Professional Documents

Culture Documents

M12 Multi Sensor

M12 Multi Sensor

Uploaded by

Kurt LeënOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

M12 Multi Sensor

M12 Multi Sensor

Uploaded by

Kurt LeënCopyright:

Available Formats

M12 Specification Security House,

Vantage Point Business Village

Dimensions Mitcheldean

Height: 56mm Gloucester

Diameter: 100.5mm GL17 0SZ

Weight: 78g United Kingdom

Material PC/ABS TEL: +44(0)1594 541900

FAX: +44(0)1594 541910

Operating Voltage 10-16V for recycling details see:-

Current Consumption 0.5mA Normal www.cooper-europe.com

14mA Alarm Settings

Alarm Contacts 1A, 30V DC, Normally Closed,

Open in Alarm

Visual Indication Non alarm pulse every

10sec(optional)

Alarm -Red Continuous

Fault - Yellow Continuous

Ambient Temp (Max) Opto mode 60°C

Opto-Heat mode 45°C

60°C Rate if Rise mode 45°C

77°C Fixed Temp mode 60°C

On

Overview

The M12 is a low current industrial standard sensor which can operate

either as an optical, opto/heat combined, rate of rise heat or fixed 77°

heat sensor via the selection switches. It is suitable for direct

On

connection to most security alarm control panels or for use with other

12V detection systems.

The detector is equipped with a set of volt free contacts. The detector

can be configured to latch or auto-reset from the alarm condition.

Also the detector has a dual LED indicator, the red LED is continuous

to indicate the alarm condition and can be configured to give a short

1 2 3 4

flash in the normal condition. Off

The yellow LED will be lit continuously to indicate a smoke sensing

chamber fault or that the detector has reached the limit of its Descript ion SW1 SW2 SW3 SW4

contamination compensating ability

Detect or Sett ing

Choosing the right detector Opto N/A N/A OFF OFF

Opto-Heat N/A N/A ON OFF

The M12 can be configured using the four position switch located

at the back of the detector as; Rate of Rise N/A N/A OFF ON

77°C Fixed N/A N/A ON ON

Optical smoke detector (SW3= Off, SW4 = Off) this detector is LED Off (Normal

suitable for most applications giving the fastest response to slow Mode) N/A Off N/A N/A

burning or smouldering fires which give rise to large visible smoke

particle.

Red LED

Puls ing(Normal N/A ON N/A N/A

Opto-heat detector (SW3= On, SW4 = Off) this will respond better Auto Res et OFF N/A N/A N/A

to fast clean burning fires yet maintain the advantage of optical Latchi ng Relay ON N/A N/A N/A

detectors when detecting smouldering fires. The thermal

enhancement of this detector allows a higher alarm threshold

which provides a greater rejection of false alarms. The detector

will also give an alarm at temperatures above 60°C. Utilising Locking Tab

Rate of Rise heat detector (SW3= Off, SW4 = On) this detector The mounting base includes an

will detector a rapid increase in temperature or temperatures 1 optional feature to prevent the

above 60°C and should be used in environments where the removal of the detector without

ambient conditions might cause false alarms if smoke detection

were to be used, for example where there is a high level of dust, the use of a tool.

fumes, steam or smoke under normal conditions.

Fixed(77°C) heat detector (SW3= On, SW4 = On) this detector 1. Remove the standard fit

will detect temperatures above 77°C and should be used in retaining clip.

environments where the ambient conditions might cause false

alarms if smoke detection were to be used, for example where 2. Insert the locking clip which

there is a high level of dust, fumes, steam or smoke under normal is located at the centre of the

conditions.

2 base as shown.

In the Optical and Opto-Heat mode the detector automatically

Mount the detector onto the base as described in Detector

compensates for gradual increase in the scatter signal due to

contamination e.g. dust build up. If excessive dust occurs, the Installation (see over) and rotate fully clockwise until it finally

yellow LED with show continuously. In these circumstances clicks.

remove the detector head and vacuum around the outside of the

mesh. If this fails to solve the problem the detector should be The detector is now locked into position. Remove by utilising a

replaced. The yellow LED will be lit continuous if the detector suitable tool (eg a thin screwdriver) into the hole in the detector

sensor signal begins to reduce below its normal level (chamber cover. Gently push the tool into the detector and rotate anti-

monitoring). clockwise.

