Professional Documents

Culture Documents

Uni16 FAQ

Uni16 FAQ

Uploaded by

efrain bulaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Uni16 FAQ

Uni16 FAQ

Uploaded by

efrain bulaCopyright:

Available Formats

Frequently Asked Questions

1. What is a Horizontal Lifeline?

A Horizontal Lifeline is a safety system that consists of a number of components,

which provides continuous attachment and hands free working to the user or users.

It should either restrain the user from accessing the area of risk or catch them in

the event of a fall whilst doing the minimum of damage to the user and system.

Typically a horizontal lifeline system utilises a cable attached at either end to a

structure and supported at regular intervals by brackets. The user attaches to the

cable via a mechanism that will allow them to move along the system and across the

brackets without the need for detaching.

2. Why choose Uniline for a horizontal lifeline system?

Uniline is a new, revolutionary product that offers exceptional benefits. It is low

stretch, has low dynamic sag, has excellent shock absorbing capabilities and has

little elasticity. This means that less of the load generated in the event of a fall is

transferred to the structure resulting in far lower end loads. The low elasticity

results in a ‘soft drop,’ i.e. the user will not bounce around following a fall and risk

further trauma as they might with a wire based system.

Uniline has a breaking strength of 76 kN, which is equivalent to that of a 12mm

stainless steel cable and almost double that of an 8 mm stainless steel cable. In

addition Uniline has a safety factor of over 3:1, which exceeds the safety factors

of 8mm stainless steel cable.

All of these features make Uniline a more flexible system, enabling it to span

greater distances than stainless steel cable between supports and accommodate a

wider range of retractable fall arrest devices. It also results in a most cost

effective solution.

3. Are there standards to govern the installation of Horizontal Lifelines?

Yes, most countries have recognised standards, which effectively governs the

manufacture and installation of horizontal and vertical safety systems and

anchorage points. In Europe all anchorage points and horizontal lifeline systems

should be designed, manufactured and installed in accordance with EN 795. Vertical

Safety Systems should conform to EN 353-1 and EN353-2. In America OSHA

standards govern the manufacture and installation of such products. Should you

need any further information, please contact us.

4. Does the Uniline Horizontal Lifeline meet those standards?

Yes, Uniline has been tested in accordance with all world standards.

5. Why do we need to install a horizontal lifeline system?

Health and Safety Regulations states that it is the employer’s responsibility to

protect the employee. When a person is working at height near to an exposed edge

or fall risk, suitable protection is required to protect them from falling.

A Uniline Horizontal Lifeline System offers a cost effective and efficient means of

providing such protection.

6. What is Uniline?

Uniline is a unique Polyester Parallel Fibre Cable, protected by a neoprene jacket and

a further outer polyester braided cover. Uniline’s strength is in the cable core and is

an incredible 76kN. (Over 7 tonnes).

7. Is Uniline a rope?

It’s a lot more than just a rope. Uniline® has been in service in the world’s most

demanding environments for over twenty years and has proven itself time and time

again. Used by Utilities Companies to pull cables above ground and beneath the

Oceans of the world, it has withstood a diverse range of environmental conditions.

For further information see our Properties of Uniline information sheet.

8. Is Uniline non-conductive?

Uniline has very high dielectric properties and is effectively non-conductive.

9. How is Uniline affected by weather conditions?

Uniline is waterproof and is unaffected by ice and salt water. Polyester is the most

resistant of all synthetic fibres for UV resistance and the neoprene inner cover

that protects the core of the cable resists degradation from the sun and ozone.

Uniline has a long in service life expectancy. For further information see our

Properties of Uniline information sheet.

10. How is Uniline affected by Chemical Contaminants?

Uniline is highly resistant to most mineral acids and is virtually unaffected by alkalis.

Uniline Safety Systems have details of a wide range of test data, so for more

specific information please contact us.

11. Can we clean the Uniline cable?

It can be hosed off or washed with a mild household detergent.

12. Is Uniline resistant to cuts?

Uniline is very strong with two outer layers protecting the inner core, where the

products strength lies. It is very difficult to cut Uniline under normal circumstances

and installers have special cable cutters to help them.

13. How does the user pass the intermediate brackets without detaching?

The patented Unigrab is designed to self orientate as it approaches the

intermediate bracket to enable the link to pass over the bracket unhindered.

