Professional Documents

Culture Documents

Spramul SS1h

Spramul SS1h

Uploaded by

Jennifer JavierOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spramul SS1h

Spramul SS1h

Uploaded by

Jennifer JavierCopyright:

Available Formats

1.

Description

Spramul SS-1h are slow-setting, anionic type of asphalt emulsions manufactured according to specifications of

ASTM D977 - “Standard Specifications for Anionic Emulsified Asphalt.”

It is a dispersion of small droplets of penetration grade asphalt cement in water with the aid of an emulsifier. The

size of the droplets is normally in the order of 1-20 microns, with some particles as big as 100 microns. Since these

droplets are negatively charged, breaking (coalescence) is purely by evaporation of water.

2. Uses

2.1 Tack Coat - a very light application of diluted asphalt emulsion. It is used to ensure a bond between a surface

being paved and the new course. Tack coating is one of the major uses of Spramul SS-1h. It is used to guarantee

adhesion of hot mix or cold mix asphalt overlay to existing asphalt paved roads.

Method of application: by spray (distributor)

2.2 Fog Seal - a light application of asphalt emulsion diluted with water, similar to tack coat. It is used to renew old

asphalt road surfaces that have become dry and embrittled with age, to fill tiny cracks and surface voids and to

inhibit ravelling. No other surface treatment is applied after fog sealing.

Method of application: by spray (distributor)

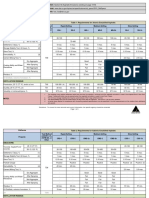

Spramul Typical Properties

Test Method SS-1h

Tests on emulsion: ASTM D244

Viscosity, Saybolt Furol @ 25 oC, s 20 - 100

Storage stability test, 24 hr., % wt. 1.0 max

Cement mixing test, % wt. 2.0 max

Sieve test, % wt. 0.10 max.

Residue by distillation, % wt. 57 min.

Particle Charge Test -

Tests on residue from distillation:

Penetration @ 25 oC, 100 g, 5 s ASTM D5 40 - 90

Ductility @ 25 oC, 5 cm/min, cm. ASTMD113 40 min

Solubility in trichloroethylene, % wt. ASTM D2042 97.5 min

3. Storing and Handling

• Emulsions are stored between 10oC and 60oC, depending on the temperature required for application. When

stored at higher temperatures, the tanks must be insulated. Hot water or steam can be used as the heating

medium. Oil burners are also used.

• Spramul should not be heated to above 60oC or else the material can no longer be used as intended. While

heating during transport and in tanks or distributors it should be agitated to eliminate or reduce skin formation.

• At tank storage, a light agitation is performed to avoid settlement (forced air is not recommended as it will cause

the emulsion to break). At drum storage it is recommended to roll the drums before use to ensure homogeneity.

• Before diluting Spramul the compatibility of the water with the emulsion must be checked. The water should

always be added to the emulsion, not the emulsion to the water.

• Spramul SS-1h must not be mixed with cationic asphalt emulsions or other types of products in storage tanks,

tank transports, or distributors.

4. Packaging

Shell Spramul SS-1h is available in bulk and 200 kg. drums.

You might also like

- AOAC 994.10 - GC - Cholesterol in Foods PDFDocument2 pagesAOAC 994.10 - GC - Cholesterol in Foods PDFdennisaberliani100% (2)

- M208Document1 pageM208FRANZ RICHARD SARDINAS MALLCO0% (1)

- Astm D6934-08 (Me6) PDFDocument2 pagesAstm D6934-08 (Me6) PDFJosé Manuel MejíaNo ratings yet

- Tests On EmulsionDocument11 pagesTests On EmulsionAbdhul Khadhir ShalayarNo ratings yet

- Aashto T-104 PDFDocument10 pagesAashto T-104 PDFthauwui8650% (2)

- S406 Specifications For The Supply of Stone PDFDocument6 pagesS406 Specifications For The Supply of Stone PDFMfanelo MbanjwaNo ratings yet

- Bitumen & Bitumen Emulsion UomDocument88 pagesBitumen & Bitumen Emulsion Uomkalana mihirangaNo ratings yet

- SS-1h Product Data Sheet: Description and Physical PropertiesDocument1 pageSS-1h Product Data Sheet: Description and Physical Propertiesjaviersamuel condoriNo ratings yet

