Professional Documents

Culture Documents

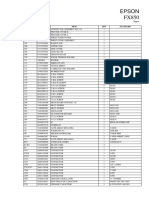

FW GD TestMode - Rev 1.3

FW GD TestMode - Rev 1.3

Uploaded by

Nma ColonelnmaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FW GD TestMode - Rev 1.3

FW GD TestMode - Rev 1.3

Uploaded by

Nma ColonelnmaCopyright:

Available Formats

IE-02193-013

ComColor FW / GD Series

TECHNICAL MANUAL

Chapter 17. Test Modes

REVISION 1.3

DECEMBER 2018

Copyright: 2017 RISO KAGAKU CORPORATION

All Rights Reserved. This Technical Manual was prepared and written for

the exclusive use of RISO Inter national Group Cert ified Dealers.

Reproduction and/or transmittal of this material in an y form or by any

means, including photocopying or record ing of the information is strictly

prohibited without the consent of RISO KAGAKU CORPORATION.

CONFIDENTIAL RISO SQUARE WEB VERSION

Test mode

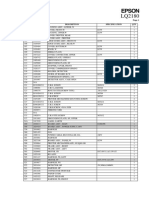

Type Test mode name ON OFF Remarks FW GD

No.

Engine system section

S 04-1-001 BP WIRE LOOSE DETECTION Detected (switching pressed) Not detected (switching released) ✔ ✔

S 04-1-002 FRONT COVER INTER LOCK SWITCH Close (switching pressed) Open (switching released) ✔

S 04-1-002 LEFT FRONT COVER INTER LOCK SWITCH Close (switching pressed) Open (switching released) ✔

S 04-1-003 PAPER ELEVATION COVER INTER LOCK SW Close (switching pressed) Open (switching released) ✔ ✔

S 04-1-004 SWITCHBACK COVER INTER LOCK SWITCH Close (switching pressed) Open (switching released) ✔ ✔

Close (Paper feed tray maximum value or

S 04-1-005 PAPER FEED TRAY INTER LOCK SW Open ✔ ✔

lower limit switch ON)

S 04-1-006 TRAY1 SET SAFETY SWITCH DETECTED (TRAY CLOSED) Detected (tray 1 closed) Not detected (tray 1 open) ✔ ✔

S 04-1-007 TRAY2 SET SAFETY SWITCH DETECTED (TRAY CLOSED) Detected (tray 2 closed) Not detected (tray 2 open) ✔ ✔

S 04-1-008 TRAY3 SET SAFETY SWITCH DETECTED (TRAY CLOSED) Detected (tray 3 closed) Not detected (tray 3 open) ✔

S 04-1-009 STRIPPER UNIT SET SWITCH Detected Not detected (Stripper unit is off) ✔ ✔

S 04-1-010 FU JAM RELEASE COVER SW Detected Not detected (door open) ✔ ✔

Detectable only when not driving the front cover lock

S 04-1-011 Front cover lock solenoid connection detection Connected Not connected ✔ ✔

solenoid.

S 04-1-012 Front cover lock plate orientation monitoring sensor Locked Lock released ✔

S 04-1-013 RIGHT FRONT COVER INTER LOCK SWITCH Close (switching pressed) Open (switching released) ✔

S 04-1-021 OPTION PCB DETECT SIGNAL Connected Not connected ✔ ✔

S 04-1-022 VENDOR DETECT SIGNAL Connected Not connected ✔ ✔

S 04-1-023 AUTO-CTL STACKING TRAY DETECT SIGNAL Connected Not connected ✔ ✔

S 04-1-024 MULTI FINISHER DETECT SIGNAL Connected Not connected ✔ ✔

S 04-1-025 FU EJECT UNIT DETECT SIGNAL Connected Not connected ✔ ✔

Paper feed section

S 05-1-001 PAPER FEED TRAY UPPER LIMIT SENSOR A Detected (light blocked) Not detected (light passes through) ✔ ✔

S 05-1-002 PAPER FEED TRAY UPPER LIMIT SENSOR B Detected (light blocked) Not detected (light passes through) ✔ ✔

S 05-1-003 PAPER FEED TRAY LOWER LIMIT SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 05-1-004 TRAY1 UPPER LIMIT SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 05-1-005 TRAY2 UPPER LIMIT SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 05-1-006 TRAY3 UPPER LIMIT SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 05-1-011 PAPER FEED TRAY PAPER DETECT SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 05-1-012 TRAY1 PAPER DETECT SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 05-1-013 TRAY2 PAPER DETECT SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 05-1-014 TRAY3 PAPER DETECT SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 05-1-016 P-FEED TRAY PAPER LENGTH DETECT SNSR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 05-1-017 TRAY1 PAPER SIZE DETECT SENSOR 1 Detected (light blocked) Not detected (light passes through) ✔ ✔

S 05-1-018 TRAY1 PAPER SIZE DETECT SENSOR 2 Detected (light blocked) Not detected (light passes through) ✔ ✔

S 05-1-019 TRAY1 PAPER SIZE DETECT SENSOR 3 Detected (light blocked) Not detected (light passes through) ✔ ✔

S 05-1-020 TRAY1 PAPER SIZE DETECT SENSOR 4 Detected (light blocked) Not detected (light passes through) ✔ ✔

S 05-1-021 TRAY2 PAPER SIZE DETECT SENSOR 1 Detected (light blocked) Not detected (light passes through) ✔ ✔

S 05-1-022 TRAY2 PAPER SIZE DETECT SENSOR 2 Detected (light blocked) Not detected (light passes through) ✔ ✔

S 05-1-023 TRAY2 PAPER SIZE DETECT SENSOR 3 Detected (light blocked) Not detected (light passes through) ✔ ✔

S 05-1-024 TRAY2 PAPER SIZE DETECT SENSOR 4 Detected (light blocked) Not detected (light passes through) ✔ ✔

S 05-1-025 TRAY3 PAPER SIZE DETECT SENSOR 1 Detected (light blocked) Not detected (light passes through) ✔

S 05-1-026 TRAY3 PAPER SIZE DETECT SENSOR 2 Detected (light blocked) Not detected (light passes through) ✔

S 05-1-027 TRAY3 PAPER SIZE DETECT SENSOR 3 Detected (light blocked) Not detected (light passes through) ✔

S 05-1-028 TRAY3 PAPER SIZE DETECT SENSOR 4 Detected (light blocked) Not detected (light passes through) ✔

S 05-1-031 P-FEED TRAY PAPER VOLUME SENSOR 1 Detected (light blocked) Not detected (light passes through) ✔

S 05-1-032 P-FEED TRAY PAPER VOLUME SENSOR 2 Detected (light blocked) Not detected (light passes through) ✔

S 05-1-033 TRAY1 PAPER VOLUME SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

Paper feed section

S 05-1-034 TRAY2 PAPER VOLUME SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 05-1-035 TRAY3 PAPER VOLUME SENSOR Detected (light blocked) Not detected (light passes through) ✔

1/316 ComColor FW/GD Series Revision 1.3

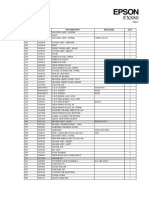

CONFIDENTIAL RISO SQUARE WEB VERSION

Test mode

Type Test mode name ON OFF Remarks FW GD

No.

S 05-1-041 EXTERNAL PAPER FEED MOTOR ENCODER Detected (light blocked) Not detected (light passes through) ✔ ✔

S 05-1-042 TRAY1 JAM DETECTION SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 05-1-043 INTERNAL PAPER TRANSFER SENSOR1 Detected (light blocked) Not detected (light passes through) ✔ ✔

S 05-1-044 TRAY2 JAM DETECTION SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 05-1-045 INTERNAL PAPER TRANSFER SENSOR2 Detected (light blocked) Not detected (light passes through) ✔ ✔

S 05-1-046 TRAY3 JAM DETECTION SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 05-1-047 INTERNAL PAPER TRANSFER SENSOR3 Detected (light blocked) Not detected (light passes through) ✔

S 05-1-048 INTERNAL PAPER MERGE SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 05-1-049 VERTICAL PAPER FEED SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 05-1-051 REGISTRATION MOTOR ENCODER Detected (light blocked) Not detected (light passes through) ✔ ✔

S 05-1-052 REGISTRATION SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 05-1-056 PAPER FEED TRAY ELEVATION SW ON (pressed) OFF (released) ✔ ✔

S 05-1-057 Internal paper feed jam release door switch Detected (door closed) Not detected (door open) ✔ ✔

Transport section

S 06-1-001 BELT HP SENSOR Detected Not detected ✔ ✔

S 06-1-002 TRANSFER BELT ENCODER Detected Not detected ✔ ✔

S 06-1-003 TOP EDGE SENSOR 1 Detected Not detected ✔ ✔

S 06-1-004 PAPER LIFT DETECTION SENSOR Detected Not detected ✔ ✔

S 06-1-005 PAPER ELEVATION IN SENSOR Detected Not detected ✔ ✔

S 06-1-006 PAPER ELEVATION SENSOR Detected Not detected ✔

S 06-1-006 PAPER ELEVATION SENSOR Detected Not detected ✔

S 06-1-021 SWITCHBACK ENTRANCE SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 06-1-021 SWITCHBACK ENTRANCE SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 06-1-022 SWITCHBACK TRANSFER SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 06-1-022 SWITCHBACK TRANSFER SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 06-1-023 SWITCHBACK SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 06-1-024 LOWER PAPER TRANSFER ENTRANCE SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 06-1-025 LOWER PAPER TRANSFER EXIT SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 06-1-031 FD PAPER EJECTION FLIPPER DETECT Connected Not connected ✔

S 06-1-031 FD PAPER EJECTION FLIPPER DETECT Connected Not connected ✔

Paper ejection section

S 07-1-001 FD PAPER EJECTION MOTOR ENCODER Detected (light blocked) Not detected (light passes through) ✔ ✔

S 07-1-002 FD PAPER EJECTION SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 07-1-003 FD PAPER EJECTION FULL SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 07-1-004 FD PAPER EJECTION PAPER DETECTION SENSOR Detected (light blocked) Not detected (light passes through) ✔

Not detected (light passes through:

S 07-1-005 FD PAPER EJECTION PAPER GUIDE HP SENSOR Detected (light blocked: at home position) ✔

not at home position)

S 07-1-011 FU PAPER EJECTION SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 07-1-012 FU PAPER EJECTION JUMP MOTOR ENCODER Detected (light blocked) Not detected (light passes through) ✔ ✔

Not detected (light passes through:

S 07-1-013 FU PAPER EJECTION WING HP SENSOR Detected (light blocked: at home position) ✔

not at home position)

Ink maintenance section

S 09-1-001 INK COOLING FAN1 CONNECT Connected Not connected Only detectable while being driven ✔ ✔

S 09-1-002 INK COOLING FAN2 CONNECT Connected Not connected ✔ ✔

S 09-1-003 INK SUPPLY VALVE K DETECT Connected Not connected ✔ ✔

S 09-1-004 INK SUPPLY VALVE C DETECT Connected Not connected ✔ ✔

2/316 ComColor FW/GD Series Revision 1.3

CONFIDENTIAL RISO SQUARE WEB VERSION

Test mode

Type Test mode name ON OFF Remarks FW GD

No.

