Professional Documents

Culture Documents

SK Installation

SK Installation

Uploaded by

Jhon Jairo Arango MarquezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SK Installation

SK Installation

Uploaded by

Jhon Jairo Arango MarquezCopyright:

Available Formats

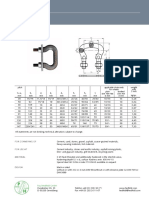

INSTALLATION DATA SHEET

Doc. No.: TI.IDS-028

SK 2005 SERIES Date: 03-09-07

Version 1.2

MODEL SK 15 SK 20

COOLING DATA:

Cooling System Available (Std.) A/C A/C

Standard Ambient Temp. Range [F] 40 - 115 40 - 115

Air inlet opening [sq. ft.] 3.2 3.8

Cooling Fan Capacity [cfm] (forced ventilation with exhaust fan) 2354 2943

Internal Cooling Fan Capacity [cfm] (exhaust air used for space heating) 1530 1648

Max. Additional Pressure Drop for Ducts [inch Water Column] 1/8 1/8

Approach Temp. [°F] 10.8 14.4

Typical Heat Rejected [BTU / HR] 43,260 53,233

Recommended Heating Duct (W x H) [in] 13 3/4 x 25 5/8 13 3/4 X 25 5/8

CONNECTIONS [in.]:

Air Discharge [NPT] 1 1

Power Input Conduit Opening(s) 1 5/8 1 5/8

NOISE LEVEL DATA:

(Measured in dB(A) at 1 m (approx. 40 in.) According to CAGI)

A/C w/Standard Cabinet 65 66

ENVELOPE DIMENSIONS & WEIGHT

Length [in.] 39 3/4 39 3/4

Width [in.] 29 1/8 29 1/8

Height [in.] 47 1/4 47 1/4

Floor Space [sq. ft.] 8.0 8.0

Weight [lbs] 710 710

Estimated Shipping Weight {lb] 763 763

ELECTRICAL DATA:

NEMA Nominal Efficiency [%] 90.2% 91.0%

Package Full Load Amps @ 208V/3ph/60 Hz/YD [FLA] 42 53

Package Full Load Amps @ 230V/3ph/60 Hz/YD [FLA] 39 51

Package Full Load Amps @ 460V/3ph/60 Hz/YD [FLA] 19 25

Package Full Load Amps @ 575V/3ph/60 Hz/YD [FLA] 16 20

Drive Motor Full Load HP 15 20

Total Package Full Load HP 15 20

Drive Motor Insulation Class F F

Drive Motor Enclosure Type TEFC TEFC

Control Cabinet Class [NEMA] 12 12

Continuous Duty [Hours / Day] 24 24

START-UP DATA:

Drive Motor Overload Set Point [A] @ 208V/3ph/60Hz/YD 27 36

Drive Motor Overload Set Point [A] @ 230V/3ph/60Hz/YD 25 32

Drive Motor Overload Set Point [A] @ 460V/3ph/60Hz/YD 12 16

Drive Motor Overload Set Point [A] @ 575V/3ph/60Hz/YD 10 13

Copyright 2007 Kaeser Compressors, Inc. Page 1 of 2

INSTALLATION DATA SHEET

Doc. No.: TI.IDS-028

SK 2005 SERIES Date: 03-09-07

Version 1.2

MODEL SK 15 SK 20

Start Timer Set-Point [sec] 6 6

Idle Timer Set-Point [min] 4 4

Recommended Disconnect Fuse Size [Amps] @ 208V/3ph/60Hz/YD * 60 70

Recommended Disconnect Fuse Size [Amps] @ 230V/3ph/60Hz/YD * 50 70

Recommended Disconnect Fuse Size [Amps] @ 460V/3ph/60Hz/YD * 25 35

Recommended Disconnect Fuse Size [Amps] @ 575V/3ph/60Hz/YD * 20 30

Recommended Disconnect Wire Size [AWG/kcmil] @ 208V/3ph/60Hz/YD ** 4 3

Recommended Disconnect Wire Size [AWG/kcmil] @ 230V/3ph/60Hz/YD ** 4 3

Recommended Disconnect Wire Size [AWG/kcmil] @ 460V/3ph/60Hz/YD ** 10 8

Recommended Disconnect Wire Size [AWG/kcmil] @ 575V/3ph/60Hz/YD ** 12 8

OIL SYSTEM DATA:

