Professional Documents

Culture Documents

DS1081 LPCO2 Refrigerated Storage Units Revision 07-18-18

DS1081 LPCO2 Refrigerated Storage Units Revision 07-18-18

Uploaded by

kidmuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DS1081 LPCO2 Refrigerated Storage Units Revision 07-18-18

DS1081 LPCO2 Refrigerated Storage Units Revision 07-18-18

Uploaded by

kidmuCopyright:

Available Formats

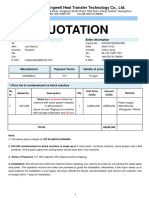

LPCO2 System

Refrigerated Storage Units

Janus Fire Systems® Low Pressure Carbon Dioxide Refrigerated Storage Units are specifically de-

signed to store the carbon dioxide agent supply utilized in the Janus Fire Systems® Low Pressure

Carbon Dioxide Fire Extinguishing System. Each storage unit consists of an insulated pressure

vessel, outer shell, integrated refrigeration unit, ASME safety relief and bleeder valve(s), and liquid

level and pressure gauges. Each unit has appropriately sized piping outlets for filling, discharge of

CO2, and connection of the extinguishing system vapor supply. Janus Fire Systems® Low Pressure

Carbon Dioxide Refrigerated Storage Units have capacities that range from 1.25 to 38 tons.

FEATURES

The pressure vessel is built in accordance with Section VIII, Division 1 of the ASME Code for Un-

fired Pressure Vessels. A 4 in (102 mm) layer of polyurethane acts as insulation between the vessel

and the painted steel (10-gauge) outer housing.

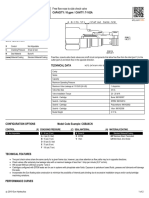

Liquid Level

Indicator

1/2” (15 mm) Pressure Refrigeration

Pilot Supply Gauge Housing

Lockout Valve

w/ Limit Switch

Safety Relief

Valve 1” (25 mm) Vapor

Equalizing Line w/

CGA Fitting

Bleeder Valve

Safety Relief

Valve

Flanged CO2 Lifting

Discharge Outlet Lugs

(Size Varies) 1-1/2” (40 mm)

Liquid Fill Line

w/ CGA Fitting

2” (50 mm)

Auxiliary Liquid Outlet

Tank

Saddles

Typical Low Pressure Carbon Dioxide Storage Unit

DS1081 Revised: 18-Jul-2018 © 2009 Janus Fire Systems. All rights reserved (2/2009) Janus Fire Systems® is a registered trademark of Janus Fire Systems.

The vessel has an integrated refrigeration system that utilizes CFC-free R-404A refrigerant. A pres-

sure switch monitors the internal pressure of the vessel and controls the refrigeration compressor.

The optimal internal pressure is 300 psi (20.7 bar). The refrigeration coils are located in the pres-

sure vessel vapor space to provide the required cooling of the CO2 vapor. When the CO2 pressure

within the vessel reaches approximately 310 psi (21.4 bar), the pressure switch closes starting

the compressor. It continues running, cooling the CO2 until pressure within the vessel drops to ap-

proximately 290 psi (20.0 bar) at which point the pressure switch opens and the compressor stops

operating. An optional external tank heater is available to maintain CO2 pressure in severe low

temperatures and is recommended where temperatures are below -10°F (-23.3°C) for seven (7)

consecutive days.

Each storage unit is fitted with pressure and liquid level gauges. In the event of power failure, a

bleeder valve set at 341 psi (23.5 bar) allows a small amount of vaporous CO2 to bleed out of the

vapor space providing natural cooling of the liquid CO2 within the vessel. An ASME VIII approved

safety valve provides emergency pressure relief should the bleeder valve be unable to maintain the

CO2 pressure and is set to open at 357 psi (24.6 bar).

The standard voltage for 42” storage units is 120V, 1 phase, 60 Hz, while the 54” and 78” storage

units are 460V, 3 phase, 60 Hz. Alternative voltage refrigeration systems are available.

Optional dual refrigeration units are available. Each refrigeration unit for this option is designed to

operate as a standalone system with individual refrigeration compressors, controls, and coils. The

refrigeration controls operate both refrigeration units independently to enable the units to cycle

separately. The refrigeration system has a separate pressure control switch set at approximately

325 psi (22.4 bar) rise to operate both units simultaneously should a high ambient condition require

additional cooling capacity.

