Professional Documents

Culture Documents

Ad 036821 001

Ad 036821 001

Uploaded by

hai sunOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ad 036821 001

Ad 036821 001

Uploaded by

hai sunCopyright:

Available Formats

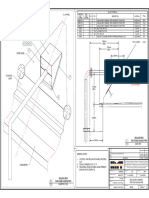

Saudi Aramco SA2636-ENG (11/2010)

MATERIAL GUIDE FOR HORIZONTAL AND VERTICAL IN-LINE PUMPS (1) NOTES:

(1) FOR PUMPS IN SOUR SERVICE, MATERIALS SHALL MEET (16) MATERIAL MUST HAVE 40-60% FERRITE FOR

THE REQUIREMENTS OF ISO-15156, WHERE APPLICABLE. BASE METAL AND 30-60% FOR WELD JOINTS,

AND SHALL COMPLY WITH SUPPLEMENTARY

(2) MATERIALS LISTED BELOW ARE ACCEPTABLE. OTHER REQUIREMENT S50. ALL WELD REPAIRS ON THE

MATERIALS ARE ALSO ACCEPTABLE PROVIDED THAT WETTED SURFACE SHALL HAVE PWHT PER

THEIR PREN=40 MINIMUM AND VENDOR DEMONSTRATES ASTM A995 S11 INCLUDING S6 & S10 (FOR

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

MINOR AND MAJOR REPAIRS) AND S5 & S12

SUCCESSFUL EXPERIENCE ON SIMILAR WATER (FOR MAJOR REPAIRS ONLY).

COMPOSITION:

ASTM A744 CN3MN (UNS J94651) / ASTM A182 F62 (UNS (17) IMPELLER MATERIAL FOR HIGH ENERGY

S08367)(MIN PREN 40). (15) PUMPS SHALL BE OF ASTM A890 GRADE 5A.

MATERIAL CODE HKA2 HKA4 HSX HSI HK HD1 HSZ (2) ASTM A743/A744 CK3MCuN (UNS J93254) / ASTM A182 F44 (UNS FOR OTHER PUMPS, ASTM A743 CN3MN

S31254)(MIN PREN 40). (15) OR ASTM A743 CK3MCUN IS ACCEPTABLE.

ASTM A351 CK3MCuN (UNS J93254) / ASTM A182 F44 (UNS

SPECIAL S31254)(MIN PREN 40) (15)

CASING A216 WCB A216 WCB A487 CA6NM A351 CF3M (3) A352 (4) A995 1B (20) (18) FOR WET HYDROCARBON, THE SHAFT

STAINLESS ASTM A995 5A (UNS J93404) / ASTM A182 F53 (UNS S32750) (MIN MATERIAL SHALL BE A276 XM19.

PREN 40) (16)

ASTM A995 6A (UNS J93380) / ASTM A182 F55 (UNS S32760) (MIN (19) FOR CLEAN LIGHT HYDROCARBON (SG<0.7)

SPECIAL PREN 40) (16) SERVICES (INTERMEDIATE PUMP STATION

IMPELLER A216 WCB A743 CA6NM A743 CA6NM A743 CF3M (3) A352 (4) A890 1B (22) ASTM A105 WELD OVERLAID WITH AWS A5.14 ERNiCrMo-3 (UNS LIGHT HYDROCARBON PUMPS ARE NOT

STAINLESS (17)

N06625) (14) CLEAN SERVICE) AND FOR BOILER FEED

NOTE: PREN = %Cr + 3.3 X %Mo + 16 X %N. MATERIALS WATER SERVICES, NON-METALLIC WEARING

SPECIAL SHALL BE IN THE SOLUTION ANNEALED CONDITION

CASING WEAR RINGS PARTS SHALL BE USED. THE ACCEPTABLE

A276 410 (6) (19) A276 410 (6) (19) A276 410 (6) (19) A276-S21800 (19) B584 C93700 A276-S31803 (7) STAINLESS AFTER WELDING, GALVANICALLY COMPATIBLE AND MATERIALS ARE:

(5) SHALL HAVE SIMILAR COMPOSITION IF WELDED.

- POLYETHER ETHER KETONE (PEEK)

(7) (21)

CONTINUOUS-CARBON-FIBER WOUND.