Oil System Capacity [gal.] 1.8 1.8

Typical Oil Consumption [fl. oz./100 h] 1.1 1.3

MAINTENANCE PARTS:

Air Inlet Filter 6.4161.0 6.4161.0

Filter Mat 5.3348.0 5.3348.0

Filter Mat for Control Cabinet 6.3572.0 6.3572.0

Fluid Filter 6.3462.0 6.3462.0

Fluid Separator Kit 6.3792.0 6.3792.0

Maintenance Kit for Optional 5-year Warranty AN5YRKTSK2 AN5YRKTSK2

Maintenance Kit for Optional 5-year Warranty, with food-grade lubricant AN5YRKTSK2F AN5YRKTSK2F

1. Electrical data may vary in accordance with motor manufacturer's specifications. Motors are EPACT compliant.

Main power supply and overcurrent protection must be installed by a qualified electrician in accordance with NEC, OSHA, and any applicable local codes.

* Dual-element time-delay fuse; based on 2005 NEC 240.6, 430.52, and Tables 430.52, 430.148,and 430.150.

** Based on 2005 NEC 110.14(C), 220.3, 310.15, Table 310.16, 430.6, 430.22, 430.24 and Tables 430.148 and 430.150.

Multi-strand copper core wire at 40 o C ambient temperature, with 60° temperature rating, and an insulation rating of 90 o C.

Copyright 2007 Kaeser Compressors, Inc. Page 2 of 2

You might also like

- ComfortStar CCI-CHI-2013Document5 pagesComfortStar CCI-CHI-2013batcommanderNo ratings yet

- Project Management Report For Construction of House in PakistanDocument26 pagesProject Management Report For Construction of House in PakistanEr Charmi Bhanushali100% (3)

- CZU Purlin Roll Forming MachineDocument5 pagesCZU Purlin Roll Forming MachineChris Rishbin100% (1)

- FF10HBK 115-127 V 60 HZ 1Document4 pagesFF10HBK 115-127 V 60 HZ 1Ewduard RojasNo ratings yet

- Lennox - Split Pared R-22Document2 pagesLennox - Split Pared R-22Saidy Jimena Plazas MarlesNo ratings yet

- On-SITE GUIDE BS 7671 2008 IEE Wiring Regulations 17th EditionDocument191 pagesOn-SITE GUIDE BS 7671 2008 IEE Wiring Regulations 17th EditionIraklis Komodromos88% (48)

- Installation Data Sheet: SX With Kaeser ControlDocument2 pagesInstallation Data Sheet: SX With Kaeser ControlaniballllcNo ratings yet

- SM T - Series tcm91 82434Document2 pagesSM T - Series tcm91 82434ANDRESNo ratings yet

- CSD100T 125T tcm91 38205Document3 pagesCSD100T 125T tcm91 38205ANDRESNo ratings yet

- Creation Inverter CatalogueDocument2 pagesCreation Inverter CatalogueEbraheem GawadNo ratings yet

- Manual Toshiba Aire Acondicionado f1229975889Document96 pagesManual Toshiba Aire Acondicionado f1229975889Nome Llamo AsiNo ratings yet

- F35HC 213 e 7Document2 pagesF35HC 213 e 7วงศกร สิงห์เอี่ยมNo ratings yet

- EMT65HLR 220-240V 50Hz 513300104Document3 pagesEMT65HLR 220-240V 50Hz 513300104shohidul5400aNo ratings yet

