Professional Documents

Culture Documents

LG4JJED-WE-0871 - Engine Control System 4JJ1 N-Series

LG4JJED-WE-0871 - Engine Control System 4JJ1 N-Series

Uploaded by

vik_md100%(1)100% found this document useful (1 vote)

267 views389 pagesOriginal Title

22. LG4JJED-WE-0871 - Engine Control System 4JJ1 N-Series

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

100%(1)100% found this document useful (1 vote)

267 views389 pagesLG4JJED-WE-0871 - Engine Control System 4JJ1 N-Series

LG4JJED-WE-0871 - Engine Control System 4JJ1 N-Series

Uploaded by

vik_mdCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 389

ISuU2U

2008-2016MY N SERIES

WORKSHOP MANUAL

ENGINE CONTROL SYSTEM

(43J1 model)

Engine Control System (4JJ1) 14-1

Engine Control System

(4JJ1)

TABLE OF CONTENTS

Specifications 143 DTC P0201, Po2o2, PO203 or PODOA

“Temperature vs Resistance. 143 (Flash Code 271, 272, 273 01 274) 1As91

Alituds vs Baromotrc Pressure 4&4 DIC POZIT (Flash Cod 542} 1a.139

Diagnostic Trovbie Code (OTC) Type DTC PO29 (Fiash Code 543} saat

Definitions a 105 DTC P0234 (Flash Code 42). . 1A-143,

Diagnostic Trouble: Code (ore) List|. 1A6 DTC P0299 (Flash Code 65). 10-146

Overview Wings 1&9 DTC POMS (Fash Code 15). iara9

Overviow Wings EINEU Tage pre p0996 (Fash Code 15)... Saatsz

Routing Diagrams = TEE Tiaa pre posse (Fash Code 14) tase

Fucl Systom Routing Diagram 1AM DTC PO341 (Flash Code 14) 10457

‘Vacuum Hose Routing Diagram . 1A DTC P0380 (Flash Code 66). . - 10-159

Component Locator 1A12 DTC POBBI (Flash Code 67) 1161

Engine Controls Component Views AZ DTC P0401 (Flash Code 93). . . os TA164

Engine Control Module (ECM) Connector DTC P0404 (Flash Code 45), A167

End Viows 1A18 —_DTE.PO409 (Fiash Code 44) 1170

Engine Contiol Connecior End Views...../. 1-21 DTC PD4ZG (Flash Code 13). sats

Diagnoste information and Procecures 132 DTC PO427 oF POA7B (Flash Code 48)... 18-175,

Engine Control System Check Sheet 122 DTC PO42B (Flash Cove 145) 18-160

Diagnostic Starting Point - Engine Controls . . 14-33. DTC P042C or P042D (Flash Code 49) 1A-182

Dagostn Sytem Chosk-Engre Care T&M DTC PDA POAT ih Code 8)... 1A87

Scan Tool Daia List... ..- 1A38—_DTC-POSOO (Flash Code 25) 10190

Scan Tool Data Defntions - 1A47 DTC POSO2 oF POSO3 (Flash Code 25)... 1A-193.

Scan Tool Output Controls 1A53_DTC POSED (Fiash Code 155) 10-199

‘Scan Tool Does Not Power Up + 1A-55 DTC P0563 (Flash Code 35). . - «14-202

Scan Tool Does Net Communicate with CAN DTC P0601 (Fiash Code 53) 14-203

Device (Euro 4 Specification). «10-56 DTC P0602 (Flash Code 154). . « 1A-204

Scan Tool Does Not Communicate with DTG Poéo4, POsdE or POEB

Keyword Device (Except Euro 4 Specifiation/1A-69 (Flash Code 183, 5107 36) 14206

Lost” Communication with The DTC P0633 (Flash Code 176). 4-207

Engine Cont Module (ECM) DTC POE3E (Flash Code 61) +a.208

{Except Euro 4 Specification). 14-63 DTC P0641 (Flash Code 55). 1A-211

Engine Cranks but Does Not Run. 14-66 DTC P0650 (Flash Code 77). . 10-214

DTC Po0%6 (Flash Code 18) 168 DTC POESI (Flash Code 56) 10217

DIC PO04S (Flash Code 33) ATO DTC PGBS or PUGET (Flash Code 416)... 14.220

DTC P0079 or POO6O (Flasn Code 38)... 18-73. «DTC POSG7 (Flash Code 57) 1a723

DTC P0087 (Flash Code 225), 1A76 DTC P1098 (Flasn Code 227) 1a226

DTC P0088 (Flash Code 118). ...- . 18-81 DTC P1261 of P1262 (Flash Code 34)..... 14-231

DTC P0089 (Flash Code 151). «10-86 DTC P1404 (Flash Code 45). 1A-232

DTC P0091 or P0082 (Flash Code 247)". |. 18-89 DTC P1465 (Flash Code 122) 18205

DTC P0093 (Flash Code 227). 1&92 DTC PI471 (Flash Code 149) 1n2a7

DTC PO101 (Flash Cod 92) 1A98 DTC P1648 (Fiash Coco 179) 1240

DTC P0102 or P0103 (Flash Code 91). . 1A-101 DTC P1621 (Flash Code 54). . . 6 TA241

DTC PO%07 or POT0R (Flash Code 32)... 1A-105 DTC P1664 (Flasn Code 76). sacra

DTC PO112 or PO113 (Flash Code 22)... 1A-109 ‘DTC P1660 (Flash Code 75). 18245

DIC PO116 (Fiash Coce 23) 1A413 DTC P2122 or P2123 (Flash Code 121)... 1A-250

DTC P0117 or P0118 (Flash Code 23). . TA-118, DTC P2127 or P2128 (Flash Code 122)... 1A-254

DTC P0122 or P0123 (Flash Code 43). 1At19 DTC P2138 (Flash Code 124). 18-258

DTC P0182 or POT6S (Flash Code 211)... 1A-129. «DTC P2146 or P2140

DTC PO192 or P9183 (Flash Code 245)... 1A-127 (Flash Code 158 or 159) 10260

DTC P2227 (Flash Code 71)... 48-265

1A-2 Engine Control System (4JJ1)

DTC P2228 or P2229 (Flash Code 71)... 14-268

DTC P242F (Flash Code 131) 10-272

DIC P2452 (Flash Code 142)............ 1274

DIC P2453 (Flash Code 147)............ 18-277

DTC P2454 or P2485 (Flash Code 47)... 14-280

DTC P2456 (Flash Code 47). 14285

DIC P2458 (Flash Code 139), 14.287

DIC P2527 or P2526 (Flash Code 233)... 14-230

DIC P253A (Flash Code 28) 14-205

DTC P256A (Flash Code 31) 14-298

DTC U0073 (Flash Code 84) 14302

DTC UO101 (Flash Code 85) ......22.... 10305,

DIC U0167 (Flash Code 177) 14-307

EGR Control Systm Chock 14.308

Glow Control System Check...» 14-312

Engine Warm Up Control System Check . 10-315

Exhaust Brake Control System Check ..... 14-318

Diesel Particulate Defuser (DPD) Controt

System Check . 18324

‘Symptoms - Engine Controls - 14-330

‘Symptoms - Engine Controls 14-330

Intermittent Condiions ...... eee... WA-B32

Herd Start 14-335

Rough, Unstable, or Incorrect Idle and

Stalling cei ceeeeeeeeeeeeeeeees ABST

High Idle Speed oo. 18-340

Cuts Out 10341

Surges... 14-343

Lack of Power, Sluggishness or Sponginess 14-345

Hesitation, Sag or Stumble 14-347

‘Abnormal Combustion Noise 10349

Poor Fuel Economy. 14.350

Excessive Smoke (Black Smoke)......... 14-352,

Excessive Smoke (White Smoke). 14-354

DPD System Manual Regeneration

Frequently .. 14-356

DPD Systom Regeneration Long Time... 14-358

Repair Instructions 14-360

Engine Control Module (ECM) Replacement 14-360

Service Programming System (SPS)

Description... . ce 18-863

Service Programming System (SPS)

(Remote Procedure)....... ce 18-363

Service Programming System (SPS)

{Pass-Thru Procedure). 10.365

Description and Operation ........ 14-366

Engine Control Module (ECM) Description. 14-366

Engine Control Component Desoription .... 14-369)

Fuel System Description 10373

Fuel System Component Description ...... 14-374

Fuel Injection System Description. 10.378

Exhaust Gas Recirculation (EGR) System

Description 140.379

Turbocharger Description «2.0.0... eee. 18-380

Diese! Particulate Defuser (DPD) System

Description cee 10883,

Special Tools and Equipment 14386

‘Special Tools and Equipment 14386

Engine Control System (4JJ1)_1A-3

Specifications

‘Temperature vs Resistance c * ‘Ohms

Engine Coolant Temperature vs. Resistance Temperature vs. Resistance Value (Approximately)

°c °F ores. (250 482 4300

“Temperature vs. Resistance Value (Approximately) 200 392 6900

120 248 115 150, 302 43900

110 230, 150 100 22 39600

100 212 190 50 122 106000

0 194 250

a 176 0 Fuel Temperature vs. Resistance

70 158 450 ea F ‘Onn

1 am = Temperature va. Resistance Value (Approximately)

