Professional Documents

Culture Documents

Reinforcement Works

Reinforcement Works

Uploaded by

prasanna ok0 ratings0% found this document useful (0 votes)

35 views5 pagesThe document provides a safe work method statement for a reinforcement works project. It outlines 3 key steps: 1) Manual bar bending, which could cause defects or injuries from improper tools or posture; 2) Rebaring using cutting tools and handling long bars, which poses injury risks; 3) Reinforcement shifting, which was not fully described but implied potential hazards. Control measures are provided to eliminate hazards through proper tools, inspection, procedures, personnel, and personal protective equipment. The project manager is responsible for ensuring the control measures are followed.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides a safe work method statement for a reinforcement works project. It outlines 3 key steps: 1) Manual bar bending, which could cause defects or injuries from improper tools or posture; 2) Rebaring using cutting tools and handling long bars, which poses injury risks; 3) Reinforcement shifting, which was not fully described but implied potential hazards. Control measures are provided to eliminate hazards through proper tools, inspection, procedures, personnel, and personal protective equipment. The project manager is responsible for ensuring the control measures are followed.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

0 ratings0% found this document useful (0 votes)

35 views5 pagesReinforcement Works

Reinforcement Works

Uploaded by

prasanna okThe document provides a safe work method statement for a reinforcement works project. It outlines 3 key steps: 1) Manual bar bending, which could cause defects or injuries from improper tools or posture; 2) Rebaring using cutting tools and handling long bars, which poses injury risks; 3) Reinforcement shifting, which was not fully described but implied potential hazards. Control measures are provided to eliminate hazards through proper tools, inspection, procedures, personnel, and personal protective equipment. The project manager is responsible for ensuring the control measures are followed.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

You are on page 1of 5

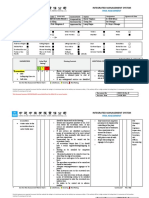

Safe Work Method Statement

Project Name: OLA Cell technologies private limited DATE:18.07.2023

Company Name

Address:

Office Contact No:

Project Manager Name Contact No:

ACIVITY : REINFORCEMENT WORKS

The person who

Procedure (in steps) Possible Hazards Risk Control Measures will ensure this

Rating (Describe what action or procedure will be happens

(Break the job down into steps. Each step (Identify the hazards associated with (See taken to eliminate or minimize the risk of injury

should accomplish some major task and each step. Examine each to find below) or damage. Use the Hierarchy of Controls

be in logical sequence.) possibilities that could lead to an accident below as a guide

or potential harm arising.) 1. Eliminate the Hazard

2. Substitute the material or equipment

3. Isolate the hazard

4. Implement Engineering control

5. Implement Administrative control

6. PPE

1. Manual bar bending. Defective tools. Do not use sub-standard tools.

Wrong application of tools. Ensure usage of right tools for right

Wrong posture. job.

Do not push tools while bending.

Hold firmly.

Adhere to correct and safe posture.

Provide protection cover on all

moving parts of machine / tool.

Document Name: Version Correct as at:

SWMS for brickwork and plastering 01 11.01.2023

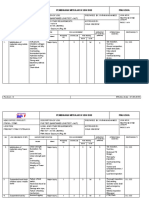

Safe Work Method Statement

The person who

Procedure (in steps) Possible Hazards Risk Control Measures will ensure this

Rating (Describe what action or procedure will be happens

(Break the job down into steps. Each step (Identify the hazards associated with (See taken to eliminate or minimize the risk of injury

should accomplish some major task and each step. Examine each to find below) or damage. Use the Hierarchy of Controls

be in logical sequence.) possibilities that could lead to an accident below as a guide

or potential harm arising.) 1. Eliminate the Hazard

2. Substitute the material or equipment

3. Isolate the hazard

4. Implement Engineering control

5. Implement Administrative control

6. PPE

2. Rebaring ( Use of high RPM Human injury Get the electrically operated tools

cutting tools, Long rebar and tackles inspected by the

handling) electrical department for fitness and

correctness.

Bar bending to be done on proper

table with proper holding

arrangements.

Deploy minimum three persons for

handling full length rebar.

Keep surrounding swing area free

for safe handling while cutting.

Move bars horizontally.

Protruding rears bent down.

Reflecting cap provided to exposed

bar.

