Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

12 viewsWPS PQR (1042)

WPS PQR (1042)

Uploaded by

Gaurang PandyaWPS and PQR for stellite -6 welding

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Data Header 3 Fig 602 & 1502Document1 pageData Header 3 Fig 602 & 1502Gaurang PandyaNo ratings yet

- Stem CarbideDocument1 pageStem CarbideGaurang PandyaNo ratings yet

- Repair Step For Mud Pump ModuleDocument6 pagesRepair Step For Mud Pump ModuleGaurang PandyaNo ratings yet

- Single Girl ChildDocument1 pageSingle Girl ChildGaurang PandyaNo ratings yet

- In House Welding Inspector ONGCDocument1 pageIn House Welding Inspector ONGCGaurang PandyaNo ratings yet

- Government: of GujaratDocument7 pagesGovernment: of GujaratGaurang PandyaNo ratings yet

- 216.4 291020 Drillen Energy ModelDocument1 page216.4 291020 Drillen Energy ModelGaurang PandyaNo ratings yet

- 3 Inch Swivel GA AssemblyDocument1 page3 Inch Swivel GA AssemblyGaurang PandyaNo ratings yet

- Data Header 2 Fig 1502Document1 pageData Header 2 Fig 1502Gaurang PandyaNo ratings yet

- Drillen UT Report-SodetailDocument1 pageDrillen UT Report-SodetailGaurang PandyaNo ratings yet

- Dees PGV 2 1502 H2SDocument1 pageDees PGV 2 1502 H2SGaurang PandyaNo ratings yet

- Indicator Marking Details For 2''Document3 pagesIndicator Marking Details For 2''Gaurang PandyaNo ratings yet

- Cementing ManifoldDocument1 pageCementing ManifoldGaurang PandyaNo ratings yet

WPS PQR (1042)

WPS PQR (1042)

Uploaded by

Gaurang Pandya0 ratings0% found this document useful (0 votes)

12 views12 pagesWPS and PQR for stellite -6 welding

Original Title

WPS PQR[1042]

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentWPS and PQR for stellite -6 welding

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

12 views12 pagesWPS PQR (1042)

WPS PQR (1042)

Uploaded by

Gaurang PandyaWPS and PQR for stellite -6 welding

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 12

[COMPANY NAME illen Energy Equipments and Services

WPS NO. DEES-WPS-001 Rev.00, Did.15.03.2019,

‘SUPPORTING PORNO, |: DEES-PQR-OO4, Dtd.15.03,2019

‘WELDING PROCESS TESMAW

WELDING TYPE(S) [MANUAL

ASME Sec. 12037

| APL 64-20%h Eaton, Addendur-Erata-10,PSL-4t0.4

NACE MR-0175:2015

APPLICABLE STANDARD(S)

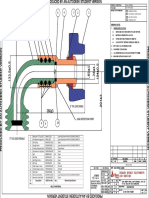

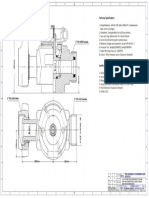

Joint Design 1s per 'awing (Hard Fai

Backing Nc Applicable

Root Spacing or anplicanie

Retainers Not Applicable

‘Minimum finished thickness

Ast anossegyaie2 GeF6C112.3

Material ‘ASTM AIS? Gz Fa 0.2/55410/UNS S41000/AISI-A10

Pino. 6

‘Group no. 123

Base metal thickness 25am to United

‘Spec No. (SEA) 513

[AWS No. (Class) EcoCeA

Fn, 7

Ano. Unassigned A Number Weld Chemistry

Electrode diameter 3.2mm

Filler metal production form Fux Coatea/ Metal Cored

Position 1G-Flat Only

Vertieal welding Not Appieable

‘Min, Preheating Temp. 250°C Minimum

ob shall be heated by electric call or Oxy-acetylene

2s Neutal fame prior to welding

Ter : 450°C max

"Temp. Measuring/~.-|~" By Jaiperature measuring scanner (laser gun)/

method g, ° Templl Stick

‘Set xr era (eel opr) 5)

ING PROCEDURE SPECIFICATION (WPS)

ri

len Hor facing overlay of Stlite< on SS42O(UNS 541000)

[wien PWHT

eyelet

| Temp. Range:720410°C

| Soaking Time: hours.

| Heating Rate:50 to 250 ‘C/hr max

| cooling Rate: 50 to 60°C

{Coa to room temperature before Applying Second eyde

cyele-2

Temp. Range:680110°C

Soaking Time: 6 hours.