Ink maintenance section

Also applicable to the following.

- R for KCRY model

S 09-1-005 INK SUPPLY VALVE M (R,B) DETECT Connected Not connected ✔

- R for KR model

- B for KB model

S 09-1-005 INK SUPPLY VALVE M (R,B) DETECT Connected Not connected ✔

S 09-1-006 INK SUPPLY VALVE Y DETECT Connected Not connected ✔ ✔

This is also applicable to the following:

S 09-1-007 INK SUPPLY VALVE P (R, GR) DETECT Connected Not connected - R of KCMYR units ✔

- Gr of KCMYGr units

S 09-1-008 PRESSURE INK TANK AIR VALVE DETECT Connected Not connected ✔ ✔

S 09-1-009 N-PRESSURE INK TANK AIR VALVE DETECT Connected Not connected ✔ ✔

S 09-1-010 PRESSURE REGULATOR VALVE CONNECT Connected Not connected ✔ ✔

S 09-1-011 N-PRESSURE REGULATOR VALVE CONNECT Connected Not connected ✔ ✔

S 09-1-012 PRESSURE TANK INK SENSOR K DETECT Connected Not connected ✔ ✔

S 09-1-013 PRESSURE TANK INK SENSOR C DETECT Connected Not connected ✔ ✔

Also applicable to the following.

- R for KCRY model

S 09-1-014 PRESSURE TANK INK SNR M (R,B) DETECT Connected Not connected ✔

- R for KR model

- B for KB model

S 09-1-014 PRESSURE TANK INK SNR M (R,B) DETECT Connected Not connected ✔

S 09-1-015 PRESSURE TANK INK SENSOR Y DETECT Connected Not connected ✔ ✔

This is also applicable to the following:

S 09-1-016 PRESSURE TANK INK SNR P (R, GR) DETECT Connected Not connected - R of KCMYR units ✔

- Gr of KCMYGr units

S 09-1-017 N-PRESSURE TANK INK SENSOR K DETECT Connected Not connected ✔ ✔

S 09-1-018 N-PRESSURE TANK INK SENSOR C DETECT Connected Not connected ✔ ✔

Also applicable to the following.

- R for KCRY model

S 09-1-019 N-PRESSURE TANK INK SNR M (R,B) DET Connected Not connected ✔

- R for KR model

- B for KB model

S 09-1-019 N-PRESSURE TANK INK SNR M (R,B) DET Connected Not connected ✔

S 09-1-020 N-PRESSURE TANK INK SENSOR Y DETECT Connected Not connected ✔ ✔

This is also applicable to the following:

S 09-1-021 N-PRESSURE TANK INK SNR P (R, GR) DET Connected Not connected - R of KCMYR units ✔

- Gr of KCMYGr units

S 09-1-022 OVERFLOW TANK INK DETECT Connected Not connected ✔ ✔

S 09-1-023 IP PCB DETECT Connected Not connected ✔ ✔

Not detected (current not

S 09-1-030 24V VOLTAGE DETECT Detected (current conducted) ✔ ✔

conducted)

Not detected (current not

S 09-1-031 24V IL-VOLTAGE DETECT Detected (current conducted) ✔ ✔

conducted)

Not detected (current not

S 09-1-032 36V VOLTAGE DETECT Detected (current conducted) ✔ ✔

conducted)

Not detected (current not

S 09-1-033 36VA IL-VOLTAGE DETECT Detected (current conducted) ✔ ✔

conducted)

Only detectable when the AIR REGULATOR VALVE is

S 09-1-034 AIR REGULATOR VALVE connection detection Connected Not connected ✔ ✔

not being driven.

S 09-1-039 PR INK TANK INK SENSOR K2 CONNECT Connected Not connected ✔ ✔

S 09-1-040 N-PR INK TANK INK SENSOR K2 CONNECT Connected Not connected ✔ ✔

S 09-1-041 INK CARTRIDGE DETECT K Detected Not detected ✔ ✔

S 09-1-042 INK CARTRIDGE DETECT C Detected Not detected ✔ ✔

Also applicable to the following.

- R for KCRY model

S 09-1-043 INK CARTRIDGE DETECT M (R,B) Detected Not detected ✔

- R for KR model

- B for KB model

S 09-1-043 INK CARTRIDGE DETECT M (R,B) Detected Not detected ✔

S 09-1-044 INK CARTRIDGE DETECT Y Detected Not detected ✔ ✔

Ink maintenance section

3/316 ComColor FW/GD Series Revision 1.3

CONFIDENTIAL RISO SQUARE WEB VERSION

Test mode

Type Test mode name ON OFF Remarks FW GD

No.

This is also applicable to the following:

S 09-1-045 INK CARTRIDGE DETECT P (R, GR) Detected Not detected - R of KCMYR units ✔

- Gr of KCMYGr units

S 09-1-046 CIRCULATION PUMP K ERROR DETECT Detected (error or not connected) Not detected (normal) ✔

S 09-1-047 CIRCULATION PUMP C ERROR DETECT Detected (error or not connected) Not detected (normal) ✔

S 09-1-048 CIRCULATION PUMP M (R,B) ERROR DETECT Detected (error or not connected) Not detected (normal) ✔

S 09-1-049 CIRCULATION PUMP Y ERROR DETECT Detected (error or not connected) Not detected (normal) ✔

This is also applicable to the following:

S 09-1-050 CIRCULATION PUMP P (R, GR) ERROR DETECT Detected (error or not connected) Not detected (normal) - R of KCMYR units ✔

- Gr of KCMYGr units

S 09-1-051 PRESSURE INK TANK INK SENSOR K Detected Not detected ✔ ✔

S 09-1-052 PRESSURE INK TANK INK SENSOR C Detected Not detected ✔ ✔

S 09-1-053 PRESSURE INK TANK INK SENSOR M (R,B) Detected (connected) Not detected (Not connected) ✔

S 09-1-053 PRESSURE INK TANK INK SENSOR M (R,B) Detected (connected) Not detected (Not connected) ✔

S 09-1-054 PRESSURE INK TANK INK SENSOR Y Detected (connected) Not detected (Not connected) ✔ ✔

This is also applicable to the following:

S 09-1-055 PRESSURE INK TANK INK SENSOR P (R, GR) Detected (connected) Not detected (Not connected) - R of KCMYR units ✔

- Gr of KCMYGr units

S 09-1-056 N-PRESSURE INK TANK INK SENSOR K Detected (connected) Not detected (Not connected) ✔ ✔

S 09-1-057 N-PRESSURE INK TANK INK SENSOR C Detected (connected) Not detected (Not connected) ✔ ✔

S 09-1-058 N-PRESSURE INK TANK INK SNR M (R,B) Detected (connected) Not detected (Not connected) ✔

S 09-1-058 N-PRESSURE INK TANK INK SNR M (R,B) Detected (connected) Not detected (Not connected) ✔

S 09-1-059 N-PRESSURE INK TANK INK SENSOR Y Detected (connected) Not detected (Not connected) ✔ ✔

This is also applicable to the following:

S 09-1-060 N-PRESSURE INK TANK INK SENSOR P (R, GR) Detected (connected) Not detected (Not connected) - R of KCMYR units ✔

- Gr of KCMYGr units

S 09-1-061 OVERFLOW TANK INK SENSOR Detected (connected) Not detected (Not connected) ✔ ✔

The detection status of 0-09-1-063

The detection status of 0-09-1-063 "WASTE INK TANK FULL

The near full and full statuses of the waste ink tank are

"WASTE INK TANK FULL SENSOR" is: SENSOR" is:

S 09-1-062 WASTE INK TANK NEAR FULL SENSOR detected in combination with 0-09-1-063 "WASTE INK ✔ ✔

ON: Near full ON: Full

TANK FULL SENSOR".

OFF: Waste ink tank set in machine OFF: Waste ink tank not set in

machine

The detection status of 0-09-1-062

The detection status of 0-09-1-062

"WASTE INK TANK NEAR FULL

"WASTE INK TANK NEAR FULL The near full and full statuses of the waste ink tank are

SENSOR" is:

S 09-1-063 WASTE INK TANK FULL SENSOR SENSOR" is: detected in combination with 0-09-1-062 "WASTE INK ✔ ✔

ON: Waste ink tank set in machine

ON: Near full TANK NEAR FULL SENSOR".

