Professional Documents

Culture Documents

Triz QFD

Triz QFD

Uploaded by

Deepak YaduvanshiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Triz QFD

Triz QFD

Uploaded by

Deepak YaduvanshiCopyright:

Available Formats

2009 Second International Workshop on Computer Science and Engineering

An Integrated Mode Research of QFD and TRIZ and Its Applications

Li Shaobo, Ma Yuqin, Yang Guanci, Li Yaqing

Key Laboratory of Advanced Manufacturing Technology Guizhou University Guiyang, China e-mail: lishaobo@gzu.edu.cn

AbstractFrom the aspects of the innovative design development, this paper analyses QFDs defects and investigates the possibilities for integrated use of QFD and TRIZ, which is on the base of QFDs and TRIZs appearance, development, contents and using characteristics. Then it makes a deep research for the two integrated technology process, and brings forward the integrated general design system for use. To the importance of conflicted matrix in the HOQ and TRIZ, it puts forward the combined using design process for the both two. Finally, on the using of the above theories, this paper optimizes the vices innovative design and solves its using problems, thereby it indicates this methods practical value. Keywords-QFD;TRIZ;integration; innovation and optimized design

one theory, so how to integrate some of these theories organically is becoming the key point for research[2][3]. II. A. SUMMARIZATION OF QFD AND TRIZ

I.

INTRODUCTION

Enterprises urgently pursue to develop new products and technologies as soon as possible to keep the competitive predominance. The product design is a very complex process which could be divided by four phases: product programming, project design, technology design and details design. How to deal with the relationship between these four phases well and to design low-cost and high-competition products is becoming the point for attention. At present, there are many ways of supporting product innovation designs, for example, QFD, TRIZ, reliability design, Robust design, AD, GDT and UDT, etc. There are many practical examples in use with the support of these methods to make the innovation design: On the condition of QFDs research, Chai Guoying in Chinese Northern Research Institute made the QFDs actual use in the general design idea for the diesel engine come true, such design idea not only makes the products of the diesel engine indeed cater for customers demands, improve the products applicability, and reduce the research period, but also finally improves the products marketing competitive capability[1]. On the basis of TRIZs solving-problems processes and characteristics, Chen Zishun in Hebei Industrial University summarized the factual using methods and steps of TRIZ in actual projects, and made a research on the machine tools reamer system, finally solved the existing problems of the reamers structure[2]. However, most of these researches and actual uses emphasize particularly on the problems of one phase or one aspect in products innovative design with

QFD Brought forward by Japanese scholar at the end of 1960s, QFD is the multi-level deducting and analyzing method of transforming customers or markets demands into design requirements, components characteristics, technology requirements and producing requirements. It reflects the directional ideology of markets guidance and the products design gist of considering customers demands. HOQ (House of Quality) is QFDs nerve centre, and its a products information storehouse which loads all customers information related to products exploitation and sets up the relationship between customers demands and products related characteristics, so that it reduces existing estrangements between customers demands and producers, and makes the apt products occupy the market with a appropriate price at the right time [3]. The structure of HOQ is shown in Figure 1.

Figure 1. The structure of House of Quality

QFD has formed three generally accepted patterns around 1990s since its birth: integrative QFD pattern with the representative of Yoji Akao, ASI four-stage pattern of John R. Hauser & Don Clausing and GOAL/QPCs matrix pattern of Bob King. During these patterns, ASI four-stage pattern illuminates QFDs key ideology most clearly, as is shown in Figure 2. In this pattern, customers requirements, design requirements, products characteristics, technical operation and producing requirements become the important design procedures. These procedures are organically linked through HOQ, so they can support the products innovation design processes effectively [4].

548

978-0-7695-3881-5/09 $26.00 2009 IEEE DOI 10.1109/WCSE.2009.120 10.1109/WCSE.2009.729

tool for solving difficult technical problems in cutting-edge technology field[6][7]. III. INTEGRATION RESEARCH OF QFD AND TRIZ