Doc Ref: PINSTM12 ISS A

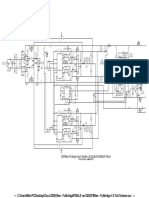

0V Det. Reset (-Ve)

+12V +12V

2 2

Fire Fire

Zone 1 Zone 1

3 3

Control Panel without Control Panel with a -Ve

Detector Reset Output Detector Reset Output

E 4 Use Latching E 4

Use Auto-Reset

0V 0V

Det. Reset (+Ve) +12V

2 2

Fire Fire

Zone 1 Zone 1

Control Panel with a +Ve 3 3

Detector reset Output

Tamper

Zone

Use Latching E 4 E 4

Use the 'E' terminal

to tamper protect the

smoke detector

0V

+12V

2 2

Fire

Zone 1 1

Tamper 3 3

Zone

E 4 E 4

Detail for connecting

multiple detectors to

a single fire zone

DETECTOR LOCATION

! Choosing a location: always refer to any local or national guidelines ie. BS5839 pt1; 2002

! In a typical domestic installation at least one detector should be fitted for each level, usually in a central location e.g. hall or landing.

! In commercial installation at least one detector should be install for each area to be protected.

! Always use the most suitable detector for the environment, see choosing the right detector.

DETECTOR INSTALLATION

! Fit detector to mounting base and rotate clockwise until the detector drops into place.

! Continue to rotate clockwise until the detector clicks and no further rotation is possible.

! If the detectors are required to be locked into position, refer to the mounting base installation instructions (see over leaf).

! Smoke detectors are supplied fitted with dust covers for general protection against airborne contaminates. These must be removed from

all detectors before the fire system is commissioned.

! NB. These dust covers do not provide adequate protection against quantities of dust generated by building work, sanding etc. Therefore,

detectors should not be installed until this type of work has been completed.

TESTING

All detectors must be tested following installation or routine service and maintenance. Authorised personnel must be informed that the fire system

will be temporarily out of service before commencing testing. When all tests are complete, restore panel to normal operation and notify authorised

personnel that the system is operational.

Smoke Detector Settiings:

! Subject the detector to be tested to a controlled amount of an approved synthetic smoke aerosol via a smoke detector test pole. Suitable

products are available for example, from No Climb Products Ltd.

! Check that the red LED on the detector lights in alarm within 30 seconds.

! Ensure that the control panel activates into alarm.

! Either reset the detector from the control panel or allow the detector to automatically reset once clear of smoke, if this option has been

selected.

! This procedure will test the smoke sensing circuitry of the Opto/Heat Detector.

Heat Detector Settings:

! Using a heat gun or hair dryer capable of generating temperatures of up to 95°C, direct the heat source towards the heat sensing

elements, visible through the side of the outer cover, from a distance of 15 to 30cm. Care should be taken not to allow the plastic surface

temperature to exceed 110°C otherwise damage may occur.

! When the temperature reaches the ‘Alarm Temperature’ (see Specifications above), check that the red LED on the detector lights in

alarm.

! Ensure that the control panel activates into alarm.

! Either reset the detector from the control panel or allow the detector to automatically reset once it has cooled down, if this option is

selected.

! This procedure will test the heat sensing circuitry of the Opto/Heat Detector.

Doc Ref: PINSTM12 ISS A

You might also like

- Sinutrain: Getting Started 02.10 EditionDocument64 pagesSinutrain: Getting Started 02.10 EditioncorreiaferNo ratings yet

- SF 50GLP ManualDocument2 pagesSF 50GLP ManualDigitalNo ratings yet

- Datasheet Detectores Ulcap320-Ulcah330 e Ulcapt340Document2 pagesDatasheet Detectores Ulcap320-Ulcah330 e Ulcapt340Yuri OliveiraNo ratings yet

- Smoke, Heat, Multi Detector and Base - Datasheet (Copper)Document2 pagesSmoke, Heat, Multi Detector and Base - Datasheet (Copper)Raton121 RahmanNo ratings yet