OFF: Waste ink tank not set in

OFF: Full

machine

S 09-1-067 PRESSURE INK TANK INK SENSOR K2 Detected (connected) Not detected (Not connected) ✔ ✔

S 09-1-070 N-PRESSURE INK TANK INK SENSOR K2 Detected (connected) Not detected (Not connected) ✔ ✔

S 09-1-071 INK PAN MOTOR STRAGE POS SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 09-1-072 INK PAN MOTOR OPEN POS SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 09-1-073 WIPER MOTOR HP SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 09-1-074 AUTHORIZATION CAM HP SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 09-1-075 BP LOWER LIMIT SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 09-1-076 BP UPPER LIMIT SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 09-1-077 BP HIT SENSOR (RL) Contact detected Contact not detected ✔ ✔

S 09-1-078 BP HIT SENSOR (FL) Contact detected Contact not detected ✔ ✔

S 09-1-079 BP HIT SENSOR (RR) Contact detected Contact not detected ✔ ✔

S 09-1-080 BP HIT SENSOR (FR) Contact detected Contact not detected ✔ ✔

S 09-1-081 BP MIDPOINT SENSOR At release position Not at release position ✔

S 09-1-085 INK LEAK DETECT SENSOR 1 Ink leak detected Ink leak not detected ✔ ✔

IF unit

4/316 ComColor FW/GD Series Revision 1.3

CONFIDENTIAL RISO SQUARE WEB VERSION

Test mode

Type Test mode name ON OFF Remarks FW GD

No.

S 10-1-001 IF UNIT COVER INTER LOCK SWITCH Detected Not detected ✔ ✔

Scanner

S 21-1-002 FB ORIGINAL SIZE SENSOR 1 Original loaded (light passes through) No original (light blocked) ✔ ✔

S 21-1-003 FB ORIGINAL SIZE SENSOR 2 Original loaded (light passes through) No original (light blocked) ✔ ✔

S 21-1-004 FB ORIGINAL COVER SENSOR Cover closed (light blocked) Cover open (light passes through) ✔ ✔

Scanner

S 21-1-005 FB ORIGINAL COVER ANGLE SENSOR Cover closed (light blocked) Cover open (light passes through) ✔ ✔

Mirror at origin (home position, light Mirror not at origin (light passes

S 21-1-006 SCANNER HP SENSOR ✔ ✔

blocked) through)

S 21-1-021 AF UNIT DETECT Original loaded (light passes through) No original (light blocked) ✔ ✔

S 21-1-022 AF ORIGINAL DETECT SENSOR Original loaded (light passes through) No original (light blocked) ✔ ✔

S 21-1-023 AF tray sensor 1 Original loaded (light passes through) No original (light blocked) ✔ ✔

S 21-1-024 AF tray sensor 2 Original loaded (light passes through) No original (light blocked) ✔ ✔

S 21-1-025 AF FEED COVER SET SW Cover closed (light blocked) Cover open (light passes through) ✔ ✔

S 21-1-026 AF REGISTRATION SENSOR Original loaded (light passes through) No original (light blocked) ✔ ✔

S 21-1-027 AF READ SENSOR (F) Original loaded (light passes through) No original (light blocked) ✔ ✔

S 21-1-028 AF READ SENSOR (B) Original loaded (light passes through) No original (light blocked) ✔ ✔

S 21-1-029 AF SEPARATION SENSOR Original loaded (light passes through) No original (light blocked) ✔ ✔

S 21-1-030 AF ORIGINAL SET SENSOR Original loaded (light passes through) No original (light blocked) ✔ ✔

S 21-1-031 AF LAST PAPER SENSOR Original loaded (light passes through) No original (light blocked) ✔ ✔

Not detection (light passes

S 21-1-032 AF WHITE PLATE HOME POSITION SENSOR Detected (light blocked, home position) ✔ ✔

through, not home position)

Not detection (light passes

S 21-1-033 AF ELEVATION TRAY HOME SENSOR Detected (light blocked, home position) ✔ ✔

through, not home position)

S 21-1-034 AF ORIGINAL WIDTH SENSOR 1 Original loaded (light passes through) No original (light blocked) ✔ ✔

S 21-1-035 AF ORIGINAL WIDTH SENSOR 2 Original loaded (light passes through) No original (light blocked) ✔ ✔

S 21-1-036 AF ORIGINAL WIDTH SENSOR 3 Original loaded (light passes through) No original (light blocked) ✔ ✔

S 21-1-037 AF ORIGINAL LENGTH SENSOR 1 Original loaded (light passes through) No original (light blocked) ✔ ✔

S 21-1-038 AF ORIGINAL LENGTH SENSOR 2 Original loaded (light passes through) No original (light blocked) ✔ ✔

S 21-1-039 AF ORIGINAL FEED POSITION SENSOR Original loaded (light passes through) No original (light blocked) ✔ ✔

Multifunction Finisher

S 23-1-001 DECURLER IN SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-002 DECURLER OUT SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-006 PUNCH OUT SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-007 COMPILE EXIT SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-008 TOP TRAY EXIT SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-009 BAFFER PATH SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-010 SIDE REGISTRATION SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-011 PUNCH MOTOR SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

Not detected (light passes through,

S 23-1-012 PUNCH MOVE HOME SENSOR Detected (light blocked, home position) ✔ ✔

not home position)

Not detected (light passes through,

S 23-1-013 PUNCH HOME SENSOR Detected (light blocked, home position) ✔ ✔

not home position)

S 23-1-014 PUNCH FRONT SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-015 PUNCH HOLE SELECT SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

Not detected (light passes through,

S 23-1-016 SIDE REGISTRATION HOME SENSOR Detected (light blocked, home position) ✔ ✔

not home position)

S 23-1-017 PUNCH BOX SET SENSOR Attached Not attached ✔ ✔

S 23-1-018 TOP TRAY FULL SENSOR Full Not full ✔ ✔

S 23-1-019 COMPILE TRAY NO PAPER SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

Not detected (light passes through,

S 23-1-020 SUB PADDLE HOME SENSOR Detected (light blocked, home position) ✔ ✔

not home position)

S 23-1-021 STAPLE 50PIN SENSOR Attached Not attached ✔ ✔

5/316 ComColor FW/GD Series Revision 1.3

CONFIDENTIAL RISO SQUARE WEB VERSION

Test mode

Type Test mode name ON OFF Remarks FW GD

No.

Not detected (light passes through,

S 23-1-022 TAMPER HOME SENSOR Detected (light blocked, home position) ✔ ✔

not home position)

Not detected (light passes through,

S 23-1-023 END WALL HOME SENSOR Detected (light blocked, home position) ✔ ✔

not home position)

S 23-1-024 END WALL OPEN SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

Multifunction Finisher

Not detected (light passes through,

S 23-1-025 SHELF HOME SENSOR Detected (light blocked, home position) ✔ ✔

not home position)

S 23-1-026 STAPLE CENTER POS SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

Not detected (light passes through,

S 23-1-027 STAPLE MOVE HOME SENSOR Detected (light blocked, home position) ✔ ✔

not home position)

S 23-1-028 STACK HEIGHT SENSOR 2 Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-029 LOW STAPLE SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-030 SELF PRIMING SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

Not detected (light passes through,

S 23-1-031 STAPLE HOME SENSOR Detected (light blocked, home position) ✔ ✔

not home position)

S 23-1-033 EJECT UP SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-034 EJECT SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-035 STACKER NO PAPER SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-036 STACK HEIGHT SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-037 TRAY HIGHT SENSOR LOWER Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-038 MIX STACK SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-039 HALF STACK SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-040 FULL STACK SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-041 STACK HEIGHT SENSOR 3 Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-042 STACKER REAR POS SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-043 LOWER LIMIT SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-044 STACKER SAFTY SWITCH Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-045 FINISHER I/F MODULE FRONT COVER SW Detected (cover closed) Not detected (cover open) ✔ ✔

S 23-1-046 FINISHER FRONT COVER SWITCH Detected (cover closed) Not detected (cover open) ✔ ✔

S 23-1-047 FOLDER ENVELOPE TRAY OPEN SW Detected (switch pressed) Not detected (switch released) ✔ ✔

S 23-1-048 FOLDER ENVELOPE TRAY SW Attached Not attached ✔ ✔

Not detected (light passes through,

S 23-1-050 KNIFE HOME SENSOR Detected (light blocked, home position) ✔ ✔

not home position)

S 23-1-051 BOOKLET COMPILE NO PAPER SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-052 BOOKLET FOLDER ROLLER EXIT SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-053 BOOKLET DRAWER SET SENSOR Attached Not attached ✔ ✔

S 23-1-054 BOOKLET STAPLER READY Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-055 BOOKLET STAPLER ERROR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-056 BOOKLET LOW STAPLE F SW Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-057 BOOKLET LOW STAPLE R SW Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-058 FEED OUT SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-059 BOOKLET TRAY BELT SW Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-060 FOLDER ENTRANCE SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-061 FOLDER PATH SENSOR 2 Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-062 FOLDER PATH SENSOR 3 Detected (light blocked) Not detected (light passes through) ✔ ✔

Not detected (light blocked

S 23-1-063 END GUIDE HOME SENSOR 1 Detected (light blocked, home position) ✔ ✔

through, not home position)

Not detected (light blocked

S 23-1-064 END GUIDE HOME SENSOR 2 Detected (light blocked, home position) ✔ ✔

through, not home position)

S 23-1-065 ENVELOP TRAY FULL SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-066 FOLDER PATH SENSOR 1 Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-067 FOLDER PATH SENSOR 4 Detected (light blocked) Not detected (light passes through) ✔ ✔

6/316 ComColor FW/GD Series Revision 1.3

CONFIDENTIAL RISO SQUARE WEB VERSION

Test mode

Type Test mode name ON OFF Remarks FW GD

No.