14. How do I enter/ exit the Uniline system?

The Unigrab is designed in such away that you can enter or exit the system from any

point along its length. Once attached, it is impossible to inadvertently detach

yourself from the Uniline. See User Instruction manual for further information.

15. Are special tools required for installation?

A small hand tool for securing the end termination is required and a heat shrink hot

gun is used to finish the system neatly. No on site swaging is required. Only

companies trained and certificated by Uniline Safety Systems are approved to

install the Uniline System.

16. How do Uniline Safety Systems know that their installers are installing the

systems correctly?

Thorough on-going training and the operation of a bi-annual audit procedure.

17. What distances can the Uniline Horizontal Lifeline span?

The Uniline Horizontal Lifeline can span up to 50 metres without intermediate

support due to its unique capabilities. This means less penetrations and less

intermediate supports than other lifelines. System parameters should be defined by

your approved installer once they have familiarised themselves with site conditions.

18. How can we be confident that our installation will be safe?

With the results of our testing procedures we have developed a sophisticated

computer simulation programme, which calculates the results of different system

configurations, numbers of users, etc and gives results such as fall distances and

end loads for your system. This programme is available to all our approved installers

and all installations are pre-checked using this simulation.

In addition Uniline Installers are selected for their ability to provide comprehensive

service and expertise in height safety to our Customers.

19. How many users can use the system?

The computer simulation can determine the maximum number of users. We would

generally recommend a maximum of six, although this figure may be exceeded or

reduced according to specific local conditions.

20. How often should the Uniline System be inspected?

In order to guarantee the on-going integrity of the system, and in accordance with

current regulations, we recommend that the system be inspected once a year by a

Uniline Safety Systems approved installer or competent person

21. What user equipment is required?

A full body harness is required by law. The user should attach to the system with

the Unigrab device and a shock absorbing lanyard or retractable fall arrest device.

Your PPE should be supplied by your installer in order to ensure compatibility with

the system and must be properly certified in accordance with current national

regulations/standards.

22. Where can we use the Uniline Horizontal Lifeline?

Uniline is the most flexible horizontal lifeline system in the world and can be used

for a wide range of height safety access applications. Please see our Uniline

Brochure or our product pages on our web site http://www.unilinesafety.com/ for

further information.

You might also like

- Data Analyst Associate Cert Training ResourcesDocument4 pagesData Analyst Associate Cert Training ResourcesjoseNo ratings yet

- User Instruction Manual Dbi Sala Advanced Digital Winch: Instructions For The Following Series ProductsDocument24 pagesUser Instruction Manual Dbi Sala Advanced Digital Winch: Instructions For The Following Series ProductssergioNo ratings yet

- Grade 11 General Mathematics Instructional PlanDocument4 pagesGrade 11 General Mathematics Instructional PlanAnthony CastilloNo ratings yet

- Uni-8 User Instruction Manual ENDocument18 pagesUni-8 User Instruction Manual EN2012sinkersNo ratings yet

- UniRail System User InstructionsDocument23 pagesUniRail System User InstructionsnandeteclimberNo ratings yet

- UPO2000E English ManualDocument66 pagesUPO2000E English ManualAugusto RadaelliNo ratings yet

- I 20user ManualDocument88 pagesI 20user Manualmdwxz52r9No ratings yet

- Keyence IV SeriesDocument110 pagesKeyence IV SeriesIssac Nochebuena100% (1)

- Modulator Series Speaker Arrays: Installation and Maintenance InstructionsDocument21 pagesModulator Series Speaker Arrays: Installation and Maintenance InstructionsnezarmahjoubNo ratings yet

- SynthSeven OM 5L V2Document92 pagesSynthSeven OM 5L V2Roberto CabreraNo ratings yet

- UT4000 Series Digital Storage Oscilloscope User ManualDocument99 pagesUT4000 Series Digital Storage Oscilloscope User ManualanumasterNo ratings yet

- Lifelines InformationDocument6 pagesLifelines Information88sanNo ratings yet

- Technical Notice PROGRESS ADJUST I 1Document28 pagesTechnical Notice PROGRESS ADJUST I 1amadordiazrubioNo ratings yet

- Fall Arrest: Product CatalogueDocument60 pagesFall Arrest: Product CatalogueBorislav VulićNo ratings yet

- YOGA Tab 3 8": Hardware Maintenance ManualDocument90 pagesYOGA Tab 3 8": Hardware Maintenance ManualGerman CaceresNo ratings yet

- DALSA Boa Manual en PDFDocument110 pagesDALSA Boa Manual en PDFCarlos MusellaNo ratings yet

