Professional Documents

Culture Documents

MCD 00002

MCD 00002

Uploaded by

ariyaCopyright:

Available Formats

You might also like

- Afloat 2Document256 pagesAfloat 2Matthaios SkantrzourakisNo ratings yet

- Timber Design: Bending Stress (F)Document7 pagesTimber Design: Bending Stress (F)nathan fajardoNo ratings yet

- Testing and Commissioning of MVHV CablesDocument7 pagesTesting and Commissioning of MVHV CablesFernando Patiño GuevaraNo ratings yet

- Norsok M001 MaterialsDocument31 pagesNorsok M001 MaterialsbreeeeezzzzzeNo ratings yet

- Mcnichols Gratings CatalogDocument28 pagesMcnichols Gratings CatalogamitkuknaNo ratings yet

- STRAPbeam DesignDocument3 pagesSTRAPbeam DesignMohamed EmamNo ratings yet

- Q A P N KP Α CaDocument49 pagesQ A P N KP Α Calagnajit dasNo ratings yet

- MCD 00001Document10 pagesMCD 00001ariyaNo ratings yet

- OrificeDocument13 pagesOrificexjaf01No ratings yet

- Product Oil - V2 - Google SheetsDocument1 pageProduct Oil - V2 - Google SheetsTabitha TaylorNo ratings yet

- RCC31 One-Way Slabs (A&D)Document15 pagesRCC31 One-Way Slabs (A&D)Md Mukarram RezaNo ratings yet

- MIDAS Information Technology Co., LTDDocument2 pagesMIDAS Information Technology Co., LTDErleNo ratings yet

- Information File: 15/9-F-15: Information On LIS Data FilesDocument2 pagesInformation File: 15/9-F-15: Information On LIS Data FilesResve YanaNo ratings yet

- Flat Slab (With Drop Only)Document147 pagesFlat Slab (With Drop Only)jveer9090No ratings yet

- Sojitz-L&T Consortium: Safe Bearing Capacity CalculationDocument4 pagesSojitz-L&T Consortium: Safe Bearing Capacity Calculation906rahulNo ratings yet

- Shear Strength Controls 21.65 Kips/bolt: Section at ADocument4 pagesShear Strength Controls 21.65 Kips/bolt: Section at AAravindanNo ratings yet

- Shear Strength Controls 21.65 Kips/bolt: Section at ADocument4 pagesShear Strength Controls 21.65 Kips/bolt: Section at AKARTHIK SGNo ratings yet

- Shear Strength Controls 21.65 Kips/bolt: Section at ADocument4 pagesShear Strength Controls 21.65 Kips/bolt: Section at AHajar AswadNo ratings yet

- Shear Strength Controls 21.65 Kips/bolt: Section at ADocument4 pagesShear Strength Controls 21.65 Kips/bolt: Section at AmaheshbandhamNo ratings yet

- Shear Strength Controls 21.65 Kips/bolt: Section at ADocument4 pagesShear Strength Controls 21.65 Kips/bolt: Section at AKARTHIK SGNo ratings yet

- STRAPbeam DesignDocument3 pagesSTRAPbeam DesignMohamed EmamNo ratings yet

- Compressors, Pumps and Pipings: Technological Institute of The PhilippinesDocument11 pagesCompressors, Pumps and Pipings: Technological Institute of The PhilippinesPatricia MirandaNo ratings yet

- E Lie ST RSA SymposiumDocument27 pagesE Lie ST RSA SymposiumAung SoneNo ratings yet

- Flexican: "Design Calculation of Bellows Subjected To Vacuum Condition" As Per CODE EJMA Clause No: 4.15Document2 pagesFlexican: "Design Calculation of Bellows Subjected To Vacuum Condition" As Per CODE EJMA Clause No: 4.15Raji SuriNo ratings yet

- Geometry Materials: AASHTO Standard Specification, Division 1ADocument5 pagesGeometry Materials: AASHTO Standard Specification, Division 1AMahesh SuranaNo ratings yet

- Design of RC Deep Beams As Per Indian, European and American Codes of PracticeDocument5 pagesDesign of RC Deep Beams As Per Indian, European and American Codes of PracticeMaitrabarun KarjeeNo ratings yet

- Geometry Materials: Link Light Rail - Ds 720 YP Mcclellan Station Column Shear CapacityDocument7 pagesGeometry Materials: Link Light Rail - Ds 720 YP Mcclellan Station Column Shear CapacityMahesh SuranaNo ratings yet

- STEELGirder Beam DesignDocument3 pagesSTEELGirder Beam DesignLee Jasper SabenianoNo ratings yet

- Geometry Materials: Link Light Rail - Ds 720 YP Mcclellan Station Column Shear CapacityDocument7 pagesGeometry Materials: Link Light Rail - Ds 720 YP Mcclellan Station Column Shear Capacityluuvandong48xf396No ratings yet

- Geometry Materials: AASHTO Standard Specification, Division 1ADocument5 pagesGeometry Materials: AASHTO Standard Specification, Division 1AHayman AhmedNo ratings yet

- Isolated and Stepped Footing - r1Document25 pagesIsolated and Stepped Footing - r1Er Renish DhadukNo ratings yet

- Eng - Mohamed Sayed Mohamed: Flat SlabDocument12 pagesEng - Mohamed Sayed Mohamed: Flat SlabYasinta Rizka FNo ratings yet

- Pile Capacity Calculation With Bore-Logs Method (Meyerhof Equation)Document82 pagesPile Capacity Calculation With Bore-Logs Method (Meyerhof Equation)mathuNo ratings yet

- RCCen31 One-Way SlabsDocument45 pagesRCCen31 One-Way SlabsMd Mukarram RezaNo ratings yet

- Column LRFDshear1Document7 pagesColumn LRFDshear1Dhey RiveraNo ratings yet

- Lap - Anchorage Length - EC 2Document9 pagesLap - Anchorage Length - EC 2Simon LsmNo ratings yet

- Termo 1' Modeli 5. Migeni.Document12 pagesTermo 1' Modeli 5. Migeni.FeritNo ratings yet

- LSB-1-0808-02-A2-001 - NewDocument5 pagesLSB-1-0808-02-A2-001 - NewariyaNo ratings yet

- Ejma 2000Document7 pagesEjma 2000jhunkujha11No ratings yet

- RCCen31 One-Way SlabsDocument45 pagesRCCen31 One-Way SlabsVIKASH PEERTHYNo ratings yet

- LRFD Live Load Distribution Factors: TxdotDocument15 pagesLRFD Live Load Distribution Factors: TxdotJordy CoolNo ratings yet

- Column Base Plate (Large Eccentricity) v2.0Document5 pagesColumn Base Plate (Large Eccentricity) v2.0Shamik GhoshNo ratings yet

- Geometry Materials: AASHTO Standard Specification, Division 1ADocument5 pagesGeometry Materials: AASHTO Standard Specification, Division 1AIndiana TejadaNo ratings yet

- Falsework Design For Steel Girder Bridge Based On NDS 2018 & AASHTO 17thDocument18 pagesFalsework Design For Steel Girder Bridge Based On NDS 2018 & AASHTO 17thjklo12No ratings yet

- Column AASHTO LRFD Shear1Document7 pagesColumn AASHTO LRFD Shear1HAITHAM ALINo ratings yet

- Geometry Materials: Link Light Rail - Ds 720 YP Mcclellan Station Column Shear CapacityDocument6 pagesGeometry Materials: Link Light Rail - Ds 720 YP Mcclellan Station Column Shear CapacitySiva SundarNo ratings yet

- Transformer Slab PDFDocument1 pageTransformer Slab PDFfdfsdfsNo ratings yet

- F.1 - Crane Pedestal Fatigue Checks - Rev 2Document20 pagesF.1 - Crane Pedestal Fatigue Checks - Rev 2christi SNo ratings yet

- Doubletees 10ldt24and10ldt24Document1 pageDoubletees 10ldt24and10ldt24markensteinsNo ratings yet

