Professional Documents

Culture Documents

R901085031P00

R901085031P00

Uploaded by

Rene HebaCopyright:

Available Formats

You might also like

- Inspection and Test Plan: DESCRIPTION: Manhole ConstructionDocument4 pagesInspection and Test Plan: DESCRIPTION: Manhole ConstructionDelta akathehusky50% (2)

- Location: M. H. Del Pilar Street, Polillo, Quezon Project Owner: Mrs. Necerina T. AzagraDocument12 pagesLocation: M. H. Del Pilar Street, Polillo, Quezon Project Owner: Mrs. Necerina T. Azagramgllacuna73% (11)

- R901085032P00Document1 pageR901085032P00Rene HebaNo ratings yet

- R901085028P00Document1 pageR901085028P00Rene HebaNo ratings yet

- R901085036P00Document1 pageR901085036P00Rene HebaNo ratings yet

- R901085037P00Document1 pageR901085037P00Rene HebaNo ratings yet

- R82-002 - Done 5Document1 pageR82-002 - Done 5rsmjuleyNo ratings yet

- Coating FultsDocument4 pagesCoating FultsAhmed BoraeyNo ratings yet

- SF4-A-100-450-100-6-SC G0-6-CS: Bill of MaterialsDocument2 pagesSF4-A-100-450-100-6-SC G0-6-CS: Bill of MaterialsSENTHILNo ratings yet

- M-CB-767101-A-0929 00a 002 CB-767101: Gas Oil Separation Plant (Gosp-4) ABJED0929-01 ABJED0929-02 ABJED0929-03Document1 pageM-CB-767101-A-0929 00a 002 CB-767101: Gas Oil Separation Plant (Gosp-4) ABJED0929-01 ABJED0929-02 ABJED0929-03Hesi KusumaNo ratings yet

- Notes: M-CB-767101-A-0865 00 004Document1 pageNotes: M-CB-767101-A-0865 00 004Hesi KusumaNo ratings yet

- C254977001P Rev01cDocument1 pageC254977001P Rev01cRAJA MOHD IRFAN KHANNo ratings yet

- D43 P 11004 21 - Rev02fDocument1 pageD43 P 11004 21 - Rev02fSajeed ZaheerNo ratings yet

- T013482002V0F1Document1 pageT013482002V0F1haseebrazvi1No ratings yet

- SF6-A-100-450-100-6-CS: Bill of MaterialsDocument7 pagesSF6-A-100-450-100-6-CS: Bill of MaterialsSENTHILNo ratings yet

- Bill of Materials: Standard Detail Reference DrawingsDocument11 pagesBill of Materials: Standard Detail Reference DrawingsSENTHILNo ratings yet

- T013512001V0F1Document1 pageT013512001V0F1haseebrazvi1No ratings yet

- T013514004V0F1Document1 pageT013514004V0F1haseebrazvi1No ratings yet

- M-CB-767102-A-1800 00 001 CB-767102: Gas Oil Separation Plant (Gosp-4) ABAEA1800-01 ABAEA1800-02 ABAEA1800-03Document1 pageM-CB-767102-A-1800 00 001 CB-767102: Gas Oil Separation Plant (Gosp-4) ABAEA1800-01 ABAEA1800-02 ABAEA1800-03Hesi KusumaNo ratings yet

- C533131003VDocument1 pageC533131003VMohamed Wasim ShaikhNo ratings yet

- M-CB-767101-A-0900 00a 001 CB-767101: ABJED0900-02 ABJED0900-03 ABJED0900-04Document1 pageM-CB-767101-A-0900 00a 001 CB-767101: ABJED0900-02 ABJED0900-03 ABJED0900-04Hesi KusumaNo ratings yet

- T013515002V0F1Document1 pageT013515002V0F1haseebrazvi1No ratings yet

- M-CB-767101-A-0930 00 003 CB-767101: ISOM 6"-CWR-6634-1LE2W Cooling Water ReturnDocument1 pageM-CB-767101-A-0930 00 003 CB-767101: ISOM 6"-CWR-6634-1LE2W Cooling Water ReturnHesi KusumaNo ratings yet

- Bill of Materials: Standard Detail Reference DrawingsDocument8 pagesBill of Materials: Standard Detail Reference Drawingsadeelaslam1211No ratings yet

- T013461001V0F1Document1 pageT013461001V0F1haseebrazvi1No ratings yet

- T013482001V0F1Document1 pageT013482001V0F1haseebrazvi1No ratings yet

- T013458001V0F1Document1 pageT013458001V0F1haseebrazvi1No ratings yet

- T013514003V0F1Document1 pageT013514003V0F1haseebrazvi1No ratings yet

- T013519001V0F1Document1 pageT013519001V0F1haseebrazvi1No ratings yet

- Mark Up Priority 5Document11 pagesMark Up Priority 5SAGARNo ratings yet

- BB 016304 001Document1 pageBB 016304 001Abir MohdNo ratings yet

- Erection Materials: DetailDocument1 pageErection Materials: DetailMohammed Omer AliNo ratings yet

- Anchor Assembly (Epab) Schedule: VB-450974 001 M 01C A29 RestrictedDocument1 pageAnchor Assembly (Epab) Schedule: VB-450974 001 M 01C A29 RestrictedbillNo ratings yet

