Professional Documents

Culture Documents

Garlock KLZ 2-101 PS-SEAL 2016.03 LR EN-NA

Garlock KLZ 2-101 PS-SEAL 2016.03 LR EN-NA

Uploaded by

NaishadhBhattOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Garlock KLZ 2-101 PS-SEAL 2016.03 LR EN-NA

Garlock KLZ 2-101 PS-SEAL 2016.03 LR EN-NA

Uploaded by

NaishadhBhattCopyright:

Available Formats

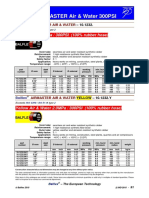

PS-SEAL®

GYLON® Powered High Performance Seal

HIGH SPEED | HIGH PRESSURE | FDA COMPLIANT

Leaders in Sealing Integrity

Advancing the Science of Sealing™

PS-SEAL®: GYLON® Powered High Performance Seal

TABLE OF CONTENTS

PS-SEAL® ............................................................................................................................................................................................. 3

PS-SEAL® STANDARD ......................................................................................................................................................................... 4

Standard seal in stock

PS-SEAL® NON-STANDARD ................................................................................................................................................................ 6

Customized seal (partially in stock)

PS-SEAL® SPECIAL ............................................................................................................................................................................. 8

Customized special seal

PS-SEAL® LIP .................................................................................................................................................................................... 10

Customized seal lip for individual installation circumstances

TECHNICAL INFORMATION ............................................................................................................................................................. 11

INSTALLATION AND ASSEMBLY ADVICE ........................................................................................................................................ 14

APPLICATION DATA SHEET .............................................................................................................................................................. 15

Leaders in Sealing Integrity

2

PS-SEAL®: GYLON® Powered High Performance Seal

PS-SEAL®

The PS-SEAL® product line stands for reliable sealing of rotating shafts

at high circumferential speed, high pressure and extreme temperatures.

Abrasive media is sealed as well as aggressive media. Radial shaft seals

typically do not perform well under these conditions as their seal lips are

made of elastomeric materials.

Garlock PS-SEALs are used in many different applications and can also

be an alternative to mechanical seals and braided packings.

The product line PS-SEAL® offers cost-effective and practical solutions to

a wide range of applications. The portfolio of Garlock shaft seals offers

standardized as well as special customized seals.

The high performance seals PS-SEAL® work with a sealing lip made of

GYLON® or other modified PTFEs. Garlock produces GYLON® using a

proprietary process.

ADVANTAGES AT A GLANCE

» Useable under high pressure and extreme vacuum

» Very suitable for high circumferential shaft speeds

» Temperature resistant from -130˚F (-90˚C) up to 500˚F (260˚C)

» Excellent chemical resistance

» Useable in food and pharma applications (FDA)

» EN 1935/2004 certificate

» SIP/CIP compatible

» Good dry running capability

» Wear resistant and low friction

Leaders in Sealing Integrity

3

PS-SEAL®: GYLON® Powered High Performance Seal

PS-SEAL® Standard Design

PS-SEAL® Standard* is a Garlock shaft seal consisting of a stainless steel 1.4571 (316SS) case, a GYLON® black seal lip and a static

sealing element made of FKM. Products with measurements listed in the table below are in common and readily available.