- Samsung VRF HEAT PUMP - AM100AXVANH - TL - Samsung Business IndiaDocument4 pagesSamsung VRF HEAT PUMP - AM100AXVANH - TL - Samsung Business Indiachandravadiyaketan1504No ratings yet

- Samsung Final VRFDocument4 pagesSamsung Final VRFchandravadiyaketan1504No ratings yet

- VRV Technology in A Compact Size.: VRVIII-S 208-230V Heat PumpDocument1 pageVRV Technology in A Compact Size.: VRVIII-S 208-230V Heat PumpJosephRusselVizmanosNo ratings yet

- Haier Esa-3065-3085 hwr08xc5 Window-Type Air Conditioner 2004 SM PDFDocument21 pagesHaier Esa-3065-3085 hwr08xc5 Window-Type Air Conditioner 2004 SM PDFhernandez.josedomingo6804No ratings yet

- Spec en 4K40Z02306P1-06Document23 pagesSpec en 4K40Z02306P1-06Ageng A. PooNo ratings yet

- Spec en 4H40Z02304P1-07Document23 pagesSpec en 4H40Z02304P1-07Ageng A. PooNo ratings yet

- NT 2178 GKDocument3 pagesNT 2178 GKAlla weerNo ratings yet

- Spec en 4G40Z02312P1-05Document23 pagesSpec en 4G40Z02312P1-05Ageng A. PooNo ratings yet

- FFU130HAX 115-127 V 60 HZ 1Document3 pagesFFU130HAX 115-127 V 60 HZ 1friofer2014No ratings yet

- F27HC 46 e 7Document2 pagesF27HC 46 e 7วงศกร สิงห์เอี่ยมNo ratings yet

- Multi F Mu3m21 English SMDocument8 pagesMulti F Mu3m21 English SMAlexandre GomesNo ratings yet

- Carrier Brochure InverterDocument2 pagesCarrier Brochure InverterakashmalayiNo ratings yet

- 2010-5 Service lcn246hv Ceiling-Cassette Indoor mfl62129309 20120105132900Document7 pages2010-5 Service lcn246hv Ceiling-Cassette Indoor mfl62129309 20120105132900joko riyantoNo ratings yet

- Technical Specifications 24000btuhr Wall Mount Gree ACsDocument7 pagesTechnical Specifications 24000btuhr Wall Mount Gree ACsNelson Mukwaya100% (1)

- Copeland CR22K6E PFV 875 Submittal SheetDocument3 pagesCopeland CR22K6E PFV 875 Submittal SheetDraganNo ratings yet

- Superior Technology For Superior Cooling: Range Available in 1.0, 1.5, 2.0 and 2.5 TRDocument2 pagesSuperior Technology For Superior Cooling: Range Available in 1.0, 1.5, 2.0 and 2.5 TRnizamudheen mnNo ratings yet

- Databook Quhz-W40vha Aug2016Document72 pagesDatabook Quhz-W40vha Aug2016Vishal KhiroyaNo ratings yet

- Matushima Servicemanual UkDocument30 pagesMatushima Servicemanual Ukgeorge dimopoulosNo ratings yet

- AM054KNMDCH1AZDocument3 pagesAM054KNMDCH1AZaandresleo86No ratings yet

- FT004256 1Document3 pagesFT004256 1cuellarcuellarNo ratings yet

- Vivax Acp-12ch35gei Service ManualDocument67 pagesVivax Acp-12ch35gei Service Manualdrm_gNo ratings yet

- Submittal Form: Indoor: Outdoor: Model #Document2 pagesSubmittal Form: Indoor: Outdoor: Model #George H. Gutierrez, PECSANo ratings yet

- 038A Hitachi Summit Models 18 To 50 FH6 and FH7 PDFDocument5 pages038A Hitachi Summit Models 18 To 50 FH6 and FH7 PDFMechanical PowerNo ratings yet

- 038A Hitachi Summit Models 18 To 50 FH6 and FH7 - 2Document5 pages038A Hitachi Summit Models 18 To 50 FH6 and FH7 - 2Mechanical PowerNo ratings yet

