Professional Documents

Culture Documents

Test Result Motor

Test Result Motor

Uploaded by

agung0 ratings0% found this document useful (0 votes)

75 views1 pageThis test certificate summarizes inspection results for an asynchronous motor.

[1] Key parameters tested include winding resistance, vibration levels, no load and locked rotor current and power, insulation resistance, withstand voltage, phase sequence, sense of rotation, and functional testing of auxiliary devices.

[2] All test results were found to be in accordance with customer specifications and quality control plans.

[3] The motor passed inspection for rated voltage of 400V, rated current of 174A, rated power of 86kW, rated frequency of 51Hz, and rated speed of 1497rpm.

Original Description:

Original Title

test result motor

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis test certificate summarizes inspection results for an asynchronous motor.

[1] Key parameters tested include winding resistance, vibration levels, no load and locked rotor current and power, insulation resistance, withstand voltage, phase sequence, sense of rotation, and functional testing of auxiliary devices.

[2] All test results were found to be in accordance with customer specifications and quality control plans.

[3] The motor passed inspection for rated voltage of 400V, rated current of 174A, rated power of 86kW, rated frequency of 51Hz, and rated speed of 1497rpm.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

75 views1 pageTest Result Motor

Test Result Motor

Uploaded by

agungThis test certificate summarizes inspection results for an asynchronous motor.

[1] Key parameters tested include winding resistance, vibration levels, no load and locked rotor current and power, insulation resistance, withstand voltage, phase sequence, sense of rotation, and functional testing of auxiliary devices.

[2] All test results were found to be in accordance with customer specifications and quality control plans.

[3] The motor passed inspection for rated voltage of 400V, rated current of 174A, rated power of 86kW, rated frequency of 51Hz, and rated speed of 1497rpm.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

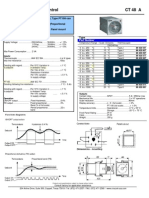

Test Certificate

Routine test Inspection certificate 3.1 acc. to EN 10204:2004

(3.1B acc. to EN 10204:1995) Page 1/1

Ser.No.: 507357 22001 Customer:

Type: MKH820E04 Plant:

QC-Plan: EMA-3.4.2-320

Voltage U rat : 400 V asyn. motor Number of Poles: 4

Current I rat : 174 A Duty: S1

Power P rat : 86 kW Enclosure: IP55

Frequency f rat : 51,0 Hz Connection: D

Speed n rat : 1497 1/min Insulation Class: H

Powerfactor p.f.: 0,770 Thermalclass:

Id.No.* Inspection Winding 1

Test conditions T: 27,4 °C r.H.: 33,8%

A1E01 Winding 1U1 - 1U2 : 0,05784 Ω

resistance at 1V1 - 1V2 : 0,05772 Ω Mean resistance: 0,05783 Ω

20°C 1W1- 1W2 : 0,05792 Ω

A1E04 Vibration level DE X: 0,21 Y: 0,17 Z: 0,09 mm/s RMS

test at no load NDE X: 0,19 Y: 0,06 Z: 0,13 mm/s RMS

A3E08 No load test U [V] I [A] P [kW] p.f. io [%]

at 51,0 Hz 400,0 77,46 1,97 0,037 44,52

A1E10 Locked rotor U [V] I [A] P [kW] p.f.

test at 51,0 Hz 91,2 174,00 6,22 0,226

A1E11 Insulation tested at: 1,0 kV/ 1min

resistance DC UVW-E: 6310 MΩ

Temperatures

Winding: 36,0 °C

Ambient: 27,0 °C

Humidity: 35,0 %

A1E12 Withstand tested at: 3,0 kV/ 1min

voltage test UVW-E: o.k.

50 Hz AC

A1E02 Terminal

Phase sequence: L1 - U L2 - V L3 - W

designation, o.k.

sense of rotation Shaftrotation seen from drive end: clockwise

A1E06 Functional test 6 PTC Thermistor NAT 180

of auxiliary o.k.

devices

Test results according to customer specifications and QC-Plan (see above). o.k.

Preding/Weiz, 19.07.2022 This test report

has been prepared electronically.