A. Theoretical Basis for Integration 1) Traditional QFDs Deficiencies Although QFD combines customers needs with quality of the elements through the HOQ very ingeniously, there are still certain problems in practical applications. The main problems existing in the product innovation design are as follows. a) Traditional QFD technology is obviously deficient for innovative demand; it needs the help of designers personal experience and knowledge. But because of the limitation of designers personal experience and knowledge structure, it is difficult for the high-innovation products coming out. Providing a tool to meet innovative design demands for traditional QFD improvement is very needed. b) The current quality plan process which based on QFD couldnt confirm the linear relationship and mutuality of HOQs elements clearly. c) QFD studies mostly focus on the products innovation in the first two stages, that is, products innovation plan and components deployment. Only very few researchers pay attention to the stage after products innovation, that is, technologic plan and producing plan. d) The goal-products function, the mechanism of parallel hierarchy structures presentation and technological urgent-in-need innovation mechanism all comes from customers demand analysis. Technical issues need to be solved is to consider the correlation between the mechanism and function and technological innovation needs TRIZs help. 2) Related Integration Research The optimization for the bottleneck problems can not be gotten from QFD, but the bottleneck problems can be overcome through a variety of solutions generated by TRIZ. Therefore, integrated research of QFD and TRIZ plays a great significance for the support of products innovation design. The combination of QFD and TRIZ the combination of QFD and experimental design have been found in many literatures at home and abroad in the process of products design with the core of QFD. Abroad, Philip J. Ross, Terninkao J and Leon Noel, etc.[4]and Tan Runhua [6], and Zhang Fuying [8], etc. at home all have made studied in these fields. B. Integration Architecture Study Guangping[9] has made a preliminary study based on QFD and TRIZ, and has gotten the general mode and process for integration design. In this paper, we use correlation matrix at the roof of HOQ to express correlations between the different technical characteristics, and then the technical characteristics of negative correlations are output. Based on combining with the TRIZ tools, ultimately

Figure 2.

The ASI mode of QFD

QFD has been widely used since its birth. The advantage of QFD is that QFD has made an effective plan since the early design stage of products and has prevented the unnecessary repetitions in the approaching finish-stage. Thats to say, designers are aware of what to do with the condition of QFD [5]. B. TRIZ TRIZ Theory of Inventive Problem Solving research began in 1946, and its a theoretical system which synthesized principles and theories in many subject fields, with the analysis of 2500000 patents in the world by the research organization formed by former Soviet Union's universities, research institutes and enterprises. Its main purpose is to form a guiding theory system for new products design innovation, with the condition of researching the scientific principles and rules regulated in the processes of humans invention and solving technical problems, and also making a summary of them [6]. Right now because of its good operational, systemic and practical features, TRIZ dominates a unique position in the global innovation and creation research fields. And its specific theory structure and general structure of problem-solving steps are shown in Figure 3.

The evolution rules of technology systems

Conflict analysis The model of issue Material Field Analysis Functional Analysis ARIZ

40 principles of invention 76 standard solutions Effect of the Treasury Knowledge-based Solutions tools Reference solution

Theoretical basis

Analysis Tools

Figure 3.

The structure of TRIZ problem-solving steps

To some extent, TRIZ has solved the problem of how to do, and has been successful in the settlements of a number of issues. World-renowned companies such as Ford, Motorola, GM, GE, IBM, HP, etc. have started to use it to solve problems based on computer-aided engineering and technology innovation, and make it an effective innovation

549

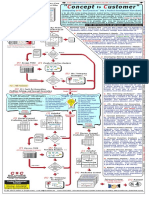

solutions are generated from the users demands. The concrete process is shown in Figure 4.

In this paper, we consider their organically combined and integrated use, in order to form a detailed design process within the mentioned above overall framework. The concrete process is as shown in Figure 5.

The importance of customer requirements

Customer Competitive Analysis

Technical knowledge and experience Profession-ally

Figure 4.

