Professional Documents

Culture Documents

Control and Shutdown Definitions

Control and Shutdown Definitions

Uploaded by

Regulo0 ratings0% found this document useful (0 votes)

15 views9 pagesThe document discusses control, monitoring, and shutdown systems for a plant. It defines control systems and safety systems. The normal control and monitoring is done through a distributed control system (DCS) that controls the process. The process safety system, designed to protect personnel and equipment in emergency situations, is the emergency shutdown system (ESD). Process safety systems must be independent of process control systems. Documentation for safety systems includes specifications, cause and effect matrices, diagrams, and study reports.

Original Description:

Control de Procesos y Parada

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses control, monitoring, and shutdown systems for a plant. It defines control systems and safety systems. The normal control and monitoring is done through a distributed control system (DCS) that controls the process. The process safety system, designed to protect personnel and equipment in emergency situations, is the emergency shutdown system (ESD). Process safety systems must be independent of process control systems. Documentation for safety systems includes specifications, cause and effect matrices, diagrams, and study reports.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

15 views9 pagesControl and Shutdown Definitions

Control and Shutdown Definitions

Uploaded by

ReguloThe document discusses control, monitoring, and shutdown systems for a plant. It defines control systems and safety systems. The normal control and monitoring is done through a distributed control system (DCS) that controls the process. The process safety system, designed to protect personnel and equipment in emergency situations, is the emergency shutdown system (ESD). Process safety systems must be independent of process control systems. Documentation for safety systems includes specifications, cause and effect matrices, diagrams, and study reports.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 9

Behnaz Motamed

September 2021

Behnaz Motamed, Control & Shutdown Definitions, Rev.00, Sep. 2021 1

Control, monitoring and shutdown

systems are designed at the earliest

phase of the project by basic or

licensor designer.

As the process moves through project

life cycle, the systems may be

developed.

Definitions presented here, may differ

from one project to another as they

are defined by Clients and standards

in each project; anyway, the concept

represented here is the same.

Behnaz Motamed, Control & Shutdown Definitions, Rev.00, Sep. 2021 2

There are some systems for control, monitoring and shutdown of

the plan. They will be related to each other through suitable

communication. This collection will be composed of major sub-

systems. In general systems can be classified as:

o Control System

o Safety System

Behnaz Motamed, Control & Shutdown Definitions, Rev.00, Sep. 2021 3

Another classification is:

o Process/distributed control system (PCS/DCS)

o Emergency shutdown, depressurization and ultimate safety

systems(ESD/EDP/USS)

o Fire & gas detection and alarm system (F&G)

o Package units, and PLC based package units (CMS, BMS, MMS,...)

o Other systems

Sometimes Process Control System (DCS) and Emergency Shutdown

System (ESD), are integrated as Integrated Control and Safety System)

(ICSS).

Behnaz Motamed, Control & Shutdown Definitions, Rev.00, Sep. 2021 4

Package units, and PLC based package units (CMS, BMS, MMS,...) is divided

into three types:

Stand-alone package, controlled by own control system (Local

Control Panel (LPC) and has no interface (or very limited) with

DCS, ESD and F&G systems

Package remotely controlled by the DCS and ESD/F&G systems

Packaged unit fully controlled by the package control cabinet (UCP)

located remotely in the Instrument Technical Room (ITR). The

package UCP is connected to the PCS/DCS, ESD and F&G systems,

for monitoring, control functions and shutdowns

The ESD activation of packages shall be implemented in the Plant

ESD system.

Behnaz Motamed, Control & Shutdown Definitions, Rev.00, Sep. 2021 5

o Control System

o Safety System

The normal control & monitoring system is done via a Distributed Control

System (DCS). This system controls the process to produce a good quality

product (on-spec product) and keeps all process variables within its safety

limit. This system is including:

o Process control loops

o Process interlocks

o Process monitoring

o Alarms

o Switches and push buttons

o Packages connected to DCS (BMS, MMS, …)

Behnaz Motamed, Control & Shutdown Definitions, Rev.00, Sep. 2021 6

o Control System

o Safety System

Process safety system of a plant is designed to protect personnel, equipment

and environment in case of abnormal, unsafe or emergency conditions.

These actions are done via an Emergency Shutdown Systems (ESD).

This system is including:

o Emergency shutdown and depressurization system (ESD/EDP)

o Fire & gas detection and alarm system (F&G)

o Package UCP connected to ESD/EDP/F&G (BMS, MMS, …)

Behnaz Motamed, Control & Shutdown Definitions, Rev.00, Sep. 2021 7

Behnaz Motamed, Control & Shutdown Definitions, Rev.00, Sep. 2021 8

The process safety system shall be independent of and in addition to the

process control devices used in normal process operation. It means protection

measures have different functions from control algorithms.