Report & Test:

Department: VTEM.TET It is therefore valid without signature. P. Berghofer

*The identification numbers (id.no.) of the individual tests performed refer to all ELIN inspection test plans

You might also like

- Cecu 3 KW T800 PDFDocument6 pagesCecu 3 KW T800 PDFAnonymous nhF45C60% (5)

- Routine Test Certificate 3ph Ind. Motor: Name Plate DataDocument1 pageRoutine Test Certificate 3ph Ind. Motor: Name Plate DataVenkateshwar Devendla100% (2)

- Test Report Thvs Shenyang Co - LTD.: Type: Serial No. 1800570 IOSK72.5Document3 pagesTest Report Thvs Shenyang Co - LTD.: Type: Serial No. 1800570 IOSK72.5arlene borborNo ratings yet

- Data Sheet - GeneratorDocument2 pagesData Sheet - GeneratorBuelvas NicanorNo ratings yet

- Installation and Operation Manual: EM-35 Digital Driver (Single and Dual Feedback)Document28 pagesInstallation and Operation Manual: EM-35 Digital Driver (Single and Dual Feedback)jorge HewitsonNo ratings yet

- 3 1500 Ex (D) RDocument1 page3 1500 Ex (D) RHernán LevyNo ratings yet

- 1 1500 PT07937Document1 page1 1500 PT07937Hernán LevyNo ratings yet

- CT Test Spare yDocument4 pagesCT Test Spare yHumayun AhsanNo ratings yet

- Power Transformer Test 007 BHARATDocument7 pagesPower Transformer Test 007 BHARATDinesh KumarNo ratings yet

- Type Test ReportDocument3 pagesType Test ReportL DKNo ratings yet

- L.E.M.T.: TEST REPORT n°51251689EADocument9 pagesL.E.M.T.: TEST REPORT n°51251689EANguyen ngoc thongNo ratings yet

- Power Transformer Test 001ADocument7 pagesPower Transformer Test 001ADinesh Kumar100% (1)

- Test Certificate: 3 - Phase GEAFOL - TransformerDocument1 pageTest Certificate: 3 - Phase GEAFOL - Transformergusfabi1No ratings yet

- 3G1F1951645571B AA 80A4 400VY 50Hz 0,55kW 3GZF021008-579Document1 page3G1F1951645571B AA 80A4 400VY 50Hz 0,55kW 3GZF021008-579amine zighaNo ratings yet

- Three-Phase-Inductionmotor With Squirrel Cage Rotor: Operationing and Installation DataDocument4 pagesThree-Phase-Inductionmotor With Squirrel Cage Rotor: Operationing and Installation DataMothafukin MorrisseyNo ratings yet

- Cast Resin Transformer Test Report Cast Resin Transformer Test Report Cast Resin Transformer Test Report Cast Resin Transformer Test ReportDocument1 pageCast Resin Transformer Test Report Cast Resin Transformer Test Report Cast Resin Transformer Test Report Cast Resin Transformer Test ReportLoo KlNo ratings yet

- CT Test Old BDocument4 pagesCT Test Old BHumayun AhsanNo ratings yet

- General Test Information:: Excitation Curve DataDocument2 pagesGeneral Test Information:: Excitation Curve DataRicky Bernard SinagaNo ratings yet

- Electrical Test Report - 10MVA Transformer-FinalDocument4 pagesElectrical Test Report - 10MVA Transformer-FinalJherie CeeNo ratings yet

- General Test Information:: Excitation Curve DataDocument2 pagesGeneral Test Information:: Excitation Curve Dataanon_42298864No ratings yet

- Technical Submittal 1000kVA PAECDocument9 pagesTechnical Submittal 1000kVA PAECGhilman HabibNo ratings yet

- Spare Feeder P10Document80 pagesSpare Feeder P10Yogesh JethwaNo ratings yet

- Messrs.: Specification For ApprovalDocument8 pagesMessrs.: Specification For ApprovalallendohorizontNo ratings yet

- 65695-200 kVA (AUX01)Document1 page65695-200 kVA (AUX01)Marudavanan SomasundaramNo ratings yet

- Program: Phase Sequence Monitoring Relay Part No. EMR4-F500-2 Article No. 221784Document2 pagesProgram: Phase Sequence Monitoring Relay Part No. EMR4-F500-2 Article No. 221784Mihai Butnaru-PaladeNo ratings yet

- Form, Test TardjoenDocument30 pagesForm, Test TardjoenDangolNo ratings yet

- Equipo VLF Tangente DeltaDocument1 pageEquipo VLF Tangente Deltaanthony herbert andrade vasquezNo ratings yet

- Protocolo de Referencia para TC y CalculosDocument23 pagesProtocolo de Referencia para TC y Calculosgonzalo fernandezNo ratings yet

- UNINDO 100kva PDFDocument2 pagesUNINDO 100kva PDFanjargoklithNo ratings yet

- Tqm-221105-c - 220kw Tech & Drawing (Tradeone)Document2 pagesTqm-221105-c - 220kw Tech & Drawing (Tradeone)Louie FernandezNo ratings yet