Integrated design system based on QFD and TRIZ

In this process, the users demands are reflected in the quality of house in QFD firstly. The house of quality can choose appropriate using-pattern from the above-mentioned patterns, in order to make the process, from customers requirements to design requirements, to the technical characteristics of the parts, then to the technical operation to production requirements, come true. In this process there will be bad phenomenon such as innovation, conflict and problem which can not be solved, and at this time it is necessary to combine QFD with TRIZ organically. First transfer the above issues into TRIZs solving problems; Second, look through 39 engineering parameters to find similar standards, and then acquire similar standard problem-solving solutions by using of the invention 40 principles. Because TRIZ is a supporting and guiding innovative tool in many fields, in order to get the optimal solution for the problem, the combination of professional technical knowledge and experience is needed, and then the ultimate solution will be found. Compared with the previous design methods, this design is able to solve the application problems of QFD which is inadequate to support the innovation, uncertainty and not handled properly by key elements and the matrix relationship in quality of house, only considering the customers needs in the specific design, lacking of innovation work and other issues. Meanwhile, it can ameliorate TRIZs supporting innovative design shortcomings. This is not only reflecting technology innovation process itself, but also is reflecting the majority of customers demands. This has a great significance for improving products capabilities and market-demanding capacities. Ultimately it will increase the products marketing capabilities. C. General Comprehensive Application Research of QFD and TRIZs conflict matrix Jianhui [10] studied and brought forward the initial application model of QFD and TRIZ conflict matrix, but this model is not detailed and specific enough. The above-mentioned integrated model of QFD and TRIZ can be said to be an integrated and holistic framework, and be affected through many approaches in actual use. HOQ is QFDs nerve center, conflict matrix and 40 invention principles are important innovation tools of TRIZ.

550

Figure 5.

HOQ structure and problem-solving process

In this process, firstly, we establish HOQ in accordance with customers demands, and then make conflict analysis to the negative correlation parameters in the correlation matrix. Secondly, we determine conflicts belonging category according to different criteria, and then find out the solution with using conflict solution matrix, which followed by the analysis, summary, research and consideration for the issues in conflict matrix with the invention principles of TRIZ. Finally, with combination of professional and technical knowledge and experience, we confirm whether the solution is in line with the actual professional and technical situation or not, in this way we get the ideal solution. In the above process, we used TRIZs conflict matrix and inventive principles. In conflict matrix, the vertical sections reflect the improving technical characteristics which are the 39 engineering parameters such as the quality of moving objects, stationary objects and so on. So do the horizontal sections, though with the reflection of deteriorating characteristics. During the above design process, we can find the corresponding solution in this form when we have identified technical requirements with the use of QFD, different technical characteristics of improvement and deterioration in the table junction is the suggesting invention theory for the solution correspondingly. And then we can use the 40 invention principles to solve problems. Were able to combine HOQs and TRIZs conflict matrix with invention principles organically, so we achieve the new products design goal of satisfying customers demands and upgrading the products market competitive capabilities.

IV.

APPLICATION

A. Products and Problems Vice is an important tool for holding and processing parts in engineering applications, its basic structure is as shown in Figure 6.

C. The Characteristics Need to Improve Analyzing the relationship between various customers needs and engineering characteristics in the HOQ above, in order to get the conflict, we use TRIZ engineering parameters to describe them. Based on the integrated analysis, we get characteristics which we have to meet: accuracy, adaptability, reliability; In order to achieve the requirements of the three characteristics, the adverse effects that may arise are: vices complexity, structural stability, manufacturing precision. D. Analysis table of conflict matrix According to TRIZs invention principles and conflict matrix, combined with the design requirements, relevant engineering parameters and principles needed are shown in table1.

Vice complexity Accuracy Adaptability Reliability 27351034 15293728 13351 Structural stability 323513 353014 -Manufacturing precision --11321

Figure 6.

Structure of the vice

After our scene investigation and consultation to the skilled workers, we get the following main defects in use a) It is linear joint between most parts of the vice and the steel tube. The tubes bearing pressure will be very large with when a larger force acting on it, due to this, the tubes surface will appear biggish impression and split marks. b) After a long-term use, the rail will be swayed and unstable; such phenomenon will influence the tubes positioning accuracy, and will bring some problems such as processing warp; c) When a longer tube is fixed by it, it is needed to rotate the tube or the vice because of the space or other reasons. But sometimes it is very difficult to achieve the ideal effects. d) When a tube is fixed by vice and is being processed, the loosen threads vice may appears for a greater force. Then the clamping loosening appears and it will lead to a decline in the processing quality. B. House of Quality According to QFD, HOQ is established with the demand of this example. Then we analyze the various customers needs and correlations of the different engineering characteristics. Ultimately we come to a conclusion in Figure 7.