MOUNTING DIMENSIONS

d1 d2 B d1 d2 B

Item code Item code

inch mm inch mm inch mm inch mm inch mm inch mm

MEC03-10005 0.315 8,0 0.709 18,0 0.197 5,0 MEC03-10026 1.772 45,0 2.441 62,0 0.394 10,0

MEC03-10048 0.394 10,0 0.866 22,0 0.236 6,0 MEC03-10028 1.772 45,0 2.559 65,0 0.394 10,0

MEC03-10006 0.472 12,0 1.102 28,0 0.315 8,0 MEC03-10029 1.890 48,0 2.559 65,0 0.394 10,0

MEC03-10007 0.591 15,0 1.181 30,0 0.315 8,0 MEC03-10030 1.969 50,0 2.559 65,0 0.394 10,0

MEC03-10008 0.630 16,0 1.181 30,0 0.315 8,0 MEC03-10031 1.969 50,0 2.756 70,0 0.394 10,0

MEC03-10010 0.669 17,0 1.102 28,0 0.315 8,0 MEC03-10032 1.969 50,0 2.835 72,0 0.394 10,0

MEC03-10009 0.669 17,0 1.378 35,0 0.315 8,0 MEC03-10033 2.165 55,0 2.835 72,0 0.394 10,0

MEC03-10011 0.787 20,0 1.378 35,0 0.315 8,0 MEC03-10035 2.362 60,0 2.953 75,0 0.315 8,0

MEC03-10012 0.899 22,0 1.575 40,0 0.315 8,0 MEC03-10036 2.362 60,0 3.150 80,0 0.394 10,0

MEC03-10014 0.984 25,0 1.378 35,0 0.315 8,0 MEC03-10037 2.441 62,0 3.150 80,0 0.394 10,0

MEC03-10013 0.984 25,0 1.654 42,0 0.315 8,0 MEC03-10038 2.559 65,0 3.346 85,0 0.394 10,0

MEC03-10050 0.984 25,0 2.047 52,0 0.276 7,0 MEC03-10039 2.756 70,0 3.543 90,0 0.394 10,0

MEC03-10015 1.102 28,0 1.850 47,0 0.394 10,0 MEC03-10040 2.874 73,0 3.937 100,0 0.394 10,0

MEC03-10016 1.181 30,0 1.850 47,0 0.394 10,0 MEC03-10041 2.953 75,0 3.937 100,0 0.394 10,0

MEC03-10017 1.260 32,0 1.850 47,0 0.315 8,0 MEC03-10042 2.953 75,0 3.740 95,0 0.512 13,0

MEC03-10018 1.260 32,0 1.850 47,0 0.394 10,0 MEC03-10043 3.150 80,0 3.937 100,0 0.394 10,0

MEC03-10019 1.378 35,0 1.850 47,0 0.315 8,0 MEC03-10054 3.346 85,0 4.724 120,0 0.500 12,7

MEC03-10020 1.378 35,0 1.969 50,0 0.394 10,0 MEC03-10044 3.543 90,0 4.331 110,0 0.394 10,0

MEC03-10004 1.500 38,1 2.500 63,5 0.500 12,7 MEC03-10051 3.740 95,0 4.724 120,0 0.472 12,0

MEC03-10021 1.575 40,0 2.165 55,0 0.394 10,0 MEC03-10001 3.937 100,0 5.118 130,0 0.512 13,0

MEC03-10022 1.575 40,0 2.362 60,0 0.394 10,0 MEC03-10002 4.331 110,0 5.512 140,0 0.512 13,0

MEC03-10023 1.575 40,0 2.441 62,0 0.394 10,0 MEC03-10052 4.724 120,0 5.906 150,0 0.472 12,0

MEC03-10049 1.575 40,0 2.677 68,0 0.394 10,0 MEC03-10003 5.512 140,0 6.496 165,0 0.394 10,0

MEC03-10025 1.654 42,0 2.441 62,0 0.315 8,0 MEC03-10053 5.906 150,0 7.087 180,0 0.472 12,0

MEC03-10024 1.654 42,0 2.362 60,0 0.394 10,0

* PS-SEAL Standard

maximum 745 psi (10 bar), maximum 400°F (205°C), no FDA

Leaders in Sealing Integrity

4

PS-SEAL®: GYLON® Powered High Performance Seal

PS-SEAL® Standard Design

STANDARD CONFIGURATION

Static Stainless

seal FKM steel case

GYLON®-seal lip

DIMENSIONS

B + 0.012

0.591 ± 0.008

20°

20

0.0

Ra ≤ 0.079

R

All statements in inch

Leaders in Sealing Integrity

5

PS-SEAL®: GYLON® Powered High Performance Seal

PS-SEAL® Non-Standard Design

Garlock PS-SEAL Non-Standard are shaft seals in standard sizes with different configurations of both seal lips and lip seal materials

(see page 13).