= iz a 70 230 740

a a mo 100 212 180

30 86 1730, 80 194 240

a = am 3 776 310

7 = 7 7 188 220

a 2 eno 80 140 50

= 7 e200 50 122 310

20 4 18700 40 ‘104 1150

30 22 26500 o & 1680

20 8 2450

Exhaust Temperature vs. Resistance 70 50 3700

*6 F Ohms 7 % 5740

‘Temperature vs. Resistance Value (Approximately) 10 14 9160

7000 1832 720 20 = 15000

950 1742 735 “30 2 25400

900 652 755 -

on a oa Ina Ar Temperature v, Relate Except Euro

200 7472 205 o oF one

ic ae = Temperature vs. Resistance Value (Approximately)

700 ee. 2m 100 212 790

850 1202, 348 90 194 240

500 ae 428 80 176 320

i560, 5022 530 70 158 430

ay Bae Ss 60 140 590

460 ane ees 50 122 810)

400 752 200 7 750

350 682 7710 0 = 1680

300 572 2560 7 = iS

1A-4 Engine Control System (4JJ1)

% F Ons Baronet

Tonporatrav,Redance Vas Roprommatayy | | ,,fttude, | Atiuio | Possuo

10, 50 3660 Meters {m) Feet (ft) Kilopascals

a 2 5550 (a)

= 4 e0T9 Oetaion ory using ani eletence sources

20 4 14700 1829, 6000 ‘77-85

Iniake Air Temperature vs. Resistance (Euro 2 and 154 500 s088

Eo 3 Spectications) =o aan aa

°c °F Ohms 314 3000 87-85

“Temperature vs. Resistance Value (Approximately) 0) 200 3008

190) 212, neo) 305 1000 94-102

a0 ‘194 zag 0 Sea Level 96-104

80 78 330 305 “1000 101-105

7 8 270

< 0 70

3 @ 380

7 To 766

Ey % m0

2 we 35%

7% = se00

@ 2 0

= 77 0

2 a 2500

Altitude vs Barometric Pressure

Barometric

Altitude Altitude Pressure

Measured in | Measured in. | Measured in

Meters (m) Feet (it) Kilopascals

(kPa)

Determine your alttude by contacting a local weather,

station or by using another reference source.

4267 14000 5-84

3962 13000, 36-66

3658 12000 61-68

3383 11000 64-72

3048 710000 66-74

2748 9000 68-77

2438 8000 71-78

2194) 7000 74-82

Engine Control System (4JJ1)_1A-5

Diagnostic Trouble Code (DTC) Type Definitions

Emission Related DTC

Action Taken When the DTC Sets - Type A

+ The ECM illuminates the maifunction indicator

amp (MIL) when the diagnostic runs and fails.

+ The ECM records the operating conditions at the

time the diagnostic fails. Tho ECM stores this

information in the Freeze Frame! Failure Records.

(Euto 4 specication)

Action Taken When the DTC Sets - Type B

+ The ECM illuminates the MIL on the second

‘consecutive driving cycle when the diagnostic runs

and fails

+ The ECM records the operating conditions at the

time the diagnostic falls. The first time the

Giagnostic falls, the ECM stores this information in

the Failure Records. If the diagnostic reports @

failure on the second consecutive driving cycle, the

ECM records the operating conditions at the time

ff failure and stores this information in the Freeze

Frame and updates the Failure Records.

Conditions for Clearing the MIL/ DTC - Type A or

Type B

+ The ECM tums OFF the MIL after 3 consecutive

ccrving cycles when the diagnostic runs and does

not fail, (Euro 4 specification)

+ The ECM turns OFF the MIL after 1 ignition cycle

when the diagnostic runs and doas not fal, (Except

Euro 4 specification)

+ Acurrent DTC clears when the diagnostic runs and

passes.

+ Ahistory DTC clears after 40 consecutive warm-up

cycles, if no fallures are reported. (Euro 4

specification)

+ A history DTC clears after 40 consecutive driving

cycles, if no failures are reported. (Except Euro 4

specification)

+ Use a scan tool to clear the MIL and the DTC.

Non-Emissions Related DTCs

Action Taken When the DTC Sets - Type C

+ The ECM illuminates the Service Vehicle Soon

(SVS) lamp when the diagnostic runs and falls.

+ The ECM records the operating conditions at the

time the diagnostic fails. The ECM stores this

information in the Failure Records.

Conditions for Clearing the SVS Lamp/ DTC - Type

c

+ The ECM turns OFF the SVS lamp after 1 driving

cycle when the diagnostic runs and doas not fil

+ Acurrent DTC clears when the diegnostic runs and

passes.

+ Ahistory DTC clears after 40 consecutive warm-up

cycles, f no fallures are reported

+ Use a scan tool to clear the SVS lamp and the

orc.

Action Taken When the DTC Sets - Type D

‘+ The ECM will not iluminate the MIL or SVS lamp.

+ The ECM records the operating conditions at the

time the diagnostic fails. The ECM stores this

information in the Failure Records. (Euro 4

specication)

Conditions for Clearing the DTC - Type D

+ Acurrent DTG clears when the diagnostic runs and

passes

+ Ahistory DTC clears after 40 consecutive warm-up

cycles, if no faiures are reported. (Euro 4

specification)

+ Anistory DTC clears ater 40 consecutive driving

cycles, if no fallures are reported. (Except Euro 4

specification)

+ Use a scan tool to clear the DTC.

1-6 Engine Control System (4JJ1)

Diagnostic Trouble Code (DTC) List

DISTR

ore | Goat | Swot | Etro DTC Descriptor

cation | SPesif

‘eatlon

Posi | 16 | A | A _ | Crankahat Postion - Camshaft Posen Garlation

Poows |= [Turbocnarger Boost Cont Solenow Grout

Poors | a8 | A | = [Exhaust Valve Conta! Solenoid Greit Low

RODE | “35 [A |= [ xaust Valve Con! Solenoid Greit High

Pooer | 25| D |B | Fuel Rail System Pressure Too Low

PO0sE | 18 | A | A [Fuel Ra System Pressure Too High (Senond Stag)

PO0ES | 15 |B |B [Fuel Pressure Regulator Performance

poost | a7 [A | A _ [Fuel Prosswe Regulator Gono Gira Low

poo | 247 | A] A _ [Fuel Presswe Regulator Convo Gout High

PO0sG | 227 _| 8 | 8 | Fuel System Leak Detected

Pow | 2 |B | Mass Air Flow Sensor Greul Rangel Perormance

POW | 8 | _A | ACY™ | Mass Air Flow Sensor Great Low input

PIS | 8 _| A | ACY™ | Mass Air Flow Sensor Great High Input

POIOT| a | A | _A | Manfoé Absolute Pressure Sensor Crt Law Input

pois | 22| A | A | Manfolé Absolute Pressure Sensor Grout High Input

Poa | 2 | A | A | Rake Ar Temperature Sensor Cs Low

Po | 22 | A | A Intake A Temperature Sensor Creu High

Pome | 2 | 8 | | Enaine Coolant Temperatire Sensor Greuit Rangel Perfomance

POT | 2 | A | A | Eneine Gaolnt Temperature Sensor rut Low

POTIe | 23 | A | A _ | Enno Coolant Temperature Sensor Gul High

Porz2 | 43 | A | A _ | Thole Postion Sensor Ccut Low

Poiz | 4 | A | A _ | Throttle Posllon Sensor Creu High

Pova2 | 217 | A | A _ [Fuel Temperature Sensor Greult Low

Pores | 211] A | A | Fuel Temperature Sensor Creu High

POIs | 2A | A | A [Fast Ra Pressure Sensor Creu Low

POISG | 245_| A | A | Fuel Rai Pressure Sensor Gre Figh

Pox | 271 | A | A _|Injotor Greut Open -Gyindor

Pose | 27 | A | A _[Inietor Creit Open Cylinder

PoRis | 273 | A | A [Injector Greut Open = Gyinaer3

Poa | 274 | A | A |Injctor Greut Open = Gyinaer a

poni7 | 642 |B | D _ [Enaine Goclant Over Temperature Condion

POO | 513 |G | D | Enaine Overspeed Gonditon

Pox | 42 | A | A _ | Turbocharger Gverboost Conalion

pease | 65 | 8 | _ | Tubocharaer Undorboost

Engine Control System (4JJ1)_1A-7

DTC Type

pre | Flash) euros | PPP DTC Descriptor

Coae | Emo | Euro 4 sctptor

aton | Sect

‘caton

pos | 15 | A 7A__|Grankshat Postion Sensor Creut

Pose | 1 | A A __[Crankshaf Poston Sensor Creu Rangel Performance

poss | 1 | A A__|Camstiat Postion Sensor Grout

post] 1 | A =| Camshaft Postion Senor Grout Range’ Performance

P0360 | 66 | C A [Glow Plug Grout

poset | 7 | © A [Glow Piug Indicator Gira

poai | 3 | A = [EGR Fiow insufcient Detected

poo] as | A A__ [EGR Control Circuit Range’ Performance

poao9| 4¢ | A | A _ [EGR Position Sensor Circuit

Poms | 143 |S = [Catalyst Temperature Sensor Grout Rangel Performance Sensor 1

pow] 48 | A = [Catalyst Temperature Sensor Grout Low Sensor

poze] 48 | A = [Catalyst Temperature Sensor raul High Sensor?

