Professional Documents

Culture Documents

TDS MACTUBES - Rev01 20201126 - en v2

TDS MACTUBES - Rev01 20201126 - en v2

Uploaded by

Jodel SerranoCopyright:

Available Formats

You might also like

- C15 On-Highway Engine Electrical System: Harness and Wire Electrical Schematic SymbolsDocument2 pagesC15 On-Highway Engine Electrical System: Harness and Wire Electrical Schematic Symbolsminh le huu100% (3)

- CUT ManualDocument7 pagesCUT ManualjannNo ratings yet

- Receiving Belt Feeder (5830 - Fe - 001) - Receiving Belt Feeder (5830 - Fe - 001)Document2 pagesReceiving Belt Feeder (5830 - Fe - 001) - Receiving Belt Feeder (5830 - Fe - 001)Carlos Enrique Zegarra SilvaNo ratings yet

- PWM DCDocument2 pagesPWM DCĐỗ Xuân BằngNo ratings yet

- Falk Steelflex T10 T20 EN 428-111Document9 pagesFalk Steelflex T10 T20 EN 428-111Timber RamNo ratings yet

- A28/P28 - Top Level Sheet: Drawing TitleDocument8 pagesA28/P28 - Top Level Sheet: Drawing Title王军No ratings yet

- DB 000 13302 0301 001 01 Member List For Module Steel StructureDocument1 pageDB 000 13302 0301 001 01 Member List For Module Steel StructurekohilanrkNo ratings yet

- Box Culvert Twin CellDocument3 pagesBox Culvert Twin CellMwesigwa DanielNo ratings yet

- Longitudinal Detail Section 1-1: Top Slab Reinforcement DetailsDocument1 pageLongitudinal Detail Section 1-1: Top Slab Reinforcement DetailsMwesigwa DaniNo ratings yet

- Fiberposter PDFDocument1 pageFiberposter PDFÁngel MorenoNo ratings yet

- Valve Schedule - 10.5.2021 (LATEST)Document83 pagesValve Schedule - 10.5.2021 (LATEST)rvkheavenNo ratings yet

- Bunkers An Analysis of The Technical and Environme... - (PG 89 - 89)Document1 pageBunkers An Analysis of The Technical and Environme... - (PG 89 - 89)Clarcy CrawfordNo ratings yet

- Catalogue - Dinmaster Monoflo PumpDocument2 pagesCatalogue - Dinmaster Monoflo PumpPawan KumarNo ratings yet

- BC 5300&5380 (1) FluidicDocument8 pagesBC 5300&5380 (1) FluidicCHARLIE BRICENo ratings yet

- OLIMEXINO-STM32 SCH LatestDocument1 pageOLIMEXINO-STM32 SCH Latestnathantshama1No ratings yet

- Ix Ecsdc4 BlockdiagramDocument36 pagesIx Ecsdc4 BlockdiagramBranko AndricNo ratings yet

- Tal Wsa PNG Iso 1PGW063402 - 00 - A01 - 00Document1 pageTal Wsa PNG Iso 1PGW063402 - 00 - A01 - 00Deborah Jasmine Saldarriaga CrisantoNo ratings yet

- ST32 (KSS021-D-1477) - Stringer-R0 PDFDocument1 pageST32 (KSS021-D-1477) - Stringer-R0 PDFmo3azNo ratings yet

- STR 2883Document4 pagesSTR 2883eng.yehia.omara.kbhNo ratings yet

- Welding Procedure Data Sheet (WPDS) Weldproc Demo: Joint Preparation and Layer/Pass SequenceDocument1 pageWelding Procedure Data Sheet (WPDS) Weldproc Demo: Joint Preparation and Layer/Pass SequenceWael AlmahdiNo ratings yet

- Robbin Group: For Approval As Drawing S552 Rev. 14Document1 pageRobbin Group: For Approval As Drawing S552 Rev. 14Marcelo GonzagaNo ratings yet

- Product Manual - R 3EL 125 - PO 8584Document71 pagesProduct Manual - R 3EL 125 - PO 8584Ravi RamdeoNo ratings yet

