Professional Documents

Culture Documents

R901084002P00

R901084002P00

Uploaded by

Rene HebaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

R901084002P00

R901084002P00

Uploaded by

Rene HebaCopyright:

Available Formats

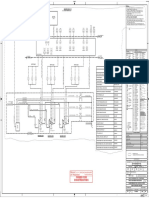

UP STANDARD DETAIL REFERENCE DRAWINGS

DETAIL OF HEAVY WELDING BOSSES FOR THREADED CONNECTIONS AE-036175

N

AWAY AWAY

CONSTRUCTION-NOTES AND DETAILS FOR ISOMETRIC PIPING

INSULATION DETAILS FOR HOT PIPING

AD-036627

AA-036911

SHOP MATERIALS INSULATION DETAILS FOR COLD PIPING AA-036913

INSTALLATION OF JACK SCREWS FOR FLANGED JOINTS AC-036630

TOWARD TOWARD PT N.B.

NOTES

NO DESCRIPTION (INS) STOCK CODE QTY

1. MATERIAL SHOWN WITH A BROKEN LINE AND SPOOLS LISTED IN THE SAUDI ARAMCO

DOWN

PIPE FABRICATION LIST ARE NOT TO BE FURNISHED BY THE VENDOR.

2. PIPING DETAILS SHALL BE CUT AT ALL POINTS MARKED F.W. (FIELD WELD).

1 PIPE , CS API 5L-B-PSL2 , SMLS , BE , 12 PPPCPVSMBESTD5F 1.8 M 3. EACH FABRICATED SECTION SHALL BE CLEARLY MARKED WITH ITS CODE NUMBER.

STD , B36.10M , FBE INT COATED 4. UNLESS OTHERWISE NOTED. (A) ALL DIMENSIONS ARE TO C OR FACE OF FLANGES.

(B) BOLT HOLES ON FLANGES STRADDLE C . (C) WELDING ELBOWS ARE LONG RADIUS.

5. FABRICATION SHALL BE IN ACCORDANCE WITH SAUDI ARAMCO SPECIFICATION 01-SAMSS-10.

FITTINGS 6. GASKET ALLOWANCE

7. PIPING MATERIAL IS

2 WELDOLET , CS A105N , STD , BE , HDR/BRN 12X2 PLWC1B00STDB20K 2

, SP-97 , FBE INT COATED PIPE SIZE SCHEDULE SPECIFICATION

3 BASKET TYPE STRAINER 12X2 SP-X101 1 REFER MTO REFER MTO REFER MTO

4 90 LR ELBOW , CS A234-WPB , SMLS , BE , 2 P9LC34SMBESTDE5 2

STD , B16.9 , FBE INT COATED

8. WELDING STRESS RELIEF - YES NO

X

FLANGES RADIOGRAPHY % 100% X-RAY SPOT X-RAY 01-SAMSS-10 SHOP FIELD

5 WN FLG , CS A105N , CL150 , FF , STD , 12 PFWC1B15FFSTD5V 2 9. TESTING SHOP HYDROSTATIC TEST - YES

THE SHOP HYDROSTATIC TEST SHALL BE CARRIED OUT ON PIECES HAVING ALL ENDS

NO

FOR CONT. SEE B16.5 , FBE INT COATED FLANGED.

SHT 003 6 WN FLG , CS A105N , CL150 , FF , STD , 12 PFWC1B15FFSTDTO 1 10. ALL PIPING MATERIAL IS IN ACCORDANCE WITH SAUDI ARAMCO ENGINEERING SPECIFICATION

E 30363930 B16.5 , FBE INT COATED , C/W JACK SAES-L-105 CLASS 1LE0U . ALL EXCEPTIONS ARE NOTED ON THE ISOMETRIC.

REFER BELOW TABLE

N 30307363 SCREWS , PROJ STD DRG NO AC-036630 11. INSULATION SHOWN ON DRAWING

12. REFER TO HYDROSTATIC TEST DIAGRAM FOR TEST LIMIT AND PRESSURE.

EL +101298 7 WN FLG , CS A105N , CL150 , FF , STD , 2 PFWC1B15FFSTD5V 2 13. FOR SMALL BORE LINES (UPTO 1-1/2" ) DIMENSIONS, ROUTING & SUPPORTING SHALL BE FIELD ADJUSTED.

14. ALL DIMENSIONS AND COORDINATES ARE IN MM. CONTRACTOR TO FIELD VERIFY ALL DIMENSIONS PRIOR TO FABRICATION OF THE SPOOL.

FLUSHING RING B16.5 , FBE INT COATED 15. FOR INTERNAL LINED PIPE, LINING SHALL BE DONE AFTER SPOOL FABRICATION & COMPLETION OF ALL HOT WORKS.