Poi | 145 | C = [Catalyst Temperature Sensor Greut Range! Performance Sensor 2

Powe] 49 | o =| Catalyst Temperature Sensor Chcult Low Sensor 2

Pow] 45 | o = [Gatayat Temperature Sensor Grau High Sensor?

por | 46 | - [Exhaust Pressure Control Valve Low

pois | 46 | = [Exhaust Pressure Control Valve High

Pos00 | 26 |B A__ [Velie Speed Sensor

Pos0 | 25 | A 7A___| Vehicle Speed Sensor Creat Low Input

P0503 | 25 | A 7A___| Vehicle Speed Sensor Grout High Input

Passo | 765 | A _| ACY [Sistem voltage

Poses | 35 |e A__ | System Voltage High

Pooor | 8 | A A__|Internal Control Module Memory Check Sum Error

PoBo2 | te | © A_|Sonivel Wodule Programming ror

Poss | 165 | A [Internal Control Module RAM Error

P0606 | st | A 7” [ECM Processor

Posos | 36] A 7A__ [Internal Control Madule AD Processing Perormance

Po6ss | 176 | > | mmabiizer Not Programmed

Posse | ot | 8 A__|Trvote Actuator Contel Rangel Performance

poss | 65 | A 7”___ [Sensor Reference Volage 1 Circuit

P0650 | 77 | A | Maifanction Indicator Lamp (ML) Control Grout

possi | 86 | A A__[ Sensor Reference Voiago 2 Grcut

Poses | 416 | C A_ [EON Power Relay Conirol Ccult Open

Poss? | 416 | A__ [ECM Power Relay Control Creat High

Poe | 7 | A | A _ | Sensor Reference Vollage 3 Gvcut

PI0m | BF] _A © [Fuel Rai Pressure Too Low

1A-8 Engine Control System (4JJ1)

DTC Type

pre | Flash) euros | PPP DTC Descriptor

Coae | Emo | Euro 4 sctptor

aton | Sect

‘caton

Piast | 3 | A A__[InesterPostive Voliage Contral Gieut Group 1

Pie | _a@ | A A__| Injector Postve Voltage Control Circuit Group 2

praoe| 45 | A — [EGR Postion Fault (Closed Poston Error)

P1404 | 45 | A | ACVB |EGR Posiion Fault (Leamed Position Eror)

Piss | 1a | A =| PM Over Accumulation

Puri] 49 | A = [OPO Insufficient Regeneration

pret] 179 | D D___|immabiizer Wrong Response

prea | &@ | _A ‘A__|Contol Module Long Tern Memory Performance

prs | 76 | © =| Senvce Vehicle Soon Lamp Control Circuit

a —_ [DPD Lamp Contal Creut

Poe | wa |B A__ [Pedal Position Sensor 1 Grcult Low input

P2123 | 21 |B A__| Pedal Position Sencor 1 Circut High Input

Paior | 22 |B A__ | Pedal Postion Sensor 2 Crcult Low input

Paia6 | 12 |B A [Pedal Positon Sensor 2 Greuit igh Input

paige | 2 |B [Pedal Positon Sensar 1-2 Votage Corelation

paa6 | 65 | A 7 _| Fuel injector Group 1 Supply Votage Greut

Pao | 169 | A ”_| Fuel njector Group 2 Supply Voltage Greut

Paar | |e =___ [Barometric Pressure Sensor Groult Range/ Performance

Pama | 7 | A [Barometric Pressure Sensor Grault Low

pam | 7 | A 7A [Barometric Pressure Sensor Greut High

Paar | Ta | A = [DPD Restcton

Paez | a2 | A = [BPD Differential Pressure Sensor Orcut

Pass | Ta | A BPO Differential Pressure Sensor Crcuit Range! Performance

puss | a7 | A =| BPD Differential Pressure Sensor Creu Low

p285 | a7 | A =| DPD Differential Pressure Sensor Grau igh

P2486 | a7 | A =| BPD Differential Pressure Sensor Leamed Poston

pase | 139 | A = [BPD Regeneration Duration

P25q7 | 233 | A | ACY | Vacuum Pressure Sensor Grcull Low

P2526 | 233 | A | Acry | Vacuum Preseure Sensor Creuit igh

Passa] 28 | C A [PTO Sensor Great

PaEEAT aI |e 7A [Engine lle Speed Selector Sensor

woo7s [a | 8 | BCVA | Control Module Communication Bus OF

uot | 8 | C = [ost Communication with TM

woe | 77 | > [Lost Communication With Vehicle immobilizer Conto] Module

*: Except Euro 2 and Euro 3 specifications

Engine Control System (4JJ1) _1A-9

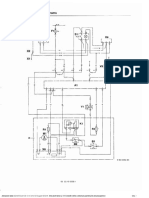

Overview Wirings

Overview Wirings

42

meeen| Bi g NI

nom =i germ ici

> om

cera] Uf > a

sett

sero wem| O He

_— ese] Oo ; a

le M8 Ben

Bs 2 4

ever ia games; ECM a ry

Ehosansenrn sere 3

exenrat eners |B] le 9

2

le

ey

seem, eee

WOOT mare @ te

eprom + \e 280] Cia] Cras a

Dos!

etn le

1A-10 Engine Control System (4JJ1)

212

@

a

e ecm

a rte ne ee

igh enon tegen ser }@ a

comme Ob} ees sean

8 Oates

ee

3

[oeet a

ef :

i # a

me g

| ‘esr

Engine Control System (4JJ1)_1A-11

Legend

1. Fuel rail 8. Vent valve

2. Pressure limiter valve 8, Per uel iter with sedimenter

3. Leak off pipe 40. Priming pump

4. Fuel injector +1. Fuel fier wih water separator

5. Fuel rtum pipe 42. Return fue! flow back valve

8. Fuel feed pipe 418. Fuel supply pump

7. Fuel tank

Vacuum Hose Routing Diagram

2

r

3

nd

Vacuum pressure sensor 5. Vacuum pump

>. Turbocharger nozzle control solenoid valve 6. Actuator control vacuum hose

‘Vacuum pipe 7. Turbocharger nazzle contre! actuator

Brake booster

1A-12_Engine Control System (4JJ1)

Component Locator

Engine Controls Component Views

Legend

‘1. Barometric pressure (BARO) sensor 2. Accelerator pedal position (APP) sensor

Legend

1. Fuel injector No.1 cylinder 6. Intake throttle valve

2. Fuel injector No.2 cylinder 7. Turbocharger nozzle control solenoid valve

3. Fuel injector No.3 cylinder (Except Euro 2 and Euro 3 specifications)

4, Fuel injector No.4 oylinder 8. Boost pressure sensor

5. Exhaust gas recirculation (EGR) valve

Engine Control System (4JJ1)_1A-13

id

1. Variable nozzle turbocharger (VNT) vacuum 2. Engine coolant temperature (ECT) sensor

pressure sensor (Except Euro 2 and Euro 3 3. Camshaft position (CMP) sensor

specifications)

Legend

1. Fuel rail pressure (FRP) regulator 5. Engine oll pressure switch

2. Fuol temperature (FT) sensor 6. Crankshaft position (CKP) sensor

3. Pressure limiter valve 7. Engine oil level switch

4, Fuel rail pressure (FRP) sensor

1A-14 Engine Control System (4JJ1)

Legend

1. Exhaust brake valve 4. Exhaust diferential pressure sensor

2. Exhaust temperature sensor 2 (in front of oxygen 5. Exhaust throtte valve

catalyst) 6. DPD assembly

3, Exhaust temperature sensor 1 (in front of fiter)

Legend

1. Mass air flow (MAF) sensor! intake cir 2. Intake air temperature (IAT) sensor (Euro 2 and

temperature (IAT) sensor (Except Euro 2 and Euro 3 specications)

Euro 3 specifications)

Engine Control System (4JJ1) 14-15

Legend

1. Vehicle speed sensor (VSS) (without ABS

model)

Legend

1. CAN resistor (LHD) (with immobilizer model) 2. CAN resistor (RHD) (with immobilizer model)

44-16 _Engine Control System (4JJ1)

NHR, NLR, NMR mode!

id

1. Engine control module (ECM) 2. Dropping resistor (Except Euro 2 and Euro 3

spectfcations)

NNR, NPR model

emonnsromet

id

1. Engine control module (ECM) 2. Dropping resistor (Euro 4 specification)

Engine Control System (4JJ1) 14-17

NLS model

id

1. Engine control module (ECM)

41-18 Engine Control System (4JJ1)