S 23-1-068 IOT EXIT SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-069 PUNCH 3 HOLE DETECT Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-070 FOLDER DETECT Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-071 BOOKLET DETECT Detected (light blocked) Not detected (light passes through) ✔ ✔

Multifunction Finisher

Not detected (light blocked

S 23-1-072 BOOKLET TAMPER HP SENSOR (F) Detected (light blocked, home position) ✔ ✔

through, not home position)

S 23-1-073 BOOKLET IN SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

Not detected (light blocked

S 23-1-074 BOOKLET TAMPER HP SENSOR (R) Detected (light blocked, home position) ✔ ✔

through, not home position)

Not detected (light blocked

S 23-1-075 BOOKLET END GUIDE HP SENSOR Detected (light blocked, home position) ✔ ✔

through, not home position)

S 23-1-076 BOOKLET NO PAPER SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-077 KNIFE FOLDING SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 23-1-078 FOLDER EXIT SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

FACE DOWN FINISHER

S 24-1-001 FDF SWITCHBACK PATH SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 24-1-002 FDF STAPLE SCRATCH PREVENTION LEVER HP SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 24-1-003 FDF RELAY 1 SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 24-1-004 FDF ENTRANCE SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 24-1-005 FDF EJECTION ROLLER ELEVATION HP SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 24-1-006 FDF LOADING TRAY UPPER LIMIT SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 24-1-007 FDF REVERSE ROLLER ELEVATION HP SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 24-1-008 FDF LOADING TRAY ELEVATION CLK SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 24-1-009 FDF LOADING TRAY PAPER SURFACE DETECT SENSOR 1 Detected (light blocked) Not detected (light passes through) ✔ ✔

S 24-1-010 FDF LOADING TRAY PAPER SURFACE DETECT SENSOR 2 Detected (light blocked) Not detected (light passes through) ✔ ✔

S 24-1-011 FDF LOADING TRAY PAPER SURFACE DETECT SENSOR 3 Detected (light blocked) Not detected (light passes through) ✔ ✔

S 24-1-012 FDF LOADING TRAY LOWER LIMIT SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 24-1-013 FDF PROCESSING TRAY PAPER DETECTION SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 24-1-014 FDF RAKING ROLLER ELEVATION HP SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 24-1-015 FDF REAR ALIGNMENT PLATE HP SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 24-1-016 FDF LOADING TRAY SHIFT SENSOR 1 Detected (light blocked) Not detected (light passes through) ✔ ✔

S 24-1-017 FDF LOADING TRAY PAPER DETECTION SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 24-1-018 FDF LOADING TRAY SHIFT CLK SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 24-1-019 FDF LOADING TRAY SHIFT SENSOR 2 Detected (light blocked) Not detected (light passes through) ✔ ✔

S 24-1-020 FDF FRONT ALIGNMENT PLATE HP SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 24-1-021 FDF ALIGNMENT PLATE POSITION SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 24-1-022 FDF STP HORIZONTAL MOVEMENT HP SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 24-1-023 FDF STP CLINCH HP SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 24-1-024 FDF STP NO STAPLE SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 24-1-025 FDF STP SELF-PRIMING SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

S 24-1-026 FDF STAPLE REPLACEMENT COVER SWITCH Detected (light blocked) Not detected (light passes through) ✔ ✔

S 24-1-027 FDF JAM COVER SWITCH Detected (light blocked) Not detected (light passes through) ✔ ✔

S 24-1-028 FDF JAM COVER SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

Auto-control stacking tray / RP stacking tray

Not detected (light blocked

S 25-1-001 AS SIDE FENCE HP SENSOR Detected (light blocked, home position) ✔ ✔

through, not home position)

Not detected (light blocked

S 25-1-002 AS END FENCE HP SENSOR Detected (light blocked, home position) ✔ ✔

through, not home position)

S 25-1-003 AS PAPER REMOVAL SW Detected (switch pressed) Not detected (switch released) ✔ ✔

S 25-1-004 AS PAPER DETECT SENSOR Detected (light blocked) Not detected (light passes through) ✔ ✔

High Capacity Feeder

S 29-1-001 HCF PAPER FEED TRAY ELEVATION SW ON (pressed) OFF (released) ✔

7/316 ComColor FW/GD Series Revision 1.3

CONFIDENTIAL RISO SQUARE WEB VERSION

Test mode

Type Test mode name ON OFF Remarks FW GD

No.

S 29-1-002 HCF PAPER FEED TRAY INTERLOCK SW ON (pressed) OFF (released) ✔

S 29-1-003 HCF PAPER FEED TRAY UPPER LIMIT SENSOR (STANDARD) Detected (light blocked) Not detected (light passes through) ✔

S 29-1-004 HCF PAPER FEED TRAY UPPER LIMIT SENSOR (CARD PAPER) Detected (light blocked) Not detected (light passes through) ✔

S 29-1-005 HCF PAPER FEED TRAY LOWER LIMIT SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 29-1-006 HCF PAPER VOLUME SENSOR 1 Detected (light blocked) Not detected (light passes through) ✔

S 29-1-007 HCF PAPER VOLUME SENSOR 2 Detected (light blocked) Not detected (light passes through) ✔

S 29-1-008 HCF PAPER VOLUME SENSOR 3 Detected (light blocked) Not detected (light passes through) ✔

S 29-1-009 HCF PAPER DETECTION SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 29-1-010 HCF PAPER LENGTH DETECT SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 29-1-011 HCF INTERMEDIATE EXIT SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 29-1-012 HCF JAM RELEASE DOOR DETECT SIGNAL ON (pressed) OFF (released) ✔

S 29-1-013 HCF PU DRIVE MOTOR FG SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 29-1-014 HCF INTERMEDIATE TRANSPORT MOTOR FG SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 29-1-015 HCF INTERMEDIATE ENTRANCE SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 29-1-016 HCF NIP RELEASE HP SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 29-1-017 HCF STRIPPER PLATE SET SW Detected (light blocked) Not detected (light passes through) ✔

S 29-1-018 HCF INTERMEDIATE TRANSFER UPPER DOOR SENSOR Detected (light blocked) Not detected (light passes through) ✔

High Capacity Stacker

S 30-1-001 HCS PAPER RECEIVING TRAY SET SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 30-1-002 HCS TROLLEY SET SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 30-1-003 HCS JAM RELEASE DOOR OPEN/CLOSE SW Detected (light blocked) Not detected (light passes through) ✔

S 30-1-004 HCS PRE-STOCKER DOOR OPEN/CLOSE SW Detected (SW pressed) Not detected (SW released) ✔

S 30-1-005 HCS ELEVATOR ELEVATION SW Detected (SW pressed) Not detected (SW released) ✔

S 30-1-011 HCS PAPER RECEIVING TRAY UPPER LIMIT SENSOR Detected (SW pressed) Not detected (SW released) ✔

S 30-1-012 HCS PAPER RECEIVING TRAY INTERMEDIATE SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 30-1-013 HCS PAPER RECEIVING TRAY LOWER LIMIT SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 30-1-016 HCS ENTRY SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 30-1-017 HCS SWITCHBACK SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 30-1-018 HCS SB SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 30-1-019 HCS INTERMEDIATE SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 30-1-020 HCS FU SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 30-1-021 HCS ELEVATION SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 30-1-022 HCS EJECTION SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 30-1-023 HCS PAPER EJECTION MOTOR FG Detected (light blocked) Not detected (light passes through) ✔

S 30-1-024 HCS PAPER RECEIVING TRAY PAPER DETECTION SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 30-1-025 HCS POST CARD FULL SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 30-1-026 HCS FULL SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 30-1-027 HCS OFFSET FULL SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 30-1-028 HCS UPPER SURFACE DETECT SENSOR 1 Detected (light blocked) Not detected (light passes through) ✔

S 30-1-029 HCS UPPER SURFACE DETECT SENSOR 2 Detected (light blocked) Not detected (light passes through) ✔

S 30-1-031 HCS SIDE PAPER GUIDE HP SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 30-1-032 HCS END PAPER GUIDE HP SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 30-1-033 HCS PAPER EJECTION WING HP SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 30-1-034 HCS OFFSET GUIDE HP SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 30-1-035 HCS END PAPER GUIDE SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 30-1-036 HCS OFFSET GUIDE SENSOR Detected (light blocked) Not detected (light passes through) ✔

High Capacity Stacker

S 30-1-037 HCS OFFSET GUIDE POSITION SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 30-1-041 HCS ELEVATOR MOTOR FG Detected (light blocked) Not detected (light passes through) ✔

S 30-1-042 HCS SWITCHBACK MOTOR FG Detected (light blocked) Not detected (light passes through) ✔

Wrapping Envelope Finisher

S 33-1-001 MM INTRODUCTION SENSOR Detected (light blocked) Not detected (light passes through) ✔

8/316 ComColor FW/GD Series Revision 1.3

CONFIDENTIAL RISO SQUARE WEB VERSION

Test mode

Type Test mode name ON OFF Remarks FW GD

No.