- Ilovepdf MergedDocument21 pagesIlovepdf MergedDHILDAARNo ratings yet

- OSM & RC Testing Summary 0260119070398 + VT 509190132Document3 pagesOSM & RC Testing Summary 0260119070398 + VT 509190132Mohammed MaherNo ratings yet

- (NP3A-220) Motor DataDocument6 pages(NP3A-220) Motor DataEn FaizulNo ratings yet

- M3JM 280SMC 2 - 3GJM281230 - DG - 110kW - 400VD - 50Hz - IE2Document1 pageM3JM 280SMC 2 - 3GJM281230 - DG - 110kW - 400VD - 50Hz - IE2Saber AbdelaalNo ratings yet

- CT Report - 2024 - 04 - 26 - 10 - 39 AMDocument4 pagesCT Report - 2024 - 04 - 26 - 10 - 39 AMBala SubramaniNo ratings yet

- VSS 500N12.7: Voltage Surge Simulator For Testing The Isolation (Voltage Withstand) Up To 12 KVDocument3 pagesVSS 500N12.7: Voltage Surge Simulator For Testing The Isolation (Voltage Withstand) Up To 12 KVouyangxin1991No ratings yet

- M3601850 SgaDocument1 pageM3601850 Sgaxuanphuc0123456No ratings yet

- OMEC - 11kW-4POLEDocument1 pageOMEC - 11kW-4POLETariq KhurshaidiNo ratings yet

- CT Test Old yDocument4 pagesCT Test Old yHumayun AhsanNo ratings yet

- 3gf11082483-Stator-New - Incoming (IEEE) - 20221002 - 113114Document3 pages3gf11082483-Stator-New - Incoming (IEEE) - 20221002 - 113114MohamedHussein MohamedHusseinNo ratings yet

- Type Test Report: Measurement Method 1 Resistance 2 Thermometer 3 ThermocouplesDocument1 pageType Test Report: Measurement Method 1 Resistance 2 Thermometer 3 ThermocouplesdiablolcNo ratings yet

- Serpro DMSDocument11 pagesSerpro DMSJKI JakartaNo ratings yet

- Test Device: 220Kv Grid MuzafargarhDocument2 pagesTest Device: 220Kv Grid MuzafargarhTalha SadiqNo ratings yet

- U1926953Document1 pageU1926953PRABHUDAYAL SHARMANo ratings yet

- UNINDO 200kva PDFDocument2 pagesUNINDO 200kva PDFanjargoklithNo ratings yet

- DTS 2687 - 132kV GIS Method Statement For HV Test & Partial Discharge Measurement - Rev.CDocument38 pagesDTS 2687 - 132kV GIS Method Statement For HV Test & Partial Discharge Measurement - Rev.Cমোঃ মহসিনNo ratings yet

- Transformer Test Report (Tr-0921B) : Test Description Acceptance Criteria Test Result RemarksDocument27 pagesTransformer Test Report (Tr-0921B) : Test Description Acceptance Criteria Test Result RemarksSIRAJ BNo ratings yet

- +K01 FinalDocument94 pages+K01 FinalMERLYNNo ratings yet

- CQY80N/ CQY80NG: Optocoupler, Phototransistor Output, With Base ConnectionDocument11 pagesCQY80N/ CQY80NG: Optocoupler, Phototransistor Output, With Base ConnectionAbdelwhab ElsaftyNo ratings yet

- Medium Voltage MotorDocument5 pagesMedium Voltage Motorfluence.ar.gbavaNo ratings yet

- Site Inspection and Test Record: 1. General Data and InformationDocument13 pagesSite Inspection and Test Record: 1. General Data and InformationwazakifyNo ratings yet

- Test Report of 80-120 MVA TransformerDocument41 pagesTest Report of 80-120 MVA TransformerMonir100% (2)

- Site Inspection and Test Record: 1. General Data and InformationDocument5 pagesSite Inspection and Test Record: 1. General Data and InformationSohail AhmedNo ratings yet

- Transformer Rectifiers PDFDocument29 pagesTransformer Rectifiers PDFSoltani AliNo ratings yet

- Commissioning Service Department Commissioning Standard Test Formats Description: SPAU 341 C3 AVR RELAYDocument2 pagesCommissioning Service Department Commissioning Standard Test Formats Description: SPAU 341 C3 AVR RELAYm khNo ratings yet

- M3JP 315MLB 6L 400V 50Hz 132kWDocument1 pageM3JP 315MLB 6L 400V 50Hz 132kWCamillo VaccaNo ratings yet

