: Technical Information No. 1EdilsonNo ratings yet

- TECHNICAL NOTE 013 Steel Sheet Piling - Drivability Vs SPT-N Values - Vibrations and Noise LevelDocument3 pagesTECHNICAL NOTE 013 Steel Sheet Piling - Drivability Vs SPT-N Values - Vibrations and Noise LevelRaed Naim Khammash100% (1)

- Service Manual: KD-A805J, KD-R800J, KD-R801E, KD-R801EX, KD-R801EY, KD-R801EU, KD-R805U, KD-R805UT, KD-R807EEDocument57 pagesService Manual: KD-A805J, KD-R800J, KD-R801E, KD-R801EX, KD-R801EY, KD-R801EU, KD-R805U, KD-R805UT, KD-R807EEMe Ego100% (1)