S 33-1-002 MM INTERMEDIATE ALIGNMENT SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 33-1-003 MM TRAILING EDGE ALIGNMENT HP SENSOR Home position (light blocked) Other (light passes through) ✔

S 33-1-004 MM SIDE ALIGNMENT HP SENSOR Home position (light blocked) Other (light passes through) ✔

S 33-1-005 MM ALIGNMENT NIP HP SENSOR Home position (light blocked) Other (light passes through) ✔

S 33-1-006 MM LEADING EDGE ALIGNMENT HP SENSOR Home position (light blocked) Other (light passes through) ✔

S 33-1-007 MM LEADING EDGE ALIGNMENT SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 33-1-008 MM ALIGNMENT EJECTION SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 33-1-009 MM MIDDLE PAPER FOLD ENTRANCE SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 33-1-010 MM MIDDLE PAPER CONTACT HP SENSOR 1 Home position (light blocked) Other (light passes through) ✔

S 33-1-011 MM MIDDLE PAPER CONTACT HP SENSOR 2 Home position (light blocked) Other (light passes through) ✔

S 33-1-012 MM MIDDLE PAPER FOLD SWITCH HP SENSOR Home position (light blocked) Other (light passes through) ✔

S 33-1-013 MM WRAPPING ENTRANCE SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 33-1-014 MM WRAPPING WAIT SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 33-1-015 MM MIDDLE PAPER EXIT SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 33-1-016 MM FORM RECEIVING SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 33-1-017 MM FORM RECEIVING NIP HP SENSOR Home position (light blocked) Other (light passes through) ✔

S 33-1-018 MM FORM REGISTRATION SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 33-1-019 MM FORM HORIZONTAL HP SENSOR Home position (light blocked) Other (light passes through) ✔

S 33-1-020 MM FORM EDGE DETECTION SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 33-1-021 MM FORM CONTACT HP SENSOR 2 Home position (light blocked) Other (light passes through) ✔

S 33-1-022 MM WRAPPING SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 33-1-023 MM FLAP ENTRANCE SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 33-1-024 MM FORM CONTACT HP SENSOR 3 Home position (light blocked) Other (light passes through) ✔

S 33-1-025 MM GLUING SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 33-1-026 MM GLUING HP SENSOR Home position (light blocked) Other (light passes through) ✔

S 33-1-027 MM FLAP BONDING EJECTION SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 33-1-028 MM PRESSURE BONDING EXIT SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 33-1-029 MM EJECTION SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 33-1-030 MM EJECTION ELEVATION EDGE SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 33-1-031 MM WATER LEVEL SENSOR Water present (floating) No water present (not floating) ✔

S 33-1-032 MM EJECTION TRAY FULL SENSOR F Detected (light blocked) Not detected (light passes through) ✔

S 33-1-033 MM EJECTION TRAY FULL SENSOR R Detected (light blocked) Not detected (light passes through) ✔

S 33-1-034 MM EJECTION PAPER GUIDE POSITION SENSOR F Form A, Form C envelope position Down ✔

S 33-1-035 MM EJECTION PAPER GUIDE POSITION SENSOR R Vertical Down ✔

Perfect Binder

S 34-1-001 PB PAPER RECEIPT SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-002 PB PAPER PASSING (COVER SIZE MEASUREMENT) SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-003 PB BODY EJECTION SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-004 PB COVER REGISTRATION SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-005 PB COVER CUT LENGTH SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-006 PB COVER POSITIONING SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-007 PB COVER CHIP TRAY PRESENCE SENSOR Detected (light blocked) Not detected (light passes through) ✔

Perfect Binder

S 34-1-008 PB STACKED BODY PRESENCE SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-009 PB TOP-BOTTOM ALIGNMENT ORIGIN SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-010 PB EDGE ALIGNMENT ORIGIN SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-011 PB BODY STACKING JAM SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-012 PB CLAMP VERTICAL ORIGIN SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-013 PB CLAMP VERTICAL RECEPTION SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-014 PB CLAMP BODY PRESENCE SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-015 PB CLAMP OPEN SENSOR Detected (light blocked) Not detected (light passes through) ✔

9/316 ComColor FW/GD Series Revision 1.3

CONFIDENTIAL RISO SQUARE WEB VERSION

Test mode

Type Test mode name ON OFF Remarks FW GD

No.

S 34-1-016 PB CLAMP CLOSED SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-017 PB CLAMP HORIZONTAL ORIGIN SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-018 PB CLAMP HORIZONTAL PASSAGE SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-019 PB GLUE ROLLER BACKLASH SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-020 PB GLUE SHEET FEED SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-021 PB GLUE SHEET CUT SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-022 PB ARRANGEMENT COVER DETECTION SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-023 PB COVER ALIGNMENT ORIGIN SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-024 PB ARRANGEMENT PLATE OPEN SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-025 PB ARRANGEMENT PLATE CLOSED SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-026 PB BOOKLET EJECTION SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-027 PB BOOKLET ALIGNMENT SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-028 PB BOOKLET EJECTION POSITION 1 SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-029 PB BOOKLET EJECTION POSITION 2 SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-030 PB EDGE REFERENCE PLATE ORIGIN Detected (light blocked) Not detected (light passes through) ✔

S 34-1-031 PB EDGE REFERENCE PLATE SHELTER Detected (light blocked) Not detected (light passes through) ✔

S 34-1-032 PB SHIELD PLATE OPEN SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-033 PB SHIELD PLATE CLOSED SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-034 PB COVER CUT ORIGIN SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-035 PB COVER CUT LIMIT SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-036 PB FRONT COVER SW Detected (light blocked) Not detected (light passes through) ✔

S 34-1-037 PB RIGHT DOOR SW Detected (light blocked) Not detected (light passes through) ✔

S 34-1-038 PB TOP COVER SW Detected (light blocked) Not detected (light passes through) ✔

S 34-1-039 PB COVER DETECTION SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-040 PB COVER TOP SURFACE SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-041 PB COVER PAPER FEED (COVER SIZE MEASUREMENT) SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-042 PB COVER PASSING SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-043 PB COVER SIZE 1 SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-044 PB COVER SIZE 2 SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-045 PB LIFT-UP LOWER LIMIT SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-046 PB BOOKLET JAM DETECTION SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-047 PB BOOKLET FEED PULSE DETECTION SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-048 PB GUIDE SWITCH OPEN SENSOR Detected (light blocked) Not detected (light passes through) ✔

S 34-1-049 PB GUIDE SWITCH CLOSED SENSOR Detected (light blocked) Not detected (light passes through) ✔

10/316 ComColor FW/GD Series Revision 1.3

CONFIDENTIAL RISO SQUARE WEB VERSION

Type Test mode No. Test mode name Action FW GD

Engine system section

D 04-2-001 Front cover lock solenoid Front cover lock drive ✔ ✔

Paper feed section

D 05-2-001 REGISTRATION MOTOR Registration motor activation. ✔ ✔

D 05-2-002 EXTERNAL PAPER FEED MOTOR (STRAIGHT) EXTERNAL PAPER FEED MOTOR (STRAIGHT) activation. ✔ ✔

D 05-2-003 EXTERNAL PAPER FEED MOTOR (VERTICAL) EXTERNAL PAPER FEED MOTOR (VERTICAL) activation. ✔ ✔

D 05-2-004 INTERNAL PAPER FEED MOTOR INTERNAL PAPER FEED MOTOR activation. ✔ ✔

D 05-2-005 TRAY1 PICKUP MOTOR TRAY1 PICKUP MOTOR activation. ✔ ✔

D 05-2-006 TRAY2 PICKUP MOTOR TRAY2 PICKUP MOTOR activation. ✔ ✔

D 05-2-007 TRAY3 PICKUP MOTOR TRAY3 PICKUP MOTOR activation. ✔

D 05-2-008 RE-FEED MOTOR RE-FEED MOTOR activation. ✔

Transport section

D 06-2-001 TRANSFER BELT SUCTION FAN1

Activation of BP Suction Fan F & BP Suction Fan R. ✔ ✔

D 06-2-002 TRANSFER BELT SUCTION FAN2 TRANSFER BELT SUCTION FAN2 activation. ✔ ✔

D 06-2-004 TRANSFER BELT SUCTION FAN ALL TRANSFER BELT SUCTION FAN activation. ✔ ✔

BP motor activation. ✔ ✔

D 06-2-011 TRANSFER BELT MOTOR The BP motor speed when executing this test mode is set according to values in TM0-04-6-101 "TM PAPER FEED SPEED SETTING".

D 06-2-012 LOWER PAPER TRANSFER MOTOR LOWER PAPER TRANSFER MOTOR activation. (Elevation/both sides) ✔

D 06-2-012 PAPER ELEVATION MOTOR 1 PAPER ELEVATION MOTOR 1 activation. ✔

D 06-2-013 LOWER PAPER TRANSFER ASSISTMOTOR LOWER PAPER TRANSFER ASSISTMOTOR activation. ✔

D 06-2-013 PAPER ELEVATION MOTOR 2 PAPER ELEVATION MOTOR 2 activation. ✔

D 06-2-014 SWITCHBACK MOTOR (NORMAL) SWITCHBACK MOTOR (NORMAL) activation. ✔ ✔

D 06-2-015 SWITCHBACK MOTOR (REVERSE) SWITCHBACK MOTOR (REVERSE) activation. ✔ ✔

LOWER PAPER TRANSFER ENTRANCE LOWER PAPER TRANSFER ENTRANCE MOTOR activation. ✔

D 06-2-016

MOTOR

D 06-2-016 HORIZONTAL TRANSPORT MOTOR 1 HORIZONTAL TRANSPORT MOTOR 1 activation. ✔

D 06-2-017 LOWER PAPER TRANSFER EXIT MOTOR LOWER PAPER TRANSFER EXIT MOTOR activation. ✔

D 06-2-017 HORIZONTAL TRANSPORT MOTOR 2 HORIZONTAL TRANSPORT MOTOR 2 activation. ✔

D 06-2-031 FD EJECT FLIPPER SOLENOID FD EJECT FLIPPER SOLENOID activation. ✔

D 06-2-031 FD EJECT FLIPPER SOLENOID FD EJECT FLIPPER SOLENOID activation. ✔

D 06-2-032 FU EJECT FLIPPER SOLENOID FU paper ejection flipper solenoid activation. ✔ ✔

Paper ejection section

D 07-2-001 FD EJECT MOTOR FD paper ejection motor activation. ✔ ✔

D 07-2-011 FU EJECT JUMP MOTOR FU EJECT JUMP MOTOR activation. ✔ ✔

D 07-2-012 FU EJECT TRANSPORT MOTOR Turn ON or OFF face up paper ejection transport motor. ✔

Print head area

D 08-2-001 HEAD DRIVE IC COOLING FAN F Head drive IC cooling fan activation. ✔

D 08-2-001 HEAD DRIVE IC COOLING FAN FL Head drive IC cooling fan FL activation. ✔

D 08-2-002 HEAD DRIVE IC COOLING FAN R Head drive IC cooling fan2 activation. ✔

D 08-2-002 HEAD DRIVE IC COOLING FAN RL Head drive IC cooling fan RL activation. ✔

D 08-2-003 HEAD DRIVE IC COOLING FAN FR Head drive IC cooling fan FR activation. ✔

D 08-2-004 HEAD DRIVE IC COOLING FAN RR Head drive IC cooling fan RR activation. ✔

Ink maintenance section

D 09-2-001 INK COOLING FAN INK COOLING FAN1, 2 activation. ✔ ✔

D 09-2-011 PRESSRE & NEGATIVE PRESSRE AIR PUMP PRESSRE & NEGATIVE PRESSRE AIR PUMP activation. ✔ ✔

D 09-2-012 AIR REGULATOR VALVE AIR REGULATOR VALVE activation. ✔ ✔

Opens pressure ink tank air valve. ✔ ✔

D 09-2-016 PRESSURE INK TANK AIR VALVE (OPEN) If left alone while being driven, the ink in the ink route may overflow.

