Professional Documents

Culture Documents

18mte61 Nano Materials Tutorial II (1961038 Srilavanya V)

18mte61 Nano Materials Tutorial II (1961038 Srilavanya V)

Uploaded by

31-PRASANNAKUMAR S SOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

18mte61 Nano Materials Tutorial II (1961038 Srilavanya V)

18mte61 Nano Materials Tutorial II (1961038 Srilavanya V)

Uploaded by

31-PRASANNAKUMAR S SCopyright:

Available Formats

High energy

ball milling

MECHANICAL METHODS

Ball milling

OPTICAL LITHOGRAPHY

TOPDOWN APPROACH BULKMATERIALS->POWDER->NANO PARTICLES PHYSICAL PROCESSING METHODS

ELECTRON BEAM LITHOGRAPHY

Lithography is a physical process involving image

LITHOGRAPHIC TECHNIQUE

transfer or patterning into various types of media

X-RAY LITHOGRAPHY

NANO IMPRINT LITHOGRAPHY

Using electrical energy we can create a shock or using

explosives.Very high energy is used to join the Shock wave sintering

material.Usage of HIP,CIP lead to chocking

MOLECULAR IMPRINTING

To get desired shapes CONSOLIDATION OF NANO MATERIALS SYNTHESIS

Plasma is nothing but the 4th state matter(Ionization of gas) Spark plasma sintering LASER ABLATION Damage is less in laser cutting-Nano strip particles

In this method we use a plasma,which is an ionised

PLASMA ARCING

gas

PHYSICAL VAPOUR DEPOSITION Involves condensation of vapour phase species

Better step coverage,less radiation,very high

SPUTTERING pressure,removal of atoms,gas inlet->5-10 uniform

deposition

Material source is heated to high temperature,film

EVAPORATION

quality not good as sputtering

BOTTOMUP APPROACH NANOPARTICLES->CLUSTERS->ATOMS

Electrolytic deposition refers to a film growth process

which consists in formation of a metallic coating onto

ELECTROLYTIC DEPOSITION

a base material occurs through the electrochemical

reduction

It consists of hydrolysis,condensation,growth of Particulate

CHEMICAL VAPOUR DEPOSITION Deposition of vapour phase of reaction species SOLGEL METHOD

particles,agglomeration of particles polymeric

Simultaneous occurence of

CO-PRECIPITATION TECHNIQUES

nucleation,growth,coarsening,agglomeration

You might also like

- Doosan DX300LCDocument1 pageDoosan DX300LCjames jbjuryhotmail.comNo ratings yet

- ResultDocument27 pagesResultAnupam MantriNo ratings yet

- Effective Viral Clearance in Mab PurificationTOYOPEARL® ResinDocument1 pageEffective Viral Clearance in Mab PurificationTOYOPEARL® ResinBruno AndreNo ratings yet

- 2040 - Cut-Off-Points - 2020 - 2021 of The Special Provision For Students Who Have Excelled in Extra Curricular Activities - New SyllabusDocument5 pages2040 - Cut-Off-Points - 2020 - 2021 of The Special Provision For Students Who Have Excelled in Extra Curricular Activities - New SyllabusGayanuka MendisNo ratings yet

- Pachateam-Poster - Pdac 2024Document1 pagePachateam-Poster - Pdac 2024misael.robles.pucpNo ratings yet

- HPLC Technical Tips PosterDocument1 pageHPLC Technical Tips PostermokhtarsimonNo ratings yet

- Arch'l As Built Continuation PG 4 - 21FDocument1 pageArch'l As Built Continuation PG 4 - 21FJaime Antonio RoselloNo ratings yet

- Course OF Study: University Grants Commission 14.08.2018Document4 pagesCourse OF Study: University Grants Commission 14.08.2018simo vonnerNo ratings yet