- AW-D138-Addressable Combined Smoke and Heat Detector-Datasheet-202205Document1 pageAW-D138-Addressable Combined Smoke and Heat Detector-Datasheet-202205yemba2008No ratings yet

- Instruction Manual: EnglishDocument24 pagesInstruction Manual: EnglishJeimy Soler TNo ratings yet

- User's Guide: OS425-LSDocument4 pagesUser's Guide: OS425-LSjuancarlos24No ratings yet

- Fuente Fcps 24s6eDocument12 pagesFuente Fcps 24s6eGuido RuizNo ratings yet

- IQA-WLPR110 Product Manual en v6 - 161230Document1 pageIQA-WLPR110 Product Manual en v6 - 161230Vigilancia VISORNo ratings yet

- CooperDocument2 pagesCoopermai mamdouhNo ratings yet

- Monitor and Control Equipment 24/7/365: Smoke & TemperatureDocument2 pagesMonitor and Control Equipment 24/7/365: Smoke & TemperaturePushpendra SinghNo ratings yet

- Series: Conventional Detector RangeDocument4 pagesSeries: Conventional Detector RangearunNo ratings yet

- CAP320, CAPT340, CAH330 - Intelligent Addressable Sensors: Specifier's GuideDocument2 pagesCAP320, CAPT340, CAH330 - Intelligent Addressable Sensors: Specifier's GuideLeomark RespondeNo ratings yet

- Wire PIR Motion Detector To Wired Alarm SystemDocument25 pagesWire PIR Motion Detector To Wired Alarm Systemkunene07No ratings yet

- Instr-Ax-7531 - en - Termometru IrDocument10 pagesInstr-Ax-7531 - en - Termometru IrtupatuNo ratings yet

- Ei140e SeriesDocument30 pagesEi140e Seriesjk79j7xr9kNo ratings yet

- Non-Contact Infrared Thermometers: Tel-Tru Manufacturing CompanyDocument2 pagesNon-Contact Infrared Thermometers: Tel-Tru Manufacturing CompanyMuhammad Reza GadranNo ratings yet

- ZEOS C SDocument2 pagesZEOS C SJunior SantosNo ratings yet

- DS-CTD382 Heat DetectorDocument1 pageDS-CTD382 Heat Detectorமாருப்-Maruff HMNo ratings yet

- Fire Protection SystemDocument8 pagesFire Protection SystemMJNo ratings yet

- R04 V-PS Photoelectric Smoke Detector Installation SheetDocument4 pagesR04 V-PS Photoelectric Smoke Detector Installation SheetDiegoNo ratings yet

- Sensor de Temperatura OS551A-MA-1 PDFDocument3 pagesSensor de Temperatura OS551A-MA-1 PDFMiguel Angel Chuquín MorachimoNo ratings yet

- Detector de Humo Inalármbrico - WS8916 - ESPDocument16 pagesDetector de Humo Inalármbrico - WS8916 - ESPHesams EnamoradoNo ratings yet

- Consillium Testing KitsDocument3 pagesConsillium Testing KitsStefanVisNo ratings yet

- Tyco Fire Alarm DevicesDocument4 pagesTyco Fire Alarm DevicesDota NgNo ratings yet

- Intelligent Addressable Sensors: UL Listed Product RangeDocument2 pagesIntelligent Addressable Sensors: UL Listed Product RangeKalpa Helitha SilvaNo ratings yet

- Gas Leak Detector: ExplanationsDocument10 pagesGas Leak Detector: ExplanationsSathiya Rajesh100% (1)

- RE-317D-SL: Addressable Smoke DetectorDocument1 pageRE-317D-SL: Addressable Smoke DetectorMOHAMMEDNo ratings yet

- IO Module A9056TDocument2 pagesIO Module A9056T许浩江No ratings yet

- Bid Specification - FV300 - HS - 7467 - ENDocument2 pagesBid Specification - FV300 - HS - 7467 - ENMarthin PurbaNo ratings yet

- DetectorsDocument6 pagesDetectorsVincent GabrielNo ratings yet

- AW-CTD382 Heat Detector Datasheet - 20211018Document1 pageAW-CTD382 Heat Detector Datasheet - 20211018icon.group.egNo ratings yet