Process safety systems documentation

The design of the safety system shall be documented, including but not

limited to:

o Specifications and philosophies

o Cause and effect matrix (ESD/EDP matrix, interlock

matrix/description)

o Alarms and trips set-point list

o Diagrams (such as ESD hierarchy diagram, safeguard diagram, logic

diagram)

o Study report (such as SIL study, depressurizing study)

Behnaz Motamed, Control & Shutdown Definitions, Rev.00, Sep. 2021 9

You might also like

- Cause and Effect Diagram For Process PlantsDocument26 pagesCause and Effect Diagram For Process PlantsBehnaz Motamed100% (2)

- Lenovo ThinkPad T480 01YR328 NM B501Document104 pagesLenovo ThinkPad T480 01YR328 NM B501rishi vaghelaNo ratings yet

- Experiment 8: Fixed and Fluidized BedDocument6 pagesExperiment 8: Fixed and Fluidized BedTuğbaNo ratings yet

- Encyclopedia of Korean Folk BeliefsDocument167 pagesEncyclopedia of Korean Folk BeliefsAria7No ratings yet

- Security Operations Center - Analyst Guide: SIEM Technology, Use Cases and PracticesFrom EverandSecurity Operations Center - Analyst Guide: SIEM Technology, Use Cases and PracticesRating: 4 out of 5 stars4/5 (1)

- 902, 906, & 908 Compact Wheel Loader Electrical System: Machine Harness Connector and Component LocationsDocument2 pages902, 906, & 908 Compact Wheel Loader Electrical System: Machine Harness Connector and Component Locationsait mimouneNo ratings yet

- SIS Lab - PracticalDocument2 pagesSIS Lab - PracticalHardik BhadouriyaNo ratings yet

- Pro Safe PLCDocument44 pagesPro Safe PLClimresNo ratings yet

- Book 1 ISMDocument140 pagesBook 1 ISMRavi Kumar VeeramNo ratings yet

- LVL 1 SisDocument32 pagesLVL 1 SisKrishonn DookhieNo ratings yet

- Safety System - Emergency Shutdown System P1Document41 pagesSafety System - Emergency Shutdown System P1عزت عبد المنعم100% (2)

- Safety SystemDocument81 pagesSafety SystemNguyễnQuíTrọngNo ratings yet

- Vds - 2227en Intruder Alarm SystemsDocument76 pagesVds - 2227en Intruder Alarm SystemsCristianLeotescuNo ratings yet

- Configuracion Redndante Et200 - IoDocument72 pagesConfiguracion Redndante Et200 - IoPatricio Acuña MolinaNo ratings yet

- Integrating Fire and Gas Safety With Process Control SystemsDocument6 pagesIntegrating Fire and Gas Safety With Process Control Systemsabbutalibb100% (1)

- EMBL01E-Module 1Document20 pagesEMBL01E-Module 1Ronny Fae FabonNo ratings yet

- SM - x551 - GACMA0 - ENG (Courier Protocol) PDFDocument96 pagesSM - x551 - GACMA0 - ENG (Courier Protocol) PDFJessada SatwinitNo ratings yet

- AED9101C: User ManualDocument32 pagesAED9101C: User ManualAntanas KontrimasNo ratings yet

- 11-Philosophy of ITER Alarm System Manageme 3WCD7T v2 1Document20 pages11-Philosophy of ITER Alarm System Manageme 3WCD7T v2 1piolinwallsNo ratings yet

- Safety Instrumented SystemsDocument10 pagesSafety Instrumented Systemsalif_rachman_3No ratings yet

- Manual 9401ADocument28 pagesManual 9401ASANTOS DALLACQUANo ratings yet

- Siemens MOTION CONTROL EMC Installation GuidelinesDocument34 pagesSiemens MOTION CONTROL EMC Installation GuidelinessunhuynhNo ratings yet

- Airframe QuantaGrid D52BQ-2U-UG 2.1Document57 pagesAirframe QuantaGrid D52BQ-2U-UG 2.1Lucho OrtegaNo ratings yet

- Instrumentation and Control EngineeringDocument2 pagesInstrumentation and Control EngineeringIan JadeNo ratings yet

- S Aa Cps MV LV Prot (Rev 0 2015)Document46 pagesS Aa Cps MV LV Prot (Rev 0 2015)nknfiveNo ratings yet

- Commissioning of A PLCDocument10 pagesCommissioning of A PLCTahir DonNo ratings yet