SPECIAL -PFA/CF REINFORCED COMPOSITE 20% MASS

IMPELLER WEAR- (3) A743/A744 CF8M IS ACCEPTABLE FOR HIGH SPEED LOW

A276 410 (6) A276 410 (6) A276 410 (6) A276 XM19 B148 C95400 HT A276-S31803 (7) STAINLESS FLOW PUMP IMPELLERS AND FOR ASME, ISO AND FRACTION RANDOM XY ORIENTED CARBON

RINGS (5) MANUFACTURER'S STANDARD PUMP CASING AND FIBER.

(7) (21)

IMPELLERS. DIFFERENTIAL PRESSURE LIMITATION SHALL

BE AS PER TABLE H.3 OF API 610 11TH ED.

(4) MANUFACTURER TO PROPOSE A SUITABLE MATERIAL OTHER ALTERNATIVE MATERIALS REQUIRE

SHAFT A322 4140 (9) A322 4140 (18) A276 410 (6) (18) A276 XM19 (8) A322 4140 A276-S31803 INCONEL 625 (13) GRADE FOR THE SERVICE. REVIEW AND APPROVAL BY STANDARD

(5) FOR MATING WEAR PARTS HAVING HARDNESS LESS THAN COMMITTEE CHAIRMAN, PUMPS, SEALS & MIXERS.

BHN 400, THEY SHALL HAVE A HARDNESS DIFFERENCE

SHAFT SLEEVE EQUIVALENT TO BHN 50. (20) A182 GRADE F51 (S31803) IS ACCEPTABLE

NA NA NA 316L SS (7) NA A276-S31803 (7) NA ALTERNATIVE FOR FORGINGS.

PACKED PUMP

(6) ALL TYPE 410 (ALTERNATIVELY 420) MARTENSITIC (21) HIGH ENERGY PUMP WEARING PARTS IN WATER

STAINLESS STEEL MUST BE IN THE QUENCHED AND INJECTION AND WATER SUPPLY SERVICES SHALL

SPECIAL TEMPERED CONDITION. NITRONIC 50/60 AND A743

THROAT BUSHINGS (5) A276 410 (6) (19) A276 410 (6) (19) A276 410 (6) (19) A276-S21800 B584 C93700 A276-S31803 (7) BE HARD FACED WITH TUNGSTON CARBIDE

STAINLESS (7) CA15 ARE ACCEPTABLE ALTERNATIVE MATERIALS USING LASER CLADDING. THIS INCLUDES THE

FOR WEAR RINGS. A276 TYPE 420 SHALL NOT BE BALANCE DRUM & BUSHING. WHEN INTERNAL SIZE

SPECIAL USED FOR SOUR SERVICES. NITRONIC 50/60 SHALL IS TOO SMALL, OTHER ALTERNATIVES MAY BE

INTER-STAGE NOT BE USED FOR APPLICATIONS EXCEEDING 200 F. PROPOSED FOR REVIEW & APPROVAL BY

A276 410 (6) A276 410 (6) A276 410 (6) A276 XM19 B148 C95400 HT A276-S31803 (7) STAINLESS

SLEEVES (5) STANDARD COMMITTEE CHAIRMAN, PUMPS, SEALS

(7) (21) & MIXERS.

(7) IMPELLER WEAR RINGS, SHAFT SLEEVES, CASING

SPECIAL WEAR RINGS AND BUSHINGS SHALL BE OVERLAID (22) A890 GRADE 3 (J93371) OR A890 GRADE 4 (J92205) IS

INTER-STAGE ACCEPTABLE ALTERNATIVE.

A276 410 (6) (19) A276 410 (6) (19) A276 410 (6) (19) A276-S21800 B584 C93700 A276-S31803 (7) STAINLESS WITH HARD MATERIALS. MANUFACTURER STANDARD

A890 GR 5A IS REQUIRED FOR WATER INJECTION PUMPS

BUSHINGS (5) MATERIALS ARE ACCEPTABLE PROVIDED THAT THE

(7) (21) PROPOSED MATERIALS ARE USED IN SIMILAR

WITH HEAD OR POWER PER STAGE EXCEEDING 1,500 FT

AND 6,000 HP UNLESS APPROVED BY STANDARD

SERVICE AND ARE OPERATING SUCCESSFULLY. COMMITTEE CHAIRMAN, PUMPS, SEALS & MIXERS.

