Professional Documents

Culture Documents

PP30OneSheet8 10 19

PP30OneSheet8 10 19

Uploaded by

siaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PP30OneSheet8 10 19

PP30OneSheet8 10 19

Uploaded by

siaCopyright:

Available Formats

ALL POWER LABS

Carbon Negative Power & Products

POWER PALLET - PP30

RENEWABLE PERFORMANCE

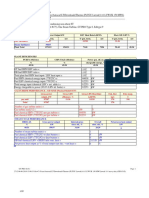

Electrical Power: Continuous: 25 kW@60 Hz / 22 kW@50 Hz

ON-DEMAND On-grid with CHP: 27 kW@60 Hz / 24 kW@50 Hz

Sound Level @ 7 meters: 75 dB(A)

POWER Biomass Consumption: 1.0 kg/kWh (dry basis)

Run Time per Hopper Fill: 5 kW: 12 hrs

Approximate @ 10 kW: 6 hrs

250 kg/m3 Fuel Density 15 kW: 4 hrs

Max. Continuous Operation: >16 hours

Start Up Time: 10-15 minutes

COMBINED HEAT & POWER (CHP)

Electrical Efficiency: ~23% (woody biomass, LHV)

~28% (syngas)

Electrical+Thermal Efficiency: >65% (biomass)

Gasifier HX+Engine Cooling+Exhaust HX: >80% (syngas) (3 stage)

CHP Heat Output: 3 stage: 2.0 kWth per 1 kWe

(without Exhaust HX) 2 stage: 1.5 kWth per 1 Kwe

Engine Coolant: Working Fluid: Up to 50% PEG

Temperature Range: 75-95°C (165-205°F)

Customer-side CHP: Loop Temp. 75-90°C (165-195°F)

Minimum Flow Rate @ 50 kWth: 2.2 m3/hr (9.5 GPM)

Minimum Heat Delivery: 0 kWth (native radiator backup)

The new Power Pallet PP30 25 kW genset is a renewable power Plumbing Connection: 1.5 inch sanitary fitting

solution that is a sensible answer to a critical need for distributed GRID TIE / PARALLELING

low-carbon energy. With standard grid-paralleling functionality, Controller: DeepSea DSE8610 MKII

Combined Heat & Power, engine enclosure, and emissions con-

OPERATING CONDITIONS

trol, the new PP30 meets the needs of modern, demanding power

Ambient Temperature: 5-40°C/40-100°F

standards.

Ambient Relative Humidity: 5-95%

APL’s unique patented multi-stage gasification architecture, in

Installed Footprint: 1.78 x 1.42 x 2.24 meters

combination with our innovative gasifier-engine thermal integra- 75 x 56 x 88 inches

tion, electronic control system and waste-heat recycling, gives the

Site Requirements: Outdoor: 1.75 m Overhead Clearance

Power Pallet unprecedented biomass fuel flexibility and efficiency. Well-ventilated, Level Pad,

The Power Pallet uses agricultural and forestry waste materials Covered from Rain and Direct Sun

Enclosed or Poorly Ventilated: Forced Convection Hood Over Flare

that can be readily sourced very near the point of generation. It

is compact and portable, easily transported to where the fuel is SHIPPING

and where the power is needed. Unlike diesel fuel or gasoline, this Dimensions: Main Crate: 185 x 145 x 140 cm / 73 x 57 x 55 in.

Hopper Crate: 83 x 83 x 114 cm / 33 x 33 x 45 in.

fuel is often available at little or no cost, and most importantly,

depending on feedstock selection and use details, the Power Pallet Weight: Main Crate: 1130 kg / 2500 lbs.

Hopper Crate: 91 kg / 200 lbs.

is capable of carbon-negative operation.