MOUNTING DIMENSIONS

d1 d2 B d1 d2 B

inch mm inch mm inch mm inch mm inch mm inch mm

0.315 8,0 0.709 18,0 0.197 5,0 1.772 45,0 2.441 62,0 0.394 10,0

0.394 10,0 0.866 22,0 0.236 6,0 1.772 45,0 2.559 65,0 0.394 10,0

0.472 12,0 1.102 28,0 0.315 8,0 1.890 48,0 2.559 65,0 0.394 10,0

0.591 15,0 1.181 30,0 0.315 8,0 1.969 50,0 2.559 65,0 0.394 10,0

0.630 16,0 1.181 30,0 0.315 8,0 1.969 50,0 2.756 70,0 0.394 10,0

0.669 17,0 1.102 28,0 0.315 8,0 1.969 50,0 2.835 72,0 0.394 10,0

0.669 17,0 1.378 35,0 0.315 8,0 2.165 55,0 2.835 72,0 0.394 10,0

0.787 20,0 1.378 35,0 0.315 8,0 2.362 60,0 2.953 75,0 0.315 8,0

0.866 22,0 1.575 40,0 0.315 8,0 2.362 60,0 3.150 80,0 0.394 10,0

0.984 25,0 1.378 35,0 0.315 8,0 2.441 62,0 3.150 80,0 0.394 10,0

0.984 25,0 1.654 42,0 0.315 8,0 2.559 65,0 3.346 85,0 0.394 10,0

0.984 25,0 2.047 52,0 0.276 7,0 2.756 70,0 3.543 90,0 0.394 10,0

1.102 28,0 1.850 47,0 0.394 10,0 2.874 73,0 3.937 100,0 0.394 10,0

1.181 30,0 1.850 47,0 0.394 10,0 2.953 75,0 3.937 100,0 0.394 10,0

1.260 32,0 1.850 47,0 0.315 8,0 2.953 75,0 3.740 95,0 0.512 13,0

1.260 32,0 1.850 47,0 0.394 10,0 3.150 80,0 3.937 100,0 0.394 10,0

1.378 35,0 1.850 47,0 0.315 8,0 3.346 85,0 4.724 120,0 0.500 12,7

1.378 35,0 1.969 50,0 0.394 10,0 3.543 90,0 4.331 110,0 0.394 10,0

1.500 38,1 2.500 63,5 0.500 12,7 3.740 95,0 4.724 120,0 0.472 12,0

1.575 40,0 2.165 55,0 0.394 10,0 3.937 100,0 5.118 130,0 0.512 13,0

1.575 40,0 2.362 60,0 0.394 10,0 4.331 110,0 5.512 140,0 0.512 13,0

1.575 40,0 2.441 62,0 0.394 10,0 4.724 120,0 5.906 150,0 0.472 12,0

1.575 40,0 2.677 68,0 0.394 10,0 5.512 140,0 6.496 165,0 0.394 10,0

1.654 42,0 2.441 62,0 0.315 8,0 5.906 150,0 7.087 180,0 0.472 12,0

1.654 42,0 2.362 60,0 0.394 10,0

Shaft diameter (d1) and width

(B are slightly adjustable.

If your application demands a shaft seal different from the PS-SEAL® Standard version we will design and manufacture a shaft seal

appropriate to your needs. The PS-SEAL® Non-Standard offers an economic way of producing special configurations, as it is based

on the standard version. Both the lip material and its configuration can be varied. Even the case can be adjusted within technical

limitations.

The PS-SEAL® Non-Standard is in principle available in the same sizes as the PS-SEAL® Standard is, but its dimensions for shaft

diameter (d1) and width (B) can be slightly modified.

Leaders in Sealing Integrity

6

PS-SEAL®: GYLON® Powered High Performance Seal

PS-SEAL® Non-Standard Design

reverse lip simple lip back to back tandem

with dust lip

The overview shows the most common configurations. Other configurations are also available upon request.

Leaders in Sealing Integrity

7

PS-SEAL®: GYLON® Powered High Performance Seal

PS-SEAL® Special Design

Due to the complex application of high performance seals, PS-SEAL Standard and PS-SEAL Non-Standard may not always

provide the best solution for application-specific needs. That is why Garlock offers other sealing options with single and multiple

lip assemblies. As far as practicable, these seals are standardized to supply our customers with cost-efficient special solutions.

We recommend consulting our application specialists for the usage of these PS-SEAL configuration options.

PS-SEAL Special is available in many different lip and housing materials.

The table below shows the gap S1 (relative to pressure) and the minimal dimensions for width and height relative

to the diameter of the shaft.

S1 [inch]

Shaft - Ø [inch] H [inch] H1 [inch] B [inch] B1 [inch] B2 [inch] B3 [inch]

73 psi 145 psi 363 psi

< 0.748 0.315 0.394 0.315 0.472 0.551 0.630 0.087 0.020 0.008

0.748-2.519 0.433 0.492 0.394 0.591 0.669 0.748 0.098 0.020 0.008

2.519-4.685 0.551 0.591 0.394 0.669 0.709 0.787 0.118 0.020 0.008

4.685-7.834 0.591 0.669 0.472 0.787 0.787 0.945 0.118 0.020 0.008

7.834-11.771 0.689 0.787 0.591 0.945 0.906 1.024 0.118 0.020 0.008

11.771-17.716 0.787 0.984 0.787 0.984 0.984 1.181 0.118 0.020 0.008

S1 [mm]

Shaft - Ø [mm] H [mm] H1 [mm] B [mm] B1 [mm] B2 [mm] B3 [mm]

5 bar 10 bar 25 bar

< 19 8 10 8 12 14 16 2,2 0,5 0,2

20-64 11 12,5 10 15 17 19 2,5 0,5 0,2

65-119 14 15 10 17 18 20 3,0 0,5 0,2

120-199 15 17 12 20 20 24 3,0 0,5 0,2

200-299 17,5 20 15 24 23 26 3,0 0,5 0,2

300-450 20 25 20 25 25 30 3,0 0,5 0,2

Leaders in Sealing Integrity

8

PS-SEAL®: GYLON® Powered High Performance Seal

PS-SEAL® Special Design

PS-SEAL SPECIAL, SINGLE LIP PS-SEAL SPECIAL, TANDEM

B + 0,2 5 bar B2+ 0,2

option

H H1

drill - Ø H7

drill - Ø H7

S1

S1

shaft-Ø h11

shaft-Ø h11

B3 + 0,2

10 and 25 bar

option

H1

H1

S1 S1

PS-SEAL SPECIAL, BACK TO BACK

B1 + 0,2

H1

drill - Ø H7

S1

shaft- Ø h11

The overview shows the most common configurations. Other configurations are also available.