BEARING BRACKET

A216 WCB A216 WCB A216 WCB A216 WCB (11) A216 WCB A216 WCB A216 WCB

(10) (8) 316SS IS ACCEPTABLE FOR ASME PUMP SHAFTS.

(23) FOR PUMPS WITH HKA2 & HKA4 MATERIAL CODE,

THE CASING CONNECTION AND BALANCLINE

(9) A434 TYPE 4140 IS AN ACCEPTABLE PIPE & FITTING MATERIALS SHALL BE ASTM A106

BASE PLATE FOR ALL MATERIAL CODES: ASTM A36. EN10028 GRADE S235J2 G2 OR G3 AND EN10025 GRADE S235J2 OR S275J2 ARE ACCEPTABLE. ALTERNATIVE SHAFT MATERIAL. GRADE B AND ASTM A105 RESPECTIVELY.

(10) DUCTILE IRON IS ACCEPTABLE MATERIAL FOR REVISION VALIDATION

ASME PUMP BEARING BRACKETS. THIS REVISION 07 IS COVERED, FOR ALL APPROVAL/

(11) FOR PACKED FIREWATER PUMPS, CAST STEEL CERTIFICATION REQUIREMENTS, PER SAEP-334, UNDER

BEARING BRACKETS SHALL BE INTERNALLY

DRAWING CERTIFICATE (DCC) NO:

COATED WITH EPOXY TO PREVENT CORROSION

FROM NORMAL PACKING LEAKAGE. 765200-0316-001

(12) WETTED FASTENERS SHALL BE COMPATIBLE

NON-WETTED BOLTING MATERIAL (12) WITH THE PUMP METALLURGY AND PUMPED

LIQUID. DESIGN CERTIFICATION REVIEW FOR KEY DRAWINGS

ALL MAT. CODES EXCEPT (DESIGN AGENCY)

OTHER

MATERIAL CODE HK (13) ASTM A182 F55 / A276 UNS 32760 IS

CODE HK REQUIRED (SAUDI ARAMCO)

ACCEPTABLE FOR SHAFT MATERIAL.

ENGG./DATE CERT. BY/DATE CONST. AGENCY/DATE OPER./ DATE BY / DATE

STUDS ASTM A193 GRADE B-7 ASTM A320 GRADE L43 (14) THE USE OF WELD OVERLAY REQUIRES THE MNO AAG AAG

APPROVAL OF STANDARD COMMITTEE

CHAIRMAN; PUMPS, SEALS AND MIXERS. 03/2016 03/2016 03/ 2016

NUTS ASTM A194 GRADE 2H ASTM A194 GRADE 7 S3 WELD OVERLAY MUST CONSIST OF AT LEAST REV.NO. DATE REVISION DESCRIPTION

FOUR LAYERS OF WELD METAL TO ACHIEVE

UNDILUTED WELD METAL COMPOSITION AFTER ADDITION OF AUXILIARY PIPING MATERIAL AND

07 FEB 2016 DELETION OF HFB1 MATERIAL CODE

FINAL MACHINING. REFER TO SAES-W-014.

ADDITIONAL LAYERS MAY BE NEEDED FOR

CASING CONNECTION & AUXILIARY SYSTEMS PIPING INCREASED EROSION AND CORROSION

JOB ORDER/EWO NO.

THIS REVISION IS NOT TO BE USED FOR

MATERIAL CODES MATERIAL CODES MATERIAL CODE RESISTANCE. ONLY GMAW, GTAW OR CONSTRUCTION UNTIL CERTIFIED AND DATED

HD1 PTAW PROCESS ALLOWED. CONFIRM OVERLAY 756200

HKA2 & HKA4 HSX, HSI & HK HSZ

COMPOSITION BY PMI PER SAES-A-206. EACH

WPS TO BE APPROVED BY STANDARDS

PIPE ATSM A312 TP316L (23) ATSM A312 TP316L A790-S31803 UNS N08024 SAUDI ARAIBIA OIL COMPANY

COMMITTEE CHAIRMAN, PUMPS, SEALS &

MIXERS. DRAWING TYPE

FITTINGS ASTM A182 F316L (23) ASTM A182 F316L A182 GRADE F51 UNS N08024 MATERIAL GUIDE FOR CETRIFUGAL PUMPS

(15) ALL WELD REPAIRS ON THE WETTED SURFACE STD

SHALL HAVE PWHT PER ASTM A744 HORIZONTAL AND VERTICAL IN-LINE

INCLUDING S3 & S5 (FOR MINOR AND MAJOR

REPAIRS) AND S2 & S7 (FOR MAJOR REPAIRS

ONLY).