- GE-3087: Drilling Engineering Spring 2021 Lecture 3: PDC Bit RecordDocument14 pagesGE-3087: Drilling Engineering Spring 2021 Lecture 3: PDC Bit RecordTu Dang TrongNo ratings yet

- 21.65 Kips/bolt Shear Strength Controls: Section at ADocument3 pages21.65 Kips/bolt Shear Strength Controls: Section at ASuneesh PNo ratings yet

- Chumba Slab 02Document8 pagesChumba Slab 02OCHILLOH STEVENo ratings yet

- Termo 1' Modeli 8. BesmiriDocument11 pagesTermo 1' Modeli 8. BesmiriFeritNo ratings yet

- Keshmen Consult SDN BHD: Design of Slab On Grade To TR34Document2 pagesKeshmen Consult SDN BHD: Design of Slab On Grade To TR34Kevin LowNo ratings yet

- Idoc - Pub - Fourth Octave Alternate Fingering Chart For Flute The Woodwind Fingering Guide PDFDocument4 pagesIdoc - Pub - Fourth Octave Alternate Fingering Chart For Flute The Woodwind Fingering Guide PDFMichael HuertaNo ratings yet

- Daniel Li Temelj Rez. FullDocument5 pagesDaniel Li Temelj Rez. FullNiko NištićNo ratings yet

- STRAPbeam DesignDocument3 pagesSTRAPbeam DesignMohamed EmamNo ratings yet

- Channel Type Tension FittingDocument4 pagesChannel Type Tension FittingJohnclaude ChamandiNo ratings yet

- RCC31R Rigorous One-Way SlabsDocument148 pagesRCC31R Rigorous One-Way SlabsMohammad Twaha JaumbocusNo ratings yet

- Fender PileDocument11 pagesFender PileVenkat PalliNo ratings yet

- RCC32R Rigorous Ribbed SlabsDocument201 pagesRCC32R Rigorous Ribbed SlabsMohammad Twaha JaumbocusNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Engineering Cover SheetDocument4 pagesEngineering Cover SheetariyaNo ratings yet

- Line Enclosure GuidelinesDocument41 pagesLine Enclosure GuidelinesariyaNo ratings yet

- Presentation For KOELDocument31 pagesPresentation For KOELariyaNo ratings yet

- LSB 3 0808 02 A2 001 DPK 00001Document9 pagesLSB 3 0808 02 A2 001 DPK 00001ariyaNo ratings yet

- Strong BackDocument12 pagesStrong BackariyaNo ratings yet

- LSB-1-0808-02-A2-001 - NewDocument5 pagesLSB-1-0808-02-A2-001 - NewariyaNo ratings yet

- Calc 2Document9 pagesCalc 2ariyaNo ratings yet

- Smayan Tamil WordsDocument3 pagesSmayan Tamil WordsariyaNo ratings yet

- OD428357735139452100Document2 pagesOD428357735139452100ariyaNo ratings yet

- Dqa 00001Document2 pagesDqa 00001ariyaNo ratings yet

- TranscriptDocument17 pagesTranscriptariyaNo ratings yet

- MCD 00001Document10 pagesMCD 00001ariyaNo ratings yet

- DPK 00002Document23 pagesDPK 00002ariyaNo ratings yet

- Calc 1Document9 pagesCalc 1ariyaNo ratings yet

- Stress - Strain CurveDocument17 pagesStress - Strain CurveariyaNo ratings yet

- ADocument4 pagesAariyaNo ratings yet

- Exxonmobil Refinery: Item Description: Work Request Number: NotesDocument32 pagesExxonmobil Refinery: Item Description: Work Request Number: NotesariyaNo ratings yet

- Form 901.7Document2 pagesForm 901.7ariyaNo ratings yet

- New ParcelDocument2 pagesNew ParcelariyaNo ratings yet

- Job List Installtion ProcedureDocument4 pagesJob List Installtion ProcedureariyaNo ratings yet

- ADocument1 pageAariyaNo ratings yet

- Hou List-G15-Esp Outlet FlueDocument2 pagesHou List-G15-Esp Outlet FlueariyaNo ratings yet

- Alex 15-12Document10 pagesAlex 15-12ariyaNo ratings yet

- Design Package Cover Sheet: Customer: METHANEXDocument53 pagesDesign Package Cover Sheet: Customer: METHANEXariyaNo ratings yet

- Pongal Kondattam FirelesscookingDocument2 pagesPongal Kondattam FirelesscookingariyaNo ratings yet

- Design Package Cover Sheet: Customer: Phillips 66, Wood RiverDocument22 pagesDesign Package Cover Sheet: Customer: Phillips 66, Wood RiverariyaNo ratings yet

- Design Package Cover Sheet: Customer: CHEMOURSDocument1 pageDesign Package Cover Sheet: Customer: CHEMOURSariyaNo ratings yet

- Design Package Cover Sheet: Customer: Phillips 66 Wood RiverDocument24 pagesDesign Package Cover Sheet: Customer: Phillips 66 Wood RiverariyaNo ratings yet

- Design Package Cover Sheet: Customer: HILCORPDocument15 pagesDesign Package Cover Sheet: Customer: HILCORPariyaNo ratings yet

- Cold PA Duct-TransportDocument3 pagesCold PA Duct-TransportariyaNo ratings yet

- Astm A194 A194m - 2013Document12 pagesAstm A194 A194m - 2013kianrob123No ratings yet

- Hardware Line CardDocument2 pagesHardware Line CardCTN2010No ratings yet

- Sluice GateslknlmDocument7 pagesSluice GateslknlmVed PrakashNo ratings yet

- Kusters Installation Guidelines - Kusters Water - Warren, OhDocument130 pagesKusters Installation Guidelines - Kusters Water - Warren, OhMark WelchNo ratings yet

- Ti SPC Ohe Atd 0060Document16 pagesTi SPC Ohe Atd 0060pradeeepgarg100% (1)

- Ruukki Load Bearing Profiled Sheet Installation InstructionsDocument20 pagesRuukki Load Bearing Profiled Sheet Installation InstructionsEmanuel PopaNo ratings yet

- Tamil Nadu Industries 935Document145 pagesTamil Nadu Industries 935deva nesanNo ratings yet

- Pedal - Powered - Washing MachineDocument17 pagesPedal - Powered - Washing MachineFaiyu MechNo ratings yet

- 2008 Norguard Catalogue FinalDocument40 pages2008 Norguard Catalogue FinalSigit Dwi AnggoroNo ratings yet

- IS - 730 (1978) - J, L, U Bolts StandardsDocument8 pagesIS - 730 (1978) - J, L, U Bolts StandardsbccharanNo ratings yet

- Iso 8734Document32 pagesIso 8734Viswatej ChoudaryNo ratings yet

- Is 10238Document6 pagesIs 10238kundank_32No ratings yet

- LowaraDocument124 pagesLowaramiguelfpintoNo ratings yet

- 17 Fastening Tips For Hardieplank Lap SidingDocument2 pages17 Fastening Tips For Hardieplank Lap SidingKrista CvarNo ratings yet

- MGE 7-0 Catalog-2011 10Document374 pagesMGE 7-0 Catalog-2011 10Roberto CasperNo ratings yet

- Architectural Fasteners & Fittings - Stainless Steel - AnzorDocument18 pagesArchitectural Fasteners & Fittings - Stainless Steel - AnzorBhaiJan59No ratings yet

- Roofing & Walling Products BrochureDocument8 pagesRoofing & Walling Products BrochureAgung PriambodhoNo ratings yet

- GLYDA Technical Data Sheet. Drop Down List 210202Document8 pagesGLYDA Technical Data Sheet. Drop Down List 210202Duc NguyenNo ratings yet

- Parker Thread SealsDocument24 pagesParker Thread SealscjfgksNo ratings yet

- Ace Catalogue CompleteDocument44 pagesAce Catalogue CompleteAnonymous AsIbqUNo ratings yet

- Metal Craft BrochureDocument2 pagesMetal Craft BrochureViswa BhuvanNo ratings yet