All statements in inch

Leaders in Sealing Integrity

9

PS-SEAL®: GYLON® Powered High Performance Seal

PS-SEAL® Lip

In shaft sealing constructions with restrictions in mounting space or where other constructional issues argue against the installation of

a ready-to-mount PS-SEAL®, the option PS-SEAL® Lip could be a solution. PS-SEAL® lip is available in different material versions (see

page 13).

The installation drawing and the associated table below show our recommended installation measurements. Garlock offers a static

sealing element in addition to the PS-SEAL® Lip to provide an optimal fit in the installation space. The standard material for these

elements is FKM, alternatively they are available in GLYON® white or GYLON® blue.

b

DEFORMED STATE 0.028 - 0.002 ORIGINAL STATE

W

H W1

S S1

passing: H7/r6

shaft - Ø h11

PS-SEAL lip

static sealing element

All statements in inch

S1 [inch]

Shaft-Ø [inch] H [inch] b [inch] W [inch] W1 [inch] S [inch]

73 psi 145 psi 363 psi

< 0.748 0.236 0.031 0.098 0.079 0.079 0.079 0.020 0.008

0.748-1.929 0.295 0.031 0.138 0.098 0.098 0.098 0.020 0.008

1.929-5.866 0.394 0.039 0.177 0.138 0.118 0.118 0.020 0.008

5.866-11.771 0.492 0.039 0.236 0.177 0.118 0.118 0.020 0.008

11.771-17.716 0.591 0.039 0.315 0.236 0.118 0.118 0.020 0.008

S1 [mm]

Shaft-Ø [mm] H [mm] b [mm] W [mm] W1 [mm] S [mm]

5 bar 10 bar 25 bar

< 19 6,0 0,8 2,5 2,0 2,0 2,0 0,5 0,2

20-49 7,5 0,8 3,5 2,5 2,5 2,5 0,5 0,2

50-149 10,0 1,0 4,5 3,5 3,0 3,0 0,5 0,2

150-299 12,5 1,0 6,0 4,5 3,0 3,0 0,5 0,2

300-450 15,0 1,0 8,0 6,0 3,0 3,0 0,5 0,2

EXAMPLE FOR SHAFT Ø3.937:

Garlock PS-SEAL® Lip Ø 3.937 x 4.724 x 0.035 inch

Static sealing element Ø 4.449 x 4.724 x 0.039 inch

Leaders in Sealing Integrity

10

PS-SEAL®: GYLON® Powered High Performance Seal

Technical Information

SEAL CASE COUNTER SURFACE

The standard material for the PS-SEAL® seal case is stainless steel As the counter surface has a major impact on

1.4571 (316SS). Other materials can be supplied on request. the efficiency and life-time of our seals, its

configuration needs also to be considered.

OPERATING PRESSURE Garlock can offer an appropriate package of

» PS-SEAL Standard ................................................ max. 145 psi seal and counter surface (protection sleeve)

» PS-SEAL Non-Standard......................................... max. 362 psi to provide an optimal and durable sealing

(depending on version) solution. For an optimal interaction between

» PS-SEAL Special ................................................... max. 362 psi sealing and abrasion the following surface

(depending on version) characteristics should be complied with:

» PS-SEAL Lip.......................................................... max. 362 psi

(depending on version) SURFACE ABRASIVENESS

Ra = ........................................ 3.94 – 15.75 µin

Rz = ...................................... 23.62 – 78.74 µin

For maximum pressure applications please check the p x v - value.

Rmax = ..............................................157.48µin

Garlock recommends an axial fixation of the PS-SEAL when it is

used in applications under high pressure.

The running surface should not have a helical

spiralling indentations as the arising conveying

TEMPERATURE RANGE effect could cause leakage.

The PS-SEAL® lip material can handle temperatures

between -130°F (–90°C) and +500 (260°C). Please note, that there is SURFACE HARDNESS

a difference between the temperature on the seal and the process- 60 HRC

temperature due to the friction which releases additional energy/heat.

Under high stress (p x v - value) of more than 290

MATERIAL psi x m/s Garlock recommends an untwisted

GYLON® is being used as lip seal material of PS-SEAL® and machined chromium oxide coating. Suitable

significantly responsible for its successful operation. We offer coatings can be ordered from Garlock. Please

highly diverse seal options and combinations of materials to cope consider a hard enough basic material when

with the very different requirements of many diverse industrial using micro-coatings.

branches. GYLON® is a modified PTFE and is used due to its high

chemical resistance, its high temperature range and its low friction.