E. Examples of conflict resolution In accordance with the conflict matrix above, we get the following ideas to solve the problem combined with TRIZ's 40 invention principles. In order to solve the problem of accuracy complexity in installation and testing, we use conflict matrix above and find 4 principles useful in TRIZ's 40 invention principles to solve the problem. They are as follows: 27. Low-cost, nondurable objects instead of expensive, durable objects; 35. Parameter changes; 10. Pre-reaction; 34. Abandoned or Repair. Then we have a try of the various principles, and principle 35 is most effective to solve this problem. In a word, we can improve rails positioning accuracy and durability by changing manufacturing precision and rigid materials. Due to space limitations, solving processes of other conflicts wont be introduced one by one here. F. The last way to solve problem Through colligating the applicable way of QFD and TRIZ, the following advices may be gotten about the tool: Firstly, the parts clamped may be locked to enlarge contact area and meanwhile the foreheads of all blocks of areas clamped are added to pads so as to decrease extrusion degree to destroy. Secondly, well get a better improvement on orientation precision and durability by improving rails manufacture precision and material rigidity. Thirdly, in order to realize the clamping problem to a small space, we may build a rotating mechanism at the bottom of vice. Finally, when the process of the assembling and clamping is over, we may add lock mechanism at the back of threads or carry lock measure in the mechanical structures.

Figure 7.

HOQ of desktop vice improving design

V.

CONCLUSION AND EXPECTATION

As is seen from the above steps, the integration based on QFD and TRIZ can be used to solve some problems about the using vice. If we can organically combine QFD with

551

TRIZ, customers demands and markets requirements are made an exhibition through the QFD part and invention design is reflected through the TRIZ part. Both advantages of doing so are fully exerted, which are very important meaning in the go-ahead of the product innovation design. However, it is a difficult process about two different theories availability integration. Some problems may be encountered in the course of application. For example, whether the results which are got by the integration design process supporting innovation design proposed in this paper are the optimal results, how to appraise them. This should be a problem need to solve .Meanwhile, with the gradual improvement of the computer technology and continuous development of the intelligent design; whether we should consider the idea in this paper that it can be made a intelligent design system or a platform so as to serve the product innovative design. Of course the idea is required to make a further research and improvement. Therefore, it will be the main research assignment to continue taking full use of this technology to solve more problems, and develop or improve it. ACKNOWLEDGMENT This research is supported by Science Foundation of Ministry of Education (205144), Outstanding Talents Project of Guizhou Province, Programs for Science and Technology Development of guizhou ([2008]3058, [2008]3047), Guizhou University Graduate Innovation Fund projects in

China (School of Science and Technology Institute 2009018). REFERENCES

CHAI Guoying,etc. The overall concept of QFD in the Diesel Engine Design[J], Vehicle Engine. 2006,(176), pp. 58-61. [2] Chen Zishunetc. Application of the improving design of TRIZ in the machine tool structure [J], Coal mining machinery. 2006,27(9), pp.116-118. [3] JONG-SEOK SHIN, KWANG-JAE KIM. Complexity reduction of a design problem in QFD using decomposition. Journal of Intelligent Manufacturing 2000(11), pp.339-354. [4] SHI Guilong, SHE Yuanguan. Theoretical research to solve the problem Based on QFD, TRIZ and Taguchi Method[J]. Systems Engineering and Electronic Technology,2008,30(5), pp.851-857. [5] Michael Schlueter. QFD by TRIZ. http www. TRIZ journal .com/ archives/ index. html. [6] Tan Runhua. Theory of Inventive Problem Solving[. Beijing, Machinery Industry Press,2004. [7] Rohan A. Shirwaiker, Gl E. Okudan. Triz and axiomatic design: a review of case-studies and a proposed synergistic use.J Intell Manuf 2008,(19) pp.3347. [8] ZHANG Fuyingetc. Based on QFD / TRIZ Integration Technology Design and Research of perforated paper tape[J]. Machine Tool and Hydraulic,2004,(11),pp.46-48. [9] HAN Guangping,etc. Integration testing of the micro-friction force sensor design based on the QFD / TRIZ / FUZZY [J]Journal of Transducer Technology,2007,20(2), pp.287-292. [10] MOU Jianhui,etc. TRIZ Theory of QFD in improving the problem,China's scientific and technological papers online,2008. [1]

552

You might also like

- FAstcat Phase 1 SolutionDocument26 pagesFAstcat Phase 1 Solutionharsh_14_88No ratings yet

- 4d. Ross 2005 PDFDocument4 pages4d. Ross 2005 PDFBernie ClintonNo ratings yet

- Process Capability IndexDocument4 pagesProcess Capability Indexchamp2357No ratings yet

- Chapter 13: Power and PoliticsDocument23 pagesChapter 13: Power and PoliticsWan Na PrommanopNo ratings yet