Heating Rate:50 9 250 °C/hr max

Cooling Rate:50 to 60°/nr

Uncontrolled Heating/Loading Temperature: 300°C Max.

Uncontrolled Cooling/ Unloading Temperature: 300°C Max.

‘ettowe 2s per table A

“Ampere ‘As per table A

“Traveling speed (mm/min) ‘As per table A

Heat input As pertable A

‘Current or polarity ‘As per table A

Taerange As per table A

‘String/weave string

‘Method of cleaning Stamless Stel wire Brush Barinaing

‘Multi or single/pass side Mult pass

‘Single oF Multi electrode Single

‘Manual oF automatic Manual welding

Peening Yes

Use of thermal process: Not appiabie

‘Multiple or Single faye up layer only

ist ssmaw | ecocr-a | 3.2mm | ocer | 90-100 | 20-26] 110-160 | 1.47

‘subsequent | SMaw | ECocra | 3.2mm | oceP | 90-140 | 20-28] 40-160 | 1.47

For Dilen Energy Equipments and Services

d-

[PoRNO.

‘COMPANY NAME

REFERENCE WPS NO.

WELDING PROCESS | SHAW.

WELDING TYPE(S)

[APPLICABLE STANDARD(S)

PROCEDURE QUALIFICATION RECORD (FOR)

len ard facing overtay of Stlite< on SS41O{UNS 541000)

eneray

ments and Services

£ DEES-POR-001,0td.15.03.2019

: DEES-WPS-001, REV.0,DUd.15.03.2019

[ASME SEC. 02017

APT GA-20thEdtion, Addendum-s,Erata-10,PSL-1t0-4 |

ApL-16C-2nd Edltion, Addendum, Erratane

NACE MR-0175:2015

Joint Design 1s per drawing (Hard Facng Overiay)

Backing Net Applicable

Root Spacing Not applicable

Retainers Nat Applicable |

"Sn om approx. fusion were

0216 | Hardness Location | ae atone)

Drawing?

AISI-410 (UNS $41000) T

Material ‘AIS=410{UNS 541000)

403.20 P-no. 6

Group ne. 3

“403.23 Size of Test Coupon Forging Mate200ni 50x25 Te

‘Spee No. (SFA) 5.3

404.12 =

zs 7

‘404.37 ‘Unassigned A Number Weld Chemistry

404.38 “3.2mm for al ayer

Filler metal production form Fax Coated/Metal Cored

1G-Fat

Tot Applieabve

Min, Preheating Temp. 270°C Minimum

y Job heated by Oxyacetylene gas Neutral flame prior

oa) 0 anc during welaing a where the

are

‘yn 1ao8z76"

‘Oct exe e020

PROCEDURE QUALIFICATION RECORD (FOR)

rillen ng overlay of Soliton SSALOUUNS 81000)

i ‘Temp. Measuring By Temperature measuring Scanner (ase un)

\ method |

407.6 | PWHT | vith PHT

cycled

‘Temp. Range:720210°C

Soaking Time: 4 hours.

Heating Rate: 80-90 °c.

Cooling Rate:60-70°¢/n.

Coal ta roam temperature before Applying second eye

cyele-2

Temp. Range:680#10°C

Soaking Time: 6 hours

Heating Rate:80-90°C/t

Cooling Rate:60-70°C/n.

407.6 | (Temp. &

time range)

Voltage ‘Ae portable A

409.22 | Am ‘As per table A

~ | Traveling speed (mm/min) ‘As per table A

Ee ais per tae 8

03.4 ity As per table A

As per table A

410.1 String/weave ‘Seng

410.5 | Method of cleaning | ‘Stainless Stal wire saush Bgrinding

‘Multi or single/pass side ut pass

‘Single or Mult electrode ‘Single

‘Manual oF automatic anwal welding

‘0.26 |Peening Yes

Use of thermal process at appicabie

“410.38 | Multiple or Single layer mutupe ayer

| saw | ecocra

L ac

[28 [ swaw | ecocea | 3.2mm

‘32mm | pce | 120-120 |24-28| 118

120-130

a [sway ecoo-a | 3.2mm

Ponda

aero

et exe e020

PROCEDURE QUAI

ard facing.