- GA 1 All Devices Part 1 Safety Custo Med EN 007Document18 pagesGA 1 All Devices Part 1 Safety Custo Med EN 007shriyamarahatta.1No ratings yet

- Safety Instrumented System - BasicsDocument12 pagesSafety Instrumented System - BasicsJuan Carlos Zerling ManriquezNo ratings yet

- What Is ESD & PSD? Difference Between ESD & PSD Field InstrumentationDocument2 pagesWhat Is ESD & PSD? Difference Between ESD & PSD Field InstrumentationKyrie AbayaNo ratings yet

- (英) 呼吸机产品功能安全企业自查表 Rev 02-230217Document6 pages(英) 呼吸机产品功能安全企业自查表 Rev 02-230217boyu wangNo ratings yet

- Application For Process Automation: Configuration of Redundant I/O ModulesDocument68 pagesApplication For Process Automation: Configuration of Redundant I/O ModulesMateo QuispeNo ratings yet

- What Is A BMS or Building Management SystemDocument27 pagesWhat Is A BMS or Building Management SystemMr. JC NiloNo ratings yet

- TS6250 Tcmodbussrv enDocument55 pagesTS6250 Tcmodbussrv enmavg.controlsNo ratings yet

- WhitePaper Invensys ISBforEMS-Requirements 09-11Document6 pagesWhitePaper Invensys ISBforEMS-Requirements 09-11GabrielNo ratings yet

- Temelin NPP - I&C Replacement: April 1997Document7 pagesTemelin NPP - I&C Replacement: April 1997Skr KhanNo ratings yet

- 1007 DISQ 0 P PH 48071 Shutdown PhilosophyDocument12 pages1007 DISQ 0 P PH 48071 Shutdown PhilosophyAnonymous XbmoAFtINo ratings yet

- ABB Safety HandbookDocument88 pagesABB Safety Handbookmanuel99a2kNo ratings yet

- 080 Collaborativerobotsystems PDFDocument8 pages080 Collaborativerobotsystems PDFCleber GomesNo ratings yet

- Centralized or DistributedDocument6 pagesCentralized or Distributeddanan widjanarkoNo ratings yet

- Functional Safety: A Practical Approach For End-Users and System IntegratorsDocument11 pagesFunctional Safety: A Practical Approach For End-Users and System IntegratorsArif MohamedNo ratings yet

- Embedded Systems (Reference Material)Document16 pagesEmbedded Systems (Reference Material)CHANDHINI JAYARAMANNo ratings yet

- p7IL91b en USDocument1,374 pagesp7IL91b en USincontkohl606No ratings yet

- Abbrivations PDFDocument10 pagesAbbrivations PDFSuresh PasumarthiNo ratings yet

- 9 Ace 1690Document350 pages9 Ace 1690JamesonNo ratings yet

- Spartan Controls Challenges of Burner Management System ApplicationsDocument12 pagesSpartan Controls Challenges of Burner Management System ApplicationsHalimi AyoubNo ratings yet

- Pub Flame Mon UkDocument22 pagesPub Flame Mon Ukkresimir.mikoc9765No ratings yet

- Safety NoteDocument4 pagesSafety NoteAngel SantosNo ratings yet

- TSX07 Manual PDFDocument474 pagesTSX07 Manual PDFHubert Vásquez CuevaNo ratings yet

- Safety and Emergency System BypassDocument14 pagesSafety and Emergency System BypassDongjie SongNo ratings yet

- Building Management SystemDocument5 pagesBuilding Management SystemKam5381No ratings yet

- EFS.10.08.02R.1 Instr & Control Req For Packg Equip PDFDocument20 pagesEFS.10.08.02R.1 Instr & Control Req For Packg Equip PDFJithuRajNo ratings yet

- Hima Safety ConsiderationsDocument21 pagesHima Safety ConsiderationsSelva KumarNo ratings yet

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneFrom EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo ratings yet

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsFrom EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsNo ratings yet

- Toyota-Lexus Automotive SRS Air bag Repair ManualFrom EverandToyota-Lexus Automotive SRS Air bag Repair ManualRating: 5 out of 5 stars5/5 (1)

- Challenges and Approaches for Selecting, Assessing and Qualifying Commercial Industrial Digital Instrumentation and Control Equipment for Use in Nuclear Power Plant ApplicationsFrom EverandChallenges and Approaches for Selecting, Assessing and Qualifying Commercial Industrial Digital Instrumentation and Control Equipment for Use in Nuclear Power Plant ApplicationsNo ratings yet

- Computer Security Aspects of Design for Instrumentation and Control Systems at Nuclear Power PlantsFrom EverandComputer Security Aspects of Design for Instrumentation and Control Systems at Nuclear Power PlantsNo ratings yet