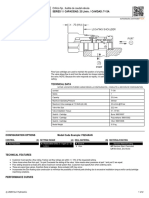

Refrigeration

Condensing Unit Refrigeration

Housing

Refrigeration

Base

CO

2 Va

por

CO

2 Liq

uid

Outer

Shell 4” (102 mm) Thick

Polyurethane Insulating Foam

Pressure

Vessel

Refrigeration Manway

Evaporator Coil Cover

Typical Low Pressure Carbon Dioxide Storage Unit Interior View

DS1081 Revised: 18-Jul-2018 Page 2 of 8

42” LPCO2 Storage Unit

4" (100 mm)

D

Discharge

E

Outlet

63.80 in

1621 mm

52.00 in

1321 mm

33.00 in

838 mm

21.00 in

533 mm

6.00 in

B C 152 mm

78.57 in

1996 mm

9.75 in

248 mm

4.00 in

102 mm 54.00 in

1.00 in 1372 mm

25 mm 0.63 in

1.00 in 16 mm

25 mm TYP.

52.00 in

1321 mm

50.00 in 55.06 in

1270 mm 1398 mm

Dimensions Empty

Nominal

Tank P/N A B C D E Weight

Capacity

in mm in mm in mm in mm in mm lb kg

1.25 ton 19354 98.5 2502 25.0 636 35.0 889 N/A¹ N/A¹ 20.8 528 3025 1372

2.75 ton 19355 158.7 4030 44.5 1131 56.0 1422 34.5 876 24.5 623 4950 2245

¹ 1.25-Ton Storage Unit only contains one lifting lug.

DS1081 Revised: 18-Jul-2018 Page 3 of 8

54” LPCO2 Storage Unit

D

6" (150 mm)

Discharge C

32.50 in

826 mm Outlet

E

78.80 in

2002 mm

67.00 in

1702 mm

42.00 in

1067 mm

30.00 in

762 mm

10.00 in

F B 254 mm

78.57 in

1996 mm

9.75 in

248 mm

54.00 in

4.00 in 1372 mm

102 mm

1.00 in

25 mm 0.63 in

1.00 in 16 mm

25 mm TYP.

52.00 in

1321 mm

50.00 in 55.06 in

1270 mm 1398 mm

Dimensions Empty

Nominal

Tank P/N A B C D E F Weight

Capacity

in mm in mm in mm in mm in mm in mm lb kg

4 ton 19356 145.6 3698 58.0 1473 8.0 203 51.4 1306 24.0 610 40.2 1021 7250 3289

6 ton 19357 201.0 5105 69.5 1765 13.0 330 54.4 1382 63.5 1613 59.2 1504 9000 4082

8 ton 19358 257.5 6541 123.3 3132 13.0 330 46.4 1179 76.0 1930 60.6 1539 11000 4989

10 ton 19359 309.2 7854 156.3 3970 13.0 330 46.2 1173 116.5 2959 66.0 1676 12500 5670

12 ton 19360 370.0 9398 221.8 5634 36.0 914 949.9 2410 178.1 4524 65.8 1671 14500 6576

DS1081 Revised: 18-Jul-2018 Page 4 of 8

78” LPCO2 Storage Unit

14.00 in 1.25 in

2.00 in 356 mm 32 mm

51 mm TYP.

8.00 in 50.97 in

203 mm 1295 mm

6.00 in

152 mm

87.38 in 44.00 in 88.30 in

2219 mm 1118 mm 2243 mm

111.00 in

2819 mm

8" (200 mm)

Flanged CO2

Discharge Outlet

20.81 in

528 mm

72.00 in

1829 mm

44.00 in C

1118 mm

61.57 in

1564 mm

103.36 in

2625 mm 95.37 in

2422 mm

72.58 in

1843 mm

54.50 in

1384 mm

42.50 in

1079 mm

2.40 in

61 mm 18.00 in

457 mm

62.18 in B

1579 mm

Nominal Dimensions Empty

Tank P/N A B C Weight

Capacity in mm in mm in mm lb kg

13 ton 97492 251.34 6384 63 1600 50 1270 14565 6606

17 ton 19361 299.34 7603 111 2819 78 1981 17186 7795

24 ton 19362 392.34 9965 204 5182 120 3048 22012 9984

31 ton 19363 476.34 12099 288 7315 180 4572 26448 11996

38 ton 19364 565.34 14360 377 9576 252 6401 31149 14128

DS1081 Revised: 18-Jul-2018 Page 5 of 8

Ordering Information (42” Low Pressure Carbon Dioxide Storage Units)

P/N Tank Size Description (see below for options)

19354 1.25 ton Storage Unit, LPCO2, 42”

19355 2.75 ton Storage Unit, LPCO2, 42”

Ordering Instructions: Specify the LPCO2 Storage Unit P/N followed by a dash and the

appropriate three digit option code as illustrated below.