FLG6 GAS8 BLT12 FLG7 GAS9 BLT13

16. TIE-IN POINTS CO-ORDINATES TO BE VERIFIED BY CONTRACTOR IN FIELD.

17. PAINTING / COATING SHALL BE IN ACCORDANCE WITH SAES-H-001/002 AND PROJECT APPROVED COATING MAP.

18. SEAL WELDING REQUIREMENT OF THREADED JOINTS SHALL BE AS PER CL.NO.9 OF SAES-L-110.

19. WELDS SHALL BE RADIOGRAPHED AS PER SAES-W-012 (FOR LINES WITH DESIGN CODE ASME B31.8/B31.4) &

CLASS: 15

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL, OR IN PART, SHALL BE OBTAINED FROM THIS DRAWING WITHOUT THE WRITTEN CONSENT OF SAUDI ARAMCO.

AS PER SAES-W-011 (FOR LINES WITH DESIGN CODE ASME B31.3).

16 FIELD MATERIALS

1SV0U 20. CONSTRUCTION OF PLANT PIPING SHALL BE IN ACCORDANCE WITH SAES-L-350.

21. ALL INTERFACE CONNECTIONS WITH OTHER PROJECT (WHEREVER APPLICABLE), CO-ORDINATES AND ELEVATIONS

30 060

SHALL BE VERIFIED BY CONTRACTOR IN FIELD.

22. INTERNAL FBE LINING CONTRACTOR TO VERIFY AND CONFIRM THE BREAK UP FLANGES PRIOR TO THE SPOOL FABRICATION

PT N.B.

1 CLASS: PDIT 23. PLANT COORDINATE SYSTEM HAS BEEN FOLLOWED AS PART OF BI-10-00930.

178 NO DESCRIPTION (INS) STOCK CODE QTY HIGH POINT OF PLANT DATUM ELEVATION 100.000m WHICH EQUALS 2.05m ABOVE MEAN SEA LEVEL

1LE0U 4561

SPOOLS TO BE FABRICATED BY VENDOR

GASKETS NO.

MARK NO. SIZE

WEIGHT NO.

MARK NO. SIZE

WEIGHT

PIECES LBS PIECES LBS

276 138 8 GASKET , SYNTHETIC W/ CENTERING RING , 12 PGGNSC20115BL02 3

51 GAS10

3 FULL FACE , 1/16" (1.6 MM) THK ,

FLG7 GAS9 BLT13

S17 CL150 , B16.5 , B16.21

20 2"N.B. 14

0 9 GASKET , SYNTHETIC W/ CENTERING RING , 2 PGGNSC20115BL02 2

GL01-12 STEM UP

CLASS: FULL FACE , 1/16" (1.6 MM) THK ,

FLG5 GAS8 BLT11 CLASS: 1SV0U CL150 , B16.5 , B16.21

4 4

EL +101574 1LE0U 14 10 GASKET , S31254 WD, FG FILLED , SPIRAL 2 PGG132SZT15BL01 2

27 3 STEM UP WOUND , 4.5 MM THK , UNS S31254 INNER

7

12X2"N.B. RING , UNS S31254 OUTER RING , CL150

2

12X2"N.B. 30 , B16.5 , B16.20

3 SPOOLS TO BE FABRICATED BY SAUDI ARAMCO

47 060

5 NO.

MARK NO. SIZE

NO.

MARK NO. SIZE

178 PDIT BOLTS PIECES PIECES

47 1 4561

951 5 11 STUD BOLT (CONT) , CR-MO A193-B7 , W/ 2 7/8 PB1BLCSACS16002 24

276 16 SF HVY HEX NUTS , A194-2H , B1.1 ,

138 GAS10 CERAMIC-FLUOROPOLYMER COATED , DIA

(IMP) X LEN (MET) - 115 mm Length

26 2"N.B.