Engine Control Module (ECM) Connector ‘Conair No. 4

End Views ‘Connector color Black

Sete ima at

47 |BRWGRN SVS lamp control (Euro 4

Pee

VSS signal (without ABS) or

2) an ee

2 RED/ BLU | (Except Euro 2 and Euro 3

= = a | amen fea

— a

2 WHT! | pattery voltage

= =m

4 BLK [ECM power ground 9 = _|Netused

5 | WE [eater voase =

SS

7 BRN | Exhaust brake lamp control _ ee

WHT reust <@ lamp control 33 BLU/ BLK | Refrigerator switch signal

oie] oles

10 | WET tow lay cone v6 | = [Rotused

eS 2

fT es

oe w [euwwmn ees meene

15 WHT! — | Exhaust brake solenoid valve 40; BLUAYEL: | BoM men ielavcontel

ey |S

Engine Control System (4JJ1) 14-19

APP sensor 1, idle up sensor MAF sensor signal (Except

a1 [wxseo|Spemeaete | | im | wn Razors

a pega

Srtenridemana | | -w| vet [pro meneansr ser

3 BLK __|ECM(sigal ground 72 | BLU/BLK | IAT sensor signal

Trem vs |veuneo | rarontanusaas

Common 1 (cylinder #1 and

UT GRN’ [EGR postion sensor signal $ san | weer [Sommon 1 (ovine At and

ee BLK | (except Euro 2 specification) tue! inipetor charge vollaus:

a0 | ix | SMP sensor and FRP sensor

shield ground

101 | YEL/BLK

CMP sensor, FRP sensor and

EGR position sensor low

reference

GRNI

ww2 | SRN

Exhaust throttle solenoid valve

‘control (Euro 4 specification)

Engine Control System (4JJ1) 14-21

Engine Control Connector End Views

Accelerator Pedal Posi

n (APP) Sensor

Barometric Prossure (BARO) Sensor

Connector No 35

Connector coir Gray

Tes adapter No assem

Pin No, | Wire coor Pin fnefon

1 | sw [Breas eterence

7 [VEL [APP sensor? sal

3 [BLU [APP sensor 2 ow eferonce

4 | 2H [eves reornce

3 [RED [APP sensor signa

3 [WHT [APP sensor Tow eforence

Conner We a

Comair cobr Tack

Tost depo He ed

Pine [Wie cor | Pin tinaon

7 BLU | arsoriow erence

2 | SER | sorcorsina

3 | eR | Sensor vols refrenee

Boost Pressure Sensor

414-22 _Engine Control System (4JJ1)

‘Connector No E24

Connector color Black

‘Test adapter No. 135616-33

Pin No. | Wire color Pin function’

7 RED _ | Sensor signal

2 BLK _ | Sensorlow reference

3 YEL _ | Sensor volts reference

Clutch Switch

‘Connector No. Bie

Connector color White

“Test adapter No. 35618-42

Pin No. | Wire color Pin function|

1 | BLK/ORN | ignition voltage feed

2__ | WHT/BLK | Switch sional

Camshaft Position (CMP) Sensor

‘Connector No. E18

‘Connector color Black

“Test adapter No. 735616-33

Pin No. | Wire color Pin function

1 _[ BLU/WAT | Sensor signal

YEL/BLK | Sensor ow reference

UTGRN

‘Sensor 6 volts reference

Crankshaft Position (CKP) Sensor

Engine Control System (4JJ1)

1-23

‘Connector No. E20

Connector color Black

Test adapter No. ¥35616-33

Pin No. | Wire color Pin function’

1 _| RED/BLU | Sensor signa

BLK _ | Sensor low reference

YEL__ | Sensor 5 volts reference

Data Link Connector (DLC)

ae =

a =

a

12 BLK/ WHT | (ECM, TCM, HSA contro! unit

erases

13 [eux wer Reeae en

we [ Rees

DPD Regeneration Switch

nS

Ea ST)

BOHOL

‘Connector No. Bat

Connector color Blue

Test adapter No. 35616-24 resco

Pin No. | Wire color Pin function

1 = [Not used Gonnector No Bi6s

2 | ETGRN’ | Class 2 serial data (EHCU Connector color Bue

RED _| [ABS module]

es neal Test adapter No, 3561633

=| Notused

Pin No, | Wire color Pin fonction

4 BLK [Ground

1 _ | BLKTORN | Switch voltage food

BLK | Ground

2 _ | BLUI WHT | Switch signal

@ | GRN’ [CaN Tigh (Euro4

WHT _ | specification) 2 pau | Not used

Keyword serial data (ECM a =] Netuned

{except Euro 4 specication) 3 = ___[Notusea

7 | ETBLU | Fc¥, HSA control unit and

SRS control unit) 6 =__[Notused

= __[Notused 7 BLK | Hlumination lamp ground

LT GRNT

=| Notused lumination lamp vol

jot use 8 FERN! | ttumination lamp voltage feed

10 = [Not used

1A-24 Engine Control System (4JJ1)

Engino Coolant Temperature (ECT) Sensor

‘Connector No. B166

Connector color Blue

Test adapter No. ¥-35616-33

Pin No, | Wire color Pin function

8 = [Not used

10 =__ [Not usec

EGR Valve

‘Connector No. E25

‘Connector color Gray

“Test adapter No. 35616-33

Pin No. | Wire color Pin function

1 | GRN/ VEL | Sensor signal

owrescrnnei BLK ‘Sensor low reference:

=| Retosed

Conner NB a

Corned aor Back Engine warm Up Switch

Test adap Wo TERSTESER

Fin No, Wr oor Fintarcon

| ur emw [Porsoror 5a

2 | FSR [pst sensor signals

EN

«| RATT | postion sensoragnl

3 | FELT aLK | Potion sensor ow leone

3 [WaT [Wor consars

7 [ORN | Wotorconrara

3 [ BURTORW [Wot con

Engine Control System (4JJ1) 14-25

Exhaust Differential Prossure Sensor

Connector No 3168

Connector color Black

Test adapter No FI8676 33

Pin No, | Wire color Pin function

Engine warmup Switch votege

1 | euxrorn [Ene

2 [BRN/RED | Engine warm up switch signal

3 = [Net used

a = _ [Net used

3 = [Not used

3 = [Notused

7_|__BUK __|iiumination famp sround

TTGRNT romeo

8 | “SRN | itumination lamp votage food

9 = __[Notuses Connector No. 35

0 = [Notused Tomecior color Black

7 ra50Te

Exhaust Brake Solenoid Valve leatndapten No: SBS

Pin No. | Wire color Pin function

7 | BLK | Sensor low reference

2_ | GRNIYEL | Sensor signal

wat?

3 | WHT | sensor 6 volts reference

Exhaust Temperature Sensor 1

y

Connector No 125

Connector color Black

Test adapter No F866 3S

in No, | Wire color Pin function

7 _| GRN’BLK | ignition voltage feed snes

WaT?

2 | WHT | solenoid valve convel

414-26 Engine Control System (4JJ1)

Exhaust Throttle Solenoid Valve

Connector Na wa

Connector color Tahtorey

Test adapior No T3561

Pin No | Wire color Pia fanation

7 _[__BtK _ | SensorTow reference 4

2 YEL/ RED | Sensor signal -_

we

Connector No.

Connector color Bue

“est adapler No F355TE33

Pin No. | Wie color Pin funeton

7_|__BtK [Solenoid vave conta

2 | RED _|gniton voltage fees

Fuel injector #1 to #4 Cylinder

Connector No 5

Connector lor Dark aay

Test adap No 73561633

Pin No, | Wire calor Pin function

1 | __BtK _ | Sonsorfow reference

2 | RED | Sensor signal

Engine Control System (4JJ1) 14-27

‘Connector No. 5, E6, E7 and EB

Connector color Gray

‘Test adaptor No. F35616-33

Pin No. | Wire color Pin function’

i GRN/ WHT

#2: BL

1 Butretu | Fuel inlector control

#8: WHT) YEL

#1 and #4: WHT

2 ee te pep | Charge voltage

Fuel Rail Pressure (FRP) Regulator

Fuol Rall Pressure (FRP) Sensor

‘Connector No. E19

‘Connector color Black

“Test adapter No. 735616-33

Pin No. | Wire color Pin function

1_| YEL/BLK | Sensor low reference

BLU/ WHT | Sensor signal

LTGRN_ | Sensor 5 volts reference

‘Connestor No, EW

Connector color White

Test adapter No. -35616-33

Pin No. | Wire color Pin function|

1

WHT) | Regulator control high side

RED |(PwM)

2

GRN/RED | Regulator low side

Fuel Temperature (FT) Sensor

414-28 Engine Control System (4JJ1)

Mass Air Flow (MAF) Intake Air Tomperature (IAT)

‘Sensor (Euro 4 specification)

‘Connector No. E22

Connector corer Gray

Test adapter No, 1 35616-33

Pin No. | Wire color Pin function’

1 BLK _ | Sensor low reference

UF GRN

2 Wut | Sensor signal

Glow Plug

‘Connector No. E14

Connector color =

Pin No. | Wire color Pin function’

1 | BLKIYEL | Power Supply

Connector No. 8

‘Connector color Black

"Test adapter No. 735616648

Pin No. | Wire color Pin function

1_| RED/ BLU | MAF sensor 12 volts reference

BLK _ | MAF sensor low reference

WHT _ | MAF sensor signal

BLU/BLK | IAT sensor signal

RED __| IAT sensor low reference

Intake Air Temperature (IAT) Sensor (Except Euro 4

specification)