- Rotor GA DrawingDocument1 pageRotor GA DrawingcelonevesNo ratings yet

- 1242 B2 ISMB200: No (S) - BEAM - B2 1Document1 page1242 B2 ISMB200: No (S) - BEAM - B2 1M. Azharuddin TamboliNo ratings yet

- Anti Static Protective Wrap: Aec FlexguardDocument3 pagesAnti Static Protective Wrap: Aec Flexguardpichet33No ratings yet

- Appendix IDocument6 pagesAppendix IkarthickmectrNo ratings yet

- Propeller Repair: Cost-Efficient Straightening and WeldingDocument2 pagesPropeller Repair: Cost-Efficient Straightening and WeldingSaNdeep ChedeNo ratings yet

- Det-1A (Typical) Det-1 (Typical) : Structural DrawingsDocument1 pageDet-1A (Typical) Det-1 (Typical) : Structural DrawingsAHMED ELMASRYNo ratings yet

- OutputDocument30 pagesOutputSreeparna DasNo ratings yet

- DAF SDS CombinedDocument11 pagesDAF SDS CombinedJhonnel PunzalanNo ratings yet

- Straight Shell D-1.0 & 0.7 M-LDocument1 pageStraight Shell D-1.0 & 0.7 M-LDeep SherawatNo ratings yet

- Power Supply Aoc 715G5654-P03-001-002H схемаDocument5 pagesPower Supply Aoc 715G5654-P03-001-002H схемаALEXISNo ratings yet

- SI 5NB0A 001 00 Eng - v1 - m56577569830747488Document1 pageSI 5NB0A 001 00 Eng - v1 - m56577569830747488brassoyNo ratings yet

- Ducto T1 v6 GridDocument1 pageDucto T1 v6 GridMarcelo Lorenzo RodriguezNo ratings yet

- 19 029 MGR CPF Ej 55 Di 031 R0Document8 pages19 029 MGR CPF Ej 55 Di 031 R0Lizz CabelloNo ratings yet

- Alberta Infrastructure and Transportation Standard F Shape BarrierDocument1 pageAlberta Infrastructure and Transportation Standard F Shape BarriertylerlhsmithNo ratings yet

- J3BGDF02BR012 01 01Document1 pageJ3BGDF02BR012 01 01saleem naheedNo ratings yet

- 10ENA01BR003 Sheet3-ModelDocument1 page10ENA01BR003 Sheet3-ModelValesh MonisNo ratings yet

- 1 - STEEL STAIRCASE GA DRAWING1.dwgDocument1 page1 - STEEL STAIRCASE GA DRAWING1.dwgnimish.aquamarineNo ratings yet

- RTPP CHP WT CVL 003 R1Document2 pagesRTPP CHP WT CVL 003 R1Sripara KrishnaNo ratings yet

- Piping Isometric Building:: Pengerang Cogeneration PlantDocument1 pagePiping Isometric Building:: Pengerang Cogeneration PlantMohd Effiezool YaserNo ratings yet

- Aceite WarcoDocument1 pageAceite WarcoGerard GomezNo ratings yet

- Lfbo 7 80 Iac Ils or Loc 32r 1787733 BDocument1 pageLfbo 7 80 Iac Ils or Loc 32r 1787733 Bjames.gimenezNo ratings yet

- 0468 Asom20 00TQ 0001 001 BDocument14 pages0468 Asom20 00TQ 0001 001 BDenny AgusNo ratings yet

- VisionCB STM32MP1 v11 - SchematicsDocument9 pagesVisionCB STM32MP1 v11 - Schematicsvo.idNo ratings yet

- 4245 Aa DC 1362502004 Is00Document1 page4245 Aa DC 1362502004 Is00Tayyab AchakzaiNo ratings yet

- Issued For Construction Modular Isometrics: Piping Isometric DrawingDocument1 pageIssued For Construction Modular Isometrics: Piping Isometric Drawing86tejasNo ratings yet

- One-Sec - Truss Marked As Str105: Section - ADocument1 pageOne-Sec - Truss Marked As Str105: Section - Asixramesh123No ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- Diagrama Unifilar TG - Nodo de AccesoDocument1 pageDiagrama Unifilar TG - Nodo de AccesoAndy GarcíaNo ratings yet