11/316 ComColor FW/GD Series Revision 1.3

CONFIDENTIAL RISO SQUARE WEB VERSION

Type Test mode No. Test mode name Action FW GD

Closes pressure ink tank air valve. ✔ ✔

If left alone while being driven, because the ink route is sealed shut, expansion and contraction of air due to temperature changes may cause the

D 09-2-017 PRESSURE INK TANK AIR VALVE (CLOSE)

head to break.

Ink maintenance section

Opens pressure regulator valve. ✔ ✔

D 09-2-018 PRESSURE REGULATOR VALVE (OPEN) If left alone while being driven, the ink in the ink route may overflow.

Opens negative pressure open air valve. ✔ ✔

D 09-2-021 NEGA PR INK TANK AIR VALVE (OPEN) If left alone while being driven, the ink in the ink route may overflow.

Closes negative pressure ink tank air valve. ✔ ✔

If left alone while being driven, because the ink route is sealed shut, expansion and contraction of air due to temperature changes may cause the

D 09-2-022 NEGA PR INK TANK AIR VALVE (CLOSE)

head to break.

Pressure regulator valve ✔ ✔

D 09-2-023 NEGA PR REGULATOR VALVE (OPEN) If left alone while being driven, the ink in the ink route may overflow.

CIRCULATION PUMP K activation. ✔ ✔

D 09-2-031 CIRCULATION PUMP K If left alone while being driven, the ink in the ink route may overflow.

CIRCULATION PUMP C activation. ✔ ✔

D 09-2-032 CIRCULATION PUMP C If left alone while being driven, the ink in the ink route may overflow.

CIRCULATION PUMP M (R,B) activation. ✔ ✔

D 09-2-033 CIRCULATION PUMP M (R,B) If left alone while being driven, the ink in the ink route may overflow.

CIRCULATION PUMP Y activation. ✔ ✔

D 09-2-034 CIRCULATION PUMP Y If left alone while being driven, the ink in the ink route may overflow.

CIRCULATION PUMP P activation. ✔

If left alone while being driven, the ink in the ink route may overflow. This is also applicable to the following:

D 09-2-035 CIRCULATION PUMP P (R, GR) - R of KCMYR units

- Gr of KCMYGr units

Opens ink supply valve K. ✔ ✔

D 09-2-036 INK SUPPLY VALVE K If left alone while being driven, the ink in the ink route may overflow.

Opens ink supply valve C. ✔ ✔

D 09-2-037 INK SUPPLY VALVE C If left alone while being driven, the ink in the ink route may overflow.

Opens ink supply valve M (R,B). ✔ ✔

D 09-2-038 INK SUPPLY VALVE M (R,B) If left alone while being driven, the ink in the ink route may overflow.

Opens ink supply valve Y. ✔ ✔

D 09-2-039 INK SUPPLY VALVE Y If left alone while being driven, the ink in the ink route may overflow.

Opens ink supply valve P. ✔

If left alone while being driven, the ink in the ink route may overflow. This is also applicable to the following:

D 09-2-040 INK SUPPLY VALVE P (R, GR) - R of KCMYR units

- Gr of KCMYGr units

IF unit

D 10-2-001 DECURLER MOTOR Decurler motor activation. (Operates at at 200 mm/s) ✔ ✔

Scanner

D 21-2-001 SCANNER LAMP Activates scanner lamp. ✔ ✔

D 21-2-002 AF READ PULSE MOTOR CW Drives AF read pulse motor at normal rotation. Speed is scan speed 1. ✔ ✔

D 21-2-003 AF FAN AF fan activation. ✔ ✔

D 21-2-004 AF SCANNER LAMP Activates AF scanner lamp. ✔ ✔

D 21-2-005 SCANNER POWER SUPPLY COOLING FAN Activates the scanner power supply cooling fan. ✔ ✔

12/316 ComColor FW/GD Series Revision 1.3

CONFIDENTIAL RISO SQUARE WEB VERSION

Type Test mode No. Test mode name Action FW GD

D 21-2-006 FB COOLING FAN Activates the FB cooling fan. ✔ ✔

D 21-2-011 AF TRAY ELEVATION MOTOR Drives AF tray elevation/lowering motor. ✔ ✔

D 21-2-012 AF PAPER FEED MOTOR FRD (SPEED 1) Drives paper feed motor at normal rotation. Speed is separation speed 1. ✔ ✔

D 21-2-013 AF PAPER FEED MOTOR FRD (SPEED 2) Drives paper feed motor at normal rotation. Speed is separation speed 2. ✔ ✔

D 21-2-014 AF PAPER FEED MOTOR FRD (POS. SPEED) Drives paper feed motor at normal rotation. Speed is insertion speed. ✔ ✔

D 21-2-015 AF PAPER FEED MTR REV (P.UP INITIAL SPD) Drives paper feed motor at reverse rotation. Speed is pickup default speed. ✔ ✔

D 21-2-021 AF READ PULSE MOTOR FRD (SPEED 2) Drives AF read pulse motor at normal rotation. Speed is scan speed 2. ✔ ✔

D 21-2-022 AF READ PULSE MOTOR REV (SHADING) Drives AF read pulse motor at reverse rotation. Speed is shading speed. ✔ ✔

D 21-2-026 AF SEPARATION CLUTCH Drives AF separation clutch. ✔ ✔

D 21-2-027 AF REGISTRATION CLUTCH Drives AF registration clutch. ✔ ✔

Multifunction Finisher

D 23-2-001 DECURLER TRANSPORT MOTOR Drives the I/F unit transport roller. ✔ ✔

TRANSPORT MOTOR (HIGH SPEED Drives the X port system roller. (Normal rotation at 1000 mm/s) ✔ ✔

D 23-2-002

FORWARD)

TRANSPORT MOTOR (MID SPEED Drives the X port system roller. (Normal rotation at 800 mm/s) ✔ ✔

D 23-2-003

FORWARD)

TRANSPORT MOTOR (LOW SPEED Drives the X port system roller. (Reverse rotation at 385 mm/s) ✔ ✔

D 23-2-004

REVERSE)

D 23-2-005 COMPILE EXIT MOTOR (HIGH SPEED FRD) Drives compile exit/buffer system roller. (Normal rotation at 1000 mm/s) ✔ ✔

D 23-2-006 COMPILE EXIT MOTOR (MID SPEED FRD) Drives compile exit/buffer system roller. (Normal rotation at 800 mm/s) ✔ ✔

D 23-2-007 COMPILE EXIT MOTOR (LOW SPEED FRD) Drives compile exit/buffer system roller. (Normal rotation at 285 mm/s) ✔ ✔

D 23-2-008 COMPILE EXIT MOTOR (HIGH SPEED REV) Drives compile exit/buffer system roller. (Reverse rotation at 1000 mm/s) ✔ ✔

D 23-2-009 COMPILE EXIT MOTOR (LOW SPEED REV) Drives compile exit/buffer system roller. (Reverse rotation at 385 mm/s) ✔ ✔

D 23-2-010 PUNCHER MOVE CLUTCH Switches between puncher and sensor movement. ✔ ✔

D 23-2-011 PADDLE MOTOR Drives compiler paddle/sub-paddle. ✔ ✔

D 23-2-012 EJECT MOTOR (1st FORWARD) Drives eject roller. (Normal rotation at 800 mm/s) ✔ ✔

D 23-2-013 EJECT MOTOR (2nd FORWARD) Drives eject roller. (Normal rotation at 610 mm/s) ✔ ✔

D 23-2-014 EJECT MOTOR (3rd FORWARD) Drives eject roller. (Normal rotation at 404 mm/s) ✔ ✔

D 23-2-015 EJECT MOTOR (4th FORWARD) Drives eject roller. (Normal rotation at 320 mm/s) ✔ ✔

D 23-2-016 EJECT MOTOR (5th FORWARD) Drives eject roller. (Normal rotation at 285 mm/s) ✔ ✔

D 23-2-017 EJECT MOTOR (1st REVERSE) Drives eject roller. (Reverse rotation at 800 mm/s) ✔ ✔

D 23-2-021 SCT EJECT MOTOR (MID SPEED FORWARD) Drives SCT eject system roller. (Normal rotation at 800 mm/s) ✔ ✔

D 23-2-022 SCT EJECT MOTOR (LOW SPEED FORWARD) Drives SCT eject system roller. (Normal rotation at 285 mm/s) ✔ ✔

D 23-2-023 SCT EJECT MOTOR (LOW SPEED REVERSE) Drives SCT eject system roller. (Reverse rotation at 385 mm/s) ✔ ✔

D 23-2-024 EJECT MOTOR (HIGH SPEED FORWARD) Drives eject roller. (Normal rotation at 1000 mm/s) ✔ ✔

D 23-2-025 EJECT MOTOR (HIGH SPEED REVERSE) Drives eject roller. (Reverse rotation at 1000 mm/s) ✔ ✔

D 23-2-026 BOOKLET PAPER PATH MOTOR (HI SPEED) Drives booklet IN roller. (800mm/s) ✔ ✔

D 23-2-027 BOOKLET PAPER PATH MOTOR (MID SPEED) Drives booklet IN roller. (250mm/s) ✔ ✔

BOOKLET PAPER PATH MOTOR (LOW Drives booklet IN roller. (50mm/s) ✔ ✔

D 23-2-028

SPEED)