- BitumenDocument6 pagesBitumenMithu HossainNo ratings yet

- Cationic Emulsified Asphalt: Standard Specification ForDocument3 pagesCationic Emulsified Asphalt: Standard Specification Forjude tallyNo ratings yet

- Shalicrystal 100: DescriptionDocument2 pagesShalicrystal 100: DescriptionbarunNo ratings yet

- Tests and Specifications: Brief Description of The Test MethodsDocument6 pagesTests and Specifications: Brief Description of The Test Methodschem_ratanNo ratings yet

- Specification of Bitumen (Asphalt) Emulsion: Rapid-Setting Cationic ASTM D 2397M - 13Document1 pageSpecification of Bitumen (Asphalt) Emulsion: Rapid-Setting Cationic ASTM D 2397M - 13Rabnawaz ImamNo ratings yet

- Astm D3665 12Document2 pagesAstm D3665 12Lupita Ramirez25% (4)

- Residue by Evaporation of Emulsified Asphalt: Standard Test Method ForDocument2 pagesResidue by Evaporation of Emulsified Asphalt: Standard Test Method ForManuel Enrique VásquezNo ratings yet

- Specification of Bitumen (Asphalt) Emulsion: Rapid-Setting Cationic ASTM D 2397M - 13Document1 pageSpecification of Bitumen (Asphalt) Emulsion: Rapid-Setting Cationic ASTM D 2397M - 13Rabnawaz ImamNo ratings yet

- Residuo Por Evaporacion - D6934.6936Document2 pagesResiduo Por Evaporacion - D6934.6936Luis RamirezNo ratings yet

- Revised Lecture by Sir JanggoDocument43 pagesRevised Lecture by Sir JanggoAriel Dela CruzNo ratings yet

- 45.4.10 AOAC Official Method 994.10 Cholesterol in Foods: C) D) E) F) G) H)Document11 pages45.4.10 AOAC Official Method 994.10 Cholesterol in Foods: C) D) E) F) G) H)Angélica VargasNo ratings yet

- AASHTO 208-01 Cationic Emulsified AsphaltDocument3 pagesAASHTO 208-01 Cationic Emulsified AsphaltDucnguyenNo ratings yet

- Soundness TestDocument3 pagesSoundness TestYasirNo ratings yet

- D 977 - 98 Rdk3ny1sruqDocument4 pagesD 977 - 98 Rdk3ny1sruqRufo CascoNo ratings yet

- Saybolt Furol VisosityDocument3 pagesSaybolt Furol VisosityChathura ChamikaraNo ratings yet

- WB Paint PDS 1952F TY II Fast Dry Final 210303 DADocument2 pagesWB Paint PDS 1952F TY II Fast Dry Final 210303 DALuis Barrios ArandaNo ratings yet

- D6934-08 (Reapproved 2016)Document2 pagesD6934-08 (Reapproved 2016)majd.saleem027No ratings yet

- C 282 - 99 - Qzi4mgDocument3 pagesC 282 - 99 - Qzi4mgEmre DalgicNo ratings yet

- Method of Test For High Float Emulsified AsphaltsDocument11 pagesMethod of Test For High Float Emulsified Asphaltsming_zhu10No ratings yet

- AASHTO M-208 Especificaciones Emulsion Asfaltica (Cationica)Document1 pageAASHTO M-208 Especificaciones Emulsion Asfaltica (Cationica)skull91No ratings yet

- Revised FinalDocument24 pagesRevised FinalShyla LuyNo ratings yet

- Epoxy Backing Grout Epigen 0301: Typical Applications ProfileDocument2 pagesEpoxy Backing Grout Epigen 0301: Typical Applications ProfileDianWidodoNo ratings yet

- Soundness of Aggregate by U Se of Sodium Sulfate or Magnésium SulfateDocument10 pagesSoundness of Aggregate by U Se of Sodium Sulfate or Magnésium SulfatesitrakiniavoNo ratings yet

- California: State: Specification: Date: Web Address: Contact: Contact InfoDocument5 pagesCalifornia: State: Specification: Date: Web Address: Contact: Contact InfoSamuel Ch. G.No ratings yet

- D 1579 - 97 Rde1nzktotcDocument2 pagesD 1579 - 97 Rde1nzktotcMarceloNo ratings yet

- Product: Penetration Grade Bitumen Cutback MC 70 Packing: New Steel Drum 180 5Kgs / BulkDocument2 pagesProduct: Penetration Grade Bitumen Cutback MC 70 Packing: New Steel Drum 180 5Kgs / BulkvinayaiyappaNo ratings yet