- Sheet 3 03252019Document1 pageSheet 3 03252019Brylle De GuzmanNo ratings yet

- TNV Series 201912Document4 pagesTNV Series 201912oliver rodriguezNo ratings yet

- Taae Rce 11 09 2022Document22 pagesTaae Rce 11 09 2022Orbenson TanNo ratings yet

- J3BGDF02BR012 01 05Document1 pageJ3BGDF02BR012 01 05Naheed AkhtarNo ratings yet

- Structural Calc Analysis of in Patient BLDG Facade Rev003Document67 pagesStructural Calc Analysis of in Patient BLDG Facade Rev003عزة الإسلامNo ratings yet

- Sistema Eletrico 226Document4 pagesSistema Eletrico 226f8ytws84csNo ratings yet

- UENR2643UENR2643-05 - SIS Electrico Diagrama PDFDocument4 pagesUENR2643UENR2643-05 - SIS Electrico Diagrama PDFJaime LopezNo ratings yet

- Structural Calc Analysis of in Patient BLDG Facade Rev02 09.11.2021Document161 pagesStructural Calc Analysis of in Patient BLDG Facade Rev02 09.11.2021عزة الإسلامNo ratings yet

- Ringkasan Saham-20210802Document90 pagesRingkasan Saham-20210802IrwanNo ratings yet

- Annexure V Bid MatrixDocument17 pagesAnnexure V Bid Matrixraj1508No ratings yet

- Meaning of Life SkillsDocument21 pagesMeaning of Life SkillsIffat AkberNo ratings yet

- A Project Report Submitted ToDocument81 pagesA Project Report Submitted ToJoshna PNo ratings yet

- Porter Model: N SawaikarDocument15 pagesPorter Model: N Sawaikarsidv20No ratings yet

- 6.1 Futures and Options AnalysisDocument2 pages6.1 Futures and Options AnalysisSuraj DecorousNo ratings yet

- Interview With Dr. J. Mark Mobius of Franklin Templeton InvestmentsDocument6 pagesInterview With Dr. J. Mark Mobius of Franklin Templeton InvestmentsMichael Cano LombardoNo ratings yet

- Ahmednagar - Bpheadmission Fees Other Fees2100088914-1708882-1937689Document1 pageAhmednagar - Bpheadmission Fees Other Fees2100088914-1708882-1937689kiran handoreNo ratings yet

- Lic Nach MandateDocument1 pageLic Nach Mandatefibiro9231No ratings yet

- Focus On Personal Finance 5th Edition by Kapoor Dlabay Hughes Hart ISBN Solution ManualDocument24 pagesFocus On Personal Finance 5th Edition by Kapoor Dlabay Hughes Hart ISBN Solution Manualtracy100% (31)

- International Business: by Charles W.L. HillDocument36 pagesInternational Business: by Charles W.L. Hilllovelyday9876No ratings yet

- Sosial Ekonomi Dan Kesejahteraan Nelayan Di Wilayah Teluk Jakarta: Literature Review Sudarmin Parenrengi, Satria Yunas, Dan Nurul HilmiyahDocument12 pagesSosial Ekonomi Dan Kesejahteraan Nelayan Di Wilayah Teluk Jakarta: Literature Review Sudarmin Parenrengi, Satria Yunas, Dan Nurul Hilmiyah068 Abiomi Ciptoning BentaliNo ratings yet

- Research Paper On Finance Topics PDFDocument6 pagesResearch Paper On Finance Topics PDFtxdpmcbkf100% (1)

- Angle Weight ChartDocument7 pagesAngle Weight ChartAbhinav KumarNo ratings yet

- Assets: Share $4 A$2 HasDocument1 pageAssets: Share $4 A$2 HasSanyln AclaNo ratings yet

- Electric Bill - VTpass - Meter Token (PHED - Port Harcourt Electric)Document2 pagesElectric Bill - VTpass - Meter Token (PHED - Port Harcourt Electric)Basil OgbunudeNo ratings yet

- Soal 1: 1. Computed Equivalent Unit For Production CostDocument10 pagesSoal 1: 1. Computed Equivalent Unit For Production CostRaihan Rohadatul 'AisyNo ratings yet