Leaders in Sealing Integrity

11

PS-SEAL®: GYLON® Powered High Performance Seal

Technical Information

LIP MATERIAL

The applied GYLON® lip materials guarantee a stopped cold flow with brilliant running characteristics when it comes to impermeability,

abrasion and frictional heat. Many different compounds can be used for different applications. To cope with rising demands in terms

of rotational speed and pressure in lubricated - as well as in dry running conditions. A higher operating safety and a longer service life

can be reached by using multiple lip-seals arrangements. Please feel free to contact us for individual consulting.

LIP MATERIAL INGREDIENTS PROPERTIES COLOR

» standard material

GYLON ® BLACK graphite Black

» perfectly suitable for lubricated applications

» special material

®

» FDA EN1935 conformity

GYLON WHITE barium sulfate White

» recommended for food, pharmaceutical and beverage industries

» partially capable of dry running

» special material

» FDA EN1935 conformity

GYLON ® BLUE glass-microspheres » very flexible (high recovery capacity) Blue

» recommended for food, pharmaceutical and beverage industries

» brilliant dry running characteristics

» special material

» FDA EN1935 conformity

F Econol » recommended for food, pharmaceutical and beverage industries Tan

» suitable for vacuum-applications

» brilliant dry running characteristics

» special material

MS molybdenum disulfide Black

» suitable for abrasive media

» special material

KF carbon fiber » suitable for partial-abrasive media Black

» good dry running characteristics

Please note: Surface finish and shaft hardness are critical in dry running applications.

Leaders in Sealing Integrity

12

PS-SEAL®: GYLON® Powered High Performance Seal

Technical Information

APPLICATION AREA

With pressure higher than 72 psi and peripheral speed higher than 36.85 in/s we recommend to check the limitations of use.

The p x v-diagram below shows the range of use of GYLON® black and GYLON® white.

P X V FOR PS-SEAL®

The p x v - value shown are valid for heavy lubrication at room temperature and for all PS-SEAL® options capable of pressures up to

45 psi. A bad state of lubrication, such as lack of lubricant or even dry running, creates a need for reducing the maximal acceptable

p x v - value as well as the necessity for an optimal counter surface.

P X V - DIAGRAM POWER LOSS THROUGH FRICTION ON SEAL LIP

10

1000

9

8

800

7

5000 min.-1

6

Pressure (bar)

600

5

Watt

4000 min.-1

4

400

3 GYLON® black

3000 min.-1

300

2

200 2000 min.-1

1 GYLON® white

100 1000 min.-1

0 500 min.-1

0 5 10 15 20 25 30 35 40 45 0

0 20 40 60 80 100 120 140 160

Speed v (m/s) Shaft-Ø (mm)

The following concentricity and shaft to bore misalignment (STBM) curves depend on the maximum speed and shaft-diameter.

The sum of both values (Runout and STBM) may not excess the maximum.

ACCEPTABLE RADIAL RUNOUT ACCEPTABLE STBM

0,2 0,2

0,15 0,15

mm

mm

0,1 0,1

0,05 0,05

0 0

0 1000 2000 3000 4000 5000 6000 0 20 40 60 80 100 120 140

Speed (min. -1) Shaft-Ø (mm)

Leaders in Sealing Integrity

13

PS-SEAL®: GYLON® Powered High Performance Seal

Installation and Assembly Advice

ASSEMBLY

PS-SEAL shaft seals must be installed without damage. Therefore

never insert over sharp edges! The use of a common mounting

paste makes installation easier.

1. R min 0.03 inch and polished

2. Shaft-Ø minus 0.196 inch

3. Shaft-Ø plus 0.157 inch

10°

1 mounting sleeve

2 3

Leaders in Sealing Integrity

14

PS-SEAL®: GYLON® Powered High Performance Seal

Application Data Sheet

SERVICE

Of course you can contact Garlock for an application-specific seal construction any time. To get this service as fast as possible,

please order our application data sheet, which also can be found on our website www.garlock.com.

Other manufacturers

Information

Company:

Item code:

Absolute pressure, [psi(a)

1 psi ], SIDE A:

Absolute pressure, [psi(a)

1 psi(a) ], SIDE B:

GARLOCK

EnPro Industries family of compa Garlock Sealing Technologies

nies Garlock de Canada, LTD

1666 Division Street, Palmyr Garlock GmbH Garlock de Mexico, S.A. De

a, NY 14522 USA Garlock China C.V.