- Technical Specifications: A. General CharacteristicsDocument2 pagesTechnical Specifications: A. General CharacteristicsanjargoklithNo ratings yet

- NL22E 24V DC: General InformationDocument2 pagesNL22E 24V DC: General InformationNaeem MemonNo ratings yet

- Motoreductor ColectorDocument12 pagesMotoreductor ColectorAdrián AvalosNo ratings yet

- Application:: BE3-81OT, BE3-81UT, BE3-81OT/UT Frequency Relays With Time DelayDocument2 pagesApplication:: BE3-81OT, BE3-81UT, BE3-81OT/UT Frequency Relays With Time DelaySopian PianNo ratings yet

- MV Panel ReportDocument10 pagesMV Panel ReportMudassirNo ratings yet

- Pickup Wiring InstructionsDocument2 pagesPickup Wiring Instructionsscribdrib100% (2)

- Load Flow AnalysisDocument15 pagesLoad Flow Analysisdinesh kumarNo ratings yet

- Gs33j64e10-01en 009Document19 pagesGs33j64e10-01en 009MobileDickNo ratings yet

- Operation Manual For Air CompressorDocument51 pagesOperation Manual For Air CompressorHassan Ejaz100% (1)

- Alternator Winding Temperature Rise Rev1Document2 pagesAlternator Winding Temperature Rise Rev1J Alberto P ArrazateNo ratings yet

- Polaroid TLA-01511C LCD Owners GuideDocument46 pagesPolaroid TLA-01511C LCD Owners GuideTony MorsonNo ratings yet

- Analog Temperature ControlDocument1 pageAnalog Temperature Controlangeljavier9No ratings yet

- XZCC23FDP120S: Product Data SheetDocument1 pageXZCC23FDP120S: Product Data SheetOmar A. GhoneimNo ratings yet

- Active and Passive ComponentsDocument4 pagesActive and Passive ComponentsBisweswar MondalNo ratings yet

- Object Sorting Machine Using Arduino-UnoDocument3 pagesObject Sorting Machine Using Arduino-UnoREYES, PATRICK HENDRYNo ratings yet

- SUNGROW - SG2500HV-MV-20 DatasheetDocument2 pagesSUNGROW - SG2500HV-MV-20 DatasheetJorgeNo ratings yet

- 307usb Ti08Document2 pages307usb Ti08Salvador ZafraNo ratings yet

- L293D Datasheet PDFDocument8 pagesL293D Datasheet PDFSanjay PatilNo ratings yet

- Breakdown in GasesDocument2 pagesBreakdown in Gasesawajidell awajidellNo ratings yet

- imageRUNNER+25452535+series+Service+Manual en 9.0 PDFDocument398 pagesimageRUNNER+25452535+series+Service+Manual en 9.0 PDFPierre Chirac100% (1)

- E2679 p5ld2-Vm Se ManualDocument90 pagesE2679 p5ld2-Vm Se ManualSubhash NaikNo ratings yet

- Peter Skov - Nokia - 5G Basestations Aalborg v1Document11 pagesPeter Skov - Nokia - 5G Basestations Aalborg v1abdulqaderNo ratings yet

- Go Getter 2 Owners ManualDocument21 pagesGo Getter 2 Owners ManualBrian LewNo ratings yet

- SOP For PHD Electrical EngineeringDocument3 pagesSOP For PHD Electrical EngineeringEdeki MondayNo ratings yet

- Mentor II: User GuideDocument48 pagesMentor II: User GuidejairoNo ratings yet

- Electrostatis Worksheet McqsDocument23 pagesElectrostatis Worksheet Mcqsns857471No ratings yet

- AX84 Hi-Octane Mods 101004Document4 pagesAX84 Hi-Octane Mods 101004Leandro BarbosaNo ratings yet

- Eliiot STC-Avionics-Installation-Part-2 PDFDocument19 pagesEliiot STC-Avionics-Installation-Part-2 PDFslam1212533% (3)

- Bistable MultivibratorDocument2 pagesBistable MultivibratorsahsNo ratings yet

- Week 6 All EditedDocument18 pagesWeek 6 All EditedGabrielle MartineNo ratings yet

- Endress-Hauser Cerabar PMC71B VIDocument6 pagesEndress-Hauser Cerabar PMC71B VITang BvNo ratings yet

- A Typical Desktop Computer Consists of A Computer System UnitDocument17 pagesA Typical Desktop Computer Consists of A Computer System UnitHary BertNo ratings yet

- FinalDocument55 pagesFinalMovin RomelNo ratings yet