- Analysis of Cryptocurrency Market and Drivers of The Bitcoin PriceDocument52 pagesAnalysis of Cryptocurrency Market and Drivers of The Bitcoin PricePeter LeeNo ratings yet

- Financial Times Europe - 18.10.22Document20 pagesFinancial Times Europe - 18.10.22Cesar Acosta CashuNo ratings yet

- Day Book 2Document2 pagesDay Book 2The ShiningNo ratings yet

- CCT Unit 3 Elasticity of Demand Butwl: P P Q P P Q Q e ElasticityDocument29 pagesCCT Unit 3 Elasticity of Demand Butwl: P P Q P P Q Q e ElasticityAyesha jamesNo ratings yet

- ASSIGNMENT 5.1 Part2Document3 pagesASSIGNMENT 5.1 Part2Lewell LazaroNo ratings yet

- Beat TYBCOM-SAMPLE-MCQS-SEM-VI LDocument14 pagesBeat TYBCOM-SAMPLE-MCQS-SEM-VI LRajkumar MootaNo ratings yet

- Снимок экрана 2022-10-17 в 18.31.03Document31 pagesСнимок экрана 2022-10-17 в 18.31.03Діана ЧерниченкоNo ratings yet

- Cashflow Project Hotel PodomoroDocument44 pagesCashflow Project Hotel PodomoroBrandy HarperNo ratings yet

- Tally AssingmentDocument19 pagesTally AssingmentTaranNo ratings yet

- Dec 16 BillDocument1 pageDec 16 BillanandNo ratings yet

- Compare and Contrast LanguageDocument5 pagesCompare and Contrast LanguageThanh Thúy TrầnNo ratings yet

- Car Claims For InsuranceDocument688 pagesCar Claims For InsuranceAshwini KrishnanNo ratings yet

- LPT Unit-1 Milk and Milk Products Technology: By-Dr. Sushma Kumari Hod, Dept. of LPT, BVC, PatnaDocument12 pagesLPT Unit-1 Milk and Milk Products Technology: By-Dr. Sushma Kumari Hod, Dept. of LPT, BVC, PatnaKaran NawaleNo ratings yet

TDS MACTUBES - Rev01 20201126 - en v2

TDS MACTUBES - Rev01 20201126 - en v2

Uploaded by

Jodel SerranoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TDS MACTUBES - Rev01 20201126 - en v2

TDS MACTUBES - Rev01 20201126 - en v2

Uploaded by

Jodel SerranoCopyright:

Available Formats

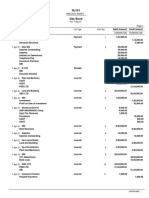

05S.60 75S.55 80110.25 09S.25 10S.20 12S.19 17S.16 20S.19 25S.

16

Mechanical and Hydraulic proper es of the fabrics

EN ISO 10319

Tensile strength - Tch (MD) 1 kN/m 50 75 80 90 105 120 175 200 250

ASTM D4595

EN ISO 10319

Strain at Tch (MD) 2 % 15 13 13 13 13 13 13 13 13

ASTM D4595

EN ISO 10319

Tensile strength - Tch (CMD) 1 kN/m 50 75 110 90 105 120 175 200 250

ASTM D4595

EN ISO 10319

Strain at Tch (CMD) 2 % 10 10 10 10 10 10 10 10 10

ASTM D4595

ASTM D4884

Factory seams strength 3 kN/m 40 53 55/73 70 70 85 140 160 190

ISO 10321

any warranty or immunity against patent infringement.

EN ISO 12236

Sta c Puncture Resistance - CBR 3 kN 5.5 6.0 10.0 10.0 12.0 14.0 22.0 25.0 26.0

ASTM D6241

Flowrate 3 ASTM D4991 l/m2/min 3600 3400 2100 1500 1200 1100 960 1200 960

Opening Pore Size O95 3 ASTM D4751 µm < 400 < 450 < 450 < 400 < 430 < 410 < 400 < 400 < 400

Physical proper es of the geotex le tubes

Warp and We Polymers 4 Polypropylene

Color 5 Black (Sand available on demand)

Geotex le tube circumference 6 m 4.3 - 8.6 - 10.8 - 17.2 - 20.0 - 21.6 - 25.9 - 28.2 - 30.20

Geotex le tube length 7 m 15 - 20 - 25 - 30 - 35 - 40

Durability; UV retained strength ASTM D4535 % 90

NOTE

shape

1. Minimum average value at 95% confidence limit;

ferri office.