BOOKLET FOLDER ROLLER MOTOR Drives folder roller. (Regular rotation) ✔ ✔

D 23-2-029

FORWARD

BOOKLET FOLDER ROLLER MOTOR Drives folder roller. (Reverse rotation) ✔ ✔

D 23-2-030

REVERSE

D 23-2-031 TRAY BELT DRIVE MOTOR Drives tray belt. ✔ ✔

D 23-2-032 BOOKLET PADDLE MOTOR Drives booklet paddle. (Rotation) ✔ ✔

D 23-2-033 FOLDER DRIVE MOTOR 2 Drives transport roller and folding roller. ✔ ✔

D 23-2-034 FOLDER DRIVE MOTOR 1 Drives transport within the folder. ✔ ✔

D 23-2-035 FOLDER ENTRANCE MOTOR (HIGH SPEED) Drives transport above the folder. ✔ ✔

13/316 ComColor FW/GD Series Revision 1.3

CONFIDENTIAL RISO SQUARE WEB VERSION

Type Test mode No. Test mode name Action FW GD

D 23-2-036 FOLDER ENTRANCE MOTOR (LOW SPEED) Drives transport above the folder. ✔ ✔

D 23-2-037 FOLDING SOLENOID 1 Drives folding solenoid 1. ✔ ✔

D 23-2-038 FOLDING SOLENOID 2 Drives folding solenoid 2. ✔ ✔

D 23-2-039 ENVELOPE TRAY LED 1 Activates envelope tray LED 1. ✔ ✔

D 23-2-040 FOLDER C SOLENOID Folder C solenoid activation. ✔ ✔

FACE DOWN FINISHER

D 24-2-001 FDF RELAY MOTOR 1 Driving of FDF relay motor 1. ✔ ✔

D 24-2-002 FDF RELAY MOTOR 2 Driving of FDF relay motor 2. ✔ ✔

D 24-2-003 FDF TRANSPORT MOTOR Driving of the FDF transport motor. ✔ ✔

D 24-2-004 FDF PAPER EJECTION MOTOR (FORWARD) Drives the FDF paper ejection motor in the forward direction. ✔ ✔

D 24-2-005 FDF REVERSE MOTOR Driving of the FDF reverse motor. ✔ ✔

D 24-2-006 FDF POWER SUPPLY COOLING FAN Driving of the FDF power supply cooling fan. ✔ ✔

D 24-2-007 FDF RELAY COOLING FAN Driving of the FDF relay cooling fan. ✔ ✔

Auto-control stacking tray / RP stacking tray

D 25-2-001 AS SIDE FENCE MOTOR (WIDEN)

Operates AS side fence motor in the widen direction. ✔ ✔

If left alone while being driven,the mechanism may be damaged.

D 25-2-002 AS SIDE FENCE MOTOR (CLOSE)

Operates AS side fence motor in the close direction. ✔ ✔

If left alone while being driven,the mechanism may be damaged.

D 25-2-003 AS END FENCE MOTOR (WIDEN)

Operates AS end fence motor in the widen direction. ✔ ✔

If left alone while being driven,the mechanism may be damaged.

D 25-2-004 AS END FENCE MOTOR (CLOSE)

Operates AS end fence motor in the close direction. ✔ ✔

If left alone while being driven,the mechanism may be damaged.

High Capacity Feeder

D 29-2-001 HCF PU DRIVE MOTOR Activation of the PU drive motor of the large-capacity paper feed unit. ✔

D 29-2-002 HCF INTERMEDIATE TRANSPORT MOTOR Activation of the intermediate transport motor of the large-capacity paper feed unit. ✔

D 29-2-003 HCF NIP RELEASE MOTOR Drives the nip release motor of the large-capacity paper feed unit in the clockwise direction. ✔

High Capacity Stacker

D 30-2-001 HCS ENTRY MOTOR Activation/stoppage of the entry motor of the large-capacity paper ejection unit. ✔

D 30-2-002 HCS SWITCHBACK MOTOR (FORWARD) Activation (in the forward direction)/stoppage of the switchback motor of the large-capacity paper ejection unit. ✔

D 30-2-003 HSC SWITCHBACK MOTOR (REVERSE) Activation (in the reverse direction)/stoppage of the switchback motor of the large-capacity paper ejection unit. ✔

D 30-2-004 HCS INTERMEDIATE TRANSPORT MOTOR Activation/stoppage of the intermediate transport motor of the large-capacity paper ejection unit. ✔

D 30-2-005 HCS ELEVATION MOTOR Activation/stoppage of the elevation motor of the large-capacity paper ejection unit. ✔

D 30-2-006 HCS PAPER EJECTION MOTOR Activation/stoppage of the paper ejection motor of the large-capacity paper ejection unit. ✔

HCS PAPER EJECTION WING MOVEMENT Activation/stoppage of the paper ejection wing movement motor of the large-capacity paper ejection unit. ✔

D 30-2-007

MOTOR

D 30-2-011 HCS ROUTE SWITCHING SOLENOID Activation/stoppage of the route switching solenoid of the large-capacity paper ejection unit. ✔

D 30-2-012 HCS OFFSET GUIDE SOLENOID Activation/stoppage of the HCS offset guide solenoid of the large-capacity paper ejection unit. ✔

Wrapping Envelope Finisher

D 33-2-001 MM ENTRY MOTOR Operates the entry motor in the transfer direction. ✔

D 33-2-002 MM ENTRY SELECTION SOLENOID Activation (in the form transfer direction)/stoppage (in the middle paper transfer direction) of the entry selection solenoid. ✔

D 33-2-003 MM ALIGNED FEEDING MOTOR Operates the aligned feeding motor in the transfer direction. ✔

D 33-2-004 MM LEADING EDGE ALIGNMENT SOLENOID Activation (alignment plate shelter position)/stoppage (alignment plate contact position) of the leading edge alignment solenoid. ✔

D 33-2-005 MM MIDDLE PAPER FOLD MOTOR Operates the middle paper fold motor in the transfer direction. ✔

D 33-2-006 MM WRAPPING FEED MOTOR Operates the wrapping feed motor in the transfer direction. ✔

D 33-2-007 MM FORM REGISTRATION MOTOR Operates the form registration motor in the transfer direction. ✔

D 33-2-008 MM WRAPPING FOLD MOTOR Operates the wrapping fold motor in the transfer direction. ✔

D 33-2-009 MM FLAP FOLD MOTOR Operates the flap fold motor in the transfer direction. ✔

D 33-2-010 MM PRESSURE BONDING MOTOR Operates the pressure bonding motor in the transfer direction. ✔

D 33-2-011 MM EJECTION ELEVATION MOTOR Operates the ejection elevation motor in the transfer direction. ✔

D 33-2-012 MM PAPER EJECTION MOTOR Operates the paper ejection motor in the transfer direction. ✔

D 33-2-013 MM ALIGNMENT COOLING FAN Checks the operation of the MM alignment cooling fan. ✔

14/316 ComColor FW/GD Series Revision 1.3

CONFIDENTIAL RISO SQUARE WEB VERSION

Type Test mode No. Test mode name Action FW GD

D 33-2-014 MM WRAPPING COOLING FAN Checks the operation of the MM wrapping cooling fan. ✔

Perfect Binder

D 34-2-001 PB PAPER TRANSFER 1 MOTOR (FEED) Activation/stoppage of the PB paper transfer 1 motor (feed). ✔

D 34-2-002 PB PAPER TRANSFER 1 MOTOR (RETURN) Activation/stoppage of the PB paper transfer 1 motor (return). ✔

D 34-2-003 PB PAPER TRANSFER 2 MOTOR (FEED) Activation/stoppage of the PB paper transfer 2 motor (feed). ✔

D 34-2-004 PB PAPER TRANSFER 2 MOTOR (RETURN) Activation/stoppage of the PB paper transfer 2 motor (return). ✔

D 34-2-005 PB GLUE AMOUNT MEASUREMENT FAN Activation/stoppage of the PB glue amount measurement fan. ✔

D 34-2-006 PB BOOKLET EJECTION 1 MOTOR (FEED) Activation/stoppage of the PB booklet ejection 1 motor (feed). ✔

D 34-2-007 PB BOOKLET EJECTION 1 MOTOR (RETURN) Activation/stoppage of the PB booklet ejection 1 motor (return). ✔

D 34-2-008 PB BOOKLET EJECTION 2 MOTOR (FEED) Activation/stoppage of the PB booklet ejection 2 motor (feed). ✔

D 34-2-009 PB BOOKLET EJECTION 2 MOTOR (RETURN) Activation/stoppage of the PB booklet ejection 2 motor (return). ✔

D 34-2-010 PB EXHAUST FAN Activation/stoppage of the PB exhaust fan. ✔

D 34-2-011 PB COVER TRANSPORT MOTOR (FEED) Activation/stoppage of the PB cover transport motor (feed). ✔

Perfect Binder

D 34-2-012 PB COVER TRANSPORT MOTOR (RETURN) Activation/stoppage of the PB cover transport motor (return). ✔

D 34-2-013 PB COVER SUCTION FAN Activation/stoppage of the PB cover suction fan. ✔

D 34-2-014 PB COVER SEPARATION FAN Activation/stoppage of the PB cover separation fan. ✔

D 34-2-015 PB PAPER DIVERGING SOLENOID Activation/stoppage of the PB paper diverging solenoid. ✔

D 34-2-016 PB COVER DIVERGING SOLENOID Activation/stoppage of the PB cover diverging solenoid. ✔

D 34-2-017 PB COVER REGISTRATION SOLENOID Activation/stoppage of the PB cover registration solenoid. ✔

D 34-2-018 PB ROLLER CRIMPING SOLENOID Activation/stoppage of the PB roller crimping solenoid. ✔

D 34-2-019 PB SUCTION CONTROL SOLENOID Activation/stoppage of the PB suction control solenoid. ✔

D 34-2-020 PB PAPER FEED DRIVE CLUTCH Activation/stoppage of the PB paper feed drive clutch. ✔

D 34-2-021 PB BOOKLET EJECTION SOLENOID Activation/stoppage of the PB booklet ejection solenoid. ✔

PB FRONT COVER LOCK RELEASE Activation/stoppage of the PB front cover lock release solenoid. ✔

D 34-2-022

SOLENOID

D 34-2-023 PB RIGHT DOOR LOCK RELEASE SOLENOID Activation/stoppage of the PB right door lock release solenoid. ✔

15/316 ComColor FW/GD Series Revision 1.3

CONFIDENTIAL RISO SQUARE WEB VERSION

Test

Type Test mode name Action Stop reception FW GD

mode No.