Tel: 800-448-6688 GPT Garlock New Zealand

Garlock Singapore

www.garlock.com Garlock PTY Garlock Great Britain Limited

Garlock USA

Garlock do Brasil Garlock Middle East

Garlock India Private Limited

Leaders in Sealing Integrity

15

KLZ 2:101_2016.03

GARLOCK Garlock Garlock de Canada, LTD Garlock de Mexico, S.A. De C.V.

an EnPro Industries family of companies GPT Garlock China Garlock New Zealand

Tel: 1-877-GARLOCK / 315.597.4811 Garlock Australia Garlock Singapore Garlock Great Britain Limited

Fax: 800.543.0598 / 315.597.3216 Garlock do Brasil Garlock Germany Garlock Middle East

www.garlock.com Garlock India Private Limited

You might also like

- The C-Value Paradox, Junk DNA, and ENCODEDocument6 pagesThe C-Value Paradox, Junk DNA, and ENCODEMartina RajnovicNo ratings yet

- Thermal Physics Long Answer QuestionsDocument5 pagesThermal Physics Long Answer QuestionsjimNo ratings yet

- Title of Document Project Client Contractor Manufacturer Design Document NumberDocument33 pagesTitle of Document Project Client Contractor Manufacturer Design Document NumberArjunNo ratings yet

- Stry&: Section General InformationDocument1 pageStry&: Section General InformationJose Francisco CanizalesNo ratings yet

- Extensometer CalibrationDocument2 pagesExtensometer CalibrationSainath AmudaNo ratings yet

- FXLV 152 ProfileDocument8 pagesFXLV 152 ProfilevrajendraupadhyayNo ratings yet

- CHROME STEEL SLEEVE Kavya Int Brochure PDFDocument4 pagesCHROME STEEL SLEEVE Kavya Int Brochure PDFjoseluispaillachoNo ratings yet

- Least-Squares Estimation Using Lagrange Multipliers: Home Search Collections Journals About Contact Us My IopscienceDocument2 pagesLeast-Squares Estimation Using Lagrange Multipliers: Home Search Collections Journals About Contact Us My Iopsciencenauji_kNo ratings yet

- 12.1031 - Balflex Vacuum Light & HeavyDocument2 pages12.1031 - Balflex Vacuum Light & HeavyJuan Alberto Mendoza VegaNo ratings yet

- Dayco Tensiometer InstructionsDocument13 pagesDayco Tensiometer InstructionsJoseph ChamiNo ratings yet

- Tabla Lee-KeslerDocument16 pagesTabla Lee-Keslerghella MendozaNo ratings yet

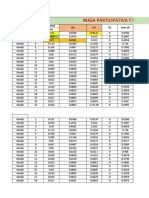

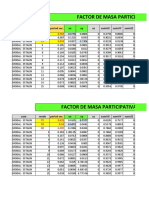

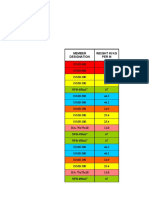

- TY TRZ TX : Case Mode Period UX UY UZ SecDocument12 pagesTY TRZ TX : Case Mode Period UX UY UZ SecRonald Chire AlvarezNo ratings yet

- 44 - Ing - 1319115187 5199Document1 page44 - Ing - 1319115187 5199Luis Matamala MoNo ratings yet

- BCS-CRM 528 SGT S11 Sep2015 - LimestoneDocument4 pagesBCS-CRM 528 SGT S11 Sep2015 - LimestonehasanuddinsambakiNo ratings yet

- 54 Ing 1240236698.06Document1 page54 Ing 1240236698.06Juan Alberto Mendoza VegaNo ratings yet

- Analisis Estatico y Dinamico Edificio 7 PisosDocument74 pagesAnalisis Estatico y Dinamico Edificio 7 PisosMario Alejandro E LNo ratings yet

- 01° Analisis Sismico Estatico XixDocument12 pages01° Analisis Sismico Estatico XixJHAMIRNo ratings yet

- 01 Modal Participating Mass RatiosDocument4 pages01 Modal Participating Mass RatiosMelissa Rios MendezNo ratings yet

- Building Roll (KBR) : Light Weight, No Sagging Nor SettlingDocument8 pagesBuilding Roll (KBR) : Light Weight, No Sagging Nor SettlingPhan LongNo ratings yet

- PrestoBlue Cell Viability Reagent Absorbance Application NoteDocument3 pagesPrestoBlue Cell Viability Reagent Absorbance Application NoteDeden IndraDinataNo ratings yet

- Properties of PipeDocument5 pagesProperties of PipeWiwi NorzahraNo ratings yet

- Flowmeter SelectionDocument4 pagesFlowmeter SelectionsrshahNo ratings yet

- Fire Protection CalculationsDocument193 pagesFire Protection CalculationsPrefer Electrical Engineering And SupplyNo ratings yet

- Table 1: Standard Normal DistributionDocument3 pagesTable 1: Standard Normal DistributionahcangNo ratings yet

- XF 2032c Il 1000002265Document2 pagesXF 2032c Il 1000002265parklane79No ratings yet

- Foil CLARK Y AIRFOIL - T1 - Re0.740 - M0.00 - N9.0Document3 pagesFoil CLARK Y AIRFOIL - T1 - Re0.740 - M0.00 - N9.0Miguel LealNo ratings yet

- BCS-CRM 113 Mar2014Document3 pagesBCS-CRM 113 Mar2014Ishmael WoolooNo ratings yet

- Modos de VibracionDocument2 pagesModos de VibracionBrayan Yahir Colchado IrcañaupaNo ratings yet