Liquid Level Gauge Options:

0 = Standard (Liquid Level Gauge w/ Contacts)

P/N as indicated above A = Liquid Level Gauge w/ 4-20 mA output

XXXXX-XXX Paint Color Options:

A = Red

B = White

Condensing Unit Options: S = Special

A = 3/4 HP – 115 V – 1 PH

B = 3/4 HP – 230 V – 1 PH

C = 3/4 HP – 230 V – 3 PH

Note:

All condensing units operate at both 50Hz and 60Hz. However, operating at

50Hz reduces the refrigeration capacity to 83%

Examples:

19354-C0B – Storage Unit, LPCO2, 42”, 1.25 ton, 230 V, 3 PH, 3/4 HP,

Standard LLG, White

19355-AAB – Storage Unit, LPCO2, 42”, 2.75 ton, 115 V, 1 PH, 3/4 HP,

LLG w/ 4-20 mA output, White

DS1081 Revised: 18-Jul-2018 Page 6 of 8

Ordering Information (54” Low Pressure Carbon Dioxide Storage Units)

P/N Tank Size Description (see below for options)

19356 4 ton Storage Unit, LPCO2, 54”

19357 6 ton Storage Unit, LPCO2, 54”

19358 8 ton Storage Unit, LPCO2, 54”

19359 10 ton Storage Unit, LPCO2, 54”

19360 12 ton Storage Unit, LPCO2, 54"

Ordering Instructions: Specify the LPCO2 Storage Unit P/N followed by a dash and the

appropriate three digit option code as illustrated below.

Liquid Level Gauge Options:

0 = Standard (Liquid Level Gauge w/ Contacts)

P/N as indicated above A = Liquid Level Gauge w/ 4-20 mA output

XXXXX-XXX Paint Color Options:

A = Red

B = White

Condensing Unit Options: S = Special

D = 1-1/2 HP – 230 V – 1 PH

E = 1-1/2 HP – 230 V – 3 PH

F = 1-1/2 HP – 380/460 V – 3 PH

G = 2 HP – 230 V – 1 PH

H = 2 HP – 230 V – 3 PH

I = 2 HP – 380/460 V – 3 PH

J = 2 HP – 575 V – 3 PH

Notes:

2 Horse Power Condensing Units are standard for 4,6, 8, 10, and 12-Ton Stor-

age Units.

All condensing units operate at both 50Hz and 60Hz. However, operating at

50Hz reduces the refrigeration capacity to 83%

Examples:

19357-G0B – Storage Unit, LPCO2, 54”, 6 ton, 230 V, 1 PH, 2 HP, Standard

LLG, White

19358-JAB – Storage Unit, LPCO2, 54”, 8 ton, 575 V, 3 PH, 2 HP, LLG w/

4-20 mA output, White

DS1081 Revised: 18-Jul-2018 Page 7 of 8

Ordering Information (78” Low Pressure Carbon Dioxide Storage Units)

P/N Tank Size Description (see below for options)

97492 13 ton Storage Unit, LPCO2, 78”

19361 17 ton Storage Unit, LPCO2, 78”

19362 24 ton Storage Unit, LPCO2, 78”

19363 31 ton Storage Unit, LPCO2, 78”

19364 38 ton Storage Unit, LPCO2, 78”

Ordering Instructions: Specify the LPCO2 Storage Unit P/N followed by a dash and the

appropriate three digit option code as illustrated below.