- Technical Service Manual For 13 SEER ComfortStarDocument34 pagesTechnical Service Manual For 13 SEER ComfortStartitomotta0% (2)

- 04-Im-Daikin Evaporadora Piso TechoDocument1 page04-Im-Daikin Evaporadora Piso TechoJulio RiveraNo ratings yet

- High Wall Unit: 42KHF / 42QHFDocument2 pagesHigh Wall Unit: 42KHF / 42QHFAhmed ElsayedNo ratings yet

- FFU160HAX 220 V 60 HZ 1Document3 pagesFFU160HAX 220 V 60 HZ 1Amauri RogérioNo ratings yet

- EMI70UERDocument4 pagesEMI70UERsantiago alberto perez moraNo ratings yet

- Spec en 4L40Z02307P1-06Document27 pagesSpec en 4L40Z02307P1-06Ageng A. PooNo ratings yet

- DatasheetDocument3 pagesDatasheetCharles NaloNo ratings yet

- Compressor Technical DataDocument3 pagesCompressor Technical DataGabriel RodriguezNo ratings yet

- F35HC 94 e 7Document2 pagesF35HC 94 e 7วงศกร สิงห์เอี่ยมNo ratings yet

- Service Manual For DEKKER PDFDocument29 pagesService Manual For DEKKER PDFEmre OzyetkinNo ratings yet

- Compressor Technical Data: NJ6226Z 220-240 V 50 HZ 142HAO4 A - Application / Limit Working ConditionsDocument3 pagesCompressor Technical Data: NJ6226Z 220-240 V 50 HZ 142HAO4 A - Application / Limit Working ConditionsFernando GomezNo ratings yet

- Samsung 4 Way Mini Wind Free Inveter CassetteDocument2 pagesSamsung 4 Way Mini Wind Free Inveter CassetteCJ SnipesNo ratings yet

- TBHD - 11132023 - Performance Data Sheet-1-2-1Document1 pageTBHD - 11132023 - Performance Data Sheet-1-2-1stronginternacionalhondurasNo ratings yet

- NJ9226E 208-230 V 60 HZ 1Document4 pagesNJ9226E 208-230 V 60 HZ 1Leonardo GiarolaNo ratings yet

- EGAS100HLR 115V 60HzDocument3 pagesEGAS100HLR 115V 60HzWillis PinedaNo ratings yet

- Creation Inverter-2020Document2 pagesCreation Inverter-2020maqsood ahmedNo ratings yet

- EDMFMT391803A - Indoor Unit FXMQ-PVMDocument4 pagesEDMFMT391803A - Indoor Unit FXMQ-PVMsurya liemzNo ratings yet

- Cassette Inverter (2020) Technical Specification SheetDocument1 pageCassette Inverter (2020) Technical Specification SheetOwais AhmedNo ratings yet

- ED-UCCP-201401A-Packaged Water Cool PDFDocument38 pagesED-UCCP-201401A-Packaged Water Cool PDFHui HuaNo ratings yet

- Specifications Cassette Type ON OFFDocument2 pagesSpecifications Cassette Type ON OFFRavi SoondurNo ratings yet

- Bam F-Hvac - 001Document117 pagesBam F-Hvac - 001Claudino Gonçalves100% (1)

- Specification Sheet Electroheat Pro150 50Hz Heat Cool Dec 2021Document3 pagesSpecification Sheet Electroheat Pro150 50Hz Heat Cool Dec 2021claverNo ratings yet

- Specification Sheet Electroheat Pro 110kW 50Hz Heat Cool Dec 2021Document3 pagesSpecification Sheet Electroheat Pro 110kW 50Hz Heat Cool Dec 2021claverNo ratings yet

- FGS80HAS 100 V 50-60 HZ 1Document3 pagesFGS80HAS 100 V 50-60 HZ 1Tomas GuaiquireNo ratings yet