- Modos de VibracionDocument2 pagesModos de VibracionRodrigo Morales AnguloNo ratings yet

- 05 Modal Participating Mass RatiosDocument3 pages05 Modal Participating Mass RatiosMelissa Rios MendezNo ratings yet

- Modos de VibracionDocument2 pagesModos de VibracionMario Alejandro E LNo ratings yet

- DAS Glass SystemsDocument2 pagesDAS Glass SystemsAvinashNo ratings yet

- Typical Drawing Tracker For A ProjectDocument3 pagesTypical Drawing Tracker For A ProjectPrashanth ShyamalaNo ratings yet

- 2016 Catalog BiologixDocument77 pages2016 Catalog BiologixRodrigo FaríasNo ratings yet

- Factor de Masa Participativa: Case Mode Period Sec. Ux Uy Uz Sumux Sumuy SumuzDocument17 pagesFactor de Masa Participativa: Case Mode Period Sec. Ux Uy Uz Sumux Sumuy SumuzStalin Acuña EscalanteNo ratings yet

- FDocument103 pagesFBEN BENNo ratings yet

- Foil CLARK Y AIRFOIL - T1 - Re0.750 - M0.00 - N9.0Document3 pagesFoil CLARK Y AIRFOIL - T1 - Re0.750 - M0.00 - N9.0Miguel LealNo ratings yet

- Oil SealDocument4 pagesOil Sealvaibhav ahujaNo ratings yet

- Jaboncilo, Mambron y MacizoDocument714 pagesJaboncilo, Mambron y MacizoAlis SolisNo ratings yet

- Price List 10th November 2022Document3 pagesPrice List 10th November 2022SYED JAWHAR PASHANo ratings yet

- Brownian Motion ModelsDocument13 pagesBrownian Motion ModelsMinahil ZafNo ratings yet

- P202301 PR B CS STD 0001Document16 pagesP202301 PR B CS STD 0001Nitin SakpalNo ratings yet

- Ficha Balflex Baldril 300 PsiDocument1 pageFicha Balflex Baldril 300 PsiJUANPANIAGUANo ratings yet

- Summary Caesar IIDocument9 pagesSummary Caesar IIpanji uteNo ratings yet

- Balinox Aisi 316L With 304 BraidDocument1 pageBalinox Aisi 316L With 304 BraidshyamNo ratings yet

- Perasalls Catalog April 2019 REV-2Document25 pagesPerasalls Catalog April 2019 REV-2Ari CleciusNo ratings yet

- Pearsalls Limited: Product CatalogueDocument25 pagesPearsalls Limited: Product CatalogueAri CleciusNo ratings yet

- Case Mode UX UY UZ Sum UX Sum UY: Period Sec 0.485 0.485Document2 pagesCase Mode UX UY UZ Sum UX Sum UY: Period Sec 0.485 0.485jose jjjNo ratings yet

- Confinedandunconfinedconcrete GeneralDocument56 pagesConfinedandunconfinedconcrete Generalclam2014No ratings yet

- Feb, 26-2024 Unit KarcherDocument6 pagesFeb, 26-2024 Unit Karcherroni roniNo ratings yet

- Foil CLARK Y AIRFOIL - T1 - Re0.360 - M0.00 - N9.0Document3 pagesFoil CLARK Y AIRFOIL - T1 - Re0.360 - M0.00 - N9.0Miguel LealNo ratings yet

- Tub Furtun Gaz Fum SuduraDocument3 pagesTub Furtun Gaz Fum SuduraeuromarketNo ratings yet

- Foil CLARK Y AIRFOIL - T1 - Re0.720 - M0.00 - N9.0Document3 pagesFoil CLARK Y AIRFOIL - T1 - Re0.720 - M0.00 - N9.0Miguel LealNo ratings yet

- Greyloc InstructionsDocument16 pagesGreyloc InstructionsDan ClarkeNo ratings yet

- How To Choose The Right Gauge Block ComparatorDocument15 pagesHow To Choose The Right Gauge Block ComparatorneramopNo ratings yet

- U1 Seccion CircularDocument31 pagesU1 Seccion CircularserviciosmbalderasNo ratings yet

- Oss CatalogDocument44 pagesOss CatalogMayowa BuariNo ratings yet

- 425 Tipo HDocument4 pages425 Tipo HRPINILLA (EICO S.A.)No ratings yet

- Balflex Din en 853 2Sn / Sae 100R2AtDocument1 pageBalflex Din en 853 2Sn / Sae 100R2AtJuan Alberto Mendoza VegaNo ratings yet

- GH - 2023 - HydraulicTests - 01 - Harbleidy Ibarra IbarraDocument87 pagesGH - 2023 - HydraulicTests - 01 - Harbleidy Ibarra IbarraHarbleidy Ibarra IbarraNo ratings yet