- Twby 07 10048 0007 - 2 - Ifc - 2019 07 26 - 01Document1 pageTwby 07 10048 0007 - 2 - Ifc - 2019 07 26 - 01aung aungNo ratings yet

- Axens Technip India Ltd. Mumbai, India.: Bill of MaterialDocument9 pagesAxens Technip India Ltd. Mumbai, India.: Bill of MaterialSiddhu DudwadkarNo ratings yet

- 9 13 Notes:: Construction IssueDocument1 page9 13 Notes:: Construction IssueХөгжилтэй ЗугаатайNo ratings yet

- 980H PDFDocument2 pages980H PDFIgnacio Lazo JhsúsNo ratings yet

- 416 eDocument2 pages416 earmando vara chavezNo ratings yet

- ag N-Ze 1507 (En)Document1 pageag N-Ze 1507 (En)TOM YEENo ratings yet

- Foundation Offset To ExcavtionDocument1 pageFoundation Offset To ExcavtionAhmed KarimNo ratings yet

- 01 - General Tracker-1Document4 pages01 - General Tracker-1MAGED ELSADIGNo ratings yet

- Planos Electricos Invertex 2 Serie 31875 UpDocument23 pagesPlanos Electricos Invertex 2 Serie 31875 UpHéctorHernándezDíazNo ratings yet

- Ms DD 4850 Civ DWG 0403 - Rev0Document1 pageMs DD 4850 Civ DWG 0403 - Rev0Dita Ardi NNo ratings yet

- Revised Y-Axis Beams PDFDocument28 pagesRevised Y-Axis Beams PDFPetreya UdtatNo ratings yet

- KAAR COW PW IC NTU FZS DWG STR 24623 Rev.01 PDFDocument1 pageKAAR COW PW IC NTU FZS DWG STR 24623 Rev.01 PDFSatyanarayana MukkuNo ratings yet

- BLDG PlanDocument1 pageBLDG PlanMax BenizaNo ratings yet

- r1-Sts 20 0119 Well Covering-ModelDocument1 pager1-Sts 20 0119 Well Covering-ModelPriyanka SapteNo ratings yet

- Desalination Plant Asbuilt S2Document1 pageDesalination Plant Asbuilt S2Berlin Andrew SionNo ratings yet

- Hegesztéstechnikai Utasítások Welding Instructions: NIS A.d., Novi SadDocument1 pageHegesztéstechnikai Utasítások Welding Instructions: NIS A.d., Novi SadBanditAkosNo ratings yet

- NabilDocument1 pageNabilAnonymous BZQOJwWIh6No ratings yet

- WHP121 ASFCA 10 Q0103 0001 Rev.20Document3 pagesWHP121 ASFCA 10 Q0103 0001 Rev.20Minh DoNo ratings yet

- ID - 1-First Floor - Sheet - I705 - FIRST - FURNITURE LAYOUTDocument1 pageID - 1-First Floor - Sheet - I705 - FIRST - FURNITURE LAYOUTkarthikeyan dhanasekaranNo ratings yet

- 1914 Boronia Park - A503 (A) DetailsDocument1 page1914 Boronia Park - A503 (A) DetailsariNo ratings yet

- NDRS FOB Part-1 Superstructure NOC DrawingsDocument3 pagesNDRS FOB Part-1 Superstructure NOC Drawingsrakesh bhartiNo ratings yet

- Block A2 - FEB 24 2021Document15 pagesBlock A2 - FEB 24 2021soso.doniNo ratings yet

- Close 20-100 Full WDDocument13 pagesClose 20-100 Full WDNurSyuhada ANo ratings yet

- 260858-E-0000-Lay-08101 SoeDocument1 page260858-E-0000-Lay-08101 SoeAnanthan SrijithNo ratings yet

- Starbucks: General Notes Project Contacts Index of Sheets Abbreviations Architectural Symbol LegendDocument56 pagesStarbucks: General Notes Project Contacts Index of Sheets Abbreviations Architectural Symbol LegendMmr Pré MoldadosNo ratings yet

- Symbols Description Symbols VSD VariableDocument24 pagesSymbols Description Symbols VSD VariableRifqi IsbillyNo ratings yet

- Data Pendukung Kuantitas Back Up Data QuantityDocument4 pagesData Pendukung Kuantitas Back Up Data QuantityZab HaziqNo ratings yet

- Ra-620575-001 (A-1)Document1 pageRa-620575-001 (A-1)muthuvelaaNo ratings yet

- 4 Ow 2651 1leouDocument4 pages4 Ow 2651 1leouRene HebaNo ratings yet

- R901085036P00Document1 pageR901085036P00Rene HebaNo ratings yet

- R901085038P00Document1 pageR901085038P00Rene HebaNo ratings yet

- TB135483 005Document1 pageTB135483 005Rene HebaNo ratings yet

- R901084002P00Document1 pageR901084002P00Rene HebaNo ratings yet

- R901085037P00Document1 pageR901085037P00Rene HebaNo ratings yet

- Ta193115 002Document1 pageTa193115 002Rene HebaNo ratings yet

- TB 135483 006Document1 pageTB 135483 006Rene HebaNo ratings yet

- R901084003P00Document1 pageR901084003P00Rene HebaNo ratings yet

- PAC Items U-8 W Remarks (4OCT2022)Document3 pagesPAC Items U-8 W Remarks (4OCT2022)Rene HebaNo ratings yet