2. Typical value; a tolerance of 2% on the declared values is admi ed;

3. Mean value;

Theorical circular

4. On demand - for some of the proposed tensile strengths grades -

the fabric polymer can be polyester (please check with the closest

tering applica ons.

flow permeabili es.

Maccaferri office the available op ons);

5. Black is the standard color however other colors are available;

sand is the most used in marine applica ons. For large projects the

color of the yarns used in the warp and we direc on can be

different and tailored according to the job requirements;

6. The geotex le tubes can be produced also in different diameters

and circumferences according to the client requirements (please

h ps://edesign.maccaferri.com/Ges one

check with the closest Maccaferri office the available op ons);

7. Shorter geotex les tubes can be manufactured on demand please

check with the closest Maccaferri office the available op ons).

depending on the

desidered filling rate

Final eliptical shape

Maccaferri operates under strict quality assurance and

management procedures. Please visit the website of your

local subsidiary for details of their Certifications.

beyond our control, we do not accept any liability for any loss or damage, however arising, which results directly or indirectly from the use of such information nor we do offer

product without any notice. The information contained herein are to the best of our knowledge accurate, but since the circumstances and conditions in which it may be used are

For the optimisation and improvement process of the technical characteristics of the products, the manufacturer reserves the right to modify the standard characteristics of the

MACTUBES

addi onal technical info please contact the closest Macca-

For addi onal info about the geotex le tubes geometry

(max filling height, es mated max working height H, max

requested geotex le tube please visit our website at

width W and volumes), the filling port spacing and any

achieve not only high tensile strengths but also high

For a quick design check or selec on of the appropriate

MACTUBES are suitable either for marine and dewa-

polypropylene fabrics obtained by weaving exclusi-

vely mono or fibrillated filament yarns in order to

MACTUBES are geotex les tubes manufactured

assembling - typically by radial s tches - woven

TECHNICAL DATA SHEET

Rev 01. Date 26.11.20

© 2020 Maccaferri. All rights reserved. Maccaferri will enforce Copyright.

You might also like

- C15 On-Highway Engine Electrical System: Harness and Wire Electrical Schematic SymbolsDocument2 pagesC15 On-Highway Engine Electrical System: Harness and Wire Electrical Schematic Symbolsminh le huu100% (3)

- CUT ManualDocument7 pagesCUT ManualjannNo ratings yet

- Receiving Belt Feeder (5830 - Fe - 001) - Receiving Belt Feeder (5830 - Fe - 001)Document2 pagesReceiving Belt Feeder (5830 - Fe - 001) - Receiving Belt Feeder (5830 - Fe - 001)Carlos Enrique Zegarra SilvaNo ratings yet

- PWM DCDocument2 pagesPWM DCĐỗ Xuân BằngNo ratings yet

- Falk Steelflex T10 T20 EN 428-111Document9 pagesFalk Steelflex T10 T20 EN 428-111Timber RamNo ratings yet

- A28/P28 - Top Level Sheet: Drawing TitleDocument8 pagesA28/P28 - Top Level Sheet: Drawing Title王军No ratings yet

- DB 000 13302 0301 001 01 Member List For Module Steel StructureDocument1 pageDB 000 13302 0301 001 01 Member List For Module Steel StructurekohilanrkNo ratings yet

- Box Culvert Twin CellDocument3 pagesBox Culvert Twin CellMwesigwa DanielNo ratings yet

- Longitudinal Detail Section 1-1: Top Slab Reinforcement DetailsDocument1 pageLongitudinal Detail Section 1-1: Top Slab Reinforcement DetailsMwesigwa DaniNo ratings yet

- Fiberposter PDFDocument1 pageFiberposter PDFÁngel MorenoNo ratings yet

- Valve Schedule - 10.5.2021 (LATEST)Document83 pagesValve Schedule - 10.5.2021 (LATEST)rvkheavenNo ratings yet