- Matrik PelatihanDocument1 pageMatrik PelatihanYogi RadityaNo ratings yet

- Areas of Study: Saturday, 20 November 2021Document1 pageAreas of Study: Saturday, 20 November 2021CINITA SATISH CSA CBENo ratings yet

- Peta Lintasan MkalDocument1 pagePeta Lintasan MkalFilzha Leeman FilzhaNo ratings yet

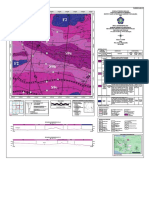

- Ejemplo de Plano HidrológicoDocument1 pageEjemplo de Plano HidrológicoGianni MoralesNo ratings yet

- Poster Ecoc Rimini 030921Document1 pagePoster Ecoc Rimini 030921Jaya Kumar KbNo ratings yet

- Procedure For Positive Material Identification at Vendor'S WorksDocument7 pagesProcedure For Positive Material Identification at Vendor'S WorksAjay BaggaNo ratings yet

- GVM ST300R User ManualDocument1 pageGVM ST300R User ManualPaco Jiménez BarbaNo ratings yet

- Peta Basemap Ini Insyaallah FixDocument1 pagePeta Basemap Ini Insyaallah Fixmuhammad alqori b.No ratings yet

- Electronic Load Controller PosterDocument1 pageElectronic Load Controller PosterSharad PatelNo ratings yet

- Lower Ground Floor With AreaDocument1 pageLower Ground Floor With AreaPKCL027 Rishabh JainNo ratings yet

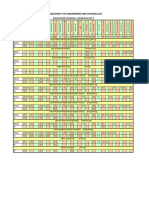

- Ned University of Engineering and Technology: Closing Marks Statistics - Admissions 2017Document1 pageNed University of Engineering and Technology: Closing Marks Statistics - Admissions 2017Abdul QadeerNo ratings yet

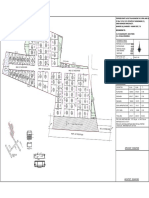

- Perspective: Vicinity Map Site Development PlanDocument1 pagePerspective: Vicinity Map Site Development PlanAce LangNo ratings yet

- 2000 - Marchal - Al - 4D Analogue Modelling - NewInsight - PosterDocument2 pages2000 - Marchal - Al - 4D Analogue Modelling - NewInsight - PosterRobert BlaireauNo ratings yet

- Man BasketDocument1 pageMan BasketsantoshNo ratings yet

- Aldrey Leonardo Master Thesis 2011Document91 pagesAldrey Leonardo Master Thesis 2011AndrewSteblevskyNo ratings yet

- Mars III RangeDocument4 pagesMars III RangeRenardNo ratings yet

- ERNSDocument5 pagesERNSalvarez.johnernestpce1965No ratings yet

- Mars3 Tech 600-12000 20200805Document6 pagesMars3 Tech 600-12000 20200805Daniel Lack PendásNo ratings yet

- ATEE Educational Effects MatrixDocument1 pageATEE Educational Effects MatrixJannatNo ratings yet

- 23295mech PseDocument4 pages23295mech PseSơn TrànNo ratings yet

- RJTT Tokyo INTL PDFDocument108 pagesRJTT Tokyo INTL PDF張允執No ratings yet

- NT2020ABSTRACTSDocument154 pagesNT2020ABSTRACTSsaricisadNo ratings yet

- 2-6 Peta Geomorfologi FitraDocument1 page2-6 Peta Geomorfologi FitraFitra JanuarNo ratings yet

- DW M8推荐书Document6 pagesDW M8推荐书NAYAN PATELNo ratings yet

- Brochure x70Document2 pagesBrochure x70Jake TingNo ratings yet

- GF GCOT B 14 4005 - 1 SignedDocument2 pagesGF GCOT B 14 4005 - 1 SignedYuan DiNo ratings yet