- ICC-ES Evaluation Report ESR-2218Document12 pagesICC-ES Evaluation Report ESR-2218Mark J LeingangNo ratings yet

- CS CouvraneufDocument28 pagesCS CouvraneufDan George IIINo ratings yet

- Engineering Drawing (SI. T3) .Doc ManasDocument50 pagesEngineering Drawing (SI. T3) .Doc ManasRavindhar Lu100% (1)

- ComponentWebCatalog 5a System Access PDFDocument43 pagesComponentWebCatalog 5a System Access PDFkaniappan sakthivelNo ratings yet

- Quick Build 3D PanelDocument4 pagesQuick Build 3D Paneldivyanshu33No ratings yet

MCD 00002

MCD 00002

Uploaded by

ariyaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MCD 00002

MCD 00002

Uploaded by

ariyaCopyright:

Available Formats

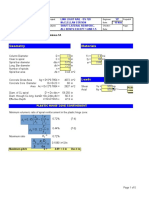

Designed by: KDY Date: 02/17/22 TEAM Industrial Services

Verified by: Date:

JSS Job ID: 4346190

Password Protected Area

Engineering Design Calculations

Strongbacks

Protected Area

Thrust Calculations

Total thrust per bore

C1/D1 C2/D2 C3/D3

Thrust component from area subject to injection pressure, Pi = 785 psi

AUEB.sb1 = 4.4 in 2 AUEB.sb2 = 0 in 2 AUEB.sb3 = 4.4 in 2

External diameter of pipe

Dh1 = 2.375 in Dh2 = 2.375 in Dh3 = 2.375 in

Thrust component from area subject to design pressure, Pd = 285 psi

ASep.sb1 = 4.4 in 2 ASep.sb2 = 4.4 in 2 ASep.sb3 = 4.4 in 2

Thrust calculated from pressure areas or direct input

TC1.D1 ≡ if TC1.D1.m = 0 lbf | TC2.D2 ≡ if TC2.D2.m = 0 lbf | TC3.D3 ≡ if TC3.D3.m = 0 lbf |

‖A | ‖A | ‖A |

‖ UEB.sb1 ⋅ P i + A Sep.sb1 ⋅ P d | ‖ UEB.sb2 ⋅ P i + A Sep.sb2 ⋅ P d | ‖ UEB.sb3 ⋅ P i + A Sep.sb3 ⋅ P d |

else | else | else |

‖T | ‖T | ‖T |

‖ C1.D1.m || ‖ C2.D2.m || ‖ C3.D3.m ||

TC1.D1 = 4717 lbf TC2.D2 = 1263 lbf TC3.D3 = 4717 lbf

Confidential and Proprietary Information Strongbacks Calculations

Registration # F-003143

Tiebar Analysis Page 1 of 10

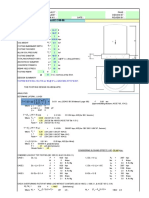

Designed by: KDY Date: 02/17/22 TEAM Industrial Services

Verified by: Date:

JSS Job ID: 4346190

Tiebar Analysis

Tiebar Data

C1/D1 C2/D2 C3/D3

Tiebar size Sb.tb1 = 0.5 in Sb.tb2 = 0.5 in Sb.tb3 = 0 in

2

Tiebar tensile area Ab1.t.tb = 0.1418 in Ab2.t.tb = 0.1418 in 2 Ab3.t.tb = 0 in 2

Number of tiebars Nb.tb1 = 2 Nb.tb2 = 2 Nb.tb3 = 0

Thrust restrained by tiebars TC1.D1 = 4717 lbf TC2.D2 = 1263 lbf TC3.D3 = 4717 lbf

Tiebar Stress

Stress in tiebars due to thrust σtb1.ps.req ≡ if Nb.tb1 ≠ 0 | σtb2.ps.req ≡ if Nb.tb2 ≠ 0 | σtb3.ps.req ≡ if Nb.tb3 ≠ 0 |

‖ | ‖ | ‖ |

TC1.D1 | TC2.D2 | TC3.D3 |

‖ ―――― ‖ ―――― ‖ ――――

‖ Nb.tb1 ⋅ Ab1.t.tb | ‖ Nb.tb2 ⋅ Ab2.t.tb | ‖ Nb.tb3 ⋅ Ab3.t.tb |

‖ | ‖ | ‖ |

else | else | else |

‖ 0 ⋅ psi | ‖ 0 ⋅ psi | ‖ 0 ⋅ psi |

‖ | ‖ | ‖ |

σtb1.ps.req = 16631.1 psi σtb2.ps.req = 4452 psi σtb3.ps.req = 0 psi

Allowable stress in tiebars σb1.tb.a.d = 25000 psi σb2.tb.a.d = 25000 psi σb3.tb.a.d = 0 psi

Results Resulttb1 = “Pass” Resulttb2 = “Pass” Resulttb3 = “Not applicable”

Tiebar Torque

Nut factor Ktq1.tb = 0.17 Ktq2.tb = 0.17 Ktq3.tb = 0

Stud nominal diameter Dtq1.tb ≡ Sb.tb1 Dtq2.tb ≡ Sb.tb2 Dtq3.tb ≡ Sb.tb3

Dtq1.tb = 0.5 in Dtq2.tb = 0.5 in Dtq3.tb = 0 in

Target bolt preload Fpr.tb1 ≡ σtb1.ps.req ⋅ Ab1.t.tb Fpr.tb2 ≡ σtb2.ps.req ⋅ Ab2.t.tb Fpr.tb3 ≡ σtb3.ps.req ⋅ Ab3.t.tb

Fpr.tb1 = 2358 lbf Fpr.tb2 = 631 lbf Fpr.tb3 = 0 lbf

Torque Tqtb1 ≡ Ktq1.tb ⋅ Dtq1.tb ⋅ Fpr.tb1 Tqtb2 ≡ Ktq2.tb ⋅ Dtq2.tb ⋅ Fpr.tb2 Tqtb3 ≡ Ktq3.tb ⋅ Dtq3.tb ⋅ Fpr.tb3

Tqtb1 = 17 ft ⋅ lbf Tqtb2 = 4 ft ⋅ lbf Tqtb3 = 0 ft ⋅ lbf

Confidential and Proprietary Information Strongbacks Calculations

Registration # F-003143

Crunch Ring Strongback Analysis Page 2 of 10

Designed by: KDY Date: 02/17/22 TEAM Industrial Services

Verified by: Date:

JSS Job ID: 4346190

Crunch Ring Strongback Analysis

Crunch Ring Strongback Data

Purpose: This analysis will calculate the frictional force caused by the Crunch Ring Strongback and the internal

stresses of the Crunch Ring Strongback due to the bolting.

References: ASME Boiler and Pressure Vessel Code, Section II, Part D, (Table for Maximum Allowable Stresses, 2019Edition)

Mechanics of Materials by Beer and Johnston, 1981

Machinery's Handbook, 23rd Edition, pages 1278-1279 and 1498-1520

Roark's Formulas for Stress & Strain, Warren C. Young, Fifth Edition, Table 30, case 17, page 464.

An Introduction To The Design And Behavior Of The Bolted Joint by Bickford, Second Edition, Page 133.

Blue dimensions are the dimensions for Crunch Ring Bending in Ear

Data for up to three crunch ring strongbacks are shown below. Data will only be provided if used.