- Bunkers An Analysis of The Technical and Environme... - (PG 89 - 89)Document1 pageBunkers An Analysis of The Technical and Environme... - (PG 89 - 89)Clarcy CrawfordNo ratings yet

- Catalogue - Dinmaster Monoflo PumpDocument2 pagesCatalogue - Dinmaster Monoflo PumpPawan KumarNo ratings yet

- BC 5300&5380 (1) FluidicDocument8 pagesBC 5300&5380 (1) FluidicCHARLIE BRICENo ratings yet

- OLIMEXINO-STM32 SCH LatestDocument1 pageOLIMEXINO-STM32 SCH Latestnathantshama1No ratings yet

- Ix Ecsdc4 BlockdiagramDocument36 pagesIx Ecsdc4 BlockdiagramBranko AndricNo ratings yet

- Tal Wsa PNG Iso 1PGW063402 - 00 - A01 - 00Document1 pageTal Wsa PNG Iso 1PGW063402 - 00 - A01 - 00Deborah Jasmine Saldarriaga CrisantoNo ratings yet

- ST32 (KSS021-D-1477) - Stringer-R0 PDFDocument1 pageST32 (KSS021-D-1477) - Stringer-R0 PDFmo3azNo ratings yet

- STR 2883Document4 pagesSTR 2883eng.yehia.omara.kbhNo ratings yet

- Welding Procedure Data Sheet (WPDS) Weldproc Demo: Joint Preparation and Layer/Pass SequenceDocument1 pageWelding Procedure Data Sheet (WPDS) Weldproc Demo: Joint Preparation and Layer/Pass SequenceWael AlmahdiNo ratings yet

- Robbin Group: For Approval As Drawing S552 Rev. 14Document1 pageRobbin Group: For Approval As Drawing S552 Rev. 14Marcelo GonzagaNo ratings yet

- Product Manual - R 3EL 125 - PO 8584Document71 pagesProduct Manual - R 3EL 125 - PO 8584Ravi RamdeoNo ratings yet

- Rotor GA DrawingDocument1 pageRotor GA DrawingcelonevesNo ratings yet

- 1242 B2 ISMB200: No (S) - BEAM - B2 1Document1 page1242 B2 ISMB200: No (S) - BEAM - B2 1M. Azharuddin TamboliNo ratings yet

- Anti Static Protective Wrap: Aec FlexguardDocument3 pagesAnti Static Protective Wrap: Aec Flexguardpichet33No ratings yet

- Appendix IDocument6 pagesAppendix IkarthickmectrNo ratings yet

- Propeller Repair: Cost-Efficient Straightening and WeldingDocument2 pagesPropeller Repair: Cost-Efficient Straightening and WeldingSaNdeep ChedeNo ratings yet

- Det-1A (Typical) Det-1 (Typical) : Structural DrawingsDocument1 pageDet-1A (Typical) Det-1 (Typical) : Structural DrawingsAHMED ELMASRYNo ratings yet

- OutputDocument30 pagesOutputSreeparna DasNo ratings yet

- DAF SDS CombinedDocument11 pagesDAF SDS CombinedJhonnel PunzalanNo ratings yet

- Straight Shell D-1.0 & 0.7 M-LDocument1 pageStraight Shell D-1.0 & 0.7 M-LDeep SherawatNo ratings yet

- Power Supply Aoc 715G5654-P03-001-002H схемаDocument5 pagesPower Supply Aoc 715G5654-P03-001-002H схемаALEXISNo ratings yet

- SI 5NB0A 001 00 Eng - v1 - m56577569830747488Document1 pageSI 5NB0A 001 00 Eng - v1 - m56577569830747488brassoyNo ratings yet

- Ducto T1 v6 GridDocument1 pageDucto T1 v6 GridMarcelo Lorenzo RodriguezNo ratings yet

- 19 029 MGR CPF Ej 55 Di 031 R0Document8 pages19 029 MGR CPF Ej 55 Di 031 R0Lizz CabelloNo ratings yet

- Alberta Infrastructure and Transportation Standard F Shape BarrierDocument1 pageAlberta Infrastructure and Transportation Standard F Shape BarriertylerlhsmithNo ratings yet