{CATION RECORD (POR

Speci Re Result

nec

[ sateen | ewer |

—Rethopteae—

Filet Weld Test (QW-180)

es

aeeatene

Soe fo

‘ean: roy ace sts 2st ae at

‘Rothe oeiparonoot som Bros

7 TS HE TRG aa) | aaa.)

Feel aaa See Rape PTAC TTS

Welders Name Krishnadas Bairag Stamp No. WOT

eat Conducted By - MS Drilen Energy Equipments and Senices.

‘ir ati aan na a wa oi ae Ho

Corea By

Organization” | Ws, Drilen Energy Equipments and Sevices

NAME Gaureng Pandya Sanjay Khuman

SIGNATURE

Saber ig

eo § (feb) é

DATE 15703 {2019 2

“14/'6ap 02-09 :Bu1j00> 49 a}ey =

: -sinoyg oui, BuIpjoH |

mL > Bap 089 ~ shi sme

JOST x 002 a1eI¢ ‘9215

re $330 Yd

juoting> 3a)

L00-49-S33q sapso>ay Wey

100-49-S33q ‘Jaued JonuOoD

seve 2 oe 2

Sees

wean saat

102 fo's0 tea He 6) ue

Freron ne. [ost rananro1]

Liquid Ponerant Examination

Report Freson ate [oraarse

a ve

Gaurers ‘Seay [wor Leven | Goal Convo bapa Fea

[rodstSenai tamer [= Fram —] DEES PRG

oman een nt

ee ee eee

— ee

iia ale PS ee |S

a

ee

oe = ee aa

bg

‘Ne an etd ay nani a ws 0 at rl a

[ese y: aura Pana [Tesi ante [ora

[>a ms A a RE Ba a

+ labo to ~y

2) Sano: | Serato ‘Tosaionainetion ena

Conctusion Tamar [Ra sa TP a NS GTRERGTy aTT w

Jnepecte by: HOF LEVEL W ovewes By

me: Garang Pancye ame: Sanjay Kaman

fos: oraeaosy (om.

G GLOBAL METALLURGICAL SERVICES

(WABL Accredited Laboratory as per SONEG 17026 : 2017)

(Chemical Anaysis | Mechanica Testing | Mealuical Testing | Corrosion Testing | Ste Services

Fast teport

Catone = notre rere IO. —I

‘oar, Vode 390030, Gt

[Tine ortee

Instrument Utd er a

Senolereaedon [2032059

ature sample aoc ray Wd Pa endion finale Scars

Sample Senn) | ov ee Pae Seo ron Pay

Specston otra ara aang tay OW ATF et onl on 15037018

ena

Serene

+ Mpls nein sei

west By

254. ids Lig 6.0, Maerua, ododara- 300010.

al: 71908252» Ena ghbalaT@gnacom « Wobsewghbataderteie

(WABL Acerdtd Laboratory as per QE 17026 : 2017)

Chemical Analysis | Mechanical Testing | Metallurgical Testing | Corson Testg |Site Services

G GLOBAL METALLURGICAL SERVICES

Test aport

cone C=1/%/25, tear Pion Engie IOC it,

atarpr, adoro” 9000 Gur nh ee

peat Maco bariation Paget

“nant Un - ection: At bon —|

Same reciedon | 1.01208 —

ature smple [fata ray WSF ‘aon af ae aon

Sample Sian) | he Pate Sample Drawn y Py

Speciendon | Entra rr ung Oviy Oo RAT Fn Test Completed om 15 05301

agitation: 100% Echant Aqua op

Palshed and ache surface of Ova test eoupan shows lar defination of Wel, HAZ and bse Metal

Nolack of ruses, Porat slagr any ther county obrerved

rd Test Raport

254 nds Lng, 61.0, Makara, Yada 300010.

ca: 740434252» Ema: baat @gia.cam © Weta um gotataaratrin

~ WESTERN

(Forney Wearza WOIAFoRGINGSEVE uD)

NATERIAL TesyCenmincare

———

= Saar

Western Heat & Forge Pvt, Ltd.

4.25" Block MIDC, Teco Rod, Bho, Pane - 411026, ia

‘Tet #91 20.6655 9200 | Fax 991202712 0410 || wow Wesemieaorge com

SELECTRODE INDUSTRIES INC.