Liquid Level Gauge Options:

0 = Standard (Liquid Level Gauge w/ Contacts)

P/N as indicated above A = Liquid Level Gauge w/ 4-20 mA output

XXXXX-XXX Paint Color Options:

A = Red

B = White

Condensing Unit Options: S = Special

K = 3 HP – 230 V – 3 PH

L = 3 HP – 380/460 V – 3 PH

M = 3 HP – 575 V – 3 PH

N = 4 HP – 230 V – 3 PH

O = 4 HP – 380/460 V – 3 PH

P = 4 HP – 575 V – 3 PH

Q = 6 HP – 230 V – 3 PH

R = 6 HP – 380/460 V – 3 PH

S = 6 HP – 575 V – 3 PH

Notes:

3 Horse Power Condensing Units are standard for 13, 17, and 24-Ton Storage

Units.

6 Horse Power Condensing Units are standard for 31 and 38-Ton Storage Units.

All condensing units operate at both 50Hz and 60Hz. However, operating at 50Hz

reduces the refrigeration capacity to 83%

Examples:

19361-K0B – Storage Unit, LPCO2, 78”, 17 ton, 230 V, 3 PH, 3 HP, Standard

LLG, White

19364-SAB – Storage Unit, LPCO2, 78”, 38 ton, 575 V, 3 PH, 6 HP, LLG w/

4-20 mA output, White

The seller makes no warranties, express or implied, including, but not limited to, the implied warranties of merchantability and

fitness for a particular purpose, except as expressly stated in the seller’s sales contract or sales acknowledgment form. Every

attempt is made to keep our product information up-to-date and accurate. All specific applications cannot be covered, nor can

all requirements be anticipated. All specifications are subject to change without notice.

1102 Rupcich Drive

Millennium Park

Crown Point, IN 46307

TEL: (219) 663-1600 FAX: (219) 663-4562

e-mail: info@janusfiresystems.com

www.janusfiresystems.com

DS1081 Revised: 18-Jul-2018 Page 8 of 8

You might also like

- DWM Copeland ManualDocument43 pagesDWM Copeland ManualChristopher Romero100% (10)

- Bauer Air CompressorDocument46 pagesBauer Air CompressorEdward FernandezNo ratings yet

- Lpco System System: Refrigerated Storage UnitsDocument8 pagesLpco System System: Refrigerated Storage UnitsSICISA Diseño ArquitectonicoNo ratings yet

- Co2 Components-ServvoDocument1 pageCo2 Components-ServvorizaNo ratings yet

- Ensemble Clapet Et VanneDocument4 pagesEnsemble Clapet Et VannegwinnruNo ratings yet

- BONTAZ BU-FCH - Leaflet Hydrogen Loop - H2 & Drain Valves 2023-06Document2 pagesBONTAZ BU-FCH - Leaflet Hydrogen Loop - H2 & Drain Valves 2023-06KEL INo ratings yet

- CXDAXCN Full Es Metric A4Document2 pagesCXDAXCN Full Es Metric A4Sara SaritaNo ratings yet

- SD fs481v enDocument1 pageSD fs481v enZsolt Péter WalterNo ratings yet

- Flanges - Flange JIS 5K & 10KDocument3 pagesFlanges - Flange JIS 5K & 10KRestu UmarNo ratings yet

- Mooney 1" Flowgrid Regulator: With Shutoff ValveDocument2 pagesMooney 1" Flowgrid Regulator: With Shutoff ValveLuis Alberto Portugal MariacalNo ratings yet

- Autoclave Full CatalogDocument481 pagesAutoclave Full CatalogGabriel Jamariqueli BueresNo ratings yet

- 13-PRCBD-INS-FS-200 - PRESSURE GAUGE (PRC-Biodiesel-022)Document2 pages13-PRCBD-INS-FS-200 - PRESSURE GAUGE (PRC-Biodiesel-022)firman harianjaNo ratings yet

- 30 PR (D) PDFDocument1 page30 PR (D) PDFhoussem houssemNo ratings yet

- Model Back-To-Back Check/shuttle Valve With Signal at Port 2Document2 pagesModel Back-To-Back Check/shuttle Valve With Signal at Port 2Erasmo LimaNo ratings yet

- Mechanical Booster Pump PRC APMB CM SeriesDocument4 pagesMechanical Booster Pump PRC APMB CM Seriesagustya alifia el hakimNo ratings yet