- SL-3,5,7 F-DS034 - UL Addressable Sensors Datasheet - 2Document2 pagesSL-3,5,7 F-DS034 - UL Addressable Sensors Datasheet - 2Cost RootsNo ratings yet

- Siga-Phs Intelligent 3D Multisensor Smoke Detector: Product Description WarningsDocument2 pagesSiga-Phs Intelligent 3D Multisensor Smoke Detector: Product Description WarningsWill F AlvesNo ratings yet

- Detector de Fumaça ZEOS-C-S - ManualDocument2 pagesDetector de Fumaça ZEOS-C-S - ManualCarlos Cesar Silva Filho100% (2)

- Security: Product Data SheetDocument2 pagesSecurity: Product Data SheetfadhlidzilNo ratings yet

- AW-D146R 4-Wire Conventional UV Flame Detector Datasheet 20221109Document1 pageAW-D146R 4-Wire Conventional UV Flame Detector Datasheet 20221109yemba2008No ratings yet

- PMD75 Paradox Detector Miscare Radio WirelessDocument2 pagesPMD75 Paradox Detector Miscare Radio WirelessCornelCiorcanNo ratings yet

- The JA-63S Independent Fire-Detector: Ceiling Height (M) Smoke Detection Heat DetectionDocument2 pagesThe JA-63S Independent Fire-Detector: Ceiling Height (M) Smoke Detection Heat DetectionDragus IonelNo ratings yet

- 12 Eaton - CAP320 - CAPT340 - CAH330 - DS - Sep17Document2 pages12 Eaton - CAP320 - CAPT340 - CAH330 - DS - Sep17Samir AjiNo ratings yet

- Omni - VSDocument2 pagesOmni - VSalexanderNo ratings yet

- 4098 9602 Heat Smoke DetectorDocument4 pages4098 9602 Heat Smoke Detectorjohn ajitNo ratings yet

- ApolloFire XP95 MultisensorDocument2 pagesApolloFire XP95 MultisensorfasiwiNo ratings yet

- I-9101 Intelligent Combination Heat and Smoke Detector Issue 1.01Document2 pagesI-9101 Intelligent Combination Heat and Smoke Detector Issue 1.01HiteshgangeleNo ratings yet

- Technical Manual: Explosion Proof Triple Infrared Flame Detector Model No.: AS-E302-IR3Document5 pagesTechnical Manual: Explosion Proof Triple Infrared Flame Detector Model No.: AS-E302-IR3Emre YıldırımNo ratings yet

- Flame SensorDocument3 pagesFlame Sensorchandrasekar ANo ratings yet

- Pni SH200Document56 pagesPni SH200TonyNo ratings yet

- 95-8790 - (X-Series-Flame-Detectors-with-Pulse-Output)Document16 pages95-8790 - (X-Series-Flame-Detectors-with-Pulse-Output)pabloperezmtz1No ratings yet

- LM120 PDFDocument2 pagesLM120 PDFPedro Manuel Jacinto PedroNo ratings yet

- Dew Point Monitor Instruction ManualDocument8 pagesDew Point Monitor Instruction ManualArtemio Enrique Zapata RobleroNo ratings yet

- Detector Linear FMDocument2 pagesDetector Linear FMJardenson CésarNo ratings yet

- Swiss Garde 360 Premium AP User ManualDocument8 pagesSwiss Garde 360 Premium AP User ManualTonyandAnthonyNo ratings yet

- Velomitor Piezo-Velocity Sensor Datasheet - 141632Document11 pagesVelomitor Piezo-Velocity Sensor Datasheet - 141632Trong Hung NguyenNo ratings yet

- 700 Series ENDocument2 pages700 Series ENKen LaszloNo ratings yet

- Takex PA-470L Data SheetDocument2 pagesTakex PA-470L Data SheetJMAC SupplyNo ratings yet

- Cooper Smoke DetectorsDocument2 pagesCooper Smoke DetectorsKen NisolaNo ratings yet

- KIDDE 1275eDocument2 pagesKIDDE 1275efptstopNo ratings yet

- DTA Series: DELTA Temperature Controller User ManualDocument11 pagesDTA Series: DELTA Temperature Controller User ManualMariana GutiNo ratings yet