- Falk Ultramite UB Right Angle Helical Bevel Gear Drive: (Inch)Document72 pagesFalk Ultramite UB Right Angle Helical Bevel Gear Drive: (Inch)Jhon Jairo Arango MarquezNo ratings yet

- MasterlisDocument76 pagesMasterlisJhon Jairo Arango MarquezNo ratings yet

- UCFC 215: Round Flange Ball Bearing Unit With Extended Inner Ring and Set Screw Locking, Cast Iron Housing, JISDocument6 pagesUCFC 215: Round Flange Ball Bearing Unit With Extended Inner Ring and Set Screw Locking, Cast Iron Housing, JISJhon Jairo Arango MarquezNo ratings yet

- QD SheaDocument21 pagesQD SheaJhon Jairo Arango MarquezNo ratings yet

- Valv CompuertaDocument1 pageValv CompuertaJhon Jairo Arango MarquezNo ratings yet

- Steel Classe 150Document1 pageSteel Classe 150Jhon Jairo Arango MarquezNo ratings yet

- INTEGRADocument24 pagesINTEGRAJhon Jairo Arango MarquezNo ratings yet

- USRWATERBORNDocument6 pagesUSRWATERBORNJhon Jairo Arango MarquezNo ratings yet

- Sihi Supernova: Modular Industrial PumpsDocument12 pagesSihi Supernova: Modular Industrial PumpsJhon Jairo Arango MarquezNo ratings yet

- SphericalDocument11 pagesSphericalJhon Jairo Arango MarquezNo ratings yet

- VDS Recommendations Hand Arm VibrationDocument1 pageVDS Recommendations Hand Arm VibrationJhon Jairo Arango MarquezNo ratings yet

- Kito RingsDocument1 pageKito RingsJhon Jairo Arango MarquezNo ratings yet

- DimensionesDocument1 pageDimensionesJhon Jairo Arango MarquezNo ratings yet

- Liquid Ring Compressor: KLH 47005, KLH 47105Document8 pagesLiquid Ring Compressor: KLH 47005, KLH 47105Jhon Jairo Arango MarquezNo ratings yet

- Activated CarboDocument2 pagesActivated CarboJhon Jairo Arango MarquezNo ratings yet

- Series Basic Model InstallationDocument1 pageSeries Basic Model InstallationJhon Jairo Arango MarquezNo ratings yet

- ScrewsDocument1 pageScrewsJhon Jairo Arango MarquezNo ratings yet

- 0421 en TransportadoresDocument4 pages0421 en TransportadoresJhon Jairo Arango MarquezNo ratings yet

- ES ES ES ES ES: Tubular Cement - Flyash Screw ConveyorsDocument53 pagesES ES ES ES ES: Tubular Cement - Flyash Screw ConveyorsJhon Jairo Arango MarquezNo ratings yet

- LanchaDocument48 pagesLanchaJhon Jairo Arango MarquezNo ratings yet

- CHAINDocument4 pagesCHAINJhon Jairo Arango MarquezNo ratings yet

- Grundfos Packaged Solutions: Grundfos Americas Brookshire, TX 77423 WWW - Grundfos.usDocument8 pagesGrundfos Packaged Solutions: Grundfos Americas Brookshire, TX 77423 WWW - Grundfos.usJhon Jairo Arango MarquezNo ratings yet

- ElevatorsDocument1 pageElevatorsJhon Jairo Arango MarquezNo ratings yet

- Zapchasti 2500Document100 pagesZapchasti 2500Jhon Jairo Arango MarquezNo ratings yet

- ELEVATORDocument1 pageELEVATORJhon Jairo Arango MarquezNo ratings yet

- Esab /oxweld Esab /oxweld: Style Replacement Tips Style Replacement TipsDocument1 pageEsab /oxweld Esab /oxweld: Style Replacement Tips Style Replacement TipsJhon Jairo Arango MarquezNo ratings yet