Document Name: Version Correct as at:

SWMS for brickwork and plastering 01 11.01.2023

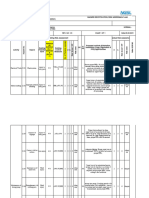

Safe Work Method Statement

The person who

Procedure (in steps) Possible Hazards Risk Control Measures will ensure this

Rating (Describe what action or procedure will be happens

(Break the job down into steps. Each step (Identify the hazards associated with (See taken to eliminate or minimize the risk of injury

should accomplish some major task and each step. Examine each to find below) or damage. Use the Hierarchy of Controls

be in logical sequence.) possibilities that could lead to an accident below as a guide

or potential harm arising.) 1. Eliminate the Hazard

2. Substitute the material or equipment

3. Isolate the hazard

4. Implement Engineering control

5. Implement Administrative control

6. PPE

3. Reinforcement Shifting to work Human injury. Clear front while handling it to site.

Location. (Manually ,By Hydra Material may fall on person. Use of leverage bars does not apply

& Tower Crane.) Using of damaged lifting tools and hand directly in bundles.

tackles. Make use of hydra or suitable lifting

machine to load on trailer.

Make sure the trailer wheels are

locked with stopper and breaks

applied.

Ensure to use good condition tools

only.

Ensure to worn the full body

harness.

Ensure to provide the plat form on

scaffold.

4. Cutting wire by tools Defective tools. Use proper binding before going to

Personal injury. cutting.

Damage of tools. Take exta care while walking

around the work site.

Remove all Combustible material

near to cutting area

Document Name: Version Correct as at:

SWMS for brickwork and plastering 01 11.01.2023

Safe Work Method Statement

The person who

Procedure (in steps) Possible Hazards Risk Control Measures will ensure this

Rating (Describe what action or procedure will be happens

(Break the job down into steps. Each step (Identify the hazards associated with (See taken to eliminate or minimize the risk of injury

should accomplish some major task and each step. Examine each to find below) or damage. Use the Hierarchy of Controls

be in logical sequence.) possibilities that could lead to an accident below as a guide

or potential harm arising.) 1. Eliminate the Hazard

2. Substitute the material or equipment

3. Isolate the hazard

4. Implement Engineering control

5. Implement Administrative control

6. PPE

5. Reinforcement Curtailment and binding of rods. Use PPE like gloves, shoes,

Carrying of rods for short helmets,etc.

distances/ at height. Avoid usage of make-shift tools.

Checking of clear distance/ cover Provide suitable pads on shoulders

with hands. and use safety gloves.

Hitting projected rods and standing Ensure proper staging.

on cantilever rods. Use measuring devices like

Persons may get injured . tape ,measuring rods, etc.

Workers may get injured on their Avoid wearing of loose cloths.

hands and shoulders.

Rods may cut or injure the fingers.

Persons may get injured and fall

down

Protruded rods may hit the persons

Document Name: Version Correct as at:

SWMS for brickwork and plastering 01 11.01.2023

Safe Work Method Statement

Personnel Summary

SUPERVISOR’S DETAILS

Supervisors Name & Qualifications: Name:

Experience:

Qualifications:

Prepared by: Signature: Date:

(Principle Contractor HSE Manager)

Reviewed by : Signature: Date:

(Principle Contractor Project Manager)

Reviewed by Signature Date:

(JLLSafety Manager)

Approved by

(JLL Project Manager) Signature Date:

Document Name: Version Correct as at:

SWMS for Brick work and plastering 01 11.01.2023

You might also like

- The Perfume Handbook PDFDocument331 pagesThe Perfume Handbook PDFNofearmak100% (8)

- JHA - Unloading of Sheet PileDocument3 pagesJHA - Unloading of Sheet PileJensen Sunga100% (1)

- Risk Assessment WorksheetDocument2 pagesRisk Assessment WorksheetHergheligiu VasileNo ratings yet

- Unit 6 IAL ChemistryDocument11 pagesUnit 6 IAL ChemistryDonggyu Lee100% (1)

- Guide To Low Voltage Busbar Trunking Systems Verified To BS EN 61439-6 PDFDocument22 pagesGuide To Low Voltage Busbar Trunking Systems Verified To BS EN 61439-6 PDFEduardo ZamoranoNo ratings yet

- Biochemical Test of BacteriaDocument33 pagesBiochemical Test of Bacteriaaziskf100% (2)

- Shuttering WorksDocument5 pagesShuttering Worksprasanna okNo ratings yet

- Risk Assessment Maintenance: L - Likelihood S - Severity RL - Risk LevelDocument3 pagesRisk Assessment Maintenance: L - Likelihood S - Severity RL - Risk LevelMohamed ElnagdyNo ratings yet