Engine Control System (4JJ1) 14-29

‘Connector No 217

Connector color Black

‘Test adapter No. F3616-16

Pin No. | Wire color Pin function

7_ | BLUTBLK [Sensor signal

2 _ | RED/BLU | Sensor low reference

Intake Throttle Valve

Idle Up Sonsor

‘Connector No. E16

Connector color Black

“Test adapter No. 35616-64A

Pin No. | Wire color Pin function|

i ‘GRN | Motor control low side (PWM)

2 | BLK/GRN | Motor drive voltage

3 BLK | Position sensor low reference

4 = __ [Not used

5 | VIO/WAT | Position sensor signal

. vex [Pasion sensor 5 vats

‘Connector No. B87

‘Connector color Write

“Test adapter No, ¥36616-33

Pin No. | Wire color Pin function

1__[ BLU/RED | Sensor low reference

YELIGRN | Sensor signal

BLU _ | Sensor 5 volts reference

PTO Switch

14-30 _Engine Control System (4JJ1)

‘Connector No Ed

Connector color Black

Test adapter No, 135616-33

Pin No. | Wire color Pin function’

1 _| VIOIWHT [PTO switch signal

2 BLK [PTO switch ground

PTO Throttle Sensor

Turbocharger Nozzle Control Solenoid Valve

SemecorN: ed

Comer oar ate

Test adapiorNo Fase

Bin Ro | Wie car | intention

7 UTR pon vlge food

a 2 | WET | scenes cons anny

— = NT Vacuum Pressure Sensor

Connedar or Bleck

Test epi Na FasG1635

Bin No: | Wie solr | Fn faneion

7 [RED | Sosoriow eerone

2 | VEL | Sensor sina

3 | BCU [Sensors vis eteenee

Engine Control System (4JJ1)

14-31

‘Connector No Eo

Connector color Black

‘Test adapter No. 135616-33

Pin No. | Wire color Pin function’

1 BLK _ | Sensor low reference

2 GRN | Sensor signal

3 YEL _ [Sensor volts reference

Vehicle Speed Sensor (VSS)

‘Connector No. 8

Connector color Gray

“Test adapter No. 35616-33

Pin No. | Wire color Pin function|

i GRY _ | lonition voltage feed

2 BLK | Sensor low reference

3__| YEUGRN | Sensor signal

1A-32__Engine Control System (4JJ1)

Diagnostic Information and Procedures

Engine Control System Check Sheet

ENGINE CONTROL SYSTEM CHECK SREET Inspec Nae

users Name edo & od Yoo

Dive’ Name casi No

ae Veil rowan Eng Ne

Lins dome Roda eines

o & em 1 Engine does not crank No intial combustion No complete combustion

aint |. Ene cons doy U onere 1

. Rae ig red Tieng eee RP a ig eed

£1 mcoroxise [2 noanions

& Other ( |

Ele a to em Tae Tata

© |D bevenbaty |S Lack of power, sgaieters, sponginess

i 3 oe

i 5 Son sag 7 race peed

Bearman |Z teventopecen B atereccevresfealeamse’ ©. Shing Wi 0

2 om |

Saran Twemaz Fearn ey

2 ores |G Amanat contusion rose OPO seen Fey

5 DSropmorton tga

2 Onmt ,

eed

3 ca 7a Tas aaa) Foy

Proven Fey

overt A

Seamer fe ooaiy Trans Taw

5 oscar

[ess tater Fam aa Tea apa

Fem [5 toy epee

8 Noe faa a Bas Taye oT

¢ 3 Deal Reh! Bonet ‘

| Boros io Bho os

E [tonscontton | 5 acannon, ton)

i lem res Tama Tiere Tenet

ee eo |

; oS at ar sng Wy Tag

E lemw pemon {2 Pech, owe 1 Comartepesd Aeon

§ [fro op aton | Deeteen © Aoncr onion

3 Om ,

Foaaront — |e ra Thon iz Coon Terao

Fo ra

aa aa 2 Rena On irs On Doe alton

aru cote

rear ate ne 8

Diagnostic Trouble " Nod )|

eaters

san ce Noting a Rarucode 5

SPD ams or near [Bd oer

oeD sikh orate 1 et at ph

ccoseun —[OPPasanain ana? a aa uA af

pe0 sine ss [ors 2 3 ce

OPO hoops aero es ze a aa

BPD rash gw i ae a a2

Ems dees presse al sha tins eo

rad HAF Win ris err pss nS os

Engine Control System (4JJ1) 14-33

Diagnostic Starting Point - Engine Controls

Begin the system diagnosis with Diagnostic System

Check - Engine Controls. The Diagnostic System

Check - Engine Controls will provide the following

information|

+ The Ientiication of the control modules which

‘command the system

+ The ability of the contral modules to communicate

through tne serial data circuit

+ The identification of any stored diagnostic trouble

codes (DTCs) and the their statuses.

‘The use of the Diagnostic System Check - Engine

Controis will Identify the correct procedure for

diagnosing the system and where the procedure is

located.

Important: Engine Control System Check Sheet must

be used to verify the customer complaint, you need to

know the correct (normal) operating behavior of the

systom and verify that the customer complaint isa valid

failure of the system,

7 Ha Ee

“al

Reading Flash Diagnostic Trouble Codes (DTC)

‘The provision for communicating with the ECM is the

Data Link Connector (DLC). The DTC{s) stored in the

ECM memory can be read either through a hand-held

diagnostic scanner such as Tech 2 plugged into the

DLC ot by counting the number of flashes of the

malfunction indicator lamp (MIL) or the service vehicle

soon (SVS) lamp when the diagnostic test terminal of

the DLC is grounded. The DLC terminal "12"

(diagnostic request) is pulled "Low" (grounded) by

Jumped to DLC terminal "4", which is @ ground wire.

‘Once terminals "12" and "4" have been connected, turn

the ignition switch ON, with the engine OFF. The MIL.

{except Euro 4 specification) or the SVS lamp (Euro 4

specication) wil indicato a DTC three times is a DTC

's present and history. I more than one DTC has been

stored in the ECM's memory, the DTCs will be output

numerical order with each DTC being displayed three

times. The flash DTC display will continue as long as

the DLC is shorted,

Unit: Second

Diagnostic Trouble Codes (DTC) Clear Method by

Accelerator Pedal Operation (Except Euro 4

Specification)

If there is no scan tool, history DTCs can be cleared

Using accelerator pedal operation

4. Tum ON the ignition, with the engine OFF.

2, Use a jumper wire and the DLC terminal "12"

(Giagnostic request) is pulled "Low" (grounded) by

jumped to DLC terminal "s*.

Depress accelerator pedal within 1 to 3 seconds.

Release accelerator pedal within 1 10 3 seconds,

Depress accelerator pedal within 1 to 3 seconds.

Release accelerator pedal within 1 to 3 seconds.

Depress accelerator pedal within 1 to 3 seconds.

Release accelerator pedal within 1 to 3 seconds.

eNoane

Notice: DO NOT touch the accelerator pedal when it is

released. Clearing DTCs may fil

1A-34 _ Engine Control System (4JJ1)

Diagnostic System Check - Engine Con-

trols

Description

“The Diagnostic System Check - Engine Controls is an

organized approach to identifying a condition that is

created by a malfunction in the electronic engine

control system. The Diagnostic System Check must be

the starting point for any criveabilty concer. The

Diagnostic System Check directs the service technician

to the next logical step in order to diagnose the

concem. Understanding and corectly using the

diagnostic table reduces diagnostic time, and prevents

the replacement of good parts.

Test Description

‘The numbers below refer to the step numbers on the

diagnostic table,

2. Lack of communication may be because of a partial

fr a total malfunction of the serial data circu.

7. The presence of DTCs which begin with U, indicate

that some other module is not communicating,

10. If there are other modules with DTCs set, refer to

the DTC list. The DTC list directs you to the appropriate

diegnostic procedure, If the control module stores

multiple DTCs, diagnose the DTCs in the following

order:

+ Component level DTCs, such as sensor DTCs,

solenoid DTCs, actuator DTCs, and relay DTCs.

Diagnose the multiple DTCs within this category in

numerical order. Begin with the lowest numbered

DTC, unless the diagnostic table directs you

otherwise,

Diagnostic System Check Engine Controls

Important:

+ DO NOT perform this diagnostic if there is not a

criveability concern, unless another procedure

directs you to this ciagnosti.

+ Before you proceed with diagnosis, search for

applicable service bulletins.

+ Unless a diagnostic procedure instructs you, DO

NOT clear the DTCs,

+ Ifthere is a condition withthe starting system, refer

to the Starting System in Section 1E Engine

Electrical

+ Ensure the battery has a full charge,

+ Engure the battery cables (+) (-) are clean and

tight

+ Ensure the ECM grounds are clean, tight, and in

the correct location.

+ Ensure the ECM hamess connectors are clean

‘and correctly connected. DO NOT attempt to crank

the engine with ECM hamess connectors

disconnect.

+ Ensure the ECM terminals are clean and correctly

mating,

+ Ensure the fuel injector ID code data is correctly

programmed in to the ECM.