- Model Closed Center, Flow Divider-Combiner Valve: Series 2 / Capacity: 3 - 15 GPM / Cavity: T-32ADocument2 pagesModel Closed Center, Flow Divider-Combiner Valve: Series 2 / Capacity: 3 - 15 GPM / Cavity: T-32AAnurag JainNo ratings yet

- Hydraulic Reservoir, Filter, and Cooling System: Better Performance Compact Design Increased Durability Easy InstallationDocument2 pagesHydraulic Reservoir, Filter, and Cooling System: Better Performance Compact Design Increased Durability Easy InstallationAndy ChalifouxNo ratings yet

- SUBMERSUBAL PUMP SeriesDocument1 pageSUBMERSUBAL PUMP SeriesYehude Guillen RomeroNo ratings yet

- TEV Ammonia SporlanDocument5 pagesTEV Ammonia SporlanDrew CruzNo ratings yet

- RGFA Full en Metric LetterDocument4 pagesRGFA Full en Metric LetteressamNo ratings yet

- CVCV Full en Metric A4Document2 pagesCVCV Full en Metric A4Ηρακλης ΤσαπραζηςNo ratings yet

- 3908 SL DatasheetDocument2 pages3908 SL DatasheetspammaniiNo ratings yet

- R514A CVHE Centravac Centrifugal Chiller Dimension DrawingsDocument13 pagesR514A CVHE Centravac Centrifugal Chiller Dimension DrawingsBegundalz PotterNo ratings yet

- Sun Cartridge CXDA-XCNDocument2 pagesSun Cartridge CXDA-XCNJustinNo ratings yet

- Surface Blowdown System: General FeaturesDocument5 pagesSurface Blowdown System: General FeaturesCristopher LobosNo ratings yet

- Model Free Flow Nose To Side Check Valve: CAPACITY: 10 GPM / CAVITY: T-162ADocument2 pagesModel Free Flow Nose To Side Check Valve: CAPACITY: 10 GPM / CAVITY: T-162AsnsnagarajanNo ratings yet

- FMC 200 Hyd 304 - 04 13Document2 pagesFMC 200 Hyd 304 - 04 13Jhon HernandezNo ratings yet

- Model Pilot-To-Close Check Valve: Series 1 / Capacity: 20 GPM / Cavity: T-11ADocument2 pagesModel Pilot-To-Close Check Valve: Series 1 / Capacity: 20 GPM / Cavity: T-11AErasmo LimaNo ratings yet

- SD fh430v enDocument1 pageSD fh430v enAlex MđäNo ratings yet

- CKBDXCV ApDocument2 pagesCKBDXCV ApŁukasz OlszewskiNo ratings yet

- Surface Condenser Specification Sheet: DesignDocument1 pageSurface Condenser Specification Sheet: DesignboeiniNo ratings yet

- 6 9 p0527 0554 LVM - enDocument28 pages6 9 p0527 0554 LVM - enchandraNo ratings yet

- TA-22ML Catalog enDocument2 pagesTA-22ML Catalog enDedi KartiwaNo ratings yet

- Sediment Trap: FeaturesDocument3 pagesSediment Trap: Featurespnoc.kblduenasNo ratings yet

- CODA Full en Us LetterDocument2 pagesCODA Full en Us Lettercesar5984No ratings yet

- Service Data Sheet: Fj180V KaiDocument1 pageService Data Sheet: Fj180V KaiThong KimNo ratings yet

- Float Guided Switch Catalogue RadixDocument2 pagesFloat Guided Switch Catalogue RadixArjun BharambeNo ratings yet

- HD263Document8 pagesHD263Ahamed IbrahimNo ratings yet

- Twinact & Uniact Relief Valve Catalogue - FORT - VALEDocument32 pagesTwinact & Uniact Relief Valve Catalogue - FORT - VALEMiguel GonzálezNo ratings yet

- CXHAXAN - Full - en - Metric - Letter BorbetDocument2 pagesCXHAXAN - Full - en - Metric - Letter BorbetRonaldNo ratings yet

- FQCA Full Es Metric A4Document2 pagesFQCA Full Es Metric A4Sara SaritaNo ratings yet

- Technical Sheet Vacuum Tube Collectors CVTDocument2 pagesTechnical Sheet Vacuum Tube Collectors CVTgonzalez2678No ratings yet

- CV20-25 Double Plate CheckvalveDocument5 pagesCV20-25 Double Plate CheckvalveVlad AncutaNo ratings yet