- SWMS-Pipe Instalation Work at Utility 25.01.21Document10 pagesSWMS-Pipe Instalation Work at Utility 25.01.21Ansari FaisalNo ratings yet

- Risk Cooling TowerDocument4 pagesRisk Cooling TowerHariharan MuthukrishananNo ratings yet

- Use of Power ToolsDocument3 pagesUse of Power ToolsNisanth ThulasidasNo ratings yet

- PipingDocument9 pagesPipingshamierrul shahliNo ratings yet

- Job Safety Analysis (Jsa) : Fabrication Works, Welding Works Using Power Tools, Hand Tools, Welding Machine WapstechDocument3 pagesJob Safety Analysis (Jsa) : Fabrication Works, Welding Works Using Power Tools, Hand Tools, Welding Machine WapstechMohamedSaidNo ratings yet

- 19.hydro Pressure Testing.Document8 pages19.hydro Pressure Testing.Mohammad Fazal KhanNo ratings yet

- MTA2018-JHA-012 Air Compressor OperationDocument10 pagesMTA2018-JHA-012 Air Compressor OperationKelvin TanNo ratings yet

- Asm Risk Assesment fv2 PDFDocument3 pagesAsm Risk Assesment fv2 PDFshijadNo ratings yet

- HiraDocument11 pagesHiraNilamSanjeev Kumar SinghNo ratings yet

- Risk Assessment Man Cage and Telehandler Pklands July 2022Document4 pagesRisk Assessment Man Cage and Telehandler Pklands July 2022Dáithí O'LaoghaireNo ratings yet

- Working On Brake System (WS)Document12 pagesWorking On Brake System (WS)John KalvinNo ratings yet

- 31.HIRA - Boom Placer OperationDocument3 pages31.HIRA - Boom Placer OperationMMRDACA07 SAFETYNo ratings yet

- Risk Assessment:: Corresponding Permit To Work NoDocument4 pagesRisk Assessment:: Corresponding Permit To Work NoNaseemandson TeamNo ratings yet

- Job Safety Analysis - Tbl-Jsa: STEP 4: Hazard Risk AssessmentDocument6 pagesJob Safety Analysis - Tbl-Jsa: STEP 4: Hazard Risk AssessmentMoaatazz Nouisri100% (1)

- Weekly HSE Inspection Closeout Report - 01Document2 pagesWeekly HSE Inspection Closeout Report - 01niyas100% (1)

- CTRA-23-STM-146 - TK - 11-995 - HotWorkDocument3 pagesCTRA-23-STM-146 - TK - 11-995 - HotWorkMohamed RizwanNo ratings yet

- Risk Assessment-FGD MECHDocument85 pagesRisk Assessment-FGD MECHVivekananth AshokanNo ratings yet

- 50 MW Artistic Wind Power Project: Job Safety Analysis Worksheet (Equipment Lifting)Document3 pages50 MW Artistic Wind Power Project: Job Safety Analysis Worksheet (Equipment Lifting)Raza Muhammad SoomroNo ratings yet

- Task Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)Document2 pagesTask Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)andreNo ratings yet

- 11.pneumatic Pressure Testing.Document7 pages11.pneumatic Pressure Testing.Mohammad Fazal KhanNo ratings yet

- CSCEC HSE-F-01 Risk Assessment Form - Excavation& Backfilling - RA-02Document12 pagesCSCEC HSE-F-01 Risk Assessment Form - Excavation& Backfilling - RA-02Dan SarmientoNo ratings yet

- HSE-RA-019 Steel Fixing - Rev 0Document15 pagesHSE-RA-019 Steel Fixing - Rev 0عمروNo ratings yet

- HIRA - MS Staircase ErectionDocument7 pagesHIRA - MS Staircase ErectionRamNo ratings yet

- P111-Rsme-Tra-007 - Tra For Cold Tie inDocument5 pagesP111-Rsme-Tra-007 - Tra For Cold Tie inDarius DsouzaNo ratings yet

- Risk Assessment Carpentry Works For Dismantling Wooden BoxesDocument10 pagesRisk Assessment Carpentry Works For Dismantling Wooden BoxesSinaNo ratings yet

- 7.OHS-PR-09-03-F02 HIRA - 30 Hydro Testing of Gas PipelineDocument5 pages7.OHS-PR-09-03-F02 HIRA - 30 Hydro Testing of Gas PipelineabbasNo ratings yet