- JABINES - PDF 1 1Document1 pageJABINES - PDF 1 1ice iceNo ratings yet

- CRP 1st SemDocument10 pagesCRP 1st SemMy hidden memoriesNo ratings yet

- 1sty Common ToiletDocument21 pages1sty Common ToiletcimpstazNo ratings yet

- Perspective: Bureau of DesignDocument1 pagePerspective: Bureau of DesignNHA EmailNo ratings yet

- Esquema Eletrico e Hidraulico DXDocument20 pagesEsquema Eletrico e Hidraulico DXLuciano GrachaNo ratings yet

- University of Delhi Undergraduate Admission Arts & Commerce 2nd Cut-Off ListDocument11 pagesUniversity of Delhi Undergraduate Admission Arts & Commerce 2nd Cut-Off ListriyaNo ratings yet

- IIT Leader Phase 1 & 2 Academic Calendar 2024-25Document8 pagesIIT Leader Phase 1 & 2 Academic Calendar 2024-25pbk.resonanceNo ratings yet

- University Admission - Academic Year 2016/2017Document8 pagesUniversity Admission - Academic Year 2016/2017Ada DeranaNo ratings yet

- Cop 2016 2017-English PDFDocument8 pagesCop 2016 2017-English PDFNaveeth MohamedNo ratings yet

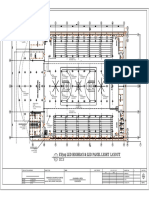

- Lighting Layout: E.L. E.L. E.L. E.L. E.L. E.L. E.L. E.LDocument1 pageLighting Layout: E.L. E.L. E.L. E.L. E.L. E.L. E.L. E.LRoberto Cabanada LlonaNo ratings yet

- Cop 2022 2023-English Ar 5th PageDocument1 pageCop 2022 2023-English Ar 5th Pagesharushalu075No ratings yet

- Tang Et Al-2003-Polymers For Advanced TechnologiesDocument5 pagesTang Et Al-2003-Polymers For Advanced TechnologiesMario Dzul CervantesNo ratings yet

- Plate 5 ModelDocument1 pagePlate 5 ModelJenna Liza LaynoNo ratings yet

- Denah Jalur PipaDocument1 pageDenah Jalur PipaArdhi RamadhaniNo ratings yet

- Control Room Parks and Plaza09262023Document25 pagesControl Room Parks and Plaza09262023Planning DepartmentNo ratings yet

- Household Service Workers Policy Reform Package PDFDocument52 pagesHousehold Service Workers Policy Reform Package PDFMan HernandoNo ratings yet

- 2021 RoadmapDocument2 pages2021 RoadmapSathia ShekarNo ratings yet

- Jaya Metal Teknika: Asia Power Machine ToolsDocument1 pageJaya Metal Teknika: Asia Power Machine ToolsRicky AngkawidjajaNo ratings yet

- Layout Feets-ModelDocument1 pageLayout Feets-ModelAnilbabu ChidiralaNo ratings yet

- Architectural 18296961912961070006 PDFDocument3 pagesArchitectural 18296961912961070006 PDFMark Christian Esguerra100% (1)

- Microbiology Homework Unit III N IVDocument7 pagesMicrobiology Homework Unit III N IVYazmin CoatlNo ratings yet

- The PMBOK® Guide NotesDocument90 pagesThe PMBOK® Guide NotesSafa SlimNo ratings yet

- FWCMS Equota - Document List - Ver1.3Document1 pageFWCMS Equota - Document List - Ver1.3Jayson TeeNo ratings yet

- Innovality Brochure Excellent-M Xb1046EDocument3 pagesInnovality Brochure Excellent-M Xb1046ERobert MontañezNo ratings yet

- 112 - Dwi Rizky Rosilila - UNIT3 - EssayDocument11 pages112 - Dwi Rizky Rosilila - UNIT3 - EssayDwi Rizky RosililaNo ratings yet