- MIT CISR Wp397 DemandShapingSurveyDocument13 pagesMIT CISR Wp397 DemandShapingSurveyAldus PagemakerNo ratings yet

- CISR Research Briefings 2006Document0 pagesCISR Research Briefings 2006Vanessa Gómez LondoñoNo ratings yet

- Embrace The Inevitable - Six Imperatives To Prepare Your Company For Cloud ComputingDocument4 pagesEmbrace The Inevitable - Six Imperatives To Prepare Your Company For Cloud ComputingswainanjanNo ratings yet

- Triz Based Software DevelopmentDocument31 pagesTriz Based Software DevelopmentNirmala PasalaNo ratings yet

- Takt TimeDocument4 pagesTakt Timemj123No ratings yet

- Engineering Modeling and Design-CRC Press (1992)Document386 pagesEngineering Modeling and Design-CRC Press (1992)NazımNo ratings yet

- Triz For Business and ManagementDocument21 pagesTriz For Business and ManagementDao Trong TuanNo ratings yet

- 2 Development Processes and OrganizationsDocument32 pages2 Development Processes and OrganizationsNani NRajNo ratings yet

- Captiva 5.3 TutorialDocument97 pagesCaptiva 5.3 TutorialNeha Saraf100% (1)

- Concept Generation - TRIZDocument13 pagesConcept Generation - TRIZbeingindraniNo ratings yet

- MIL-HDBK-470A VOL 1, Design Developing Maintainable ProductDocument719 pagesMIL-HDBK-470A VOL 1, Design Developing Maintainable ProductdaymonNo ratings yet

- Risk Management in ERP Project Introduction: Review of The LiteratureDocument22 pagesRisk Management in ERP Project Introduction: Review of The LiteratureChaima LejriNo ratings yet

- Brian-Morrison Design For ExcelenceDocument42 pagesBrian-Morrison Design For ExcelencemstevkaNo ratings yet

- Project 1-5 Chapters NaveenDocument116 pagesProject 1-5 Chapters NaveenHari Prasad Anupoju100% (1)

- CMMI For Acquisition (CMMI-ACQ) Primer, Version 1.3Document57 pagesCMMI For Acquisition (CMMI-ACQ) Primer, Version 1.3Software Engineering Institute PublicationsNo ratings yet

- Opl TutorialDocument10 pagesOpl TutorialYassine BouiguaNo ratings yet

- Enjoy Flexible Product Design With zw3dDocument11 pagesEnjoy Flexible Product Design With zw3dTms ArnNo ratings yet

- Case Quality - Management - CaDocument10 pagesCase Quality - Management - CaGauri SinghNo ratings yet

- BPM Aris Part1Document10 pagesBPM Aris Part1smallik3No ratings yet

- Introduction To Soft ComputingDocument9 pagesIntroduction To Soft ComputingrenumathavNo ratings yet

- Brian Fitzgerald, Klaas-Jan Stol, Sten Minör, Henrik Cosmo - Scaling A Software Business - The Digitalization Journey-Springer (2017) PDFDocument265 pagesBrian Fitzgerald, Klaas-Jan Stol, Sten Minör, Henrik Cosmo - Scaling A Software Business - The Digitalization Journey-Springer (2017) PDFMaraNo ratings yet

- Discrete Simulation Software RankingDocument12 pagesDiscrete Simulation Software RankingRapidEyeMovementNo ratings yet

- Ch.2 Logistics System EngineeringDocument31 pagesCh.2 Logistics System EngineeringAbhijeet DebNo ratings yet

- Using MonteCarlo Simulation To Mitigate The Risk of Project Cost OverrunsDocument8 pagesUsing MonteCarlo Simulation To Mitigate The Risk of Project Cost OverrunsJancarlo Mendoza MartínezNo ratings yet

- Advance Teardown MethodsDocument14 pagesAdvance Teardown MethodssarantceNo ratings yet

- An Ontology Based Architecture For Implementing Semantic Integration of Supply Chain ManagementDocument19 pagesAn Ontology Based Architecture For Implementing Semantic Integration of Supply Chain ManagementAiTheruMinasseNo ratings yet

- Conceptual Modeling For Information SystemsDocument28 pagesConceptual Modeling For Information SystemsgabilasticNo ratings yet

- BCG Why Cement Producers Need To Embrace Industry 4.0 Dec 2018 - tcm9 208964Document7 pagesBCG Why Cement Producers Need To Embrace Industry 4.0 Dec 2018 - tcm9 208964ISA SOINDNo ratings yet