- PAC Items U-8 - Updating - PIPING MECHANICALDocument1 pagePAC Items U-8 - Updating - PIPING MECHANICALRene HebaNo ratings yet

- TB 135483 001Document1 pageTB 135483 001Rene HebaNo ratings yet

- NP-JSA-WHD-003-General Excavation Works (R-5)Document9 pagesNP-JSA-WHD-003-General Excavation Works (R-5)Rene HebaNo ratings yet

- Np-Jsa-Whd-038 - Fabrication & Erection of Piping Rev. 03Document10 pagesNp-Jsa-Whd-038 - Fabrication & Erection of Piping Rev. 03Rene HebaNo ratings yet

- Np-Jsa-Whd-061-Equipment Opening and Line Breaking & Tie in WorksDocument9 pagesNp-Jsa-Whd-061-Equipment Opening and Line Breaking & Tie in WorksRene HebaNo ratings yet

- Np-Hip-Whd-052 - Road Works & RepairDocument6 pagesNp-Hip-Whd-052 - Road Works & RepairRene HebaNo ratings yet

- DISCIPLINE: Non-Destructive Testing GROUP: Building Materials - Reinforced Concrete Structures Test: Pile Integrity TestDocument1 pageDISCIPLINE: Non-Destructive Testing GROUP: Building Materials - Reinforced Concrete Structures Test: Pile Integrity TesternarendersainiNo ratings yet

- Ingi FLANGE INSULATION GASKETDocument4 pagesIngi FLANGE INSULATION GASKETroyNo ratings yet

- Method Statement For Construction of Box Culvert - Anil KumarDocument3 pagesMethod Statement For Construction of Box Culvert - Anil KumarAsad AshfaqNo ratings yet

- Retaining Walls and Road PavementDocument14 pagesRetaining Walls and Road PavementPraise SamuelNo ratings yet

- 4 Simple Concepts of Prehistoric ArchitectureDocument7 pages4 Simple Concepts of Prehistoric ArchitecturepiolopxsNo ratings yet

- Brick Roman 1Document178 pagesBrick Roman 1Romuald MilcarekNo ratings yet

- LC33-e-DAS-GAD-2021 03 05-R8-NEW RL290.40Document1 pageLC33-e-DAS-GAD-2021 03 05-R8-NEW RL290.40Thrk TwrNo ratings yet

- BASEMENTDocument1 pageBASEMENTAyushi VermaNo ratings yet

- 00.syllabus in Construction Materials and TestingDocument10 pages00.syllabus in Construction Materials and TestingCarjez LoveNo ratings yet

- Lightweight ConcreteDocument2 pagesLightweight ConcreteAnish PandeyNo ratings yet

- A Technical Report AmadiDocument51 pagesA Technical Report Amadiscrewball's animesNo ratings yet

- Weygan ResearchDocument7 pagesWeygan ResearchKaila WeyganNo ratings yet

- Case Study On Weave Designs and Fabric Mechanical PropertiesDocument7 pagesCase Study On Weave Designs and Fabric Mechanical PropertiesSwati Sharma100% (1)

- Unit 5 - Stress & StrainsDocument14 pagesUnit 5 - Stress & StrainsMidhul MineeshNo ratings yet

- Brochure - Masterflow 9500Document12 pagesBrochure - Masterflow 9500vinayNo ratings yet

- Q-FSI Corporate ProfileDocument12 pagesQ-FSI Corporate ProfileDavid JacksonNo ratings yet

- ACI-373r 97Document26 pagesACI-373r 97Pablo Augusto Krahl100% (1)

- NEBOSH International Construction CertificateDocument10 pagesNEBOSH International Construction Certificateahmed HOSNY100% (1)

- Specification For Base & Surface CoursesDocument62 pagesSpecification For Base & Surface Coursessri10888No ratings yet

- Sipco Brimo-Kol Pouring Grade Sealant: More Color, More ChoiceDocument2 pagesSipco Brimo-Kol Pouring Grade Sealant: More Color, More Choiceمحمد عزتNo ratings yet

- Steel Trusses Roof Framing DetailsDocument26 pagesSteel Trusses Roof Framing DetailsqweqweNo ratings yet

- 2021 Product Presentation Asian Coatings Phil 10-13-2021Document96 pages2021 Product Presentation Asian Coatings Phil 10-13-2021Phio Josh JarlegoNo ratings yet

- Red ElectricaDocument2 pagesRed ElectricaFelipe JaramilloNo ratings yet

- Tritosil W70-TDSDocument4 pagesTritosil W70-TDSRANo ratings yet

- Annex A. Handling and Storage of Sheet Piles - En12063-1999Document9 pagesAnnex A. Handling and Storage of Sheet Piles - En12063-1999Alex Sandro Borges PereiraNo ratings yet

- Petra University (Architecture - Ebook) - Metal - Building - Systems - Design - and - Specifications-20610-Part151Document2 pagesPetra University (Architecture - Ebook) - Metal - Building - Systems - Design - and - Specifications-20610-Part151Bharat SinghNo ratings yet

- Thep Khong GiDocument9 pagesThep Khong GiQuân BùiNo ratings yet

- The Methods of Using Low Cost HousingDocument20 pagesThe Methods of Using Low Cost HousingAamna FatimaNo ratings yet

R901085031P00

R901085031P00

Uploaded by

Rene HebaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

R901085031P00

R901085031P00

Uploaded by

Rene HebaCopyright:

Available Formats

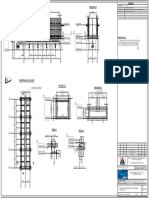

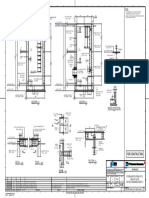

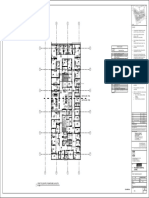

UP STANDARD DETAIL REFERENCE DRAWINGS

DETAIL OF HEAVY WELDING BOSSES FOR THREADED CONNECTIONS AE-036175

N

AWAY AWAY

CONSTRUCTION-NOTES AND DETAILS FOR ISOMETRIC PIPING

INSULATION DETAILS FOR HOT PIPING

AD-036627

AA-036911

SHOP MATERIALS INSULATION DETAILS FOR COLD PIPING AA-036913

INSTALLATION OF JACK SCREWS FOR FLANGED JOINTS AC-036630

TOWARD TOWARD PT N.B.

NOTES

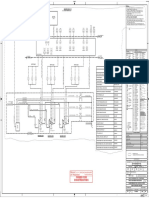

NO DESCRIPTION (INS) STOCK CODE QTY

1. MATERIAL SHOWN WITH A BROKEN LINE AND SPOOLS LISTED IN THE SAUDI ARAMCO

DOWN

PIPE FABRICATION LIST ARE NOT TO BE FURNISHED BY THE VENDOR.

2. PIPING DETAILS SHALL BE CUT AT ALL POINTS MARKED F.W. (FIELD WELD).

1 PIPE , CS API 5L-B-PSL2 , SMLS , BE , 10 PPPCPVSMBESTD5F 53.0 M 3. EACH FABRICATED SECTION SHALL BE CLEARLY MARKED WITH ITS CODE NUMBER.

STD , B36.10M , FBE INT COATED 4. UNLESS OTHERWISE NOTED. (A) ALL DIMENSIONS ARE TO C OR FACE OF FLANGES.

(B) BOLT HOLES ON FLANGES STRADDLE C . (C) WELDING ELBOWS ARE LONG RADIUS.

10"N.B. 5. FABRICATION SHALL BE IN ACCORDANCE WITH SAUDI ARAMCO SPECIFICATION 01-SAMSS-10.

FITTINGS 6. GASKET ALLOWANCE

7. PIPING MATERIAL IS

2 45 LR ELBOW , CS A234-WPB , SMLS , BE , 10 P4LC34SMBESTDE5 1

STD , B16.9 , FBE INT COATED PIPE SIZE SCHEDULE SPECIFICATION

REFER MTO REFER MTO REFER MTO

FLANGES

3 WN FLG , CS A105N , CL150 , FF , STD , 10 PFWC1B15FFSTD5V 10

B16.5 , FBE INT COATED

8. WELDING STRESS RELIEF - YES NO

X

PIPE SUPPORTS RADIOGRAPHY % 100% X-RAY SPOT X-RAY 01-SAMSS-10 SHOP FIELD

9. TESTING SHOP HYDROSTATIC TEST - YES NO

4 WEAR PAD FOR PIPE 10 WA01-10-750-CS 2 THE SHOP HYDROSTATIC TEST SHALL BE CARRIED OUT ON PIECES HAVING ALL ENDS

FLANGED.

1991

10. ALL PIPING MATERIAL IS IN ACCORDANCE WITH SAUDI ARAMCO ENGINEERING SPECIFICATION

FOR CONT. SEE SAES-L-105 CLASS 1LE0U . ALL EXCEPTIONS ARE NOTED ON THE ISOMETRIC.

FIELD MATERIALS REFER BELOW TABLE

FLG3 GAS5 BLT6 SHT 030 11. INSULATION SHOWN ON DRAWING

12. REFER TO HYDROSTATIC TEST DIAGRAM FOR TEST LIMIT AND PRESSURE.

E 30224485 13. FOR SMALL BORE LINES (UPTO 1-1/2" ) DIMENSIONS, ROUTING & SUPPORTING SHALL BE FIELD ADJUSTED.

PT N.B. 14. ALL DIMENSIONS AND COORDINATES ARE IN MM. CONTRACTOR TO FIELD VERIFY ALL DIMENSIONS PRIOR TO FABRICATION OF THE SPOOL.

N 31000472 15. FOR INTERNAL LINED PIPE, LINING SHALL BE DONE AFTER SPOOL FABRICATION & COMPLETION OF ALL HOT WORKS.

S4 NO DESCRIPTION (INS) STOCK CODE QTY 16. TIE-IN POINTS CO-ORDINATES TO BE VERIFIED BY CONTRACTOR IN FIELD.

EL +100387 17. PAINTING / COATING SHALL BE IN ACCORDANCE WITH SAES-H-001/002 AND PROJECT APPROVED COATING MAP.

WA01-10-750-CS GASKETS

18. SEAL WELDING REQUIREMENT OF THREADED JOINTS SHALL BE AS PER CL.NO.9 OF SAES-L-110.

19. WELDS SHALL BE RADIOGRAPHED AS PER SAES-W-012 (FOR LINES WITH DESIGN CODE ASME B31.8/B31.4) &

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL, OR IN PART, SHALL BE OBTAINED FROM THIS DRAWING WITHOUT THE WRITTEN CONSENT OF SAUDI ARAMCO.