STD. DWG. SAUDI ARABIA

PLANT NO. INDEX DRAWING NO. SHEET NO. REV. NO.

990 G AD-036821 001 07

Saudi Aramco 2636-ENG. (11/2010)

EXCEL

Saudi Aramco: Company General Use

You might also like

- AMS5688Document7 pagesAMS5688Federica FiorentiniNo ratings yet

- Ams4945h 2020Document10 pagesAms4945h 2020BauyrzhanNo ratings yet

- Material Guide For Horizontal and Vertical In-Line PumpsDocument1 pageMaterial Guide For Horizontal and Vertical In-Line PumpsEr Bishwonath Shah100% (1)

- Ad 036821 001Document1 pageAd 036821 001AmolNo ratings yet

- SAE - AMS 4050hv004Document9 pagesSAE - AMS 4050hv004Nilesh PatilNo ratings yet

- Ams4943l 2020Document8 pagesAms4943l 2020BauyrzhanNo ratings yet

- Sae Ams5545e 2006 PDFDocument8 pagesSae Ams5545e 2006 PDFwangxiaomin1977No ratings yet

- Aerospace Material SpecificationDocument6 pagesAerospace Material SpecificationSinai PerezNo ratings yet

- AMS 5355jv005Document11 pagesAMS 5355jv005Anonymous T6GllLl0100% (2)

- SAE - AMS 5759lv003Document6 pagesSAE - AMS 5759lv003Nilesh PatilNo ratings yet

- Aerospace Material SpecificationDocument8 pagesAerospace Material SpecificationNav Talukdar100% (2)

- Aerospace Material SpecificationDocument5 pagesAerospace Material SpecificationAnonymous T6GllLl0No ratings yet

- XAS46 Part ListDocument82 pagesXAS46 Part ListAndi100% (3)

- Service Manual: Chassis, Mast & Options P17500 P20000Document7 pagesService Manual: Chassis, Mast & Options P17500 P20000LuisTocoraNo ratings yet

- Build Your Own Cajon DrumDocument5 pagesBuild Your Own Cajon DrumBiscuit_WarriorNo ratings yet

- Ad 036821 002Document1 pageAd 036821 002AmolNo ratings yet

- Wire Cable/ Wire Cable/: NotesDocument10 pagesWire Cable/ Wire Cable/: Notesmahesh reddy mNo ratings yet

- Aerospace Material Specification: Titanium Alloy Tubing, Seamless, Hydraulic 3.0al - 2.5V Cold Worked, Stress RelievedDocument9 pagesAerospace Material Specification: Titanium Alloy Tubing, Seamless, Hydraulic 3.0al - 2.5V Cold Worked, Stress Relievedvsraju2No ratings yet

- D92-1026.tarea 11-3.HARN - ENG PX9 2013 BCDocument5 pagesD92-1026.tarea 11-3.HARN - ENG PX9 2013 BCmarioNo ratings yet

- Ams 5391 HDocument9 pagesAms 5391 HEhab HarbNo ratings yet

- AMS 5699 G (Provided by Customer)Document8 pagesAMS 5699 G (Provided by Customer)mini p shendeNo ratings yet

- Ams 4083MDocument7 pagesAms 4083MivanNo ratings yet

- AMS6265RDocument8 pagesAMS6265REmanuel MarkmanNo ratings yet

- Sae Ams 5387Document8 pagesSae Ams 5387desingbuschprojectsNo ratings yet

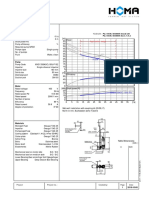

- For Approval For Reference: Part List & Materials of ConstructionDocument1 pageFor Approval For Reference: Part List & Materials of ConstructionNaeem DeenNo ratings yet

- AMS4930LDocument8 pagesAMS4930Lremaja1249No ratings yet

- AMS4029MDocument5 pagesAMS4029M黄当甲No ratings yet

- Aerospace Material SpecificationDocument7 pagesAerospace Material SpecificationAnonymous T6GllLl0No ratings yet