- Risk Assessment Hanging DoorsDocument11 pagesRisk Assessment Hanging DoorsMitchRappNo ratings yet

- Jha Clarke Engine PumpDocument4 pagesJha Clarke Engine Pumpperquino oasanNo ratings yet

- Risk Assessment - Usage of Overhead Crane - Ben Ching Engineering (1) .Rev.1Document3 pagesRisk Assessment - Usage of Overhead Crane - Ben Ching Engineering (1) .Rev.1Kono Nor AtanNo ratings yet

- Hiradc - Hot WorkDocument4 pagesHiradc - Hot WorkAlieya MustafaNo ratings yet

- Diesel Generator Hazard Assessment PDF Master HireDocument6 pagesDiesel Generator Hazard Assessment PDF Master HireMuhammad MalikNo ratings yet

- Jsa Fan Coil Unites MaintenanceDocument5 pagesJsa Fan Coil Unites MaintenanceASLAM MULANINo ratings yet

- TRA of Ladder & PlatformDocument2 pagesTRA of Ladder & PlatformandreNo ratings yet

- ISLA JHA Removal of BarricadeDocument3 pagesISLA JHA Removal of Barricadeaasafety06No ratings yet

- TTEC Fencing RADocument7 pagesTTEC Fencing RAGeml TrinidadNo ratings yet

- Working at HeightDocument4 pagesWorking at HeightFILE 1131No ratings yet

- Risk Assessment For Mechanical: Preparation WorkDocument3 pagesRisk Assessment For Mechanical: Preparation Workahmedalderbi801No ratings yet

- Deshuttering WorkDocument1 pageDeshuttering WorkAhmed AbdulfatahNo ratings yet

- Concrete Risk AssessmentDocument1 pageConcrete Risk AssessmentTariq saifiNo ratings yet

- Lifting Equipment at Work: A Brief GuideDocument36 pagesLifting Equipment at Work: A Brief GuideDrishti MehtaNo ratings yet

- Risk Assessment Green Dream - HIDD AL SAADIYAT VILLA - SP4 - 58 - V1Document29 pagesRisk Assessment Green Dream - HIDD AL SAADIYAT VILLA - SP4 - 58 - V1طارق رضوانNo ratings yet

- Risk Assessment SK GraphiteDocument8 pagesRisk Assessment SK GraphiteWasim KhanNo ratings yet

- JSA-018 Lifting With Mobile CraneDocument5 pagesJSA-018 Lifting With Mobile CraneMoaatazz Nouisri0% (1)

- 2.8c Risk Assessment - 074 Construction of Substation Floor, Wall, Stairs by Casting in Place Rev. July 2019Document7 pages2.8c Risk Assessment - 074 Construction of Substation Floor, Wall, Stairs by Casting in Place Rev. July 2019kamranshamoo1No ratings yet

- Jsa Welding GrindingDocument5 pagesJsa Welding GrindingWiedz PrastNo ratings yet

- Safe Work ProcedureDocument5 pagesSafe Work ProcedureSurya Narayan MahapatraNo ratings yet

- Risk Assessment For Installation, Testing & Commissioning of Fire Pumps SetDocument11 pagesRisk Assessment For Installation, Testing & Commissioning of Fire Pumps SetAmie GTunedNo ratings yet

- Jsa For Chemical Ware HouseDocument4 pagesJsa For Chemical Ware Housesalauddin0mohammedNo ratings yet

- Pile Test (Maintained Load Test - MLT)Document4 pagesPile Test (Maintained Load Test - MLT)Shures Kumar SubramaniyamNo ratings yet

- Hira For Pipe Coating Monsher Fire Protectioin System P. L.Document31 pagesHira For Pipe Coating Monsher Fire Protectioin System P. L.Nikhil ManjrekarNo ratings yet

- 11 Construction of Kill LineDocument9 pages11 Construction of Kill LinePangky AbasoloNo ratings yet

- PCR-LP-362-Tower Crane Dismantling (LTM1450-8.1)Document17 pagesPCR-LP-362-Tower Crane Dismantling (LTM1450-8.1)Geethika SandaruwanNo ratings yet

- Risk Assessment of Fabrication, Welding, Cutting WorkDocument7 pagesRisk Assessment of Fabrication, Welding, Cutting WorkAbdul MujeebNo ratings yet

- 22.# Hiradec Dosing PumpDocument7 pages22.# Hiradec Dosing PumpPankaj PandeyNo ratings yet