3 12 STUD BOLT (CONT) , CR-MO A193-B7 , W/ 2 7/8 PB1BLCSACS16002 12

FOR CONT. SEE 12"N.B. FLUSHING RING SF HVY HEX NUTS , A194-2H , B1.1 ,

FLG5 GAS8 BLT11 1"N.B. CERAMIC-FLUOROPOLYMER COATED , DIA

RB-901102

OW-5082 4 15 (IMP) X LEN (MET) - 135 mm Length

E 30363930 EL +101574 30 13 STUD BOLT (CONT) , CR-MO A193-B7 , W/ 2 5/8 PB1BLCSACS16002 8

CLASS: 8 SF HVY HEX NUTS , A194-2H , B1.1 , REFERENCE DRAWINGS

N 30305969

1LE0U 2 CERAMIC-FLUOROPOLYMER COATED , DIA

EL +100372 DRAWING CONTROL SHEET FOR J.O. 10-00930-0002 RD-086148

CLASS: 12X2"N.B. (IMP) X LEN (MET) - 80 mm Length

PIPING PLAN RA-685466.001

1SV0U FOR CONT. SEE

VALVES / IN-LINE ITEMS P&ID NA-518622.003

SHT 001

E 30363930 14 GATE VALVE , CS A216-WCB , CL150 , FF , 2 PVGC2S15FF8ABWV 2 LINE DESIGNATION TABLE RD-912750

N 30305278 B16.5 , B16.10 DIMS , API 600, OS&Y , HYDROSTATIC TEST DIAGRAM RA-901145-001

EL +101298 BB , B61/B62 BRONZE TRIM (LESS THAN PROJECT PIPING MATERIAL SPECIFICATION RE-685500

16% ZINC) , INT FBE LND BODY , HW PIPE SUPPORT STANDARD RE-901041

INSTRUMENTS

15 FLUSHING RING 2 FLUSHING RING 2

16 PRESSURE DIFFERENTIAL TRANSMITTER 2 060-PDIT-4561 2

REVISION VALIDATION

PIPE SUPPORTS THIS REVISION NO. 00 IS COVERED, FOR ALL APPROVAL AND CERTIFICATION

REQUIREMENTS, PER SAEP-334, UNDER DRAWING COMPLETION CERTIFICATE NO:

17 GUIDE FOR BARE PIPE 12 GL01-12 1 10-00930-0002-001

Worley PIECE MARKS

DESIGN CERTIFICATION

ENGG./DATE

(DESIGN AGENCY)

CERTIFIED BY/DATE

REVIEW FOR KEY DRAWINGS

REQUIRED

CONST. AGENCY/DATE

(SAUDI ARAMCO)

OPERATIONS/DATE BY/DATE

OTHER

3 4 RAM

04/07/23

WAB

04/07/23

MKH

04/07/23

AMM

04/07/23

07 May 2023 REV.NO. DATE REVISION DESCRIPTION

00 04/07/23 ISSUED FOR CONSTRUCTION

JOB ORDER/EWO NO.

THIS REVISION IS NOT TO BE USED FOR

10-00930-0002

ISSUED FOR CONSTRUCTION

CONSTRUCTION UNTIL CERTIFIED AND DATED

SAUDI ARABIAN OIL COMPANY

DRAWING TYPE

ISO 12"-OW-5062-1LE0U ISO

TANK DEWATERING PUMPS G-0117A/B

CHEMICAL DESIGN OPERATING TEST PRESS. TEST RADIOGRAPHY % INSULATION TRACING PAINTING STRESS LINE ID

CLEANING TEMP. PRESS. TEMP. PRESS. (PSIG) MEDIUM SHOP FIELD THK. TYPE SYS NO. TERMINAL NORTH

(DEG. F) (PSIG) (DEG. F) (MM) SAUDI ARABIA

(PSIG) RAS TANURA

PLANT NO. INDEX DRAWING NUMBER SHT. NO. REV. NO.

NO 150 55 120 0.07-13.7 NOTE-12 WATER NOTE-19 NOTE-19 0 mm NO NOTE-17 SYS-02 OW-5062

060 L RB-901084 002 00

Saudi Aramco 2825 ENG. (05/05)

RESTRICTED

SA-TR-799 SMART CADD-03

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 4 Ow 2651 1leouDocument4 pages4 Ow 2651 1leouRene HebaNo ratings yet

- R901085036P00Document1 pageR901085036P00Rene HebaNo ratings yet

- R901085037P00Document1 pageR901085037P00Rene HebaNo ratings yet

- R901085038P00Document1 pageR901085038P00Rene HebaNo ratings yet

- R901084003P00Document1 pageR901084003P00Rene HebaNo ratings yet

- Ta193115 002Document1 pageTa193115 002Rene HebaNo ratings yet

- TB135483 005Document1 pageTB135483 005Rene HebaNo ratings yet

- Np-Hip-Whd-052 - Road Works & RepairDocument6 pagesNp-Hip-Whd-052 - Road Works & RepairRene HebaNo ratings yet

- TB 135483 006Document1 pageTB 135483 006Rene HebaNo ratings yet

- PAC Items U-8 W Remarks (4OCT2022)Document3 pagesPAC Items U-8 W Remarks (4OCT2022)Rene HebaNo ratings yet

- NP-JSA-WHD-003-General Excavation Works (R-5)Document9 pagesNP-JSA-WHD-003-General Excavation Works (R-5)Rene HebaNo ratings yet

- TB 135483 001Document1 pageTB 135483 001Rene HebaNo ratings yet

- PAC Items U-8 - Updating - PIPING MECHANICALDocument1 pagePAC Items U-8 - Updating - PIPING MECHANICALRene HebaNo ratings yet

- Np-Jsa-Whd-038 - Fabrication & Erection of Piping Rev. 03Document10 pagesNp-Jsa-Whd-038 - Fabrication & Erection of Piping Rev. 03Rene HebaNo ratings yet

- Np-Jsa-Whd-061-Equipment Opening and Line Breaking & Tie in WorksDocument9 pagesNp-Jsa-Whd-061-Equipment Opening and Line Breaking & Tie in WorksRene HebaNo ratings yet