- Sae Ams 4157D - 2007Document5 pagesSae Ams 4157D - 2007مرکز پژوهش متالورژی رازی RMRCNo ratings yet

- Raw Materials / Ferrous Hot Rolled Plate Astm A36: (Superseded)Document2 pagesRaw Materials / Ferrous Hot Rolled Plate Astm A36: (Superseded)singlaNo ratings yet

- URANUS® 926: General Recommendations For WeldingDocument4 pagesURANUS® 926: General Recommendations For Weldingrohitshukla23No ratings yet

- 360 Reference Tables: Gray Cast Iron Fresh WaterDocument5 pages360 Reference Tables: Gray Cast Iron Fresh WaterGuido BerdinaNo ratings yet

- SAE AMS 5122j-2008Document5 pagesSAE AMS 5122j-2008raulNo ratings yet

- D92-1020-ABCD: TolerancesDocument4 pagesD92-1020-ABCD: Tolerancescarlosar1477No ratings yet

- AMS4016MDocument5 pagesAMS4016M黄当甲No ratings yet

- Aerospace Material SpecificationDocument9 pagesAerospace Material SpecificationHòa NguyễnNo ratings yet

- Aerospace Material SpecificationDocument6 pagesAerospace Material SpecificationadiNo ratings yet

- Aerospace Material Specification: Electroless Nickel Plating Low PhosphorusDocument7 pagesAerospace Material Specification: Electroless Nickel Plating Low PhosphorusSURYAS63No ratings yet

- Ams 4985CDocument13 pagesAms 4985CBacksniper100% (1)

- Aerospace Material Specification: AMS5876™ Rev. EDocument7 pagesAerospace Material Specification: AMS5876™ Rev. EMohammad LavasaniNo ratings yet

- TDS MR15 60 MG34091Document1 pageTDS MR15 60 MG34091ebooktechnologieNo ratings yet

- Sae Ams5837f 1999Document7 pagesSae Ams5837f 1999이연지No ratings yet

- Sae 4676dDocument6 pagesSae 4676dwilsao77No ratings yet

- Saeams4911p 2018Document8 pagesSaeams4911p 2018Manish SrivastavaNo ratings yet

- Asna 2554 2019-09 LDocument238 pagesAsna 2554 2019-09 Lleander1985No ratings yet

- Issued For Construction: ZAIT Engineering Solutions Pty LTDDocument1 pageIssued For Construction: ZAIT Engineering Solutions Pty LTDAhmedBoutlyNo ratings yet

- Aerospace Material SpecificationDocument6 pagesAerospace Material Specificationvsraju2No ratings yet

- Aerospace Material SpecificationDocument7 pagesAerospace Material SpecificationAnonymous T6GllLl0No ratings yet

- Sae Ams 5796D 2000 (En) PDFDocument6 pagesSae Ams 5796D 2000 (En) PDFLidija StojanovaNo ratings yet

- Sae Ams 5536N-2012Document6 pagesSae Ams 5536N-2012Mehdi Mokhtari100% (1)

- Common Valve MateriasDocument3 pagesCommon Valve MateriasagrovadoNo ratings yet

- MRCSB-HMT-T-GA-0001 Dome Construction Drawings - Rev-0 - pg19Document1 pageMRCSB-HMT-T-GA-0001 Dome Construction Drawings - Rev-0 - pg19arshi LerwickMNo ratings yet

- Industrial Gas Generator Illustrated Parts CatalogueDocument11 pagesIndustrial Gas Generator Illustrated Parts CataloguejuanaNo ratings yet

- FabCO 811N1 PDFDocument2 pagesFabCO 811N1 PDFAlejandroAcuñaMaureiraNo ratings yet

- Abac - After Market PartsDocument6 pagesAbac - After Market PartsAANo ratings yet

- Industrial Gas Generator Illustrated Parts CatalogueDocument28 pagesIndustrial Gas Generator Illustrated Parts CataloguejuanaNo ratings yet

- FIT UP REPORT-Shell To ShellDocument1 pageFIT UP REPORT-Shell To Shellsuria qaqcNo ratings yet

- Sae Ams 5519N-2014Document5 pagesSae Ams 5519N-2014Mehdi MokhtariNo ratings yet

- Automatic Water Heater 94SMSS1Document14 pagesAutomatic Water Heater 94SMSS1Reoeuele Duran CalzitaNo ratings yet