+ Ensure the Immobilizer security information is

conrectly programmed into the ECM and

Immobilizer control unit (ICU),

+ If there are fuel system DTC's (P0087, PODS,

P0059, P0093 or P1093), diagnose sensor DTCs,

solenoid DTCs, actuator DTCs and relay DTCs

first

+ If thore are DPD systom DTC's (P1495, P1471,

P242F, P2452, P2453 or P2458), diagnose sensor

DTCs, solenoid DTCs, actuator DTCs and relay

DTCs first

Diagnostic System Check - Engine Controls (Euro 4 Specification)

Sep) ‘ation Value(s) Yes Ne

Tnstalla sean tool

1 = Go to Scan Too!

Does the scan tool tum ON? Goto step? _| Does Not Power Up

7. Turn ON the ignition, withthe engine OFF

2. Attempt to establish communication with the {Go to Scan Too!

2 ECHL - oes Not

‘Communicate with

Does the sean tool communicate with the ECM? Goto Stop 3 CAN Devico

Notice: If en immobilizer system is actve the ECM

\will disable the fuel injection causing the engine to

stall immediately after staring and energze the

3 | starter cut relay to disable cranking. Attempt to >

‘rank the engine.

Doos the engin crank? Goto Stop 4 Goto Step 5

‘Allempt to star the engine (Go 10 Engine

a — Cranks but Does

Does the engine start and ide? Goto Sep 6 Rat

Engine Control System (4JJ1) 14-35

Sep ‘Actor Value(s) Yes No

Does the scan tool display ECM DTCs P0633, Problem fs relating

P1618 or 0167? ta starting systom,

5 = Refer to Starting

Goto Appicablo | _systom in Section

ore AE Engine Electrical

Selact the DTC cisplay funciion for the folowing

‘control modules:

ECM

+ Transmission control module (TCM) (Smoother

only)

6 =

* Electronic hydraulic control unit (EHCU) (it so

equipped)

‘Immobilizer control unt {ICU) (so equipped)

oes the scan tool display any DTCs? Goto Step7 Goto Step 11

Does the scan tool display DTCs which begin with

7 | U-or other control module communication fault = Go to Applicable

Dros? pre Goto Sep 8

'g | Does the scan tool display ECM DTCs POEOT, _ Go to Applicable

P0602, P0604, POBOS, POGUE or P1621? pie Goto Stop 9

‘| Does the scan tol display ECM DTC POSES? _ Go to Applicable

ore Goto Stop 10.

40. | | there any other code in any controler that has: _ (Go to Applicable

not been diagnosed? pre Goto Step 11

Te the customers concer withthe Wansmission? Goto Diagnostic

‘System Check

" Transmission

- CContrels in Section

5A Transmission

Control System Goto Step 12

Ts the customers concern with the antilock brake Go to Diagnostic

system? ‘System Check -

R = ABS Contos in

‘Section 4C1 ABS!

ASR Goto Stop 13,

Is the customers concem with the immobilizer Go to Diagnostic

system? ‘System Check -

8 = Immobilizer

Controls in Section

81 Secunty and Lock | Goto Step 14

1A-36 Engine Control System (4JJ1)

Sep ‘Actor Value(s) Yes No

7. Review the following symptoms.

2, Refer to the sppiicable symptom diagnostic

table

+ Hard Start

+ Rough, Unstable, or Incorrect ile and

Stalling

+ High idle Speed

+ Cuts Out

+ Surges

+ Lack of Power, Siuggishness or

4 Sponginess: =

+ Hesitation, Sag or Stumble

+ Abnormal Comaustion Noise

+ Poor Fuel Economy

+ Excessive Smoke (Black Smoke)

+ Excessive Smoke (White Smoke)

+ DPD. System Manual Regeneration

Frequently

+ DPD System Regeneration Long Time

fem Ree a Go to intermittent

Did you find and correct the coneltion? System OK Coneitions.

Diagnostic System Check - Engine Controls (Except Euro 4 Specification)

Sep) Raton Valuels) Yes No

Install a sean tool

a = Goto Scan Too!

Does the scan tool turn ON? Goto Step? _| Does Not Power Up

1. Turn ON the ignition, withthe engine OFF.

2. Attempt to establish communication with the

listed control modules,

+ ECM

‘+ Transmission control module (TCM)

{Smoother only}

3 + Hil start aid (HSA) control unit (if so _

equipped)

+ Supplemental restraint system (SRS)

Control unit (if so equipped)

‘+ Immobitizer control unit (ICU) «It so

cuipped Goto Scan Too!

sre) Does Not

Does the scan fol communicate wth all the listed Communicate with

contol modes? Gotwsteps | Keyword Device

Notice: ifan immobilizer system is acive the EM

vil disable the fuel injection causing the engine to

stall immediately after staring and energize the

3 | starter cut relay to disable cranking. Attempt to =

‘crank the engine

Does the engine crank? Goto step Goto step 5

‘Allempt to start the engine Goo Engine

4 = Cranks but Does

oes the engine start and idle? Goto Step 6 Not Run

Does the scan tool display EOM DTCs POESS, Problem i relating

P1616 or 0167? to starting system,

5 _ Refer to Starting

Goto Applicable | system in Section

pre 1E Engine Electrical

Engine Control System (4JJ1) 14-37

Step ‘ston Vauets) Yer Ne

Seloct Hie DTC elepay Tunaton forthe folowing

control modules:

+ ECM

+ ToM (Smoother only)

| *EHCU Gr s0 equipped) -

+ HSA contol unt (if s0 equipped)

+ SRS control unt (itso equipped)

+ ICU (ifs0 equippes)

Does the scan tol display any DTCs? Goto Step 7 Goto Step 11

Doos the scan tool display DTCs which begin with

7 | U or ether contro! module communication fault Go to Applicable

DTCs? ore Goto Step 8

| Sees the sean too! display ECM DTCs PO6OT _ Go Appieabie

062, PO04, PD606, POGOB or P1621? ore. Goto Stop 8

‘| ees the scan tool display ECM DTC POSER? Go Applicable

= ore, Goto Step 10

{0 | there any other code in any controler that has _ Gow Applicable

not been dagnosec? ore. Goto step 11

1s the customers concem with the Wersmission Goto Diagnose

syste? System Check

“Transmission

a - Contos in Section

5A Transmission

Control System | Goto Step 12

is the customers concam withthe art-lock brake Go to Diagnoste

system? System Check -

2 = ABS Controls in

Section 4C1 ABS!

ASR Got Step 13

Ts the customers concem with the HSA system? Goo Diagnosie

8 _ System Check-

ss HSA Controls in

Section HSA | Goto Step 14

Ts the customers concer wih the SRS airbag Goto Diagnostic

system? System Check -

14 2 SRS Controls in

Seaton 8 SRS

Contr Systam | Goto Step 15

Ts the customers concem with the Immobilizer Go to Diagnostic

system? System Check -

18 - Immobilizer

Contes in Section

81 Socuniy and Lock| Goto Stop 18

1A-38 Engine Control System (4JJ1)

Sep ‘Actor Value(s) Yes No

7. Review the following symptoms.

2, Refer to the sppiicable symptom diagnostic

table

+ Hard Start

+ Rough, Unstable, or Incorrect ile and

Stalling

+ High idle Speed

+ Cuts Out

16 + Surges -

+ Lack of Power, Siuggishness or

Sponginess,

+ Hesitation, Sag or Stumble

+ Abnormal Comaustion Noise

+ Poor Fuel Economy

+ Excessive Smoke (Black Smoke)

+ Excessive Smoke (White Smoke)

Go to Intermittent

Die you fin and correct the conestion? system OK Gonations.

Engine Control System (4JJ1) 14-39

Scan Tool Data List

The Engine Scan Tool Data List contains all engine

related parameters that are available on the scan tool

‘A given parameter may appear in any one of the data

lists, and in some cases may appear more than once,

fr in more than one data list in order to group certain

related parameters together. Use the Engine Scan Too!

Data List only after the following is determines:

Euro 2 Specification

+ The Engine Controls - Diagnostic System Check is

completed,

+ On-board diagnostics are functioning properly.

‘Scan tool values from a properly running engine may

be used for comparison with the engine you are

diagnosing, The Engine Sean Tool Data List represents

values that would be seen on a normal running engine.

Only the parameters listed below are referenced in this

service manual for use in diagnosis.