GAS FILTRATION

FUEL COST COMPARISON (VARIES by REGION) Dry Filtration System: Cyclone+Bag House Gang

Diesel/LPG $0.25 - $0.75/kWh Clean-in-place Shaker System

HX Temp Control: Prevents Tar and H2O Condensation

Gasoline $0.25 - $0.75/kWh

Gas Cooling Pre-filtration: Engine Coolant HX Controls to 80-100°C

Gasified Biomass $0.00 - $0.06/kWh HX In-situ Cleanable

All specifications are subject to change without notice

GAS-MAKING SYSTEM

Gasifier Type: APL v5.x Patented Multistage

Heat Recycling Downdraft

Materials: 304/310/321 SS / Mild Steel

Hearth: Coated Ceramic

Char-Ash Removal: Automated Auger

to 16 hour batch vessel

Fuel Feed: Automated: Hopper to Reactor

Hopper Capacity: 333 liters (88 gallons)

Hopper Filling: Batch: Manual while operating

Automatic: Continuous Feed Gate (optional)

Control System: On-Board Automation

Flare: Clean Swirl Combustor Auto Ignitor / Manual Mixture

ENGINE

ALL Power Labs Type: Ashok Leyland: Hino-Toyota Design

Displacement: 4.0 liter

APL is the global leader in small-scale gasification technology. We make

Cylinder Configuration: Inline 4 cylinder

biomass-fueled power generators that are ready for everyday work, to

serve real-world, distributed-energy needs. Our compact gasifiers are Compression Ratio: 12:1

now at work in over thirty countries, and support research at more RPM: 1500 @50 Hz, 1800@60 Hz

than fifty universities around the world.

Valve Configuration: Overhead, Pushrod

Our APL team is an unusual combination of hands-on fabricators and Engine Block: Cast Iron: Industrial Diesel Based

university-trained scientists and engineers. The result is a powerful Cylinders Lined for In-frame Rebuild

combination of technical ability and physical know-how for developing Pistons: Aluminum Alloy: Center Dished

innovative energy solutions. Ring-trench Inserts Prevent Sticking

We are deeply committed to supporting and developing biomass energy Cylinder Head: Cast Iron Crossflow

Circumferal Squish Combustion w/ Hardened Exhaust Inserts

conversion by curating and disseminating comprehensive information

and data on gasification science and technology—online, in work- Ignition: Electronic: ECU Controlled

shops, and free open house events. Lube Oil Capacity: 8 liters (8.5 quarts)

Our facility is in Berkeley, CA. Please contact us to arrange a visit the Coolant Capacity: 15 liters (16 quarts)

next time you are in the Bay Area. We would love to show you around. Auto Shutdown: Low Oil Pressure

High Coolant Temperature

System voltage: 12 VDC

Charging System: AC Genhead Switch-mode Charger

System Voltage: 12 VDC

Recommended Battery: Grp 24 Marine: 75Ah, 880 CCA

Auxilliary Components: Cooling Fans

ECU Controlled 12 VDC Water Pump

Auxillary Parasitic Load 850 Watt, 300 Watt w/o Radiator

Speed Control: Elect. Gov. Woodward L-Series

Automated Mixture Control Bosch Wide-Band O2 Sensor

GENERATOR

Type: Marathon 284CSL1542, 12 wire

WARRANTY AVR: DSE A106 MK II

ALL Power Labs products are covered by a 100% money back guaran- Available Voltages: 120-277, 240-480 VAC

tee. If you buy something & find yourself unimpressed with the value

of the product or company, we’ll refund all your money (minus ship- Available 3φ Topologies: Series or Parallel, Delta or Star

ping costs) within 30 days of delivery. APL directly warrants all parts we Total Harmonic Distortion: <5%

manufacture (i.e. gasifiers, electronics, & related components) for two Efficiency: 92%

years or 4000 hours, & passes along the OEM warranty for parts we

Motor Surge Starting Cap: >300%

source & configure into our end products (e.g. engines & genheads).

See http://allpowerlabs.com/products/warranty for full details. Maximum Step-load 50% of Rated Power

All specifications are subject to change without notice

ALL Power Labs - 1010 Murray Street Berkeley, CA 94710 U.S.A.