- The Lean Enterprise: Lean Foundations Continuous Improvement TrainingDocument28 pagesThe Lean Enterprise: Lean Foundations Continuous Improvement TrainingPablo Riquelme GonzálezNo ratings yet

- Agile Software Development Methods 2010 e Ga CoDocument76 pagesAgile Software Development Methods 2010 e Ga CoJan Liwski100% (1)

- Architecture of Integrated Information Systems: Objectives Lecture 21.05.04Document19 pagesArchitecture of Integrated Information Systems: Objectives Lecture 21.05.04freshpomeloNo ratings yet

- IT Project Management Lab ManualDocument19 pagesIT Project Management Lab ManualAbhay PatidarNo ratings yet

- Agile Program Management: Moving From Principles To PracticeDocument30 pagesAgile Program Management: Moving From Principles To PracticeNarsing Rao PampariNo ratings yet

- Data Science SpecializationDocument21 pagesData Science SpecializationSEENU MANGALNo ratings yet

- Lean Brief Takt TimeDocument2 pagesLean Brief Takt TimeBala Kumar M PNo ratings yet

- Application of WCM Methodologies For First Time Quality ImprovementDocument110 pagesApplication of WCM Methodologies For First Time Quality ImprovementSalih ErdemNo ratings yet

- Ideas For Modeling and Simulation of Supply Chains With ArenaDocument10 pagesIdeas For Modeling and Simulation of Supply Chains With ArenaEbenezer BrightNo ratings yet

- Simulation of Plant Scale ManufacturingDocument6 pagesSimulation of Plant Scale ManufacturingTim ChegeNo ratings yet

- 1syllabus Machine Learning and Data Mining 2015Document9 pages1syllabus Machine Learning and Data Mining 2015Romeo BalingaoNo ratings yet

- QFD: A Tool of Product Design and Development: Dr. Pravin KumarDocument28 pagesQFD: A Tool of Product Design and Development: Dr. Pravin KumarPravin KumarNo ratings yet

- NPTEL - Acceptance SamplingDocument105 pagesNPTEL - Acceptance SamplingShailesh Gupta0% (1)

- " Oncept Ustomer": SolutionsDocument1 page" Oncept Ustomer": SolutionsJac DNo ratings yet

- Monte Carlo MethodDocument23 pagesMonte Carlo MethodCHINGZU212No ratings yet

- Strategic Dimensions of Maintenance Management: Albert H.C. TsangDocument33 pagesStrategic Dimensions of Maintenance Management: Albert H.C. TsanghuseNo ratings yet

- Energy Technology PerspectivesDocument458 pagesEnergy Technology PerspectivesCanice Maher100% (1)

- Peluang Dan Tantangan Implementasi System Dynamics - Dr. Ir. Muhammad Tasrif, M.eng.Document23 pagesPeluang Dan Tantangan Implementasi System Dynamics - Dr. Ir. Muhammad Tasrif, M.eng.anon_798166981No ratings yet

- ERP and SCM Systems Integration: The Case of A Valve Manufacturer in ChinaDocument9 pagesERP and SCM Systems Integration: The Case of A Valve Manufacturer in ChinaiacikgozNo ratings yet

- Presented By:: Priyanka LawateDocument24 pagesPresented By:: Priyanka Lawatepriyankalawate100% (1)

- MT5001 Desc - Assignm & Syllabus (201617)Document8 pagesMT5001 Desc - Assignm & Syllabus (201617)LiuZetongNo ratings yet

- Module 3 - Aggregate PlanningDocument2 pagesModule 3 - Aggregate PlanningvinnyNo ratings yet

- FulltextDocument96 pagesFulltextscribdpgoranNo ratings yet

- ScamperDocument35 pagesScamperKate Hera RiegoNo ratings yet

- Enhancing Warehouse Operations Through Artificial Intelligence: Pallet Damage Classification With Deep Learning InsightsDocument8 pagesEnhancing Warehouse Operations Through Artificial Intelligence: Pallet Damage Classification With Deep Learning InsightsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Using Work Factor Method With The MOST System For Accurate Disassembly Time EvaluationDocument6 pagesUsing Work Factor Method With The MOST System For Accurate Disassembly Time EvaluationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Requirements Process: MasteringDocument6 pagesRequirements Process: MasteringmichaelNo ratings yet