- Qaulity Control ReportDocument13 pagesQaulity Control ReportYhaneNo ratings yet

- Slow Setting Bitumen Emulsion: Product Data SheetDocument2 pagesSlow Setting Bitumen Emulsion: Product Data Sheetmijanur rahmanNo ratings yet

- C 484 - 99 R03 - Qzq4naDocument2 pagesC 484 - 99 R03 - Qzq4nacurt volvoNo ratings yet

- Bitumen Properties 2Document3 pagesBitumen Properties 2amanbhu1991No ratings yet

- Impreglon 410M DataSheetDocument2 pagesImpreglon 410M DataSheetMehrad LahutiNo ratings yet

- C 484 - 99 Qzq4nc05oqDocument2 pagesC 484 - 99 Qzq4nc05oqMarceloNo ratings yet

- Soundness of Aggregate by Use of Sodium Sulfate or Magnesium SulfateDocument5 pagesSoundness of Aggregate by Use of Sodium Sulfate or Magnesium SulfateEvert RiveraNo ratings yet

- AsphaltDocument4 pagesAsphaltMae GonzalesNo ratings yet

- 134 TDS Updated Feb 2016 78-8141-8528-2 Rev ADocument6 pages134 TDS Updated Feb 2016 78-8141-8528-2 Rev AUriel GarciaNo ratings yet

- Corrosion Resistance of Heat Exchanger Fin Materials Rev ADocument15 pagesCorrosion Resistance of Heat Exchanger Fin Materials Rev Afarep76121No ratings yet

- Croda NF-TDocument3 pagesCroda NF-Tnirai101259No ratings yet

- Handbook On Concrete PDFDocument71 pagesHandbook On Concrete PDFrajan sharma100% (1)

- Tehnički List - LIMEPOR 100Document2 pagesTehnički List - LIMEPOR 100MARKO MATUHANo ratings yet

- AASHTO T-104 (Año 2007)Document10 pagesAASHTO T-104 (Año 2007)Roberto VasquezNo ratings yet

- Multipurpose Binder, Primer & Laminating Resin Epigen 0402: Potable Water SuitabilityDocument2 pagesMultipurpose Binder, Primer & Laminating Resin Epigen 0402: Potable Water Suitabilityjulius hasan33No ratings yet

- Designation: C 1203 - 91 (Reapproved 2002)Document5 pagesDesignation: C 1203 - 91 (Reapproved 2002)angeljosechuquiureNo ratings yet

- Experiment No:: Date: TITLE: Soundness Test On Cement. AIM: To Verify The Soundness of Given Sample of Cement. TheoryDocument2 pagesExperiment No:: Date: TITLE: Soundness Test On Cement. AIM: To Verify The Soundness of Given Sample of Cement. TheoryRahul SharmaNo ratings yet

- Mesamoll eDocument4 pagesMesamoll eKatherine Cobo OteroNo ratings yet

- Cutback Asphalt (Slow-Curing Type) : Standard Specification ForDocument2 pagesCutback Asphalt (Slow-Curing Type) : Standard Specification ForFrengkiNo ratings yet

- PCE Product Data Sheet: Description and Physical PropertiesDocument1 pagePCE Product Data Sheet: Description and Physical PropertiesArmando DCNo ratings yet

- Soundness Test For AggregateDocument3 pagesSoundness Test For AggregateMastani BajiraoNo ratings yet

- Kemp TR 375Document3 pagesKemp TR 375S SURESHNo ratings yet

- Particles and Moisture Effect On Dielectric Strength of Transformer Oil PDFDocument6 pagesParticles and Moisture Effect On Dielectric Strength of Transformer Oil PDFalumnopitagorasNo ratings yet

- Astm D1461 85 2001Document2 pagesAstm D1461 85 2001narendra rawatNo ratings yet

- Long QuizDocument8 pagesLong QuizJOHN PAULO A. GALINATONo ratings yet

- Langmuir Adsorption IsothermDocument8 pagesLangmuir Adsorption Isothermsexycassie100% (5)

- Aakash Home Assignment 2 SolutionsDocument9 pagesAakash Home Assignment 2 SolutionsPranav KapadiaNo ratings yet

- Forensic: InternihnalDocument16 pagesForensic: InternihnalCorred Taz'ae100% (1)