- Cylinder Head: ComponentsDocument3 pagesCylinder Head: ComponentsZainul ArifinNo ratings yet

- Specifications, Applications, Service Instructions & Parts: Pressure-Relief ValveDocument4 pagesSpecifications, Applications, Service Instructions & Parts: Pressure-Relief Valvejohn jimenezNo ratings yet

- LOGIC CARTRIDGE LODCXDN - Full - en - Us - LetterDocument2 pagesLOGIC CARTRIDGE LODCXDN - Full - en - Us - LetterHassan KhattabNo ratings yet

- 210 прямого действияDocument2 pages210 прямого действияAlexanderNo ratings yet

- Parker Pneumatic LV / EZ Series Lockout Valves: Material Specifications Operating InformationDocument2 pagesParker Pneumatic LV / EZ Series Lockout Valves: Material Specifications Operating InformationSoriSori2008No ratings yet

- KSB Sicca HP Cast Gate Valve PDFDocument4 pagesKSB Sicca HP Cast Gate Valve PDFJamalNo ratings yet

- Model Flow Divider Valve: Series 2 / Capacity: 3 - 15 GPM / Cavity: T-32ADocument2 pagesModel Flow Divider Valve: Series 2 / Capacity: 3 - 15 GPM / Cavity: T-32AErasmo LimaNo ratings yet

- Model Free Flow Nose To Side Check Valve With Bypass OrificeDocument2 pagesModel Free Flow Nose To Side Check Valve With Bypass OrificeRenjithSivaNo ratings yet

- SAMNYANg AVVDocument5 pagesSAMNYANg AVVanisyariskiNo ratings yet

- EKOplus SeawaterDocument4 pagesEKOplus SeawaterAhmedRamadanNo ratings yet

- Parker H Series 2-Valve Manifold CatalogDocument6 pagesParker H Series 2-Valve Manifold CatalogAngler's Lab (Angler's Lab)No ratings yet

- Lenz 57XLDocument1 pageLenz 57XLclaudioNo ratings yet

- Valve List - F-5001Document3 pagesValve List - F-5001Ajay PrajapatiNo ratings yet

- HD 282 Butterfly Valves R02 17Document4 pagesHD 282 Butterfly Valves R02 17Satish IndiaNo ratings yet

- Check and Relief ValvesDocument16 pagesCheck and Relief ValvesAdriana Herrera FloresNo ratings yet

- Operation Manual He225 - He400 - He430 - He500 1250-0031-4 Rev KDocument13 pagesOperation Manual He225 - He400 - He430 - He500 1250-0031-4 Rev KOleksandr KovtunNo ratings yet

- LPG Inert 2019 Sapphire PlusDocument8 pagesLPG Inert 2019 Sapphire PluskidmuNo ratings yet

- LPG Inert 2017 Price ListDocument9 pagesLPG Inert 2017 Price ListkidmuNo ratings yet

- GasPoint II UM BilingualDocument156 pagesGasPoint II UM BilingualkidmuNo ratings yet

- Price List LPG Sapphire LPCB 25-11-2019Document8 pagesPrice List LPG Sapphire LPCB 25-11-2019kidmuNo ratings yet

- LPG Firetrade Inet PH 2 130618 Rev02Document4 pagesLPG Firetrade Inet PH 2 130618 Rev02kidmuNo ratings yet

- INET PH 2 - 020218 - Contact PG Rev00Document1 pageINET PH 2 - 020218 - Contact PG Rev00kidmuNo ratings yet

- Sps His Hon Dts fs24x Plus A4 en 5 22Document2 pagesSps His Hon Dts fs24x Plus A4 en 5 22kidmuNo ratings yet

- DS1311 Engineered Dry ChemicalDocument14 pagesDS1311 Engineered Dry ChemicalkidmuNo ratings yet

- DS1311 Large Dry ChemicalDocument12 pagesDS1311 Large Dry ChemicalkidmuNo ratings yet

- DS1308 SV 500 Series Marine Novec 2021Document20 pagesDS1308 SV 500 Series Marine Novec 2021kidmuNo ratings yet

- DS1351 LV Series Marine FM-200Document20 pagesDS1351 LV Series Marine FM-200kidmuNo ratings yet

- DS1352 MV Series Marine FM-200Document20 pagesDS1352 MV Series Marine FM-200kidmuNo ratings yet