- End Suction Pump: Key Features and BenefitsDocument2 pagesEnd Suction Pump: Key Features and BenefitsJhon Jairo Arango MarquezNo ratings yet

- Aerospace Acronym & Abbreviation GuideDocument44 pagesAerospace Acronym & Abbreviation GuideArun JayankondanNo ratings yet

- Antenna PortsDocument5 pagesAntenna PortsmoqcuhlxqxklntbfexNo ratings yet

- Usb Rly08 CDocument4 pagesUsb Rly08 Caghamdi2206No ratings yet

- Faro Laser Scanner Focus 70Document2 pagesFaro Laser Scanner Focus 70malchukNo ratings yet

- Registration For Aristok Technologies Recruitment Drive-2024 Graduating BatchDocument2 pagesRegistration For Aristok Technologies Recruitment Drive-2024 Graduating Batchshashiranjan3713No ratings yet

- Tutorial 3: Bmit3094 Advanced Computer NetworksDocument2 pagesTutorial 3: Bmit3094 Advanced Computer Networksterence yapNo ratings yet

- Sophos Switch Ds PDFDocument6 pagesSophos Switch Ds PDFRoger PrimoNo ratings yet

- IT-205 (OS) Course OutlineDocument3 pagesIT-205 (OS) Course OutlineWaleed HussainNo ratings yet

- Seguridad Electronica Control de AccesoDocument39 pagesSeguridad Electronica Control de AccesoChristians Pacco TaipeNo ratings yet

- Comp Network Ass 1 v2Document23 pagesComp Network Ass 1 v2Uchi RomeoNo ratings yet

- 1 - 1946 - B7 - NTC AmendmentsDocument13 pages1 - 1946 - B7 - NTC AmendmentsVilma Santos RectoNo ratings yet

- Ans IP AISSCE Practical Exam 2023Document7 pagesAns IP AISSCE Practical Exam 2023Bunny KanungoNo ratings yet

- XTM ManualDocument387 pagesXTM ManualFernanda SosaNo ratings yet

- 13-Chapter 13 - TransistorsDocument28 pages13-Chapter 13 - Transistorssrinu247100% (3)

- 18 - T3k Canvas - ENDocument4 pages18 - T3k Canvas - ENTran Nhat NamNo ratings yet

- Week 2Document24 pagesWeek 27x6t2v4j6xNo ratings yet

- Sag GeneratorDocument8 pagesSag GeneratorMadhu BalajiNo ratings yet

- CIS QuizDocument1 pageCIS QuizElyssaNo ratings yet

- 7442 Datasheet PDFDocument4 pages7442 Datasheet PDFPerezNo ratings yet

- CASY - ModelTT - CustomerTrainingGuideDocument96 pagesCASY - ModelTT - CustomerTrainingGuideGeovanniNo ratings yet

- GSM Network ArchitectureDocument55 pagesGSM Network Architecturealeesha1987No ratings yet

- Cyber SecurityDocument23 pagesCyber SecurityAvi SharanNo ratings yet

- Signal Conditioning Failure Modes 2Document8 pagesSignal Conditioning Failure Modes 2Raluca EftimoiuNo ratings yet

- Release Note Update: Truportal™ 1.8.0Document2 pagesRelease Note Update: Truportal™ 1.8.0Edwin LinNo ratings yet

- Morphoaccess-Sigma-Lite-Ds r01 LT en PDFDocument2 pagesMorphoaccess-Sigma-Lite-Ds r01 LT en PDFJose Flavio GonçaloNo ratings yet

- Huawei Guide M2000Document127 pagesHuawei Guide M2000Aayush1988No ratings yet

- A Novel Two-Factor Honeytoken Authentication Mechanism: Vassilis Papaspirou Leandros Maglaras Mohamed Amine FerragDocument7 pagesA Novel Two-Factor Honeytoken Authentication Mechanism: Vassilis Papaspirou Leandros Maglaras Mohamed Amine Ferraglola yupNo ratings yet