- J3BGDF02BR012 01 01Document1 pageJ3BGDF02BR012 01 01saleem naheedNo ratings yet

- 10ENA01BR003 Sheet3-ModelDocument1 page10ENA01BR003 Sheet3-ModelValesh MonisNo ratings yet

- 1 - STEEL STAIRCASE GA DRAWING1.dwgDocument1 page1 - STEEL STAIRCASE GA DRAWING1.dwgnimish.aquamarineNo ratings yet

- RTPP CHP WT CVL 003 R1Document2 pagesRTPP CHP WT CVL 003 R1Sripara KrishnaNo ratings yet

- Piping Isometric Building:: Pengerang Cogeneration PlantDocument1 pagePiping Isometric Building:: Pengerang Cogeneration PlantMohd Effiezool YaserNo ratings yet

- Aceite WarcoDocument1 pageAceite WarcoGerard GomezNo ratings yet

- Lfbo 7 80 Iac Ils or Loc 32r 1787733 BDocument1 pageLfbo 7 80 Iac Ils or Loc 32r 1787733 Bjames.gimenezNo ratings yet

- 0468 Asom20 00TQ 0001 001 BDocument14 pages0468 Asom20 00TQ 0001 001 BDenny AgusNo ratings yet

- VisionCB STM32MP1 v11 - SchematicsDocument9 pagesVisionCB STM32MP1 v11 - Schematicsvo.idNo ratings yet

- 4245 Aa DC 1362502004 Is00Document1 page4245 Aa DC 1362502004 Is00Tayyab AchakzaiNo ratings yet

- Issued For Construction Modular Isometrics: Piping Isometric DrawingDocument1 pageIssued For Construction Modular Isometrics: Piping Isometric Drawing86tejasNo ratings yet

- One-Sec - Truss Marked As Str105: Section - ADocument1 pageOne-Sec - Truss Marked As Str105: Section - Asixramesh123No ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- Diagrama Unifilar TG - Nodo de AccesoDocument1 pageDiagrama Unifilar TG - Nodo de AccesoAndy GarcíaNo ratings yet

- Sheet 3 03252019Document1 pageSheet 3 03252019Brylle De GuzmanNo ratings yet

- TNV Series 201912Document4 pagesTNV Series 201912oliver rodriguezNo ratings yet

- Taae Rce 11 09 2022Document22 pagesTaae Rce 11 09 2022Orbenson TanNo ratings yet

- J3BGDF02BR012 01 05Document1 pageJ3BGDF02BR012 01 05Naheed AkhtarNo ratings yet

- Structural Calc Analysis of in Patient BLDG Facade Rev003Document67 pagesStructural Calc Analysis of in Patient BLDG Facade Rev003عزة الإسلامNo ratings yet

- Sistema Eletrico 226Document4 pagesSistema Eletrico 226f8ytws84csNo ratings yet

- UENR2643UENR2643-05 - SIS Electrico Diagrama PDFDocument4 pagesUENR2643UENR2643-05 - SIS Electrico Diagrama PDFJaime LopezNo ratings yet

- Structural Calc Analysis of in Patient BLDG Facade Rev02 09.11.2021Document161 pagesStructural Calc Analysis of in Patient BLDG Facade Rev02 09.11.2021عزة الإسلامNo ratings yet

- Ringkasan Saham-20210802Document90 pagesRingkasan Saham-20210802IrwanNo ratings yet

- Annexure V Bid MatrixDocument17 pagesAnnexure V Bid Matrixraj1508No ratings yet

- Meaning of Life SkillsDocument21 pagesMeaning of Life SkillsIffat AkberNo ratings yet

- A Project Report Submitted ToDocument81 pagesA Project Report Submitted ToJoshna PNo ratings yet

- Porter Model: N SawaikarDocument15 pagesPorter Model: N Sawaikarsidv20No ratings yet

- 6.1 Futures and Options AnalysisDocument2 pages6.1 Futures and Options AnalysisSuraj DecorousNo ratings yet

- Interview With Dr. J. Mark Mobius of Franklin Templeton InvestmentsDocument6 pagesInterview With Dr. J. Mark Mobius of Franklin Templeton InvestmentsMichael Cano LombardoNo ratings yet