Crunch ring strongback data

Strongback 1 Strongback 2 Strongback 3

Largest diameter in strongback block Dsb1 = 4.375 in Dsb2 = 4.375 in Dsb3 = 0 in

Strongback bore diameter dsb1.bo = 2.36 in dsb2.bo = 2.36 in dsb3.bo = 0 in

Gap at Splitline Lgap.sb1 = 0.125 in Lgap.sb2 = 0.125 in Lgap.sb3 = 0 in

Bolt circle diameter (half joint studs) dsb1.bc = 4.5 in dsb2.bc = 4.5 in dsb3.bc = 0 in

Width of Clamp (in contact with header) Wsb1 = 1.5 in Wsb2 = 1.5 in Wsb3 = 0 in

Tie Bar Hole Diameter ( only when dh.sb1 = 0.625 in dh.sb2 = 0.625 in dh.sb3 = 0 in

tiebars are not on splitline)

Confidential and Proprietary Information Strongbacks Calculations

Registration # F-003143 Page 3 of 10

Crunch Ring Strongback half-joint studs

tiebars are not on splitline)

Designed by: KDY Date: 02/17/22 TEAM Industrial Services

Verified by: Date:

JSS Job ID: 4346190

Crunch Ring Strongback half-joint studs

Half joint stud material StudMaterialb1 = “SA-193 Grade B7”

Crunch Ring Stud Size Sb.sb1 = 0.5 in Sb.sb2 = 0.5 in Sb.sb3 = 0 in

Total number of Studs Nb.sb1 = 2 Nb.sb2 = 2 Nb.sb3 = 0

Prestress as a percentage of yield percy.b1 = 46% percy.b2 = 46% percy.b3 = 50%

Length of moment arm inducing tipping Ltb1.tip = 0 in Ltb2.tip = 0 in Ltb3.tip = 0 in

Number of Nuts on half-joint studs Nn1.hj = 8 Nn2.hj = 8 Nn3.hj = 0

The analysis below may apply to up to three different sets of variables, the function is defined in general terms

and each data set is then run through the function and outputs the final calculated stress.

CrunchRingStresses ⎛⎝Fb , Nb.sb , tcr , Wsb , dh.tb , dbc.sb , dsb.bo , Dh⎞⎠ ≡ try |

‖ |

⎛ ⎞

Summation of forces in X-direction R2 ‖ Pcr ← Fb ÷ ⎝Dh ⋅ Wsb⎠ |

‖ R2 ← Fb ÷ 2 |

R2 - Fx = 0 R2 = Fx = Fy ‖ Area ← ⎛t - d ⎞ ⋅ W |

Cross sectional area Area ‖ ⎝ cr h.tb⎠ sb |

‖ R2 |

Tensile Stress of Crunch Ring Strongback σ1 ‖ σ1 ← ―― |

‖ Area |

Distance from bolt centerline to bore A ‖ A ← ⎛⎝dbc.sb - dsb.bo⎞⎠ ÷ 2 |

‖ Fb tcr⎛ ⎞ |

‖M←― ⋅ ⎜ ― - A ⎟ |

Summation of moment about R2 M ‖ 2 ⎝2 ⎠ |

M - Fx ( t/2 + R - R*sin45 ) - Fy ( R*sin45 ) + BL ( R + A ) = 0 ‖ tcr |

‖c←― |

Neutral fiber c ‖ 2 |

‖ 1 |

‖ I ← ―⋅ Wsb ⋅ ⎛⎝tcr - dh.tb ⎞⎠

3 3

|

Moment of inertia I ‖ 12 |

‖ |M⋅c| |

‖ σ2 ← |―― | |

Bending Stress of Crunch Ring Strongback σ2 ‖ | I | |

‖ σc ← ||σ1|| + ||σ2|| |

‖ return ⎡ σ σ σ P ⎤ |

Combined Stresses of Crunch Ring Strongback σc ‖ ⎣ 1 2 c cr ⎦ |

on error |

‖ |

⎡ ⎤

‖ return ⎣ 0 psi 0 psi 0 psi 0 psi ⎦ |

Confidential and Proprietary Information Strongbacks Calculations

Crunch#Ring

Registration Strongback Results

F-003143 Page 4 of 10

Designed by: KDY Date: 02/17/22 TEAM Industrial Services

Verified by: Date:

JSS Job ID: 4346190

Crunch Ring Strongback Results

Bolting force applied CR Strongback 1 CR Strongback 2 CR Strongback 3

| |

Stud prestress σb.sb1.ps ≡ percy.b1 ⋅ σb1.sb.y.o σb.sb2.ps ≡ percy.b2 ⋅ σb2.sb.y.o σb.sb3.ps ≡ percy.b3 ⋅ σb3.sb.y.o

| |

σb.sb1.ps = 42090 psi | σb.sb2.ps = 42090 psi | σb.sb3.ps = 0 psi

| |

| |

Stud preload Fpr.b1 ≡ σb.sb1.ps ⋅ Ab1.t.sb | Fpr.b2 ≡ σb.sb2.ps ⋅ Ab2.t.sb | Fpr.b3 ≡ σb.sb3.ps ⋅ Ab3.t.sb

| |

Fpr.b1 = 5968 lbf Fpr.b2 = 5968 lbf Fpr.b3 = 0 lbf

| |

| |

Bolt force applied on pipe Fsb1 ≡ Fpr.b1 ⋅ Nb.sb1 | Fsb2 ≡ Fpr.b2 ⋅ Nb.sb2 | Fsb3 ≡ Fpr.b3 ⋅ Nb.sb3

| |

Fsb1 = 11937 lbf | Fsb2 = 11937 lbf | Fsb3 = 0 lbf

| |

Holding force of ring Ff.sb1 ≡ 2 ⋅ μcr ⋅ Fsb1 | Ff.sb2 ≡ 2 ⋅ μcr ⋅ Fsb2 | Ff.sb3 ≡ 2 ⋅ μcr ⋅ Fsb3

| |

Ff.sb1 = 7162 lbf | Ff.sb2 = 7162 lbf | Ff.sb3 = 0 lbf

ResultF.f1 = “Pass” ResultF.f2 = “Pass” ResultF.f3 = “Not applicable”

Note: calculated friction force must be 1.5x greater than the required restraint load to "pass"

Maximum internal crunch ring stresses due to half-joint bolting

⎡⎣ σcr1.1 σcr1.2 σcr1.c Pcr1 ⎤⎦ ≡ CrunchRingStresses ⎛⎝Fsb1 , Nb.sb1 , tcr1 , Wsb1 , dh.sb1 , dsb1.bc , dsb1.bo , Dh1⎞⎠

⎡⎣ σcr2.1 σcr2.2 σcr2.c Pcr2 ⎤⎦ ≡ CrunchRingStresses ⎛⎝Fsb2 , Nb.sb2 , tcr2 , Wsb2 , dh.sb2 , dsb2.bc , dsb2.bo , Dh2⎞⎠

⎡⎣ σcr3.1 σcr3.2 σcr3.c Pcr3 ⎤⎦ ≡ CrunchRingStresses ⎛⎝Fsb3 , Nb.sb3 , tcr3 , Wsb3 , dh.sb3 , dsb3.bc , dsb3.bo , Dh3⎞⎠

Maximum allowable plate stress

1.5x allowable in tension for combined stress σpl.sb.comb.a ≡ 1.5 ⋅ σpl.sb.a.d σpl.sb.comb.a = 30000 psi

CR Strongback 1 CR Strongback 2 CR Strongback 3

Tensile Stress of Crunch Ring Strongback σ1 σcr1.1 = 10402 psi σcr2.1 = 10402 psi σcr3.1 = 0 psi

Bending Stress of Crunch Ring Strongback σ2 σcr1.2 = 17494 psi σcr2.2 = 17494 psi σcr3.2 = 0 psi

Combined Stresses of Crunch Ring Strongback σc σcr1.c = 27897 psi σcr2.c = 27897 psi σcr3.c = 0 psi

Resultcr1.d = “Pass” Resultcr2.d = “Pass” Resultcr3.d = “Not applicable”

Confidential and Proprietary Information Strongbacks Calculations

Registration # F-003143 Page 5 of 10

Designed by: KDY Date: 02/17/22 TEAM Industrial Services

Verified by: Date:

JSS Job ID: 4346190

Crunch Ring Half-Joint Stud Torque

CR Strongback 1 CR Strongback 2 CR Strongback 3

| |

Stud size Sb.sb1 = 0.5 in Sb.sb2 = 0.5 in Sb.sb3 = 0 in

| |

Stud tensile area Ab1.t.sb = 0.1 in 2 | Ab2.t.sb = 0.1 in 2 | Ab3.t.sb = 0.0 in 2

| |

Stud prestress σb.sb1.ps = 42090 psi | σb.sb2.ps = 42090 psi | σb.sb3.ps = 0 psi

| |

Nut factor Ktq1 = 0.2 | Ktq2 = 0.2 | Ktq3 = 0

| |

Stud nominal diameter Dtq1 = 0.5 in | Dtq2 = 0.5 in | Dtq3 = 0 in

| |

Target bolt preload Fpr.b1 = 5968 lbf Fpr.b2 = 5968 lbf Fpr.b3 = 0 lbf

| |

Torque Torquepl1 ≡ Ktq1 ⋅ Dtq1 ⋅ Fpr.b1 | Torquepl2 ≡ Ktq2 ⋅ Dtq2 ⋅ Fpr.b2 | Torquepl3 ≡ Ktq3 ⋅ Dtq3 ⋅ Fpr.b3

| |

Result Torquepl1 = 42 ft ⋅ lbf | Torquepl2 = 42 ft ⋅ lbf | Torquepl3 = 0 ft ⋅ lbf

| |

| |

Tipping effect of Crunch Ring due to Tiebars

CR Strongback 1 | CR Strongback 2 | CR Strongback 3

| |

Moment arm of tipping effect Ltb1.tip = 0 in | Ltb2.tip = 0 in | Ltb3.tip = 0 in

| |

Force inducing tipping F1.tip ≡ TC1.D1 ÷ 2 F2.tip ≡ TC2.D2 ÷ 2 F3.tip ≡ TC3.D3 ÷ 2

| |

F1.tip = 2358 lbf | F2.tip = 631 lbf | F3.tip = 2358 lbf

| |

Tipping moment M1.tip ≡ F1.tip ⋅ Ltb1.tip | M2.tip ≡ F2.tip ⋅ Ltb2.tip | M3.tip ≡ F3.tip ⋅ Ltb3.tip

| |

M1.tip = 0 ft ⋅ lbf | M2.tip = 0 ft ⋅ lbf | M3.tip = 0 ft ⋅ lbf

| |

Required stress in half-joint σtip1.req ≡ if Wsb1 ≠ 0 | | σtip2.req ≡ if Wsb2 ≠ 0 | | σtip3.req ≡ if Wsb3 ≠ 0 |

studs to resist tip (to prestress) ‖ | | ‖ | | ‖ |

‖ ――――|M 1.tip ‖ ――――|M 2.tip ‖ ――――|M 3.tip

| |

‖ Wsb1 ⋅ Ab1.t.sb | | ‖ Wsb2 ⋅ Ab2.t.sb | | ‖ Wsb3 ⋅ Ab3.t.sb |

‖ | ‖ | ‖ |

else | | else | | else |

‖ | ‖ | ‖ |

‖ 0 ⋅ psi | ‖ 0 ⋅ psi | ‖ 0 ⋅ psi |

σtip1.req = 0 psi σtip2.req = 0 psi σtip3.req = 0 psi

Allowable stress in half-joint σb.sb1.ps = 42090 psi σb.sb2.ps = 42090 psi σb.sb3.ps = 0 psi

studs to resist tip

Result

Resultcr1.tip.i = “Not applicable” Resultcr2.tip.i = “Not applicable” Resultcr3.tip.i = “Not applicable”

Confidential and Proprietary Information Strongbacks Calculations

Registration # F-003143

Buckling of Pipe due to Crunch Ring Page 6 of 10

Designed by: KDY Date: 02/17/22 TEAM Industrial Services

Verified by: Date:

JSS Job ID: 4346190

Buckling of Pipe due to Crunch Ring

Reference: Roark's Formulas for Stress & Strain, Warren C. Young, Fifth Edition, Table 30, case 17, page 464.

Header Input Data

Modulus of Elasticity Eh = 27900 ksi Injection Pressure Pi = 785 psi Pi = 785 psi

Pipe yield stress σpe.h.y.o = 29900 psi Operating Pressure Po = 220 psi

Poisson's Ratio ν = 0.3

Analysis

σbuckling ⎛⎝Dh , th , Wsb , Pcr⎞⎠ ≡ ‖ if Dh = 0 in ∨ th = 0 ∨ Wsb = 0| |

‖ | |

‖ ‖ ‖ return 0 psi | |

‖ |

External Radius of pipe Rh ‖ R h ← Dh ÷ 2 |

Pressure acting to buckle pipe qh ‖ qh ← Pcr - Po |

‖ |

‖ a ← ―― Wsb |

Factor a

‖ 2 |

‖ 1 |

‖ ―

4 |

‖ ⎛ 3 ⋅ ⎛⎝1 - ν 2 ⎞⎠ ⎞ |

Factor λ ‖ λ ← ⎜―――― ⎟ |

2 2

‖ ⎜⎝ Rh ⋅ th ⎟⎠ |

‖ 3 |

Factor D ‖ D ← ―――― Eh ⋅ th |

‖ ⎛

12 ⋅ ⎝1 - ν ⎠ 2⎞ |

‖ |

Maximum Moment per unit length ‖ M ← qh ⋅ e -λ ⋅ a ⋅ sin ⎛λ ⋅ a⎞ |

‖ max ―― 2

⎝ ⎠

|

Mmax ‖ 2⋅λ

|

‖ qh

Maximum deflection ymax ‖ ymax ← -―――

⎛

⋅ ⎝1 - e -λ ⋅ a

⋅ cos ⎛⎝λ ⋅ a⎞⎠⎠ |

⎞

4 |

‖ 4⋅D⋅λ |

‖ σ ← ‖ σ ← 0 psi | |

Circumferential membrane stress σpe.h.2 pe.h.2 ‖ 1 |

‖ | | |

‖ ‖ ymax ⋅ Eh | |

σ ← |――― | + |

| ν ⋅ σ |

1| |

‖ ‖ 2 |

‖ | Rh | |

‖ |

‖ -6 ⋅ Mmax |

Meridional bending stress σpe.h.1b ‖ σpe.h.1b ← ――― 2 |

‖ th |

Circumferential bending stress σpe.h.2b ‖ σpe.h.2b ← ν ⋅ σpe.h.1b |

‖ ⎛ ⎞ |

Maximum calculated stress σpe.h.max ‖ σpe.h.max ← max ⎝σpe.h.2 , σpe.h.1b , σpe.h.2b⎠ |

‖ return σpe.h.max ||

‖

Confidential and Proprietary Information Strongbacks Calculations

Registration # F-003143 Page 7 of 10

Header Data

Designed by: KDY Date: 02/17/22 TEAM Industrial Services

Verified by: Date:

JSS Job ID: 4346190

Header Data

C1/D1 C2/D2 C3/D3

External diameter of pipe Dh1 = 2.375 in Dh2 = 2.375 in Dh3 = 2.375 in

Minimum wall thickness th1 = 0.154 in th2 = 0.154 in th3 = 0.154 in

Length of header under injection Wsb1 = 1.5 in Wsb2 = 1.5 in Wsb3 = 0 in

External pressure due to crunch ring Pcr1 = 3350.659 psi Pcr2 = 3350.659 psi Pcr3 = 0 psi

Maximum allowable calculated stress σpe.h.allow ≡ 90% ⋅ σpe.h.y.o σpe.h.allow = 26910 psi

Definitions C1/D1 C2/D2 C3/D3

σC1.D1 ≡ σbuckling ⎛⎝Dh1 , th1 , Wsb1 , Pcr1⎞⎠ σC2.D2 ≡ σbuckling ⎛⎝Dh2 , th2 , Wsb2 , Pcr2⎞⎠ σC3.D3 ≡ σbuckling ⎛⎝Dh3 , th3 , Wsb3 , Pcr3⎞⎠

Results

σC1.D1 = 25741 psi σC2.D2 = 25741 psi σC3.D3 = 0 psi

Results

Buckling C1/D1 Buckling C2/D2 Buckling C3/D3

Resultσ.C1.D1.i = “Pass” Resultσ.C2.D2.i = “Pass” Resultσ.C3.D3.i = “Not applicable”

Flatbar / Ear Bending

Flatbar Calculation (C1/D1)