- USV-Unit Shut-Down ValveDocument12 pagesUSV-Unit Shut-Down ValveReguloNo ratings yet

- Utility Quick Stimate Rule of ThumbDocument11 pagesUtility Quick Stimate Rule of ThumbReguloNo ratings yet

- Pre Commissioning ProceduresDocument56 pagesPre Commissioning ProceduresRegulo100% (1)

- Dynamic BlowBy & UndercarryDocument10 pagesDynamic BlowBy & UndercarryReguloNo ratings yet

- Saudi Arabia Founding DayDocument9 pagesSaudi Arabia Founding DayReguloNo ratings yet

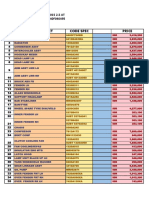

- KPI RefineriesDocument270 pagesKPI RefineriesReguloNo ratings yet

- Heating and Cooling in Greenhouses 1Document23 pagesHeating and Cooling in Greenhouses 1ReguloNo ratings yet

- Energy Performance Index-KPI SDocument12 pagesEnergy Performance Index-KPI SReguloNo ratings yet

- Unexplained Mysteries - Mona Lisa's Eyes Reveal CodeDocument33 pagesUnexplained Mysteries - Mona Lisa's Eyes Reveal CodeFirst LastNo ratings yet

- Total Width of The ACP PanelDocument8 pagesTotal Width of The ACP PanelARYA100% (1)

- Mobil PajeroDocument2 pagesMobil Pajeroesemelekete wele2No ratings yet

- The Ultimate Guide To Arduino LibraryDocument76 pagesThe Ultimate Guide To Arduino LibraryNguyễn Hòa75% (4)

- Edible PackagingDocument7 pagesEdible Packagingyouthsafetyinitiative244No ratings yet

- Ielts Writing Tu NoiDocument7 pagesIelts Writing Tu NoiQuang Anh TốngNo ratings yet

- Antares Eng Rev02Document2 pagesAntares Eng Rev02Steven BrownNo ratings yet

- Anatomy by DR Naser AlBarbariDocument24 pagesAnatomy by DR Naser AlBarbariTanmay JhulkaNo ratings yet

- Case Study TPM Jet AirwaysDocument15 pagesCase Study TPM Jet AirwaysSanjay Domdiya100% (1)

- Turbo Charger - ProjectDocument36 pagesTurbo Charger - ProjectSam Sams100% (2)

- 2017 - Electronic Control of Linear-To-circular Polarization Conversion Using A Reconfigurable MetasurfaceDocument6 pages2017 - Electronic Control of Linear-To-circular Polarization Conversion Using A Reconfigurable Metasurfaceab4azizNo ratings yet

- The Myth of PlutoDocument6 pagesThe Myth of PlutoZsuzsanna ZöldNo ratings yet

- VC - SM TransportDocument2 pagesVC - SM Transportsureshkumar mNo ratings yet

- prEN 12390-11 - DRAFTDocument32 pagesprEN 12390-11 - DRAFTCarlos GilNo ratings yet

- To Study Well Design Aspects in HPHT EnvironmentDocument40 pagesTo Study Well Design Aspects in HPHT Environmentnikhil_barshettiwat100% (1)

- Fortran CF DDocument160 pagesFortran CF DLahcen AkerkouchNo ratings yet

- What Aspects of "Life" Are Covered by Vedic AstrologyDocument4 pagesWhat Aspects of "Life" Are Covered by Vedic AstrologyMariana SantosNo ratings yet

- Substation Construction and CommissioningDocument83 pagesSubstation Construction and CommissioningShung Tak ChanNo ratings yet

- C21 - Curriculum Diploma in Mechanical EngineeringDocument118 pagesC21 - Curriculum Diploma in Mechanical EngineeringsathishkandulaNo ratings yet

- Context CluesDocument7 pagesContext CluesasherNo ratings yet

- La Belle Dame Sans MerciDocument6 pagesLa Belle Dame Sans MerciAyman HasanNo ratings yet

- Momiji North Bend MenuDocument8 pagesMomiji North Bend MenuAndy MoeNo ratings yet

- By Products of Fish and PrawnDocument9 pagesBy Products of Fish and PrawnNarasimha MurthyNo ratings yet

- Magic TutorialDocument3 pagesMagic TutorialGaurav SainiNo ratings yet

- Kaong PaperDocument10 pagesKaong PapermikxendyNo ratings yet

- Code & EthicsDocument9 pagesCode & EthicsEjaz AhmedNo ratings yet