AS PER SAES-W-011 (FOR LINES WITH DESIGN CODE ASME B31.3).

FLG3 5 GASKET , SYNTHETIC W/ CENTERING RING , 10 PGGNSC20115BL02 5 20. CONSTRUCTION OF PLANT PIPING SHALL BE IN ACCORDANCE WITH SAES-L-350.

21. ALL INTERFACE CONNECTIONS WITH OTHER PROJECT (WHEREVER APPLICABLE), CO-ORDINATES AND ELEVATIONS

S7 FULL FACE , 1/16" (1.6 MM) THK , SHALL BE VERIFIED BY CONTRACTOR IN FIELD.

22. INTERNAL FBE LINING CONTRACTOR TO VERIFY AND CONFIRM THE BREAK UP FLANGES PRIOR TO THE SPOOL FABRICATION

0 CL150 , B16.5 , B16.21 23. PLANT COORDINATE SYSTEM HAS BEEN FOLLOWED AS PART OF BI-10-00930.

GL01-10 00 HIGH POINT OF PLANT DATUM ELEVATION 100.000m WHICH EQUALS 2.05m ABOVE MEAN SEA LEVEL

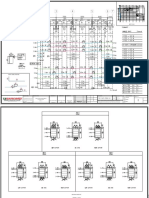

12 000 SPOOLS TO BE FABRICATED BY VENDOR

6

BOLTS NO.

1990 104 PIECES

MARK NO. SIZE

WEIGHT

LBS

NO.

PIECES

MARK NO. SIZE

WEIGHT

LBS

6 STUD BOLT (CONT) , CR-MO A193-B7 , W/ 2 7/8 PB1BLCSACS16002 60

0 1 S7 SF HVY HEX NUTS , A194-2H , B1.1 ,

00

FLG3 12 00 GL01-10 CERAMIC-FLUOROPOLYMER COATED , DIA

FLG3 GAS5 BLT6 60 (IMP) X LEN (MET) - 115 mm Length

REST

1988

105

1 FLG3 GAS5 BLT6 PIPE SUPPORTS

S7 0

GL01-10 FLG3 200 S8 7 GUIDE FOR BARE PIPE 10 GL01-10 5

1 00

60 106 LS01-10

1987 8 LINE STOP FOR BARE PIPE 10 LS01-10 1

REST SPOOLS TO BE FABRICATED BY SAUDI ARAMCO

1

00 PIECE MARKS NO. NO.

MARK NO. SIZE MARK NO. SIZE

0 S4

PIECES PIECES

FLG3 GAS5 BLT6 12 00

60 107 WA01-10-750-CS 104 105 106 107 108

S7

1985

GL01-10

183 1

32 FLG3 GAS5 BLT6

60

REST

108 FLG3

1

REST

2 259

10"N.B.

S7

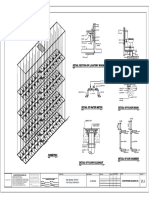

REFERENCE DRAWINGS

FLG3 GL01-10

DRAWING CONTROL SHEET FOR J.O. 10-00930-0002 RD-086148

FOR CONT. SEE

SHT 032 PIPING PLAN RA-685466.001

E 30170263 P&ID NA-518622.008

183

N 31000289 LINE DESIGNATION TABLE RD-912750

EL +100387 HYDROSTATIC TEST DIAGRAM RA-901147-001

PROJECT PIPING MATERIAL SPECIFICATION RE-685500

PIPE SUPPORT STANDARD RE-901041

REVISION VALIDATION

THIS REVISION NO. 00 IS COVERED, FOR ALL APPROVAL AND CERTIFICATION

REQUIREMENTS, PER SAEP-334, UNDER DRAWING COMPLETION CERTIFICATE NO:

10-00930-0002-001

Worley DESIGN CERTIFICATION

ENGG./DATE

(DESIGN AGENCY)

CERTIFIED BY/DATE

REVIEW FOR KEY DRAWINGS

REQUIRED

CONST. AGENCY/DATE

(SAUDI ARAMCO)

OPERATIONS/DATE BY/DATE

OTHER

RAM WAB MKH AMM

04/07/23 04/07/23 04/07/23 04/07/23

07 May 2023 REV.NO. DATE REVISION DESCRIPTION

00 04/07/23 ISSUED FOR CONSTRUCTION

JOB ORDER/EWO NO.

THIS REVISION IS NOT TO BE USED FOR

10-00930-0002

ISSUED FOR CONSTRUCTION

CONSTRUCTION UNTIL CERTIFIED AND DATED

SAUDI ARABIAN OIL COMPANY

DRAWING TYPE

ISO 10"-OW-5063-1LE0U ISO

EQUALIZATION TANKS

CHEMICAL DESIGN OPERATING TEST PRESS. TEST RADIOGRAPHY % INSULATION TRACING PAINTING STRESS LINE ID

CLEANING TEMP. PRESS. TEMP. PRESS. (PSIG) MEDIUM SHOP FIELD THK. TYPE SYS NO. TERMINAL NORTH

(DEG. F) (PSIG) (DEG. F) (MM) SAUDI ARABIA

(PSIG) RAS TANURA

PLANT NO. INDEX DRAWING NUMBER SHT. NO. REV. NO.