- Nitrogen Syngas Moscow Russia 2008 Ammonia Casale Technologies For Ammonia Plant RevampingDocument20 pagesNitrogen Syngas Moscow Russia 2008 Ammonia Casale Technologies For Ammonia Plant RevampingZata AmaliaNo ratings yet

- TDSH283 ASAC002FrickRWBCompressorPartsDocument108 pagesTDSH283 ASAC002FrickRWBCompressorPartsurp30234100% (2)

- POTS - 27022021 - CI and MI Scope of WorkDocument10 pagesPOTS - 27022021 - CI and MI Scope of WorkPhong leNo ratings yet

- Abac Compressor PriceList PDFDocument20 pagesAbac Compressor PriceList PDFpogisimpatikoNo ratings yet

- Cen-Cenelec Guide 38: Guide For Multifuel StationsDocument76 pagesCen-Cenelec Guide 38: Guide For Multifuel StationsKais MessaoudiNo ratings yet

- 070.450-SPL XJS-XJF Compressor (Jul 2015)Document68 pages070.450-SPL XJS-XJF Compressor (Jul 2015)Nilton García Juárez100% (3)

- Multi MitsubishiDocument204 pagesMulti MitsubishiMaleyPedro GonzalesNo ratings yet

- Liquefied Natural Gas and Floating LNG: A Technology ReviewDocument65 pagesLiquefied Natural Gas and Floating LNG: A Technology ReviewLinnie McleodNo ratings yet

- CSW-71D - CD31ZZ-069QDocument37 pagesCSW-71D - CD31ZZ-069QOtávio PagnoncelliNo ratings yet

- Equipment List Rev A PDFDocument3 pagesEquipment List Rev A PDFAde Okta YurwendraNo ratings yet

- Basic Field ServiceDocument62 pagesBasic Field ServicenofriandiNo ratings yet

- COLD STORAGE Bankable ProjectsDocument23 pagesCOLD STORAGE Bankable Projectsravi rishavNo ratings yet

- Quotation: Guangzhou Kingwell Heat Transfer Technology Co., LTDDocument11 pagesQuotation: Guangzhou Kingwell Heat Transfer Technology Co., LTDFlorencio SandovalNo ratings yet

- Six Weeks Training Report of DLWDocument27 pagesSix Weeks Training Report of DLWvinaykumaryadav90% (20)

- Ingersoll Rand Compressor - 2545 Engineering DataDocument4 pagesIngersoll Rand Compressor - 2545 Engineering DataJNo ratings yet

- Cubex Mining Products 2006Document10 pagesCubex Mining Products 2006Diogo Cordova100% (1)

- R290 in Locul Lui R410ADocument11 pagesR290 in Locul Lui R410AClaudia MadalinaNo ratings yet

- Product Description (MTC)Document9 pagesProduct Description (MTC)Syafiq HarsonNo ratings yet

- BoosterDocument14 pagesBoosterSergiSerranoNo ratings yet

- CN 03-001 GE Gemini - New FacilityDocument2 pagesCN 03-001 GE Gemini - New FacilityJavier PalaciosNo ratings yet

- +0300053EN - Manual - UchillerDocument112 pages+0300053EN - Manual - UchillerMarcelo FreitasNo ratings yet

- 2003-UFC 3-450-01 - Noise and Vibration ControlDocument152 pages2003-UFC 3-450-01 - Noise and Vibration ControlAndres PalacioNo ratings yet

- ISO - CEN - API Comparison PDFDocument12 pagesISO - CEN - API Comparison PDFlayth100% (2)

- Energy Recovery in Compressed Air SystemsDocument5 pagesEnergy Recovery in Compressed Air SystemsBramJanssen76100% (1)

- FrontDocument24 pagesFrontBEST STREET WORKOUT LCNo ratings yet

- Vilter 400 Series Parts Chart en 6275204 4Document1 pageVilter 400 Series Parts Chart en 6275204 4FABRICIO DELGADONo ratings yet

- IA Compressor & SystemDocument51 pagesIA Compressor & SystemKazi Irfan100% (2)

- SIEMENST - Testing and Validation of Large Gas TurbinesDocument13 pagesSIEMENST - Testing and Validation of Large Gas TurbinesMuhammad ImranNo ratings yet