+1-510-845-1500 Email: sales@allpowerlabs.com Web: allpowerlabs.com 730-00005 6-26-19

You might also like

- H TEC Datenblatt ME450 EN 23 03Document2 pagesH TEC Datenblatt ME450 EN 23 03Juan Carlos RozoNo ratings yet

- BOWIN SERVICE MANUAL (Ceiling LED) PDFDocument28 pagesBOWIN SERVICE MANUAL (Ceiling LED) PDFCarolina Diaz MurillasNo ratings yet

- 574 Embraco ATMO2015Document10 pages574 Embraco ATMO2015VivekNo ratings yet

- Enapter Datasheet AEM-Multicore-225kg enDocument2 pagesEnapter Datasheet AEM-Multicore-225kg enRoque Alfredo Da Rosa AvilaNo ratings yet

- M2power System-12.11.23Document2 pagesM2power System-12.11.23ricardogaravitoNo ratings yet

- Plug LX-15T and LX-30T Liquefaction PproductsDocument2 pagesPlug LX-15T and LX-30T Liquefaction PproductsLiu YangtzeNo ratings yet

- Rashladnik Vode - Zrak VodaDocument22 pagesRashladnik Vode - Zrak Vodalovac1No ratings yet

- On Geothermal Net ZeroDocument65 pagesOn Geothermal Net Zerosandesh negiNo ratings yet

- BP65 Diesel Generating Set: Standby Power 50Hz 52KW / 65KVA Prime Power 50Hz 48KW / 60KVADocument5 pagesBP65 Diesel Generating Set: Standby Power 50Hz 52KW / 65KVA Prime Power 50Hz 48KW / 60KVARobet PrasetyoNo ratings yet

- Indop Product Catalogue 2019 enDocument24 pagesIndop Product Catalogue 2019 enđorđeNo ratings yet

- CoergyDocument32 pagesCoergyNguyen Thanh TrungNo ratings yet

- Lean Burn Overview - Spanish Notes - Rev IIDocument50 pagesLean Burn Overview - Spanish Notes - Rev IIluis miguel sanchez estrellaNo ratings yet

- High Performance Ventilation RecoveryDocument52 pagesHigh Performance Ventilation RecoverySohaib Faraz KhanNo ratings yet

- Siemens SGT750 DataDocument2 pagesSiemens SGT750 DataHiwa KhalediNo ratings yet

- Standby Power 50Hz Prime Power 50Hz - : Standard FeaturesDocument5 pagesStandby Power 50Hz Prime Power 50Hz - : Standard FeaturesMrShaz ZainalNo ratings yet

- EnergyPod-2-Spec-Sheet - Primus PowerDocument4 pagesEnergyPod-2-Spec-Sheet - Primus PowerAjinkya JoshiNo ratings yet

- Cal TA100Document2 pagesCal TA100Diego MorotoNo ratings yet

- CHP Unit TEDOM Cento T160 SPDocument4 pagesCHP Unit TEDOM Cento T160 SPHernan GiorgettiNo ratings yet

- BP40 Diesel Generating Set: Standby Power 50Hz 35KW / 44KVA Prime Power 50Hz 32KW / 40KVADocument5 pagesBP40 Diesel Generating Set: Standby Power 50Hz 35KW / 44KVA Prime Power 50Hz 32KW / 40KVAAhmad ZikriNo ratings yet

- Low Grade Whu Potential-Textile SectorDocument20 pagesLow Grade Whu Potential-Textile SectorAna lisbeth Galindo NogueraNo ratings yet

- Energy Consumption Breakdown of An Industrial Plant Is Given Below: Measured Data For Existing Chiller SystemsDocument2 pagesEnergy Consumption Breakdown of An Industrial Plant Is Given Below: Measured Data For Existing Chiller SystemsMeriem NguirNo ratings yet

- TS0086UK03 - DB - Rev0Document24 pagesTS0086UK03 - DB - Rev0amirokhovatNo ratings yet

- Standby Power 440KW / 550KVA Prime Power 50Hz 400KW / 500KVADocument5 pagesStandby Power 440KW / 550KVA Prime Power 50Hz 400KW / 500KVAWidya AnugrahNo ratings yet