- HammerDocument128 pagesHammerIulian MihaiNo ratings yet

- Introduction To Chemistry: NAME: .. .. SCHOOLDocument3 pagesIntroduction To Chemistry: NAME: .. .. SCHOOLIdrisNo ratings yet

- TubosDocument12 pagesTubosASHIK TNo ratings yet

- Atlas Copco Roto Inject Fluid JECDocument2 pagesAtlas Copco Roto Inject Fluid JECアラファト イスラム教No ratings yet

- Piping Fabrication & Laing PDFDocument19 pagesPiping Fabrication & Laing PDFSachidananda SwarNo ratings yet

- Frame Adhesives & HardenersDocument1 pageFrame Adhesives & HardenersSoleil JimenezNo ratings yet

- Steel Shield 1200Document2 pagesSteel Shield 1200Moin AltafNo ratings yet

- 077 Soap ProductionDocument3 pages077 Soap Productionkkd108No ratings yet

- Work Method Statement For Painting Existing WallDocument11 pagesWork Method Statement For Painting Existing WallMohd Hafizi AzlanNo ratings yet

- Extraction of Gold: by Dr. Ahmed AmeedDocument12 pagesExtraction of Gold: by Dr. Ahmed AmeedSimbaNo ratings yet

- OP Super Glue 1002Document4 pagesOP Super Glue 1002Sinead1990No ratings yet

- Vascomill MMS FA 2 EsiteDocument1 pageVascomill MMS FA 2 EsiteDaniel ReyesNo ratings yet

- 1-A Colored Substance That Is Spread Over A Surface and Dries To Leave A Thin Decorative or Protective Coating. Decorative or Protective CoatingDocument60 pages1-A Colored Substance That Is Spread Over A Surface and Dries To Leave A Thin Decorative or Protective Coating. Decorative or Protective Coatingjoselito lacuarinNo ratings yet

- Plating Specification: DSP-01-Duplex NickelDocument4 pagesPlating Specification: DSP-01-Duplex NickelALEX MURPHYNo ratings yet

- Tt2820hmxmhz - Lav Capot h66 1 (230v 1 60hz) H.messico - 2853Document28 pagesTt2820hmxmhz - Lav Capot h66 1 (230v 1 60hz) H.messico - 2853Jose AntonioNo ratings yet

- AFFF 3% F-25 PD4344: Foam ConcentrateDocument2 pagesAFFF 3% F-25 PD4344: Foam ConcentrateArturNo ratings yet

- SS 316 (0.5 FN) : Stainless Steel ElectrodeDocument1 pageSS 316 (0.5 FN) : Stainless Steel Electrodeflasher_for_nokiaNo ratings yet

- A4.3-93 R2006PVDocument6 pagesA4.3-93 R2006PVMohamed YousufNo ratings yet

- Boiler Plate PDFDocument2 pagesBoiler Plate PDFStefano FavaroNo ratings yet

- Grinding Mills Brochure V14Document8 pagesGrinding Mills Brochure V14shrikant mishraNo ratings yet

- Twi Cswip 3.1 Set-4bDocument5 pagesTwi Cswip 3.1 Set-4bmiteshNo ratings yet

- 25CR20NIDocument2 pages25CR20NIShariq KhanNo ratings yet

- Mobile WorkbenchDocument5 pagesMobile Workbenchcfh666100% (3)

- Donaldson ultrafilter-DFTDocument4 pagesDonaldson ultrafilter-DFTsyrinxNo ratings yet

- Pad Eyes DimensionDocument1 pagePad Eyes DimensionrewmarineNo ratings yet

- Application of Paints and CoatingsDocument18 pagesApplication of Paints and CoatingsNash100% (2)

- Summative Test TleDocument18 pagesSummative Test TleGillyn Ruiz - AntonioNo ratings yet

- NA9800000Document2 pagesNA9800000Noe floresNo ratings yet

- MillingDocument76 pagesMillingAbduljebar SemuNo ratings yet