- UNI-Rep L PN16Document2 pagesUNI-Rep L PN16Omar GuillenNo ratings yet

- Why Industrial Bearings Fail: Analysis, Maintenance, and PreventionFrom EverandWhy Industrial Bearings Fail: Analysis, Maintenance, and PreventionNo ratings yet

- An Review of Research On E MarketplacesDocument13 pagesAn Review of Research On E MarketplacesNaishadhBhattNo ratings yet

- Engineered Solutions LS enDocument28 pagesEngineered Solutions LS enNaishadhBhattNo ratings yet

- OMS200 - 151F0504 (Technical Data)Document1 pageOMS200 - 151F0504 (Technical Data)NaishadhBhattNo ratings yet

- Engineered Solutions LS enDocument28 pagesEngineered Solutions LS enNaishadhBhattNo ratings yet

- International Journal of Heat and Mass Transfer: Cheen Su An, Man-Hoe KimDocument6 pagesInternational Journal of Heat and Mass Transfer: Cheen Su An, Man-Hoe KimnaveenNo ratings yet

- Sand Filter ReferenceDocument3 pagesSand Filter ReferencesddalviNo ratings yet

- Wasteless Economic Method of Production of Phenol and AcetoneDocument14 pagesWasteless Economic Method of Production of Phenol and AcetoneSiswand BIn Mohd AliNo ratings yet

- Seton Hill University: Organic Chemistry II Lab - OxidationDocument6 pagesSeton Hill University: Organic Chemistry II Lab - Oxidationapi-530322563No ratings yet

- Chem62017 ExampDocument16 pagesChem62017 ExampAAVANINo ratings yet

- DEIR Appendix Y PDFDocument7 pagesDEIR Appendix Y PDFL. A. PatersonNo ratings yet

- Lab Report (Final)Document8 pagesLab Report (Final)MARK OLIVER MURILLONo ratings yet

- Temperature Effects: ConcreteDocument23 pagesTemperature Effects: ConcreteShainee Delle PalmeraNo ratings yet

- United States Patent Office: Patented Apr. 17, 1973Document6 pagesUnited States Patent Office: Patented Apr. 17, 1973julianpellegrini860No ratings yet

- NaBH4 Reduction of CyclohaxanoneDocument5 pagesNaBH4 Reduction of Cyclohaxanonenurul1110No ratings yet

- Conversion PDFDocument2 pagesConversion PDFGavin TexeirraNo ratings yet

- Bathinda District, Punjab: Ground Water Information BookletDocument21 pagesBathinda District, Punjab: Ground Water Information BookletkhushdeepNo ratings yet

- Ecole Polytechnique Federale de LausanneDocument44 pagesEcole Polytechnique Federale de LausanneSyed Yahya HussainNo ratings yet

- Mooring Line As A Spring Mass SystemDocument29 pagesMooring Line As A Spring Mass SystemArun K RajNo ratings yet

- Reinforcing Heat Shrinkable Cable Repair SleeveDocument2 pagesReinforcing Heat Shrinkable Cable Repair Sleevesales3167No ratings yet

- Dike Wall and Slab Design Calculation - RevisedDocument84 pagesDike Wall and Slab Design Calculation - RevisedRichard ChavezNo ratings yet

- The Effect of Fiber Addition On Low Cement CastablesDocument4 pagesThe Effect of Fiber Addition On Low Cement CastablesAndrian Hadiana100% (1)

- MCQ On Manufacturing of CompositesDocument4 pagesMCQ On Manufacturing of CompositesAnilKumar43% (7)

- AWS A5.32-1997 Specification For Welding Shielding GasesDocument26 pagesAWS A5.32-1997 Specification For Welding Shielding GasesIngrid Elena Pardo CadenasNo ratings yet

- Cambridge International General Certificate of Secondary EducationDocument16 pagesCambridge International General Certificate of Secondary Educationyuke kristinaNo ratings yet

- RCC Combined Footing DesignDocument16 pagesRCC Combined Footing DesignD.V.Srinivasa Rao0% (1)

- Connector Design - Materials and Connector ReliabilityDocument16 pagesConnector Design - Materials and Connector ReliabilityXiang Liu100% (1)

- Physics II Problems PDFDocument1 pagePhysics II Problems PDFBOSS BOSSNo ratings yet

- Experiment On Moisture Content in CoalDocument4 pagesExperiment On Moisture Content in Coaluser 00467% (6)

- Solution of Elasticity Problems of PotentialsDocument10 pagesSolution of Elasticity Problems of Potentialsbadr amNo ratings yet

- AZG Mikro Mineral 2 Oct2013Document49 pagesAZG Mikro Mineral 2 Oct2013Arifatush Yuni HariyantiNo ratings yet

- Significant Increase of Contact Resistance of Silver Contacts Mechanical Switching ActionsDocument7 pagesSignificant Increase of Contact Resistance of Silver Contacts Mechanical Switching Actionsachaugule_1No ratings yet