- Ahmednagar - Bpheadmission Fees Other Fees2100088914-1708882-1937689Document1 pageAhmednagar - Bpheadmission Fees Other Fees2100088914-1708882-1937689kiran handoreNo ratings yet

- Lic Nach MandateDocument1 pageLic Nach Mandatefibiro9231No ratings yet

- Focus On Personal Finance 5th Edition by Kapoor Dlabay Hughes Hart ISBN Solution ManualDocument24 pagesFocus On Personal Finance 5th Edition by Kapoor Dlabay Hughes Hart ISBN Solution Manualtracy100% (31)

- International Business: by Charles W.L. HillDocument36 pagesInternational Business: by Charles W.L. Hilllovelyday9876No ratings yet

- Sosial Ekonomi Dan Kesejahteraan Nelayan Di Wilayah Teluk Jakarta: Literature Review Sudarmin Parenrengi, Satria Yunas, Dan Nurul HilmiyahDocument12 pagesSosial Ekonomi Dan Kesejahteraan Nelayan Di Wilayah Teluk Jakarta: Literature Review Sudarmin Parenrengi, Satria Yunas, Dan Nurul Hilmiyah068 Abiomi Ciptoning BentaliNo ratings yet

- Research Paper On Finance Topics PDFDocument6 pagesResearch Paper On Finance Topics PDFtxdpmcbkf100% (1)

- Angle Weight ChartDocument7 pagesAngle Weight ChartAbhinav KumarNo ratings yet

- Assets: Share $4 A$2 HasDocument1 pageAssets: Share $4 A$2 HasSanyln AclaNo ratings yet

- Electric Bill - VTpass - Meter Token (PHED - Port Harcourt Electric)Document2 pagesElectric Bill - VTpass - Meter Token (PHED - Port Harcourt Electric)Basil OgbunudeNo ratings yet

- Soal 1: 1. Computed Equivalent Unit For Production CostDocument10 pagesSoal 1: 1. Computed Equivalent Unit For Production CostRaihan Rohadatul 'AisyNo ratings yet

- Analysis of Cryptocurrency Market and Drivers of The Bitcoin PriceDocument52 pagesAnalysis of Cryptocurrency Market and Drivers of The Bitcoin PricePeter LeeNo ratings yet

- Financial Times Europe - 18.10.22Document20 pagesFinancial Times Europe - 18.10.22Cesar Acosta CashuNo ratings yet

- Day Book 2Document2 pagesDay Book 2The ShiningNo ratings yet

- CCT Unit 3 Elasticity of Demand Butwl: P P Q P P Q Q e ElasticityDocument29 pagesCCT Unit 3 Elasticity of Demand Butwl: P P Q P P Q Q e ElasticityAyesha jamesNo ratings yet

- ASSIGNMENT 5.1 Part2Document3 pagesASSIGNMENT 5.1 Part2Lewell LazaroNo ratings yet

- Beat TYBCOM-SAMPLE-MCQS-SEM-VI LDocument14 pagesBeat TYBCOM-SAMPLE-MCQS-SEM-VI LRajkumar MootaNo ratings yet

- Снимок экрана 2022-10-17 в 18.31.03Document31 pagesСнимок экрана 2022-10-17 в 18.31.03Діана ЧерниченкоNo ratings yet

- Cashflow Project Hotel PodomoroDocument44 pagesCashflow Project Hotel PodomoroBrandy HarperNo ratings yet

- Tally AssingmentDocument19 pagesTally AssingmentTaranNo ratings yet

- Dec 16 BillDocument1 pageDec 16 BillanandNo ratings yet

- Compare and Contrast LanguageDocument5 pagesCompare and Contrast LanguageThanh Thúy TrầnNo ratings yet

- Car Claims For InsuranceDocument688 pagesCar Claims For InsuranceAshwini KrishnanNo ratings yet

- LPT Unit-1 Milk and Milk Products Technology: By-Dr. Sushma Kumari Hod, Dept. of LPT, BVC, PatnaDocument12 pagesLPT Unit-1 Milk and Milk Products Technology: By-Dr. Sushma Kumari Hod, Dept. of LPT, BVC, PatnaKaran NawaleNo ratings yet