Scan Tool Parameter | Units Displayed | Typical Data Value at Engine | Typical Data Value at 1700

Ile RPM

Operating Conditions Engine idling or 1700 RPM/ Engine coolant temperature Is between 75 to 85°C (167 to

185°} Accelerator pedal is constent/ Neutral or Park/ Accessories OFF/ Vehicle located at sea level

Engine Speed RPM Nearly 600 RPM Nearly 1700 RPM

Desired Idle Speed RPM 600 RPM 600 RPM

Calculated Engine Load % Less than 25% Less than 15%

Engine Coolant Temperature | __“C!°F 7510 85°C 167 1 185 | 7510 85°C) 167 to 185F

Engine Coolant Temperature Vals 04 108 volts 04 to 06 valis

Sensor

intake Air Temperature “Orr BW ATC CIO 104 | _2OWATCI BIO 104F

Intake Air Temperature Vals 741023 volts Ta102.3 vols

Sensor

Fuel Temperature “oF 2010 60°C/50t MOF | 2010 60GI SOT 40F

Fuel Temperature Sensor Valls 08 to 23 volts 0.81023 volts

Barometric Pressure KPalpst__| Nearly 100 KPal 14.5 psiat_ | Nearly 100kPal 14.5 psi at

sea level sea level

Barometric Pressure Sensor Volts Nearly 2.3 volts at sea level_| Nearly 2.3 vlls at sea level

Boost Pressure KPalpsi | Nearly 100 kPal 14.5 psiat [Less than 115 kPal 16.7 paiat

sea level sea level

Boost Pressure Sensor Vols Nearly 1.0 voltat sea level | Less than 1.3 volls at sea

level

Desired Fuel Rail Pressure | MPa/psi ‘Nearly 30 MPa’ 4,300 psi_| More than 30 MPa’ 4.400 psi

Ful Ral Prossure MPai psi | 271033 MPal3,900 psi to _| Mora than 30 MPal 4,400 psi

4,800 psi

Fuel Rail Pressure Sensor Vols 7101.5 volts More than 1.6 volts

FRP Regulator Command % 30t0 48% 3010 40%

(Ful Rail Pressure)

FRP Regulator Foodback mA 900 to 1100 mA 00 to 1000 mA

(Fuel Rail Pressure)

‘Accelerator Pedal Postion % 0% 1200 20%

‘APP Sensor 1 (Accelerator Volts Nearly 0.5 volts 080 1.4 vals

Padal Position}

"APP Sensor 2 (Accolarator Volts Nearly 4.8 volis 3.7043 valls

Padal Position)

Intake Throtle Solenoid % 0% 0%

Command

14-40 _Engine Control System (4JJ1)

Scan Tool Parameter | Units Displayed | Typical Data Value al Engine | Typical Dala Value at 1700

tale RPM

Desired intake Throtle % More than 80% Wore than 90%

Position

Intake Throtle Position % More than 100% More than 100%

Intake Thratle Position Volts More than 3.9 vols ‘More than 3.9 volls

Sensor

Tale Up Sensor Volts 031006 volts 031006 vols

Fuel Compensation Gyi. 1 mn 60 10 5.0 mmn(varies) 0.0 ma

Fuel Compensation Cyl. 2 min “6.0 10 5.0 mm"(varies) 0.0 mm’

Fuel Compensation Cyl. 3 mn “6.0 to 5.0 mm(varies) 0.0 mm’

Ful Compensation Cyl. 4 am? “5010 5.0 mm®varies) 0.0 mm?

Fuel Supply Pump Status | Not Learned? Leamed Leamed

Learned

Rall Pressure Feedback Mode| Shutoff Mode? Feedback Mode Feedback Mode

Slart Mode! Wait

Mode! Wait to

Restart

Feedback Mode

Engine Running Status | Of igniton On! Running Running

ranking’

Running

Vehicle Speed ‘km/h! MPH O kmh! O MPH 0 kmh’ O MPH

Tgniion Key START Switch | On OF Of Off

Ignition Key ON Switch ‘Onl Off On On

Taniion Valage Volts 22016 30.0 vols 22010 30.0 vols

Batiory Voltage Volts 22.0 130.0 vols 22.010 30.0 vols

hitch Pedal Switch ‘Applied? ‘Applied or Released ‘Applied or Released

Released

Neal Switch Neutral in Gear Neatal Neutral

Park Brake Switch ‘Applied? Applied or Released ‘Applied or Released

Released

Exhaust Brake Switch ‘On Of OF of

Exhaust Brake Valve ‘Oni om oF oF

‘Command

Exhaust Brake Gul Request | Inactive! Adve Inactive inactive

fiom ABS Module

Exhaust Brake Gut Request | Inactive! Active Tnadtve inactive

from TOM

PTO Switch ‘On Of oF of

PTO Remote Throttle. % 0% 0%

PTO Remote Throttle Sensor | ___Volls Less than 0.4 vols ess than 0.4 vals

Engine Warm Up Switch ‘On om oF of

‘A Signal ‘On OF OF Off

Refigorator Switch ‘Ov om Off Off

Engine Control System (4JJ1) 14-41

‘Scan Tool Parameter | Units Displayed | Typical Data Value at Engine | Typical Dala Value at 1700

Ide RPM

Engine Oil Level Switen | Low/ Normal Normal Normal

Glow Plug Relay Command Oni Off Off Off

Glow Plug Lamp Command ‘Oni Off Off Off

Immobilizer Signal Received! Not Received Received

Received

‘Wrong Immobilizer Signal | Received’ Not Not Received Not Received

Received

Immobilizer Function Yesi No Yes Yes

Programmed

Security Wait Time Tnactive! Time Tnactive Tnactive

(hour: minute:

second)

Euro 3 Specification

‘Scan Tool Parameter | Urits Displayed | Typical Data Value at Engine | Typical Data Value at 1700

Idle

RPM

Operating Conditions: Engine

185°F/ Accelerator pedal is co

instant’ Neutral or P

idling or 1700 RPM/ Engine coolant temperature is between 75 to 85°C (167 to

sarki Accessories OFF/ Vehicle located at sea level

(Fuel Rall Pressure)

Engine Speed RPM Nearly 600 RPM Nearly 1700 RPM

Desired idle Speed RPM ‘600 RPM ‘600 RPM

Calculated Engine Load % Less than 25% ess than 15%

Engine Coolant Temperature °OrF 7510 85°C) 167 19 185F | 7510 85°C) 16710 185F

Engine Coolant Temperature Volts 04 t 06 volts Oat 06 volts

Sensor

Intake Air Temperature “OF 720 t0 40°07 68 0 104°F 20 to 40°C) 68 to 104"

Intake Air Temperature Volts 14 102.3 volts 14 t0 2.3 volts

Sensor

Fuel Temperature =orF 720 10 60°C) 60 10 140"F 720 t0 60°C) 50 to 140°F

Fuel Temperature Sensor Volts 08 to 2.3 volts 0810 23volts

Barometric Pressure kPal psi Nearly 100 KPa/ 14.5 psiat | Nearly 100 kPa 14.5 psi at

sea level sea level

Barometric Pressure Sensor Volts Nearly 2.3 volts ai sea level | Noarly 23 volls at sea level

Boost Pressure KPal psi Nearly 100 kPa’ 14.5 psi at_| Less than 175 KPa 16.7 psi at

sea level sea level

Boost Pressure Sensor Volts Nearly 7.0 voltat sea level | Less than 1.3 volts at sea

level

Desired Fuel Rail Pressure MPal psi Nearly 30 MPa/4,300 psi_| More than 30 MPa’ 4,400 psi

Fuel Rail Pressure MPal psi 27 to 33 MPal 3,900 psi to | More than 30 MPa’ 4,400 psi

4,800 psi

Fuel Rail Pressure Sensor Volts 7A to 1.5 volts More than 7.6 volts

FRP Regulator Command % 30 to 45% 30 10 40%

(Fuel Rall Prossuro)

FRP Ragulaior Feedback mA {900 to 1100 mA {B00 to 1000 mA

1A-42 Engine Control System (4JJ1)

Scan Tool Parameter | Units Displayed | Typical Data Value at Engine | Typical Data Value at 1700

Ile RPM

‘Accoleraior Pedal Posiion % 0% 1210.20%

APP Sensor 1 (Accelerator Volts: Nearly 0.5 volts 0.8 to 1.4 volts

Pedal Position)

"APP Sensor 2 (Accelerator Volts Nearly 4.5 vols 3.7 104.3 valle

Pedal Position}

Dosired EGR Position % 0% O%

EGR Solenoid Command 1 % 0% 0%

EGR Position 1 Low High Low or High Low or High

EGR Position 2 Lowi High Low or High Low or High |

EGR Position 3 Lowi High Low or High Low or High |

Intake Throttle Solenoid % 0% 0%

Command

Desired Intake Throttle % More than €0% More than 90%

Position

Intake Throtle Position % More than 100% More than 100%

Intake Throtle Position Volts More than 3.9 volts More than 3.9 volts

Sensor

Idle Up Sensor Volts 0.31006 volts 0.310 0.6 valts

Fuel Compensation Gyi. 1 ran “516 5.0 mmovaries) 0.0 rare

Ful Compensation Oyl. 2 Tan 76.010 5.0 man(varies) 0.0 mane

Fuel Compensation Cyl. 3 mi “60 10 5.0 mm(varies) 0.0 mm’

Fuel Compensation Cyl. 4 mn “60 10 5.0 mm"(varies) 0.0 mm

Fuel Supply Pump Status | Not Learned? Leamed Leamed

Leamed

Ral Pressure Feedback Mode | Shutoff Mode? Feedback Mode Feedback Mode

Start Mode! Wait

Mode! Wait to

Restart

Feedback Mode

Engine Running Status | Of ignition On! Running Running

ranking!