- Sand FillingDocument1 pageSand FillingGyanendra Narayan NayakNo ratings yet

- Unloading Method StatementDocument3 pagesUnloading Method Statementprasanna okNo ratings yet

- PCC & ConcDocument4 pagesPCC & Concprasanna okNo ratings yet

- ExcavationDocument3 pagesExcavationprasanna ok100% (1)

- Scaffolding WorksDocument7 pagesScaffolding Worksprasanna okNo ratings yet

- Unloading Method StatementDocument3 pagesUnloading Method Statementprasanna okNo ratings yet

- Journal Homepage: - : IntroductionDocument5 pagesJournal Homepage: - : IntroductionIJAR JOURNALNo ratings yet

- Developing and Using HR Audit ToolsDocument32 pagesDeveloping and Using HR Audit ToolsJablack Angola MugabeNo ratings yet

- Arco-КЛАПАНА-2018 01 05Document260 pagesArco-КЛАПАНА-2018 01 05Алексей ТозикNo ratings yet

- Presentation No. 2 - Sensory ImageryDocument8 pagesPresentation No. 2 - Sensory Imageryandie hinchNo ratings yet

- Crew Size Simulation Cardiac Arrest TapiaiDocument12 pagesCrew Size Simulation Cardiac Arrest TapiaiJamison ParfittNo ratings yet

- ZRZT 55-90 (VSD) (FF)Document25 pagesZRZT 55-90 (VSD) (FF)Erick GuzmanNo ratings yet

- Emergency Preparedness Audit - GuideDocument20 pagesEmergency Preparedness Audit - GuideMaricris Napigkit SerranoNo ratings yet

- Worksheet 25 - 26 - 3rd - MSP - EDocument8 pagesWorksheet 25 - 26 - 3rd - MSP - EMelissaNo ratings yet

- Best Practice Guide For Bus and Coach Tyre Maintenance - Revised 20150731Document32 pagesBest Practice Guide For Bus and Coach Tyre Maintenance - Revised 20150731Messay EsheteNo ratings yet

- Guide Falsework AustraliaDocument4 pagesGuide Falsework AustraliaHafizah MohdNo ratings yet

- Module 2.3b Reading MaterialsDocument3 pagesModule 2.3b Reading MaterialsLuis MunozNo ratings yet

- Human Genome ProjectDocument57 pagesHuman Genome ProjectIsma Velasco100% (1)

- FP10000Q and FP6000Q User ManualDocument8 pagesFP10000Q and FP6000Q User Manualaleka imanuelNo ratings yet

- Polymer Materials From Recycled Plastic in Road ConstructionDocument7 pagesPolymer Materials From Recycled Plastic in Road ConstructionYuv RajNo ratings yet

- City of Naga Scholar ProfileDocument2 pagesCity of Naga Scholar ProfileFaith James ServanoNo ratings yet

- Urine Case 2010-2Document9 pagesUrine Case 2010-2hendra_darmawan_4No ratings yet

- CIMON IXT15 Datasheet 2023.06.06Document1 pageCIMON IXT15 Datasheet 2023.06.06habacuc8891No ratings yet

- Internal Sources of RecruitmentDocument3 pagesInternal Sources of RecruitmentakinravNo ratings yet

- Anti ScalantDocument14 pagesAnti ScalantassurendranNo ratings yet

- Ce208 Lab ReportDocument3 pagesCe208 Lab ReportHarsh SharmaNo ratings yet

- Mrs. Annapurna TiwariDocument15 pagesMrs. Annapurna Tiwarikuruvagadda sagarNo ratings yet

- Applications of Bioacoustics in Animal Ecology: Ecological Complexity August 2020Document6 pagesApplications of Bioacoustics in Animal Ecology: Ecological Complexity August 2020Mickey ValleeNo ratings yet

- Man#251 Rev BDocument10 pagesMan#251 Rev Bjuan dalmassoNo ratings yet

- Cementitious Slurries From CeresitDocument7 pagesCementitious Slurries From CeresitMostafa Hussein AbdouNo ratings yet

- Method of Statement-Condesate Water Tank MovingDocument5 pagesMethod of Statement-Condesate Water Tank Movingfaizan.razaNo ratings yet

- Installation and Maintenance Instructions For Ashcroft Type 91 Series Adapter KitDocument1 pageInstallation and Maintenance Instructions For Ashcroft Type 91 Series Adapter KitvaltierrillaNo ratings yet