- BenchmarkingDocument21 pagesBenchmarkingdni oduNo ratings yet

- Staff Wellbeing Poster PrintDocument1 pageStaff Wellbeing Poster PrintNguyen Phuong LinhNo ratings yet

- Sample Evaluation FormsDocument7 pagesSample Evaluation FormsEdwin Delos Reyes AbuNo ratings yet

- Advertising Research - MJDocument28 pagesAdvertising Research - MJMuhammad Sameer Husain100% (1)

- Chapter 2: Writing Process Writing Is A Process Which Involves Four Steps: - Planning - Drafting - Revising - Editing & ProofreadingDocument11 pagesChapter 2: Writing Process Writing Is A Process Which Involves Four Steps: - Planning - Drafting - Revising - Editing & ProofreadingStein Bright Lateavi LawsonNo ratings yet

- Attachment For Professionals: Dr. Alice Arianto, Psy.DDocument52 pagesAttachment For Professionals: Dr. Alice Arianto, Psy.DSiti BahiyahNo ratings yet

- Purnima GorlaDocument2 pagesPurnima GorlaPurnima GorlaNo ratings yet

- Relationship Between Motivation and PerformanceDocument24 pagesRelationship Between Motivation and PerformancekierselennNo ratings yet

- Metropolitan Business AcademyDocument1 pageMetropolitan Business AcademyNHRSportsNo ratings yet

- Definition of Business PolicyDocument10 pagesDefinition of Business Policyvarun rajNo ratings yet

- 963 TOEFL EssaysDocument657 pages963 TOEFL EssaysLuân NguyễnNo ratings yet

- The Assessment Scales: B1 Content Communicative Achievement Organisation Language 5Document1 pageThe Assessment Scales: B1 Content Communicative Achievement Organisation Language 5jkllNo ratings yet

- Lecture-1 (Ch. 1, Uma)Document19 pagesLecture-1 (Ch. 1, Uma)Tahseen RazaNo ratings yet

- Actfl Opi CertificateDocument1 pageActfl Opi Certificateapi-242936638100% (1)

- 3 RaiDocument44 pages3 RaiDr Shabbir100% (2)

- IPC Tabernacle Dallas, Inc.Document6 pagesIPC Tabernacle Dallas, Inc.IPC TabernacleNo ratings yet

- Attitude + Social Norms 3-12Document2 pagesAttitude + Social Norms 3-12Irro Asentista CabelloNo ratings yet

- Shoe Horn Sonata Part ThreeDocument13 pagesShoe Horn Sonata Part ThreeIsmail HajiNo ratings yet

- Liezel Ann Palo - ResumeDocument3 pagesLiezel Ann Palo - ResumePISD Teachers67% (3)

- Marketing Communications 2 (MC201) Outline 2011Document3 pagesMarketing Communications 2 (MC201) Outline 2011Maxine IgnatiukNo ratings yet

- Karan BhiseDocument3 pagesKaran BhiseINTERNATIONAL JOURNAL FOR EDUCATIONAL RESEARCH STUDIESNo ratings yet

- Learning Activity Sheets Grade 12 - Trends, Networks and Critical Thinking in The 21 CenturyDocument4 pagesLearning Activity Sheets Grade 12 - Trends, Networks and Critical Thinking in The 21 CenturyEbb Lian Anino50% (2)

- Motivation of Taj 26,11Document5 pagesMotivation of Taj 26,11bonigala.jaanviNo ratings yet

- My 2nd Joseph Zbukvic Workshop - PTDocument8 pagesMy 2nd Joseph Zbukvic Workshop - PTNalin SwaroopNo ratings yet

- M8 - Assignment (Emotion)Document2 pagesM8 - Assignment (Emotion)bry uyNo ratings yet

- KABATAANG ESSAY - Fake NewsDocument6 pagesKABATAANG ESSAY - Fake NewsEmanoel Noveda0% (1)

- Social Identity and Intergroup ConflictDocument17 pagesSocial Identity and Intergroup ConflictApoorva ThakurNo ratings yet

- Annotation Template For Master Teacher I-IV (Highly Proficient Teachers)Document6 pagesAnnotation Template For Master Teacher I-IV (Highly Proficient Teachers)dan joseph santos100% (1)

- Popular Culture Nature Scope and DefinitionDocument3 pagesPopular Culture Nature Scope and DefinitionNianjan chatterjeeNo ratings yet