- MSE Datasheet - 2022 - r30022Document1 pageMSE Datasheet - 2022 - r30022Rahil HussainNo ratings yet

- Green Building Design - Passive StrategiesDocument107 pagesGreen Building Design - Passive StrategiesSadaf SalehiNo ratings yet

- 210923-HL-ClassFactSheet-05-pdf - Original FileDocument2 pages210923-HL-ClassFactSheet-05-pdf - Original Filejohnward19951995No ratings yet

- Refrigeration Systems Lecture Notes - Batch 7 Bsme-3ADocument7 pagesRefrigeration Systems Lecture Notes - Batch 7 Bsme-3AkhinojidaNo ratings yet

- Session 1 - Advancement Technologies in Pyro-ProcessingDocument85 pagesSession 1 - Advancement Technologies in Pyro-Processingmahendra sen100% (1)

- (Catalog SOFC) PID000155 - FCE - DFC300 - r1 - HiresDocument2 pages(Catalog SOFC) PID000155 - FCE - DFC300 - r1 - HiresppourmoghaddamNo ratings yet

- Supplementary Paper 4 - Set B Regn No: - NameDocument16 pagesSupplementary Paper 4 - Set B Regn No: - NameAnuj ShahiNo ratings yet

- PD - Midea - Brochure Aqua Thermal Super - 20221118 - V5Document4 pagesPD - Midea - Brochure Aqua Thermal Super - 20221118 - V5Mihai GustiucNo ratings yet

- C65 Microturbine: Achieve Ultra-Low Emissions and Reliable Electrical Generation From Digester GasDocument2 pagesC65 Microturbine: Achieve Ultra-Low Emissions and Reliable Electrical Generation From Digester GasMohd Äwiw Vießar AvondrahNo ratings yet

- Affordable Heat With Micro CHP: EAUC Energy Seminar Chimneys Hotel and Conference Centre 28 January, 2016Document21 pagesAffordable Heat With Micro CHP: EAUC Energy Seminar Chimneys Hotel and Conference Centre 28 January, 2016Xiaoyang XuNo ratings yet

- Tecogen CM-60 & CM-75: Combined Heat and Power ModulesDocument2 pagesTecogen CM-60 & CM-75: Combined Heat and Power Modules20gradoshoy hvacNo ratings yet

- Image Shown May Not Reflect Actual Configuration: Metric EnglishDocument3 pagesImage Shown May Not Reflect Actual Configuration: Metric EnglishMarcelo FernandezNo ratings yet

- Greenstar 34CDi Classic Natural Gas ErP DatasheetDocument1 pageGreenstar 34CDi Classic Natural Gas ErP DatasheetravNo ratings yet

- The Organic Rankine Cycle (ORC) : CHP: Technology UpdateDocument26 pagesThe Organic Rankine Cycle (ORC) : CHP: Technology UpdatedolphinNo ratings yet

- Image Shown May Not Reflect Actual Configuration: Metric EnglishDocument3 pagesImage Shown May Not Reflect Actual Configuration: Metric EnglishJessica Tatiana Muñoz OrtizNo ratings yet

- 528 AllDocument16 pages528 AllbxbbfNo ratings yet

- Free Electricity: Making The Most of A CHP System DesignDocument16 pagesFree Electricity: Making The Most of A CHP System DesignsebascianNo ratings yet

- CET® Onsite Alternate EnergyDocument7 pagesCET® Onsite Alternate EnergyPrashant DeshmaneNo ratings yet

- Genset Caterpillar 200 kVADocument5 pagesGenset Caterpillar 200 kVAridho kusumaNo ratings yet

- Power Plant and Calculations - Thumb Rules For Power PlantDocument5 pagesPower Plant and Calculations - Thumb Rules For Power PlantSIPL CPP100% (1)

- 2 01 PDFDocument35 pages2 01 PDFmuhammad arif101719No ratings yet

- CHP Technical Data Sheet For: Cento 160 Natural Gas Indoor CanopyDocument6 pagesCHP Technical Data Sheet For: Cento 160 Natural Gas Indoor CanopyHernan GiorgettiNo ratings yet