- Bee Spec Sheet V7 PDFDocument5 pagesBee Spec Sheet V7 PDFCông QuýNo ratings yet

- VLSI Implementation of Block Error Correction Coding TechniquesDocument54 pagesVLSI Implementation of Block Error Correction Coding TechniquesHemant RajkumarNo ratings yet

- 6 Stage Pipelining ExplainedDocument4 pages6 Stage Pipelining ExplainedturbosreeNo ratings yet

- Low and High Transmitter Block DiagramDocument6 pagesLow and High Transmitter Block DiagramRainier RamosNo ratings yet

- Auto Mower: Operator S ManualDocument25 pagesAuto Mower: Operator S ManualBrandon NevilleNo ratings yet

- All CodesDocument9 pagesAll CodesSebastian ShultzNo ratings yet

- Mpdi K3000Document2 pagesMpdi K3000Juan JuanNo ratings yet

- Linksys Official Support - Linksys EA6900 AC1900 Smart Wi-Fi Dual-Band Router Frequently Asked QuestionsDocument5 pagesLinksys Official Support - Linksys EA6900 AC1900 Smart Wi-Fi Dual-Band Router Frequently Asked QuestionsRi KiNo ratings yet

- 3 Steps To Selecting The Right AC DriveDocument4 pages3 Steps To Selecting The Right AC DriveGaniNo ratings yet

- GMS2 Operating ManualDocument0 pagesGMS2 Operating Manualgomore14No ratings yet

- D2KFBNeo - Fullbridge V.3b FINALEDocument1 pageD2KFBNeo - Fullbridge V.3b FINALEshandy susandiNo ratings yet

- 851 Series: Applications DescriptionDocument26 pages851 Series: Applications Descriptionantono1971No ratings yet

- Systems Theory and Management Information SystemsDocument393 pagesSystems Theory and Management Information SystemsWycliffNo ratings yet

- Gelacio Guevara CVDocument1 pageGelacio Guevara CVMiguel GuevaraNo ratings yet

- Bum 64Document74 pagesBum 64sylvain poujadeNo ratings yet

- Basic Programming Simatic S7-300Document41 pagesBasic Programming Simatic S7-300Jaziel Cabral100% (1)

- Major Section of CRT Color TV and Their FunctionsDocument28 pagesMajor Section of CRT Color TV and Their FunctionsBerlin Alcayde100% (1)

- EC 8691 Course Outline & IntroductionDocument16 pagesEC 8691 Course Outline & IntroductionmaragatharajNo ratings yet

- Zte ScriptDocument4 pagesZte ScriptdashdungaNo ratings yet

- Manual Md110 Expanding CabinetsDocument45 pagesManual Md110 Expanding Cabinetsdanilo.rcte100% (1)

- Frequencimetro IBQ101 - 102 User ManualDocument17 pagesFrequencimetro IBQ101 - 102 User ManualJmallNo ratings yet

- Coverage CookbookDocument95 pagesCoverage CookbookNeela DharaniNo ratings yet

- Marantz SR4200Document29 pagesMarantz SR4200LeBrave19No ratings yet

- klv22bx300 PDFDocument112 pagesklv22bx300 PDFPravin JadavNo ratings yet

- 3699 FU Tiller 105 105 NG20Document18 pages3699 FU Tiller 105 105 NG20Nabeel MohammedNo ratings yet

- 44 45 25 35 PDFDocument264 pages44 45 25 35 PDFDAVID LOPEZNo ratings yet

- R07ds0959ej0400 bcr16fm14ljDocument9 pagesR07ds0959ej0400 bcr16fm14ljJacky NplNo ratings yet

- Microondas Goldstar MA-2005sv PDFDocument46 pagesMicroondas Goldstar MA-2005sv PDFscripalinNo ratings yet

- EC2402 - OCN Two Marks Questions and AnswersDocument37 pagesEC2402 - OCN Two Marks Questions and AnswersshanmugachitraNo ratings yet

- Principles of Pressure Transducer Function and Sources of Error in Clinical UseDocument5 pagesPrinciples of Pressure Transducer Function and Sources of Error in Clinical UseLAURA CAMILA FRANCO ZAMBRANONo ratings yet