Running

Vehicle Speed ‘enihi MPH Okman? 0 MPH ‘Okinih/ O MPH

Ignition Key START Switch ‘Oni OF Off Off

Ignition Key ON Switch ‘Oni Of On On

ignition Voltage Volts 22.0 1 30.0 volts 22.010 30.0 vols

Batiory Vollage Volts 22015 30.0 vols 22010 80.0 vols

‘Ghuich Pedal Switch Applied? ‘Applied or Released ‘Applied or Released

Released

Neual Switch Neutal In Gear Neal Neutral

Park Brake Switch ‘Applied! ‘Applied oF Released ‘Applied or Released

Released

Exhaust Brake Switch ‘Oni Of Off Off

Engine Control System (4JJ1) 14-43

Scan Tool Parameter | Units Displayed | Typical Data Value at Engine | Typical Dala Value at 1700

Idle RPM

Exhaust Brake Valve ‘On! Off Of Of

‘Command

Exhaust Brake Cut Request | Inactive! Active Inactive Inactive

from ABS Module

Exhaust Brake Cut Request | Inactive! Active Inactive Inactive

from TCM

‘ASR Commanded APP % 100% 100%

(Accelerator Pedal Position)

PTO Switch ‘On Off Of Of

PTO Remote Throttle % 0% 0%

PTO Remote Throttle Sensor Volts Less than 0.4 volts ‘Less than 0.4 volts

Engine Warm Up Switch On! Off Of Off

‘AIC Signal On! Off Off Off

Refrigerator Switch ‘Onl Off Of Off

Engine Oli Level Switch | Low/ Normal Normal Normal

Glow Plug Relay Command ‘On’ Off ‘Of Off

Glow Plug Lamp Command ‘Oni Off OF Off

Immobilizer Signal Yesi No Yes Yes

Wrong Immobilizer Signal Yes! No No No

Immobilizer Function Yesi No Yes Yes

Programmed

‘Seourity Wait Time Tnactivel Time Inactive Tnactive

(hour: minute:

‘second}

Except Euro 2 and Euro 3 Specifications

Scan Tool Parameter

Units Displayed

Typical Data Value at Engine

Idle

Typical Data Value at 1700

RPM

Operating Conditions: Engine

185°F\ Accelerator pedal is co

idling or 7700 RPM/ Engine coolant temperature is between 75 to 85°C (167 to

ynstan¥ Neutral or Park/ Accessories OFF/ Vehicle

located at sea level! DPD is not

under regeneration

Engine Speed RPM Nearly 600 RPM Nearly 1700 RPM

Desired idle Speed RPM ‘600 RPM ‘600 RPM

Calculated Engine Load % Tess than 25% Less than 15%

‘Coolant Temperature “OIF 78 t0 85°C) 167 10 185°F | 7510 ASC) 167 to 185°F

Engine Coolant Temperature Volts 0.4 06 volts O4t0 06 volts

Sensor

Intake Air Temperature “Or 20 to 40°07 68 t0 104°F 20 to 40°C/ 68 to 104°F

Intake Alr Temperature Volts T4123 volts 14 102.3 volls

Sensor

Fuel Temperature “OIF 720 10 60°C) 60 to HOF 720 to 60°C) 60 to 140°F

Fuel Temperature Sensor Volts 08 to25 volts 081023 volts

1A-44 Engine Control System (4JJ1)

‘Scan Tool Parameter | Units Displayed | Typical Data Value at Engine | Typical Dala Value at 1700

Idle RPM

MAF (Mass Air Flow) acyl More than 0.2g/cylatsea | More than 0.2 g/ cyl at sea,

level level

‘Averaged MAF (Mass Air gs ‘More than 5 gi s at sea level | More than 25 g/ s at sea level

Flow)

MAF Sensor (Mass Air Flow) Vals Morethan 1.2 volts atsea_| More than 2.0 volts at sea

level level

Barometric Pressure kPal psi Neatly 100 kPa/ 14.5 psiat | Nearly 100 kPa’ 14.5 psi at

sea level sea level

Barometric Pressure Sensor Volts Nearly 2.3 volts at sea level | Nearly 2.3 volis at sea level

Desired Turbocharger % 10 to.20% 25 t0 35%

Position

Desired Boost Pressure kPal psi Neatly 100 kPa 14.5 psi at_ | Less than 175 kPa/ 16.7 psi at

sea level sea level

Boast Pressure kPal psi Neatly 100 kPai 14.5 psiat | Less than 175 KPa/ 16.7 psi at

‘sea level sea level

Boost Pressure Sensor Volts Nearly 7.0 voltat sea level | Less than 1.3 volts at sea

level

Desired Fuel Rail Pressure MPai psi Nearly 30 MPa/ 4,300 psi_| More than 60 MPa’ 8,700 psi

Fuel Rail Pressure MPai psi 27 to 33 MPal 3,900 psi to_| More than 60 MPa’ 8,700 psi

4,800 psi

Fuel Rail Pressure Sensor Volts 1410 15 vols More than 2.0 volts

FRP Regulator Command % 30 to 45% 30 t0 40%

(Fuel Rall Pressure)

FRRP Regulator Commanded | mm/sec More than 650 mm/sec | More than 1600 mm see

Fuel Flow

FRP Ragulaior Feedback mA {900 to 1100 mA {800 to 1000 mA

Current (Fuel Rail Pressure)

‘Aacelerator Pedal Position % 0% 1216 20%

‘APP Sensor 1 (Accelerator Valts Nearly 0.5 volts OBto tavalts

Pedal Position)

‘APP Sensor 2 (Accelerator Vals: Nearly 4.5 volts 371043 volts

Pedal Position}

Desired EGR Position % Less than 95% Less than 55%

EGR Position 1 % Less than €5% Less than 55%

EGR Position 1 Low! High Tow or High Low or High

EGR Position 2 Low/ High Low oF High Low or High

EGR Position 3 Low! High Low oF High Low or High

Trlake Throttle Solenoid % O% 0%

‘Command

Desired Intake Throttle % More than 90% ‘More than 90%

Position

Intake Throitle Position % More than 100% Mare than 100%

Intake Throttle Position Valls More than 3.9 volts ‘Mora than 3.9 volts

Sensor

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Zanotti FZ 238 FZ 248 FZ 248/2 FZ 258 285538027 SFZ User ManualDocument40 pagesZanotti FZ 238 FZ 248 FZ 248/2 FZ 258 285538027 SFZ User Manualvik_md100% (1)

- LG4HG-WE-0871-4HG1 - Engine 4HG1Document519 pagesLG4HG-WE-0871-4HG1 - Engine 4HG1vik_md100% (9)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Wabco EBS DDocument40 pagesWabco EBS Dvik_md100% (3)

- 6SDEED-WE-0325AR - Engine Emmision (6SD1-TC (Common Rail) Model)Document364 pages6SDEED-WE-0325AR - Engine Emmision (6SD1-TC (Common Rail) Model)vik_mdNo ratings yet

- MG6HFED-WE-0991 - Engine Control System (6HF1 Model)Document386 pagesMG6HFED-WE-0991 - Engine Control System (6HF1 Model)vik_mdNo ratings yet

- Isuzu Sistema Elektrooborudovaniya 1Document1 pageIsuzu Sistema Elektrooborudovaniya 1vik_mdNo ratings yet

- 6heed-We-0001 - Emission and Electrical Diagnosis 6HH1 EVTDocument78 pages6heed-We-0001 - Emission and Electrical Diagnosis 6HH1 EVTvik_mdNo ratings yet

- 6HSEED-WE-775HK - Emission and Electrical DiagnosisDocument97 pages6HSEED-WE-775HK - Emission and Electrical Diagnosisvik_mdNo ratings yet

- DW 80 ManDocument12 pagesDW 80 Manvik_mdNo ratings yet

- Lg4jjed-We - 4jj1 Euro 5 With DPDDocument379 pagesLg4jjed-We - 4jj1 Euro 5 With DPDvik_mdNo ratings yet

- In190 Gysmi - Repare 195Document14 pagesIn190 Gysmi - Repare 195vik_mdNo ratings yet

- Lg4hke4wd-Wsp-0851co - 4hk1 Euro 4 With DPDDocument1,230 pagesLg4hke4wd-Wsp-0851co - 4hk1 Euro 4 With DPDvik_md100% (1)

- Gysmi: 64163 8 A4 Fonction: Schema - BlocDocument9 pagesGysmi: 64163 8 A4 Fonction: Schema - Blocvik_mdNo ratings yet

- Тормозное давление Volvo fh12Document5 pagesТормозное давление Volvo fh12vik_mdNo ratings yet

- Scania Aps RuDocument12 pagesScania Aps Ruvik_md100% (2)

- Spare Parts Catalogue - March 2014Document20 pagesSpare Parts Catalogue - March 2014vik_mdNo ratings yet

- BAXI Eco Four котлы - инструкцияDocument34 pagesBAXI Eco Four котлы - инструкцияvik_mdNo ratings yet

- Thermo 90Document26 pagesThermo 90vik_mdNo ratings yet

- Eber B3L D3LDocument3 pagesEber B3L D3Lvik_mdNo ratings yet

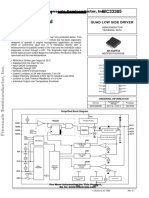

- Automotive Quad Low Side Driver: MC33385 SemiconductorDocument11 pagesAutomotive Quad Low Side Driver: MC33385 Semiconductorvik_mdNo ratings yet

- Autocom CARS 201700Document2,851 pagesAutocom CARS 201700vik_mdNo ratings yet

- Taura D McsDocument15 pagesTaura D Mcsvik_mdNo ratings yet

- Description: LM2576 SeriesDocument8 pagesDescription: LM2576 Seriesvik_mdNo ratings yet