- Mil S 18729C PDFDocument8 pagesMil S 18729C PDFPaulus MarioNo ratings yet

- Advanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactFrom EverandAdvanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactNo ratings yet

- Blastmaster Tornado Internal Pipe Blasting Tool Operators Manual 1090614Document28 pagesBlastmaster Tornado Internal Pipe Blasting Tool Operators Manual 1090614Sahab DeenNo ratings yet

- Oil Heater Instuction ManualDocument5 pagesOil Heater Instuction ManualEhsan Mohammadi100% (1)

- The Philippine Green Building CodeDocument60 pagesThe Philippine Green Building CodeRoland Arimado100% (1)

- Ubersicht: MXS1336ASC (180) - P102Document12 pagesUbersicht: MXS1336ASC (180) - P102sameeh kadourahNo ratings yet

- Sika®-1: Product Data SheetDocument2 pagesSika®-1: Product Data SheetKhin Sandi KoNo ratings yet

- 06 Convergence Algorithm and Diagnostics-LibreDocument25 pages06 Convergence Algorithm and Diagnostics-LibreKamesh ReddiNo ratings yet

- Catalago RexrothDocument64 pagesCatalago RexrothDaniel GonzalezNo ratings yet

- CAD/CAM/CIMDocument11 pagesCAD/CAM/CIMNPMYS23No ratings yet

- Kingsbury Bulletin PDFDocument40 pagesKingsbury Bulletin PDFJOSE MARTIN MORA RIVEROSNo ratings yet

- Conducting Machining Tests of Wood and Wood-Base Materials: Standard Test Methods ForDocument19 pagesConducting Machining Tests of Wood and Wood-Base Materials: Standard Test Methods ForAnonymous 4GNAkbVRTNo ratings yet

- Welding ErrorsDocument42 pagesWelding ErrorsNDTInstructorNo ratings yet

- AdhesiveDocument24 pagesAdhesiveArpit Goel100% (1)

- Exampro GCSE Chemistry: C3 Chapter 2 HigherDocument26 pagesExampro GCSE Chemistry: C3 Chapter 2 HigherAref DahabrahNo ratings yet

- Basf - Ape SystemDocument86 pagesBasf - Ape SystemdixmitNo ratings yet

- Chap4 3Document8 pagesChap4 3AhmedSeragNo ratings yet

- A Method of Bead Making in Ashanti.Document2 pagesA Method of Bead Making in Ashanti.Francesca Mengozzi FuentesNo ratings yet

- Chemical Industri ProcessDocument1,030 pagesChemical Industri ProcessApri Ginanjar100% (1)

- Wog-2013-Etp-Ptpli-Be-105 R5 Basic Design Package (Sbme-Vdt-700-2775 Stat - A) (Stamp)Document30 pagesWog-2013-Etp-Ptpli-Be-105 R5 Basic Design Package (Sbme-Vdt-700-2775 Stat - A) (Stamp)Rentu PhiliposeNo ratings yet

- School of Mechanical Engineering: Lab Manual of Semester - V U5AEA20 - Aircraft Structures Repair LabDocument31 pagesSchool of Mechanical Engineering: Lab Manual of Semester - V U5AEA20 - Aircraft Structures Repair LabAasto Ashrita AastikaeNo ratings yet

- Irritec - USA - List Price PDFDocument48 pagesIrritec - USA - List Price PDFJhohan Steven Muñoz Pineda100% (1)

- Lathe Machine ToolDocument59 pagesLathe Machine ToolSiva BhaskarNo ratings yet

- Kabeldon Parallel Connector CSEP-A For Cables With Cu Tape Screen English 2012Document2 pagesKabeldon Parallel Connector CSEP-A For Cables With Cu Tape Screen English 2012iyilmaz1No ratings yet

- Materiale PiezoelectriceDocument68 pagesMateriale PiezoelectriceTanya WhiteNo ratings yet

- AdweaDocument12 pagesAdweaUnni Cyriac100% (1)

- FORMULARIO Per Lo Stampaggio Della PlasticaDocument78 pagesFORMULARIO Per Lo Stampaggio Della PlasticaAhsan RiazNo ratings yet

- Patent Pervious ConcreteDocument28 pagesPatent Pervious ConcreteChong Ting ShengNo ratings yet

- Washing Machine OK OWMDocument44 pagesWashing Machine OK OWMProjNo ratings yet