Flatbar / Crunch Ring ear bending

Length of moment arm of Ear Lma.fb.1 = 2.57 in Lma.fb.2 = 0 in Lma.fb.3 = 1.5 in

Thickness of ear tear.fb.1 = 1.5 in tear.fb.2 = 0 in tear.fb.3 = 1.25 in

Width of ear wear.fb.1 = 4.375 in wear.fb.2 = 0 in wear.fb.3 = 1 in

Flatbar ⎛⎝Lma.fb , TCX.DX , tear.fb , wear.fb , Efb⎞⎠ ≡ if Lma.fb = 0 in |

‖ |

return ⎡⎣ 0 in 0 ft ⋅ lbf 0 in 0 in 4 0 psi ⎤⎦ |

‖

|

else |

‖ |

Moment arm ‖ X ← L ma.fb

|

Calculating Stresses ‖ TCX.DX |

‖ M ← ―― ⋅ X

2 |

M⋅C ‖ |

Where σ = ―― ‖ C ← t ear.fb ÷ 2

|

I ‖ 1 3 |

‖ I ← ―⋅ wear.fb ⋅ tear.fb |

‖ 12

|

‖ M⋅C 1 |

Bending stress in strap ‖ σbend.flatbar ← ――⋅ ― |

‖ I Efb

|

‖ return ⎡⎣ X M C I σbend.flatbar ⎤⎦ ||

‖

Confidential and Proprietary Information Strongbacks Calculations

⎡⎣ X1.fb Mfb.1 Cfb.1 Ifb.1 σbend.fb.1 ⎤⎦ ≡ Flatbar ⎛⎝Lma.fb.1 , TC1.D1 , tear.fb.1 , wear.fb.1 , Efb.1⎞⎠

Registration # F-003143 Page 8 of 10

|

Bending stress in strap ‖ σbend.flatbar ← ――⋅ ― |

Designed by: KDY Date: 02/17/22 TEAM Industrial

‖ I Efb

Services

Verified by: Date: ‖ return ⎡⎣ X M C I σbend.flatbar ⎤⎦

|

||

JSS Job ID: 4346190

‖

⎡⎣ X1.fb Mfb.1 Cfb.1 Ifb.1 σbend.fb.1 ⎤⎦ ≡ Flatbar ⎛⎝Lma.fb.1 , TC1.D1 , tear.fb.1 , wear.fb.1 , Efb.1⎞⎠

⎡⎣ X2.fb Mfb.2 Cfb.2 Ifb.2 σbend.fb.2 ⎤⎦ ≡ Flatbar ⎛⎝Lma.fb.2 , TC2.D2 , tear.fb.2 , wear.fb.2 , Efb.2⎞⎠

⎡⎣ X3.fb Mfb.3 Cfb.3 Ifb.3 σbend.fb.3 ⎤⎦ ≡ Flatbar ⎛⎝Lma.fb.3 , TC3.D3 , tear.fb.3 , wear.fb.3 , Efb.3⎞⎠

Flatbar Strongback C1/D1 Flatbar Strongback C2/D2 Flatbar Strongback C2/D2

Moment arm X1.fb = 2.57 in X2.fb = 0 in X3.fb = 1.5 in

Calculating Stresses

M⋅C

Where σ = ―― Mfb.1 = 505 ft ⋅ lbf Mfb.2 = 0 ft ⋅ lbf Mfb.3 = 295 ft ⋅ lbf

I

Cfb.1 = 0.75 in Cfb.2 = 0 in Cfb.3 = 0.625 in

Ifb.1 = 1 in 4 Ifb.2 = 0 in 4 Ifb.3 = 0 in 4

Bending stress in Flatbar σbend.fb.1 = 3694 psi σbend.fb.2 = 0 psi σbend.fb.3 = 19405 psi

Allowable stress in Flatbars ⎛⎝1.5 ⋅ σpl.sb.a.d⎞⎠ σpl.sb.comb.a = 30000 psi

Results

Flatbar Strongback C1/D1 Flatbar Strongback C2/D2 Flatbar Strongback C2/D2

Resultfb.1.d = “Pass” Resultfb.2.d = “Not applicable” Resultfb.3.d = “Pass”

Protected Area

Confidential and Proprietary Information Strongbacks Calculations

Registration # F-003143 Page 9 of 10

Designed by: KDY Date: 02/17/22 TEAM Industrial Services

Verified by: Date:

JSS Job ID: 4346190

Strongback Weight

Enclosure

Weight of component (SolidWorks generated)

Wsb.C1.D1 = 25 lb Wsb.C2.D2 = 0 lb Wsb.C3.D3 = 0 lb

Studs and Nuts

Half-joint stud 1 Half-joint stud 2 Half-joint stud 3

Size Sb.sb1 = 0.5 in Sb.sb2 = 0.5 in Sb.sb3 = 0 in

Length Lst.hj.1 = 8 in Lst.hj.2 = 8 in Lst.hj.3 = 0 in

Quantity Ns1.hj = 2 Ns2.hj = 2 Ns3.hj = 0 ft

Number of half-joint nuts Nn1.hj = 8 Nn2.hj = 8 Nn3.hj = 0

lb lb lb

Weight per inch wpis1 = 0.06 ― wpis2 = 0.06 ― wpis3 = 0.06 ―

in in in

Weight per nut wpnn1 = 0.07 lb wpnn2 = 0.07 lb wpnn3 = 0.07 lb

Total weight of fasteners Wfasteners.b ≡ wpis1 ⋅ Lst.hj.1 ⋅ Ns1.hj + wpnn1 ⋅ Nn1.hj ↲ Wfasteners.b = 2.82 lb

+ wpis2 ⋅ Lst.hj.2 ⋅ Ns2.hj + wpnn2 ⋅ Nn2.hj ↲

+ wpis3 ⋅ Lst.hj.3 ⋅ Ns3.hj + wpnn3 ⋅ Nn3.hj

Tiebars and Nuts

Tiebar stud 1 Tiebar stud 2 Tiebar stud 3

Size Sb.tb1 = 0.5 in Sb.tb2 = 0.5 in Sb.tb3 = 0 in

Length Ltb.1 = 8 in Ltb.2 = 8 in Ltb.3 = 0 in

Quantity Ntb1 = 2 Ntb2 = 2 Ntb3 = 0 ft

Number of half-joint nuts Nn1.tb = 7 Nn2.tb = 7 Nn3.tb = 0

lb lb lb

Weight per inch wpitb1 = 0.06 ― wpitb2 = 0.06 ― wpitb3 = 0 ―

in in in

Weight per nut wpntb.n1 = 0.07 lb wpntb.n2 = 0.07 lb wpntb.n3 = 0 lb

Total weight of fasteners Wfasteners.tb ≡ wpitb1 ⋅ Ltb.1 ⋅ Ntb1 + wpntb.n1 ⋅ Nn1.tb ↲ Wfasteners.tb = 2.69 lb

+ wpitb2 ⋅ Ltb.2 ⋅ Ntb2 + wpntb.n2 ⋅ Nn2.tb ↲

+ wpitb3 ⋅ Ltb.3 ⋅ Ntb3 + wpntb.n3 ⋅ Nn3.tb

Wfasteners ≡ Wfasteners.b + Wfasteners.tb Wfasteners = 5.51 lb

Totals

Total weight Weightencl ≡ Wsb.C1.D1 + Wsb.C2.D2 + Wsb.C3.D3 + Wfasteners

Weightencl = 31 lb

Confidential and Proprietary Information Strongbacks Calculations

Registration # F-003143 Page 10 of 10

You might also like

- Afloat 2Document256 pagesAfloat 2Matthaios SkantrzourakisNo ratings yet

- Timber Design: Bending Stress (F)Document7 pagesTimber Design: Bending Stress (F)nathan fajardoNo ratings yet

- Testing and Commissioning of MVHV CablesDocument7 pagesTesting and Commissioning of MVHV CablesFernando Patiño GuevaraNo ratings yet

- Norsok M001 MaterialsDocument31 pagesNorsok M001 MaterialsbreeeeezzzzzeNo ratings yet