- Siemens HL-class: The Next Generation of Siemens Advanced Air-Cooled Gas TurbinesDocument2 pagesSiemens HL-class: The Next Generation of Siemens Advanced Air-Cooled Gas Turbinespartha6789No ratings yet

- Cog en Era Ti OnDocument22 pagesCog en Era Ti Onashwini_kumar1984No ratings yet

- ME413 (Cogeneration) (261117) 1Document8 pagesME413 (Cogeneration) (261117) 1md mahdiNo ratings yet

- Built For The Year 2000 and Beyond: Marketing PotentialDocument2 pagesBuilt For The Year 2000 and Beyond: Marketing PotentialAwadhNo ratings yet

- 03.report CCPP Luwuk 150 MWDocument2 pages03.report CCPP Luwuk 150 MWgancanNo ratings yet

- ACS800, Liquid-Cooled 0.6 To 6 MW: ABB Low Voltage Wind Turbine ConvertersDocument4 pagesACS800, Liquid-Cooled 0.6 To 6 MW: ABB Low Voltage Wind Turbine ConvertersMadson FernandesNo ratings yet

- 1 s2.0 S0306261917304543 MainDocument19 pages1 s2.0 S0306261917304543 MainHebaNo ratings yet

- BP400 Diesel Generating Set: Standby Power 50Hz Prime Power 50HzDocument5 pagesBP400 Diesel Generating Set: Standby Power 50Hz Prime Power 50HzAlwinNo ratings yet

- 2331electrical Load TBEADocument2 pages2331electrical Load TBEAKaushikNo ratings yet

- 2331electrical Load TBEADocument2 pages2331electrical Load TBEAAyman SaberNo ratings yet

- 2331electrical Load TBEADocument2 pages2331electrical Load TBEAAyman SaberNo ratings yet

- 2331electrical Load TBEADocument2 pages2331electrical Load TBEAKaushikNo ratings yet

- Diesel Generating Set BF-C395-60: Standby Power 60Hz Prime Power 60HzDocument5 pagesDiesel Generating Set BF-C395-60: Standby Power 60Hz Prime Power 60Hzkevindelmonte1996No ratings yet

- Thermodynamics An Engineering Approach 8Th Edition Cengel Solutions Manual Full Chapter PDFDocument68 pagesThermodynamics An Engineering Approach 8Th Edition Cengel Solutions Manual Full Chapter PDFupwindscatterf9ebp100% (10)

- Better Technology For A Cleaner EnvironmentDocument40 pagesBetter Technology For A Cleaner EnvironmentSantosh TiwariNo ratings yet

- Bowman 1986Document17 pagesBowman 1986siaNo ratings yet

- H2-EFuels UeckerdtDocument42 pagesH2-EFuels UeckerdtsiaNo ratings yet

- UserCom37 TA ENDocument24 pagesUserCom37 TA ENsiaNo ratings yet

- ASTM E1131 - Standard Test Method For Compositional Analysis by ThermogravimetryDocument6 pagesASTM E1131 - Standard Test Method For Compositional Analysis by ThermogravimetrysiaNo ratings yet

- Characterization of Paint Formulated Using SecondaDocument8 pagesCharacterization of Paint Formulated Using SecondasiaNo ratings yet

- Ranjit's ResumeDocument1 pageRanjit's ResumeRanjit KaranNo ratings yet

- Monthly Questions (February) (E-Math)Document48 pagesMonthly Questions (February) (E-Math)Wei Ting ChuiNo ratings yet

- Sump Well-20 KL PDFDocument3 pagesSump Well-20 KL PDFvisali garikapatiNo ratings yet

- Diploma in MarineDocument18 pagesDiploma in MarineKaung Min MoNo ratings yet

- P2 Forces and Terminal Velocity HigherDocument12 pagesP2 Forces and Terminal Velocity HigherdownendscienceNo ratings yet

- Hurst Signals - Introducing The FLD Trading StrategyDocument7 pagesHurst Signals - Introducing The FLD Trading StrategyvewejNo ratings yet