NO 150 262 120 49 NOTE-12 WATER NOTE-19 NOTE-19 0 mm NO NOTE-17 SYS-02 OW-5063

060 L RB-901085 031 00

Saudi Aramco 2825 ENG. (05/05)

SA-TR-799 RESTRICTED SMART CADD-03

You might also like

- Inspection and Test Plan: DESCRIPTION: Manhole ConstructionDocument4 pagesInspection and Test Plan: DESCRIPTION: Manhole ConstructionDelta akathehusky50% (2)

- Location: M. H. Del Pilar Street, Polillo, Quezon Project Owner: Mrs. Necerina T. AzagraDocument12 pagesLocation: M. H. Del Pilar Street, Polillo, Quezon Project Owner: Mrs. Necerina T. Azagramgllacuna73% (11)

- R901085032P00Document1 pageR901085032P00Rene HebaNo ratings yet

- R901085028P00Document1 pageR901085028P00Rene HebaNo ratings yet

- R901085036P00Document1 pageR901085036P00Rene HebaNo ratings yet

- R901085037P00Document1 pageR901085037P00Rene HebaNo ratings yet

- R82-002 - Done 5Document1 pageR82-002 - Done 5rsmjuleyNo ratings yet

- Coating FultsDocument4 pagesCoating FultsAhmed BoraeyNo ratings yet

- SF4-A-100-450-100-6-SC G0-6-CS: Bill of MaterialsDocument2 pagesSF4-A-100-450-100-6-SC G0-6-CS: Bill of MaterialsSENTHILNo ratings yet

- M-CB-767101-A-0929 00a 002 CB-767101: Gas Oil Separation Plant (Gosp-4) ABJED0929-01 ABJED0929-02 ABJED0929-03Document1 pageM-CB-767101-A-0929 00a 002 CB-767101: Gas Oil Separation Plant (Gosp-4) ABJED0929-01 ABJED0929-02 ABJED0929-03Hesi KusumaNo ratings yet

- Notes: M-CB-767101-A-0865 00 004Document1 pageNotes: M-CB-767101-A-0865 00 004Hesi KusumaNo ratings yet

- C254977001P Rev01cDocument1 pageC254977001P Rev01cRAJA MOHD IRFAN KHANNo ratings yet

- D43 P 11004 21 - Rev02fDocument1 pageD43 P 11004 21 - Rev02fSajeed ZaheerNo ratings yet

- T013482002V0F1Document1 pageT013482002V0F1haseebrazvi1No ratings yet

- SF6-A-100-450-100-6-CS: Bill of MaterialsDocument7 pagesSF6-A-100-450-100-6-CS: Bill of MaterialsSENTHILNo ratings yet

- Bill of Materials: Standard Detail Reference DrawingsDocument11 pagesBill of Materials: Standard Detail Reference DrawingsSENTHILNo ratings yet

- T013512001V0F1Document1 pageT013512001V0F1haseebrazvi1No ratings yet

- T013514004V0F1Document1 pageT013514004V0F1haseebrazvi1No ratings yet

- M-CB-767102-A-1800 00 001 CB-767102: Gas Oil Separation Plant (Gosp-4) ABAEA1800-01 ABAEA1800-02 ABAEA1800-03Document1 pageM-CB-767102-A-1800 00 001 CB-767102: Gas Oil Separation Plant (Gosp-4) ABAEA1800-01 ABAEA1800-02 ABAEA1800-03Hesi KusumaNo ratings yet

- C533131003VDocument1 pageC533131003VMohamed Wasim ShaikhNo ratings yet

- M-CB-767101-A-0900 00a 001 CB-767101: ABJED0900-02 ABJED0900-03 ABJED0900-04Document1 pageM-CB-767101-A-0900 00a 001 CB-767101: ABJED0900-02 ABJED0900-03 ABJED0900-04Hesi KusumaNo ratings yet

- T013515002V0F1Document1 pageT013515002V0F1haseebrazvi1No ratings yet

- M-CB-767101-A-0930 00 003 CB-767101: ISOM 6"-CWR-6634-1LE2W Cooling Water ReturnDocument1 pageM-CB-767101-A-0930 00 003 CB-767101: ISOM 6"-CWR-6634-1LE2W Cooling Water ReturnHesi KusumaNo ratings yet

- Bill of Materials: Standard Detail Reference DrawingsDocument8 pagesBill of Materials: Standard Detail Reference Drawingsadeelaslam1211No ratings yet

- T013461001V0F1Document1 pageT013461001V0F1haseebrazvi1No ratings yet

- T013482001V0F1Document1 pageT013482001V0F1haseebrazvi1No ratings yet

- T013458001V0F1Document1 pageT013458001V0F1haseebrazvi1No ratings yet

- T013514003V0F1Document1 pageT013514003V0F1haseebrazvi1No ratings yet

- T013519001V0F1Document1 pageT013519001V0F1haseebrazvi1No ratings yet

- Mark Up Priority 5Document11 pagesMark Up Priority 5SAGARNo ratings yet

- BB 016304 001Document1 pageBB 016304 001Abir MohdNo ratings yet

- Erection Materials: DetailDocument1 pageErection Materials: DetailMohammed Omer AliNo ratings yet

- Anchor Assembly (Epab) Schedule: VB-450974 001 M 01C A29 RestrictedDocument1 pageAnchor Assembly (Epab) Schedule: VB-450974 001 M 01C A29 RestrictedbillNo ratings yet