MANUFACTURERS OF SPECIAL WELDING ALLOYS

PRODUCT CONFORMANGE REPORT

Product Aatratoy 005 ‘Sees) (re) 0x 14 (92m x 350)

Class AWSIASME A519 © CoCr-A loin, 6o16t993

Order No S454

Cousomer Shoo} Tadors Selarode

Ina Order ho. $2482

“ppodnais Chenin Corpor oT Wes Neal ype values aos EUTOROT EE

c [si se] [we [me [ew |v [aa]

Bra] 439) 005 [ss | 9.90

as e_| sn | sb | Pb Za Fe 70

zit a2

‘Woche was, wad ‘ype vabe ase ENTODOA DT

Terson est (Charpy Vk test (CV)

[Cond test | Rat] Rat | Ron | A est ‘own own

romp. [R02 temp. | tevduat rames_| average

re) | wea | aa | wa | Tay rol ro i

Tena virion

Ober tas

Remaree cot

“hie product ie manufactured in he U

_Wehernt cert tate ruc cong

al

00 erednay sen ee

Pingo Sn 1 1748 SA Fncon fehl obscar

Teugnone e180 800 recesteaTetrs aw

Zeal ogevcrotcon cain, 198

me enorannr vreun {0 Conor Wy

NINGTONETATON Aan

avon ner tStivavenca

pe

Sar aeet

Ct exp erce0

SELECTRODE INDUSTRIES INC.

MANUFACTURERS OF SPECIAL WELDING ALLOYS.

PRODUCT CONFORMANCE REPORT

Predict Aatratloy 2006 ‘Sana} (rm) 82" 4" (4mm x 350mm)

Class AWSIASMEA S19 CocrA Laine, ortes70

customer

(Order, S404

Cunomer Shri Tadars stcroa8

naa ‘OraerN, 82462

Tossa Gia Conpolion a Was Ws yp aces axe ENIODOE DE

c[si[uele|s ow mol mw] cv] v[ A] a]

esr] 430 | 000 3005 | 188 | 008

[| co] wa] so [so] po | ag | on | fo To.

we [68 zit 7

Vecranea on al wo me ‘yoni aon ENTGRDOTE

“Tension ae (Charpy Voch test (CVN)

[Cond test | Ra] Ratt | Rm | AS test evn ‘evn

tomo. | Rpo.2 tomp.| tndvidualnames | average

Cel | wes [Pa wea | Te re) ow

“eateral woraton Sen,

‘ete SOE

aa Ran We)

Tal vatues or weld metal properties athe result fom statisti samlng of ute ss

We herent cary hat ne product compl wih he above mestoned standart

‘Company —Selctode indus, ne. Tesuedby _— Watibew Garucco

230 Broad Signature

unington Staton NY 11746 (USA) Functon

Tewprone: 601 S47 5470 Fax 631 S47 8475 ae

‘Ematinfo@solectode com crt No,

230 BROADWAY AUSTRALIA 100 Commerce Way

HUNTINGTON STATION, ASIA ALQUPPA

NEWYORK NY 11745 CATINAMERICA PENNSYLVANIA 15001

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Data Header 3 Fig 602 & 1502Document1 pageData Header 3 Fig 602 & 1502Gaurang PandyaNo ratings yet

- Stem CarbideDocument1 pageStem CarbideGaurang PandyaNo ratings yet

- Repair Step For Mud Pump ModuleDocument6 pagesRepair Step For Mud Pump ModuleGaurang PandyaNo ratings yet

- Single Girl ChildDocument1 pageSingle Girl ChildGaurang PandyaNo ratings yet

- In House Welding Inspector ONGCDocument1 pageIn House Welding Inspector ONGCGaurang PandyaNo ratings yet

- Government: of GujaratDocument7 pagesGovernment: of GujaratGaurang PandyaNo ratings yet

- 216.4 291020 Drillen Energy ModelDocument1 page216.4 291020 Drillen Energy ModelGaurang PandyaNo ratings yet

- 3 Inch Swivel GA AssemblyDocument1 page3 Inch Swivel GA AssemblyGaurang PandyaNo ratings yet

- Data Header 2 Fig 1502Document1 pageData Header 2 Fig 1502Gaurang PandyaNo ratings yet

- Drillen UT Report-SodetailDocument1 pageDrillen UT Report-SodetailGaurang PandyaNo ratings yet

- Dees PGV 2 1502 H2SDocument1 pageDees PGV 2 1502 H2SGaurang PandyaNo ratings yet

- Indicator Marking Details For 2''Document3 pagesIndicator Marking Details For 2''Gaurang PandyaNo ratings yet

- Cementing ManifoldDocument1 pageCementing ManifoldGaurang PandyaNo ratings yet