- Alternative Strategies - CorporateDocument35 pagesAlternative Strategies - CorporateFungJingYun VivianNo ratings yet

- Modeling Wood Structural Panel Portal Frame ResponseDocument2 pagesModeling Wood Structural Panel Portal Frame ResponseGuillaumeHNONo ratings yet

- Migrate DHCP Scope(s) To Windows Server 2022 - PeteNetLiveDocument6 pagesMigrate DHCP Scope(s) To Windows Server 2022 - PeteNetLiveYudy KurniawanNo ratings yet

- Broadband Sequence Williston Cs PDFDocument2 pagesBroadband Sequence Williston Cs PDFKevin MusterNo ratings yet

- Super WorkingDocument10 pagesSuper WorkingixploreNo ratings yet

- Sterling Selections Corp v. LLDA GR 171427, 2011Document12 pagesSterling Selections Corp v. LLDA GR 171427, 2011doora keysNo ratings yet

- The Sproutie MK II HF Regen Receiver - Dave Richards AA7EEDocument81 pagesThe Sproutie MK II HF Regen Receiver - Dave Richards AA7EEdetroit_me25530% (1)

- How To Merge Two Switches With Different Active Zone SetsDocument3 pagesHow To Merge Two Switches With Different Active Zone SetslpuliceNo ratings yet

- The Business Value of Design: InsightsDocument18 pagesThe Business Value of Design: Insightsamber krishanNo ratings yet

- Open Circuit and Close Circuit Operations: Mechanical Operation (2150502)Document18 pagesOpen Circuit and Close Circuit Operations: Mechanical Operation (2150502)ABHISHEKNo ratings yet

- Prakas 511 Part 2standard Drawing 3cell Box Culvert PDFDocument51 pagesPrakas 511 Part 2standard Drawing 3cell Box Culvert PDFYa SamolNo ratings yet

- APROS Models For Thermal Hydraulic Analyses of Forsmark's NPPS, Kärnteknik 2008Document3 pagesAPROS Models For Thermal Hydraulic Analyses of Forsmark's NPPS, Kärnteknik 2008Otso CronvallNo ratings yet

- Fumigation Planning Guide: FactsDocument7 pagesFumigation Planning Guide: FactstahirNo ratings yet

- Customer Engagement - A Literature Review: October 2016Document7 pagesCustomer Engagement - A Literature Review: October 2016Nlke NzkeNo ratings yet

- B3-201-2018 - Developing and Using Justifiable Asset Health Indices For Tactical and Strategic Risk ManagementDocument10 pagesB3-201-2018 - Developing and Using Justifiable Asset Health Indices For Tactical and Strategic Risk ManagementNamLeNo ratings yet

- 24 Micro-Cap Multibagger Stocks To Buy Now PDFDocument11 pages24 Micro-Cap Multibagger Stocks To Buy Now PDFPravin YeluriNo ratings yet

- Karhula - Model Z-Y100Z-2 - Manual.Document8 pagesKarhula - Model Z-Y100Z-2 - Manual.German ZuletaNo ratings yet

- Unofficial Manual For Sknote Disto: Normal Stereo ModeDocument4 pagesUnofficial Manual For Sknote Disto: Normal Stereo ModedbiscuitsNo ratings yet

- Controlling Function of ManagementDocument32 pagesControlling Function of Managementnohel01No ratings yet

- ISAE 3000 ICI-Pakistan-Sustainability-Report-2019-2020Document69 pagesISAE 3000 ICI-Pakistan-Sustainability-Report-2019-2020saqlain khanNo ratings yet

- Legal Provisions Relating To Managing Director / Whole-Time DirectorDocument10 pagesLegal Provisions Relating To Managing Director / Whole-Time DirectorSoumitra ChawatheNo ratings yet

- Integrated Mobility & Service Plan - TumakuruDocument20 pagesIntegrated Mobility & Service Plan - TumakuruVinay RajNo ratings yet

- Ix Astronic BlockdiagramDocument34 pagesIx Astronic BlockdiagramЕвгений АксёновNo ratings yet