- Twby 07 10048 0007 - 2 - Ifc - 2019 07 26 - 01Document1 pageTwby 07 10048 0007 - 2 - Ifc - 2019 07 26 - 01aung aungNo ratings yet

- Axens Technip India Ltd. Mumbai, India.: Bill of MaterialDocument9 pagesAxens Technip India Ltd. Mumbai, India.: Bill of MaterialSiddhu DudwadkarNo ratings yet

- 9 13 Notes:: Construction IssueDocument1 page9 13 Notes:: Construction IssueХөгжилтэй ЗугаатайNo ratings yet

- 980H PDFDocument2 pages980H PDFIgnacio Lazo JhsúsNo ratings yet

- 416 eDocument2 pages416 earmando vara chavezNo ratings yet

- ag N-Ze 1507 (En)Document1 pageag N-Ze 1507 (En)TOM YEENo ratings yet

- Foundation Offset To ExcavtionDocument1 pageFoundation Offset To ExcavtionAhmed KarimNo ratings yet

- 01 - General Tracker-1Document4 pages01 - General Tracker-1MAGED ELSADIGNo ratings yet

- Planos Electricos Invertex 2 Serie 31875 UpDocument23 pagesPlanos Electricos Invertex 2 Serie 31875 UpHéctorHernándezDíazNo ratings yet

- Ms DD 4850 Civ DWG 0403 - Rev0Document1 pageMs DD 4850 Civ DWG 0403 - Rev0Dita Ardi NNo ratings yet

- Revised Y-Axis Beams PDFDocument28 pagesRevised Y-Axis Beams PDFPetreya UdtatNo ratings yet

- KAAR COW PW IC NTU FZS DWG STR 24623 Rev.01 PDFDocument1 pageKAAR COW PW IC NTU FZS DWG STR 24623 Rev.01 PDFSatyanarayana MukkuNo ratings yet

- BLDG PlanDocument1 pageBLDG PlanMax BenizaNo ratings yet

- r1-Sts 20 0119 Well Covering-ModelDocument1 pager1-Sts 20 0119 Well Covering-ModelPriyanka SapteNo ratings yet

- Desalination Plant Asbuilt S2Document1 pageDesalination Plant Asbuilt S2Berlin Andrew SionNo ratings yet

- Hegesztéstechnikai Utasítások Welding Instructions: NIS A.d., Novi SadDocument1 pageHegesztéstechnikai Utasítások Welding Instructions: NIS A.d., Novi SadBanditAkosNo ratings yet

- NabilDocument1 pageNabilAnonymous BZQOJwWIh6No ratings yet

- WHP121 ASFCA 10 Q0103 0001 Rev.20Document3 pagesWHP121 ASFCA 10 Q0103 0001 Rev.20Minh DoNo ratings yet

- ID - 1-First Floor - Sheet - I705 - FIRST - FURNITURE LAYOUTDocument1 pageID - 1-First Floor - Sheet - I705 - FIRST - FURNITURE LAYOUTkarthikeyan dhanasekaranNo ratings yet

- 1914 Boronia Park - A503 (A) DetailsDocument1 page1914 Boronia Park - A503 (A) DetailsariNo ratings yet

- NDRS FOB Part-1 Superstructure NOC DrawingsDocument3 pagesNDRS FOB Part-1 Superstructure NOC Drawingsrakesh bhartiNo ratings yet

- Block A2 - FEB 24 2021Document15 pagesBlock A2 - FEB 24 2021soso.doniNo ratings yet

- Close 20-100 Full WDDocument13 pagesClose 20-100 Full WDNurSyuhada ANo ratings yet

- 260858-E-0000-Lay-08101 SoeDocument1 page260858-E-0000-Lay-08101 SoeAnanthan SrijithNo ratings yet

- Starbucks: General Notes Project Contacts Index of Sheets Abbreviations Architectural Symbol LegendDocument56 pagesStarbucks: General Notes Project Contacts Index of Sheets Abbreviations Architectural Symbol LegendMmr Pré MoldadosNo ratings yet

- Symbols Description Symbols VSD VariableDocument24 pagesSymbols Description Symbols VSD VariableRifqi IsbillyNo ratings yet

- Data Pendukung Kuantitas Back Up Data QuantityDocument4 pagesData Pendukung Kuantitas Back Up Data QuantityZab HaziqNo ratings yet

- Ra-620575-001 (A-1)Document1 pageRa-620575-001 (A-1)muthuvelaaNo ratings yet

- 4 Ow 2651 1leouDocument4 pages4 Ow 2651 1leouRene HebaNo ratings yet

- R901085036P00Document1 pageR901085036P00Rene HebaNo ratings yet

- R901085038P00Document1 pageR901085038P00Rene HebaNo ratings yet

- TB135483 005Document1 pageTB135483 005Rene HebaNo ratings yet

- R901084002P00Document1 pageR901084002P00Rene HebaNo ratings yet

- R901085037P00Document1 pageR901085037P00Rene HebaNo ratings yet

- Ta193115 002Document1 pageTa193115 002Rene HebaNo ratings yet

- TB 135483 006Document1 pageTB 135483 006Rene HebaNo ratings yet

- R901084003P00Document1 pageR901084003P00Rene HebaNo ratings yet

- PAC Items U-8 W Remarks (4OCT2022)Document3 pagesPAC Items U-8 W Remarks (4OCT2022)Rene HebaNo ratings yet