PMS section

Carry out compensation using the following steps

(1) Touch the 3 diagonally opposite points on the panel to calculate the compensation amount for those positions.

U 01-3-001 PANEL CALIBRATION × ✔ ✔

(2) Display the confirmation screen, touch the 3 points and confirm that they have been compensated correctly. If

compensation fails, go back to step (1) (redo compensation)

Automatically adjusts the touch pane threshold value (ON/OFF threshold value). Adjustment values are saved in the

TOUCH PANEL THRESHOLD

U 01-3-002 data flush of the panel micro computer. × ✔ ✔

LEVEL ADJUST

Do not touch the touch panel when executing this TM.

REv information recorded in the buffer is stored in a CSV file and written to a USB memory device.

Buffer data should not be cleared after writing when TM0-01-6-041 "REMOTE CONTROL FUNCTION SELECTION"

are set to "Enable".

U 01-3-011 REV INFORMATION WRITE Execution is possible when TM0-01-6-051 "REMOTE REV FUCNTION ON/OFF" in this menu is enabled. When ○ ✔ ✔

Enable, this TM is displayed in the menu. Execution by inputting the TM number shall also be possible.

When disabled, it will not appear in the menu list of this menu. Execution by inputting the TM number shall also be

unavailable.

Generates manual event code set in TM0-01-6-054 "REMOTE MANUAL EVENT CODE1 SETTING " and TM0-01-

6-055 "REMOTE MANUAL EVENT CODE2 SETTING", as a Rev event.

This menu can only be executed when TM0-01-6-051 "REMOTE REV FUCNTION ON/OFF" is enabled. When

U 01-3-012 MANUAL EVENT CODE SET × ✔ ✔

Enable, this TM is displayed in the menu. Execution by inputting the TM number shall also be possible.

When disabled, it will not appear in the menu list of this menu. Execution by inputting the TM number shall also be

unavailable.

The transmit log file recording the transmission history between the transmission module and management server is

saved to an external memory device (USB memory device).

When executed without connecting a USB memory device, the action will end in an error when there is insufficient

USB memory capacity.

U 01-3-013 TRANSMIT LOG USB SAVE ○ ✔ ✔

* This menu can be executed only when TM0-01-6-041 "REMOTE CONTROL FUNCTION SELECTION" is enabled.

When Enable, this TM is displayed in the menu. Execution by inputting the TM number shall also be possible.

When disabled, it will not appear in the menu list of this menu. Execution by inputting the TM number shall also be

unavailable.

When the remote agent function is ON, the CSV file, which serves as the source for generating transmission failure

files (XML) between the transmission server and remote management server, is stored on an external memory

device (USB memory device). When executed without connecting a USB memory device, the action will end in an

TRANSMIT FAIL DATA USB error when there is insufficient USB memory capacity.

U 01-3-014 ○ ✔ ✔

SAVE * This menu can be executed only when TM0-01-6-041 "REMOTE CONTROL FUNCTION SELECTION" is enabled.

When Enable, this TM is displayed in the menu. Execution by inputting the TM number shall also be possible.

When disabled, it will not appear in the menu list of this menu. Execution by inputting the TM number shall also be

unavailable.

16/316 ComColor FW/GD Series Revision 1.3

CONFIDENTIAL RISO SQUARE WEB VERSION

Test

Type Test mode name Action Stop reception FW GD

mode No.

Display the following count values in a list and print. Print content is the count type and value. Count values are

listed in 8 to 10 digits (zero suppression).

- Detailed count 1 - 21

- Maintenance count (Paper feed system, paper ejection system)

- Finisher count 1 - 8

- Cleaning count (extras, strong, normal)

- Offset staple taper receiving tray count 1 - 3

U 01-3-021 COUNT INFORMATION PRINT ○ ✔ ✔

Print conditions are as follows (cannot be changed)

- Output size: A4 (millimeters), Letter (Inches)

- Paper feed tray - Paper feed tray (Because specification processing is manual, print is carried out even when

different size paper is loaded

- Paper ejection tray: Standard paper ejection tray (FD paper receiving tray)

- Duplex print setting: Both sides

- Quantity: 1

PMS section

PMS and engine TM that fulfill the following conditions are extracted and printed in the reference chart. Contents for

print should be the TM number, TM name (English only), and setting value.

If there are no TMs that fulfill the following conditions, print "With no change" (none).

- TM for service engineer

- Setting value can be changed

U 01-3-022 TEST MODE CONFIG PRINT ○ ✔ ✔

- Setting value saved on main unit as non-volatile

- Setting value changed from default

Print conditions are the same as TM0-01-3-021 "Print count information".

* Prints the numbers and the setting values only for TM unshown on the panel.

* Refer to "Information print output material.xls" for the layout of print contents.

PMS and engine TM that fulfill the following conditions are extracted and printed in the reference chart. Contents for

print should be the TM number, TM name (English only), and setting value.

If there are no TMs that fulfill the following conditions, print "With no change" (none).

- TM for service engineer/manufacturing/development

- Setting value can be changed

U 01-3-023 TEST MODE CONFIG PRINT 2 ○ ✔ ✔

- Setting value saved on main unit as non-volatile

- Setting value changed from default

Print conditions are the same as TM0-01-3-021 "Print count information".

* Prints the numbers and the setting values only for unshown test mode on the panel. The print layout is the same as

TM0-01-3-022 "Test mode setting print".

17/316 ComColor FW/GD Series Revision 1.3

CONFIDENTIAL RISO SQUARE WEB VERSION

Test

Type Test mode name Action Stop reception FW GD

mode No.

Conducts a communication check between the main unit (transmission module) and management server.

The management server receiver can be checked in TM0-01-6-061 "AUTHENTICATION SERVER CONNECTION".

ADMIN SERVER * This menu can be executed only when TM0-01-6-041 "REMOTE CONTROL FUNCTION SELECTION" is enabled.

U 01-3-031 ○ ✔ ✔

COMMUNICATION TEST When Enable, this TM is displayed in the menu. Execution by inputting the TM number shall also be possible.

When disabled, it will not appear in the menu list of this menu. Execution by inputting the TM number shall also be

unavailable.

Sets printed content of charge count print (J) via USB memory device.

- Read destination: Directly under USB memory folder File name: ChargeCountTest.csv

CHARGE COUNT PRINT(J) [Precaution]

U 01-3-036 × ✔ ✔

IMPORT Executing immediately after inserting a USB memory device may cause W049-0280-6. Execute the following steps.

- After inserting a USB memory device, wait 5 seconds before executing

- Re-execute if W049-0280-6 appears

Saves printed content of charge count print (J) to USB memory device.

- Write destination: Directly under USB memory folder File name: ChargeCountTest.csv

Overwrite procedures are carried out if a file with the same name already exists.

CHARGE COUNT PRINT(J)

U 01-3-037 [Precaution] × ✔ ✔

EXPORT

Executing immediately after inserting a USB memory device may cause W049-0280-6. Execute the following steps.

- After inserting a USB memory device, wait 5 seconds before executing

- Re-execute if W049-0280-6 appears

Reads user information and retail store information from a USB memory device printed in a charge count.

- Read destination: Directly under USB memory folder File name: ChargeCountTest.csv

CHARGE COUNT PRINT(G) [Precaution]

U 01-3-038 × ✔ ✔

IMPORT Executing immediately after inserting a USB memory device may cause W049-0280-6. Execute the following steps.

- After inserting a USB memory device, wait 5 seconds before executing

- Re-execute if W049-0280-6 appears

Writes user information and retail store information to a USB memory device printed in a charge count.

- Write destination: Directly under USB memory folder File name: ChargeCountTest.csv

Overwrite procedures are carried out if a file with the same name already exists.

CHARGE COUNT PRINT(G)

U 01-3-039 [Precaution] × ✔ ✔

EXPORT

Executing immediately after inserting a USB memory device may cause W049-0280-6. Execute the following steps.

- After inserting a USB memory device, wait 5 seconds before executing

- Re-execute if W049-0280-6 appears

18/316 ComColor FW/GD Series Revision 1.3

CONFIDENTIAL RISO SQUARE WEB VERSION

Test

Type Test mode name Action Stop reception FW GD

mode No.

PMS section

Restoring default setting values to engine control HDD

The store data when executing this TM differs from the storage destination when executing TM0-01-3-041 "TEST

MODE VALUE STORE".

Restoring default setting values

U 01-3-040 This TM is executed internally while TM0-01-4-002 "Factory default" is running. Supplement × ✔ ✔

to engine control PCB

Because the engine control PCB was damaged during unpacking, it is assumed that the HDD factory setting values

are not reflected the first time the power is turned ON, and the TM is executed internally and factory setting values

are saved.

Saves engine part test mode setting values to PMS HDD. Used when replacing PCB.

U 01-3-041 TEST MODE VALUE STORE ○ ✔ ✔

Data saved to the HDD is restored to PCB on TM0-01-3-042 "Test mode setting value restore".

In TM0-01-3-041 "TEST MODE VALUE STORE", engine part test mode setting values saved to the PMS HDD are

U 01-3-042 TEST MODE VALUE RESTORE restored to the engine PCB. Used when replacing PCB. ○ ✔ ✔

* Turn the machine power OFF and ON again after executing this TM.

Stores the saved setting information from HDD to a USB memory device.