- Mcnichols Gratings CatalogDocument28 pagesMcnichols Gratings CatalogamitkuknaNo ratings yet

- STRAPbeam DesignDocument3 pagesSTRAPbeam DesignMohamed EmamNo ratings yet

- Q A P N KP Α CaDocument49 pagesQ A P N KP Α Calagnajit dasNo ratings yet

- MCD 00001Document10 pagesMCD 00001ariyaNo ratings yet

- OrificeDocument13 pagesOrificexjaf01No ratings yet

- Product Oil - V2 - Google SheetsDocument1 pageProduct Oil - V2 - Google SheetsTabitha TaylorNo ratings yet

- RCC31 One-Way Slabs (A&D)Document15 pagesRCC31 One-Way Slabs (A&D)Md Mukarram RezaNo ratings yet

- MIDAS Information Technology Co., LTDDocument2 pagesMIDAS Information Technology Co., LTDErleNo ratings yet

- Information File: 15/9-F-15: Information On LIS Data FilesDocument2 pagesInformation File: 15/9-F-15: Information On LIS Data FilesResve YanaNo ratings yet

- Flat Slab (With Drop Only)Document147 pagesFlat Slab (With Drop Only)jveer9090No ratings yet

- Sojitz-L&T Consortium: Safe Bearing Capacity CalculationDocument4 pagesSojitz-L&T Consortium: Safe Bearing Capacity Calculation906rahulNo ratings yet

- Shear Strength Controls 21.65 Kips/bolt: Section at ADocument4 pagesShear Strength Controls 21.65 Kips/bolt: Section at AAravindanNo ratings yet

- Shear Strength Controls 21.65 Kips/bolt: Section at ADocument4 pagesShear Strength Controls 21.65 Kips/bolt: Section at AKARTHIK SGNo ratings yet

- Shear Strength Controls 21.65 Kips/bolt: Section at ADocument4 pagesShear Strength Controls 21.65 Kips/bolt: Section at AHajar AswadNo ratings yet

- Shear Strength Controls 21.65 Kips/bolt: Section at ADocument4 pagesShear Strength Controls 21.65 Kips/bolt: Section at AmaheshbandhamNo ratings yet

- Shear Strength Controls 21.65 Kips/bolt: Section at ADocument4 pagesShear Strength Controls 21.65 Kips/bolt: Section at AKARTHIK SGNo ratings yet

- STRAPbeam DesignDocument3 pagesSTRAPbeam DesignMohamed EmamNo ratings yet

- Compressors, Pumps and Pipings: Technological Institute of The PhilippinesDocument11 pagesCompressors, Pumps and Pipings: Technological Institute of The PhilippinesPatricia MirandaNo ratings yet

- E Lie ST RSA SymposiumDocument27 pagesE Lie ST RSA SymposiumAung SoneNo ratings yet

- Flexican: "Design Calculation of Bellows Subjected To Vacuum Condition" As Per CODE EJMA Clause No: 4.15Document2 pagesFlexican: "Design Calculation of Bellows Subjected To Vacuum Condition" As Per CODE EJMA Clause No: 4.15Raji SuriNo ratings yet

- Geometry Materials: AASHTO Standard Specification, Division 1ADocument5 pagesGeometry Materials: AASHTO Standard Specification, Division 1AMahesh SuranaNo ratings yet

- Design of RC Deep Beams As Per Indian, European and American Codes of PracticeDocument5 pagesDesign of RC Deep Beams As Per Indian, European and American Codes of PracticeMaitrabarun KarjeeNo ratings yet

- Geometry Materials: Link Light Rail - Ds 720 YP Mcclellan Station Column Shear CapacityDocument7 pagesGeometry Materials: Link Light Rail - Ds 720 YP Mcclellan Station Column Shear CapacityMahesh SuranaNo ratings yet

- STEELGirder Beam DesignDocument3 pagesSTEELGirder Beam DesignLee Jasper SabenianoNo ratings yet

- Geometry Materials: Link Light Rail - Ds 720 YP Mcclellan Station Column Shear CapacityDocument7 pagesGeometry Materials: Link Light Rail - Ds 720 YP Mcclellan Station Column Shear Capacityluuvandong48xf396No ratings yet

- Geometry Materials: AASHTO Standard Specification, Division 1ADocument5 pagesGeometry Materials: AASHTO Standard Specification, Division 1AHayman AhmedNo ratings yet

- Isolated and Stepped Footing - r1Document25 pagesIsolated and Stepped Footing - r1Er Renish DhadukNo ratings yet

- Eng - Mohamed Sayed Mohamed: Flat SlabDocument12 pagesEng - Mohamed Sayed Mohamed: Flat SlabYasinta Rizka FNo ratings yet

- Pile Capacity Calculation With Bore-Logs Method (Meyerhof Equation)Document82 pagesPile Capacity Calculation With Bore-Logs Method (Meyerhof Equation)mathuNo ratings yet

- RCCen31 One-Way SlabsDocument45 pagesRCCen31 One-Way SlabsMd Mukarram RezaNo ratings yet

- Column LRFDshear1Document7 pagesColumn LRFDshear1Dhey RiveraNo ratings yet

- Lap - Anchorage Length - EC 2Document9 pagesLap - Anchorage Length - EC 2Simon LsmNo ratings yet

- Termo 1' Modeli 5. Migeni.Document12 pagesTermo 1' Modeli 5. Migeni.FeritNo ratings yet

- LSB-1-0808-02-A2-001 - NewDocument5 pagesLSB-1-0808-02-A2-001 - NewariyaNo ratings yet

- Ejma 2000Document7 pagesEjma 2000jhunkujha11No ratings yet

- RCCen31 One-Way SlabsDocument45 pagesRCCen31 One-Way SlabsVIKASH PEERTHYNo ratings yet

- LRFD Live Load Distribution Factors: TxdotDocument15 pagesLRFD Live Load Distribution Factors: TxdotJordy CoolNo ratings yet

- Column Base Plate (Large Eccentricity) v2.0Document5 pagesColumn Base Plate (Large Eccentricity) v2.0Shamik GhoshNo ratings yet

- Geometry Materials: AASHTO Standard Specification, Division 1ADocument5 pagesGeometry Materials: AASHTO Standard Specification, Division 1AIndiana TejadaNo ratings yet

- Falsework Design For Steel Girder Bridge Based On NDS 2018 & AASHTO 17thDocument18 pagesFalsework Design For Steel Girder Bridge Based On NDS 2018 & AASHTO 17thjklo12No ratings yet

- Column AASHTO LRFD Shear1Document7 pagesColumn AASHTO LRFD Shear1HAITHAM ALINo ratings yet

- Geometry Materials: Link Light Rail - Ds 720 YP Mcclellan Station Column Shear CapacityDocument6 pagesGeometry Materials: Link Light Rail - Ds 720 YP Mcclellan Station Column Shear CapacitySiva SundarNo ratings yet

- Transformer Slab PDFDocument1 pageTransformer Slab PDFfdfsdfsNo ratings yet

- F.1 - Crane Pedestal Fatigue Checks - Rev 2Document20 pagesF.1 - Crane Pedestal Fatigue Checks - Rev 2christi SNo ratings yet

- Doubletees 10ldt24and10ldt24Document1 pageDoubletees 10ldt24and10ldt24markensteinsNo ratings yet

- GE-3087: Drilling Engineering Spring 2021 Lecture 3: PDC Bit RecordDocument14 pagesGE-3087: Drilling Engineering Spring 2021 Lecture 3: PDC Bit RecordTu Dang TrongNo ratings yet

- 21.65 Kips/bolt Shear Strength Controls: Section at ADocument3 pages21.65 Kips/bolt Shear Strength Controls: Section at ASuneesh PNo ratings yet

- Chumba Slab 02Document8 pagesChumba Slab 02OCHILLOH STEVENo ratings yet

- Termo 1' Modeli 8. BesmiriDocument11 pagesTermo 1' Modeli 8. BesmiriFeritNo ratings yet