- PAC Items U-8 - Updating - PIPING MECHANICALDocument1 pagePAC Items U-8 - Updating - PIPING MECHANICALRene HebaNo ratings yet

- TB 135483 001Document1 pageTB 135483 001Rene HebaNo ratings yet

- NP-JSA-WHD-003-General Excavation Works (R-5)Document9 pagesNP-JSA-WHD-003-General Excavation Works (R-5)Rene HebaNo ratings yet

- Np-Jsa-Whd-038 - Fabrication & Erection of Piping Rev. 03Document10 pagesNp-Jsa-Whd-038 - Fabrication & Erection of Piping Rev. 03Rene HebaNo ratings yet

- Np-Jsa-Whd-061-Equipment Opening and Line Breaking & Tie in WorksDocument9 pagesNp-Jsa-Whd-061-Equipment Opening and Line Breaking & Tie in WorksRene HebaNo ratings yet

- Np-Hip-Whd-052 - Road Works & RepairDocument6 pagesNp-Hip-Whd-052 - Road Works & RepairRene HebaNo ratings yet

- DISCIPLINE: Non-Destructive Testing GROUP: Building Materials - Reinforced Concrete Structures Test: Pile Integrity TestDocument1 pageDISCIPLINE: Non-Destructive Testing GROUP: Building Materials - Reinforced Concrete Structures Test: Pile Integrity TesternarendersainiNo ratings yet

- Ingi FLANGE INSULATION GASKETDocument4 pagesIngi FLANGE INSULATION GASKETroyNo ratings yet

- Method Statement For Construction of Box Culvert - Anil KumarDocument3 pagesMethod Statement For Construction of Box Culvert - Anil KumarAsad AshfaqNo ratings yet

- Retaining Walls and Road PavementDocument14 pagesRetaining Walls and Road PavementPraise SamuelNo ratings yet

- 4 Simple Concepts of Prehistoric ArchitectureDocument7 pages4 Simple Concepts of Prehistoric ArchitecturepiolopxsNo ratings yet

- Brick Roman 1Document178 pagesBrick Roman 1Romuald MilcarekNo ratings yet

- LC33-e-DAS-GAD-2021 03 05-R8-NEW RL290.40Document1 pageLC33-e-DAS-GAD-2021 03 05-R8-NEW RL290.40Thrk TwrNo ratings yet

- BASEMENTDocument1 pageBASEMENTAyushi VermaNo ratings yet

- 00.syllabus in Construction Materials and TestingDocument10 pages00.syllabus in Construction Materials and TestingCarjez LoveNo ratings yet

- Lightweight ConcreteDocument2 pagesLightweight ConcreteAnish PandeyNo ratings yet

- A Technical Report AmadiDocument51 pagesA Technical Report Amadiscrewball's animesNo ratings yet

- Weygan ResearchDocument7 pagesWeygan ResearchKaila WeyganNo ratings yet

- Case Study On Weave Designs and Fabric Mechanical PropertiesDocument7 pagesCase Study On Weave Designs and Fabric Mechanical PropertiesSwati Sharma100% (1)

- Unit 5 - Stress & StrainsDocument14 pagesUnit 5 - Stress & StrainsMidhul MineeshNo ratings yet

- Brochure - Masterflow 9500Document12 pagesBrochure - Masterflow 9500vinayNo ratings yet

- Q-FSI Corporate ProfileDocument12 pagesQ-FSI Corporate ProfileDavid JacksonNo ratings yet

- ACI-373r 97Document26 pagesACI-373r 97Pablo Augusto Krahl100% (1)

- NEBOSH International Construction CertificateDocument10 pagesNEBOSH International Construction Certificateahmed HOSNY100% (1)

- Specification For Base & Surface CoursesDocument62 pagesSpecification For Base & Surface Coursessri10888No ratings yet

- Sipco Brimo-Kol Pouring Grade Sealant: More Color, More ChoiceDocument2 pagesSipco Brimo-Kol Pouring Grade Sealant: More Color, More Choiceمحمد عزتNo ratings yet

- Steel Trusses Roof Framing DetailsDocument26 pagesSteel Trusses Roof Framing DetailsqweqweNo ratings yet

- 2021 Product Presentation Asian Coatings Phil 10-13-2021Document96 pages2021 Product Presentation Asian Coatings Phil 10-13-2021Phio Josh JarlegoNo ratings yet

- Red ElectricaDocument2 pagesRed ElectricaFelipe JaramilloNo ratings yet

- Tritosil W70-TDSDocument4 pagesTritosil W70-TDSRANo ratings yet

- Annex A. Handling and Storage of Sheet Piles - En12063-1999Document9 pagesAnnex A. Handling and Storage of Sheet Piles - En12063-1999Alex Sandro Borges PereiraNo ratings yet

- Petra University (Architecture - Ebook) - Metal - Building - Systems - Design - and - Specifications-20610-Part151Document2 pagesPetra University (Architecture - Ebook) - Metal - Building - Systems - Design - and - Specifications-20610-Part151Bharat SinghNo ratings yet

- Thep Khong GiDocument9 pagesThep Khong GiQuân BùiNo ratings yet

- The Methods of Using Low Cost HousingDocument20 pagesThe Methods of Using Low Cost HousingAamna FatimaNo ratings yet