- Chapter-2 - Matter-and-EnergyDocument26 pagesChapter-2 - Matter-and-EnergyJam BermejoNo ratings yet

- AbinayaDocument110 pagesAbinayaVOOGLS PUBLICATIONNo ratings yet

- Test Report: M/s. Ajwani Infrastructure Pvt. LTDDocument6 pagesTest Report: M/s. Ajwani Infrastructure Pvt. LTDSandesh JidewarNo ratings yet

- ElectrochemistryDocument20 pagesElectrochemistryAkhil JamwalNo ratings yet

- The Fundamentals OF ELECTROCHEMISTRYDocument30 pagesThe Fundamentals OF ELECTROCHEMISTRYAshwaniNo ratings yet

- Resinas de SiliconaDocument32 pagesResinas de SiliconaWALTER KLISSMAN100% (1)

- Solutions Manual Chapter22Document62 pagesSolutions Manual Chapter22더브레인코어과학관No ratings yet

- Sphere Beam: Non-Demountable Sphere Beam For Monitoring The Accuracy of Medium-Sized Coordinate Measuring MachinesDocument2 pagesSphere Beam: Non-Demountable Sphere Beam For Monitoring The Accuracy of Medium-Sized Coordinate Measuring Machinescmm5477No ratings yet

- Def Stan 91 090 Issue 5 AvgasDocument20 pagesDef Stan 91 090 Issue 5 AvgasHimzo CerkezovicNo ratings yet

- Volumetric Analysis - Class Assignment Part 01 PDFDocument2 pagesVolumetric Analysis - Class Assignment Part 01 PDFyug agarwalNo ratings yet

- Electro-Membrane Salt Splitting Process To Produce Lithium HydroxideDocument12 pagesElectro-Membrane Salt Splitting Process To Produce Lithium HydroxideazturanNo ratings yet

- Oil Analysis OverviewDocument36 pagesOil Analysis OverviewWaleed El-azabNo ratings yet

- Deka Lamsari 05101181621058Document59 pagesDeka Lamsari 05101181621058meuthia fatmaNo ratings yet

- ATOOCV1!2!13 Optical Activity in Absence of Chiral Carbon Biphenyls Allenes and SpiranesDocument13 pagesATOOCV1!2!13 Optical Activity in Absence of Chiral Carbon Biphenyls Allenes and Spiranesvanshkhurana8077No ratings yet

- Errors in LabDocument4 pagesErrors in LabNUR AINI SHAHIDA SAPRINo ratings yet

- Solutions and Solubility 2021Document3 pagesSolutions and Solubility 2021Mauro De LollisNo ratings yet

- Zylar 631: Methyl Methacrylate Butadiene Styrene (MBS)Document3 pagesZylar 631: Methyl Methacrylate Butadiene Styrene (MBS)Fernando Garcia HiguitaNo ratings yet

- Monk Elemental Bending - GM BinderDocument6 pagesMonk Elemental Bending - GM BinderGinoNo ratings yet

- Chemsheets As 1047 Calorimetry 2Document1 pageChemsheets As 1047 Calorimetry 2Дильназ Болатбеккызы100% (1)

- Chemistry HL P2Document12 pagesChemistry HL P2Juan Fernando Velasco ForeroNo ratings yet

- 2017 Unit 3 Chemistry KTT 2 Combustion Question BookDocument10 pages2017 Unit 3 Chemistry KTT 2 Combustion Question Bookmichael scottNo ratings yet

- Heat Treatment Processes Case Hardening or Carburizing and QuenchingDocument18 pagesHeat Treatment Processes Case Hardening or Carburizing and QuenchingvivekpattniNo ratings yet

- Esquemas de Asociación PDFDocument1 pageEsquemas de Asociación PDFAntonioNo ratings yet

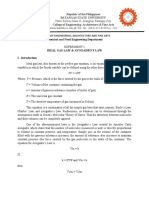

- Chemical and Food Engineering Department Ideal Gas Law & Avogadro'S LawDocument5 pagesChemical and Food Engineering Department Ideal Gas Law & Avogadro'S Lawchristan yapNo ratings yet

- Sensors For Onboard Diesel Oil CBMDocument6 pagesSensors For Onboard Diesel Oil CBMBrian CareelNo ratings yet

- Dod-P-15328d 2017Document88 pagesDod-P-15328d 2017Cordova RaphaelNo ratings yet