- Keshmen Consult SDN BHD: Design of Slab On Grade To TR34Document2 pagesKeshmen Consult SDN BHD: Design of Slab On Grade To TR34Kevin LowNo ratings yet

- Idoc - Pub - Fourth Octave Alternate Fingering Chart For Flute The Woodwind Fingering Guide PDFDocument4 pagesIdoc - Pub - Fourth Octave Alternate Fingering Chart For Flute The Woodwind Fingering Guide PDFMichael HuertaNo ratings yet

- Daniel Li Temelj Rez. FullDocument5 pagesDaniel Li Temelj Rez. FullNiko NištićNo ratings yet

- STRAPbeam DesignDocument3 pagesSTRAPbeam DesignMohamed EmamNo ratings yet

- Channel Type Tension FittingDocument4 pagesChannel Type Tension FittingJohnclaude ChamandiNo ratings yet

- RCC31R Rigorous One-Way SlabsDocument148 pagesRCC31R Rigorous One-Way SlabsMohammad Twaha JaumbocusNo ratings yet

- Fender PileDocument11 pagesFender PileVenkat PalliNo ratings yet

- RCC32R Rigorous Ribbed SlabsDocument201 pagesRCC32R Rigorous Ribbed SlabsMohammad Twaha JaumbocusNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Engineering Cover SheetDocument4 pagesEngineering Cover SheetariyaNo ratings yet

- Line Enclosure GuidelinesDocument41 pagesLine Enclosure GuidelinesariyaNo ratings yet

- Presentation For KOELDocument31 pagesPresentation For KOELariyaNo ratings yet

- LSB 3 0808 02 A2 001 DPK 00001Document9 pagesLSB 3 0808 02 A2 001 DPK 00001ariyaNo ratings yet

- Strong BackDocument12 pagesStrong BackariyaNo ratings yet

- LSB-1-0808-02-A2-001 - NewDocument5 pagesLSB-1-0808-02-A2-001 - NewariyaNo ratings yet

- Calc 2Document9 pagesCalc 2ariyaNo ratings yet

- Smayan Tamil WordsDocument3 pagesSmayan Tamil WordsariyaNo ratings yet

- OD428357735139452100Document2 pagesOD428357735139452100ariyaNo ratings yet

- Dqa 00001Document2 pagesDqa 00001ariyaNo ratings yet

- TranscriptDocument17 pagesTranscriptariyaNo ratings yet

- MCD 00001Document10 pagesMCD 00001ariyaNo ratings yet

- DPK 00002Document23 pagesDPK 00002ariyaNo ratings yet

- Calc 1Document9 pagesCalc 1ariyaNo ratings yet

- Stress - Strain CurveDocument17 pagesStress - Strain CurveariyaNo ratings yet

- ADocument4 pagesAariyaNo ratings yet

- Exxonmobil Refinery: Item Description: Work Request Number: NotesDocument32 pagesExxonmobil Refinery: Item Description: Work Request Number: NotesariyaNo ratings yet

- Form 901.7Document2 pagesForm 901.7ariyaNo ratings yet

- New ParcelDocument2 pagesNew ParcelariyaNo ratings yet

- Job List Installtion ProcedureDocument4 pagesJob List Installtion ProcedureariyaNo ratings yet

- ADocument1 pageAariyaNo ratings yet

- Hou List-G15-Esp Outlet FlueDocument2 pagesHou List-G15-Esp Outlet FlueariyaNo ratings yet

- Alex 15-12Document10 pagesAlex 15-12ariyaNo ratings yet

- Design Package Cover Sheet: Customer: METHANEXDocument53 pagesDesign Package Cover Sheet: Customer: METHANEXariyaNo ratings yet

- Pongal Kondattam FirelesscookingDocument2 pagesPongal Kondattam FirelesscookingariyaNo ratings yet

- Design Package Cover Sheet: Customer: Phillips 66, Wood RiverDocument22 pagesDesign Package Cover Sheet: Customer: Phillips 66, Wood RiverariyaNo ratings yet

- Design Package Cover Sheet: Customer: CHEMOURSDocument1 pageDesign Package Cover Sheet: Customer: CHEMOURSariyaNo ratings yet

- Design Package Cover Sheet: Customer: Phillips 66 Wood RiverDocument24 pagesDesign Package Cover Sheet: Customer: Phillips 66 Wood RiverariyaNo ratings yet

- Design Package Cover Sheet: Customer: HILCORPDocument15 pagesDesign Package Cover Sheet: Customer: HILCORPariyaNo ratings yet

- Cold PA Duct-TransportDocument3 pagesCold PA Duct-TransportariyaNo ratings yet

- Astm A194 A194m - 2013Document12 pagesAstm A194 A194m - 2013kianrob123No ratings yet

- Hardware Line CardDocument2 pagesHardware Line CardCTN2010No ratings yet

- Sluice GateslknlmDocument7 pagesSluice GateslknlmVed PrakashNo ratings yet

- Kusters Installation Guidelines - Kusters Water - Warren, OhDocument130 pagesKusters Installation Guidelines - Kusters Water - Warren, OhMark WelchNo ratings yet

- Ti SPC Ohe Atd 0060Document16 pagesTi SPC Ohe Atd 0060pradeeepgarg100% (1)

- Ruukki Load Bearing Profiled Sheet Installation InstructionsDocument20 pagesRuukki Load Bearing Profiled Sheet Installation InstructionsEmanuel PopaNo ratings yet

- Tamil Nadu Industries 935Document145 pagesTamil Nadu Industries 935deva nesanNo ratings yet

- Pedal - Powered - Washing MachineDocument17 pagesPedal - Powered - Washing MachineFaiyu MechNo ratings yet

- 2008 Norguard Catalogue FinalDocument40 pages2008 Norguard Catalogue FinalSigit Dwi AnggoroNo ratings yet

- IS - 730 (1978) - J, L, U Bolts StandardsDocument8 pagesIS - 730 (1978) - J, L, U Bolts StandardsbccharanNo ratings yet

- Iso 8734Document32 pagesIso 8734Viswatej ChoudaryNo ratings yet

- Is 10238Document6 pagesIs 10238kundank_32No ratings yet

- LowaraDocument124 pagesLowaramiguelfpintoNo ratings yet

- 17 Fastening Tips For Hardieplank Lap SidingDocument2 pages17 Fastening Tips For Hardieplank Lap SidingKrista CvarNo ratings yet

- MGE 7-0 Catalog-2011 10Document374 pagesMGE 7-0 Catalog-2011 10Roberto CasperNo ratings yet

- Architectural Fasteners & Fittings - Stainless Steel - AnzorDocument18 pagesArchitectural Fasteners & Fittings - Stainless Steel - AnzorBhaiJan59No ratings yet

- Roofing & Walling Products BrochureDocument8 pagesRoofing & Walling Products BrochureAgung PriambodhoNo ratings yet

- GLYDA Technical Data Sheet. Drop Down List 210202Document8 pagesGLYDA Technical Data Sheet. Drop Down List 210202Duc NguyenNo ratings yet

- Parker Thread SealsDocument24 pagesParker Thread SealscjfgksNo ratings yet

- Ace Catalogue CompleteDocument44 pagesAce Catalogue CompleteAnonymous AsIbqUNo ratings yet

- Metal Craft BrochureDocument2 pagesMetal Craft BrochureViswa BhuvanNo ratings yet

- ICC-ES Evaluation Report ESR-2218Document12 pagesICC-ES Evaluation Report ESR-2218Mark J LeingangNo ratings yet

- CS CouvraneufDocument28 pagesCS CouvraneufDan George IIINo ratings yet

- Engineering Drawing (SI. T3) .Doc ManasDocument50 pagesEngineering Drawing (SI. T3) .Doc ManasRavindhar Lu100% (1)

- ComponentWebCatalog 5a System Access PDFDocument43 pagesComponentWebCatalog 5a System Access PDFkaniappan sakthivelNo ratings yet

- Quick Build 3D PanelDocument4 pagesQuick Build 3D Paneldivyanshu33No ratings yet