- The Work at Height Safety Association: Technical Guidance Note 8Document7 pagesThe Work at Height Safety Association: Technical Guidance Note 8tiagofernandes000No ratings yet

- CIBANO 500-AppNote-Testing CB With Undervoltage coil-ENUDocument11 pagesCIBANO 500-AppNote-Testing CB With Undervoltage coil-ENUMila CalderónNo ratings yet

- Op-87436 87437 Im 96M11892 GB WW 1085-2Document2 pagesOp-87436 87437 Im 96M11892 GB WW 1085-2Santi ElisahNo ratings yet

- Ideapad Y400y500 HMM 1st Edition Sep 2012 EnglishDocument103 pagesIdeapad Y400y500 HMM 1st Edition Sep 2012 EnglishJoshua WashingtonNo ratings yet

- Baseline 25 Series Network Mini Dome Camera Quick Start GuideDocument49 pagesBaseline 25 Series Network Mini Dome Camera Quick Start GuideAntonio SantosNo ratings yet

- Iv-Series-Pcsoft Um 207GB 244003 e 1122-4 PDFDocument302 pagesIv-Series-Pcsoft Um 207GB 244003 e 1122-4 PDFrimou000No ratings yet

- Moovi 30.50 Ul - 120v - Boom BarrierDocument13 pagesMoovi 30.50 Ul - 120v - Boom BarriergatemotorsupplieruaeNo ratings yet

- Network Dome Camera: Quick Start GuideDocument34 pagesNetwork Dome Camera: Quick Start GuideMario Ezequiel Rodriguez RiveroNo ratings yet

- 04 04 17 SisemaqDocument286 pages04 04 17 SisemaqOsmar JrNo ratings yet

- 8536 Dbi Sala Uni 8 Oh BCR enDocument12 pages8536 Dbi Sala Uni 8 Oh BCR enFlorin PătrulescuNo ratings yet

- IV-H Series IV-HG Series: User's ManualDocument134 pagesIV-H Series IV-HG Series: User's ManualEdgar Orendain ArriagaNo ratings yet

- Acti9 CatalogueDocument29 pagesActi9 CatalogueGabriela TiuNo ratings yet

- Digitech Rp200a Manuel Utilisateur en 30521Document40 pagesDigitech Rp200a Manuel Utilisateur en 30521Magno DelmiroNo ratings yet

- Is MicroinstDocument30 pagesIs MicroinstDanelyNo ratings yet

- Elpro 240U-E Industrial WIFI Wireless EthernetSerial Device Server User ManualDocument87 pagesElpro 240U-E Industrial WIFI Wireless EthernetSerial Device Server User ManualfaeduardoNo ratings yet

- FrogLine Tuff Post Concrete Round HandbookDocument21 pagesFrogLine Tuff Post Concrete Round HandbookNirooban VigneswaranNo ratings yet

- Anti-Corrosion Network Dome Camera: Quick Start GuideDocument38 pagesAnti-Corrosion Network Dome Camera: Quick Start Guiderendi valentinoNo ratings yet

- Life LineDocument10 pagesLife LineMukdad Al KaabiNo ratings yet

- 2015 June Manual Instruction For Hikvision NVR Network Set UpDocument225 pages2015 June Manual Instruction For Hikvision NVR Network Set UpMëñghëñg ŁïmNo ratings yet

- Micro Vee ManualDocument18 pagesMicro Vee Manualdanske79No ratings yet

- STH10 Manual - 255341ADocument29 pagesSTH10 Manual - 255341Aedilorenzo1No ratings yet

- User Guide: SeriesDocument20 pagesUser Guide: SeriesDennis OngNo ratings yet

- UD06510B - Baseline - Quick Start Guide of E Series Network Speed Dome - V5.5.0 - 20170815(快速指南)Document41 pagesUD06510B - Baseline - Quick Start Guide of E Series Network Speed Dome - V5.5.0 - 20170815(快速指南)Trần Thanh HòaNo ratings yet

- Lenovo Tab 2 A7-30 HMM en 201507Document66 pagesLenovo Tab 2 A7-30 HMM en 201507lavaeyeNo ratings yet

- FCTB Manual 255326N2_0_0Document68 pagesFCTB Manual 255326N2_0_0kris nonsoNo ratings yet

- Manuals XRN-6410DB4XRN-6410B4XRN-3210B4 230411 ENDocument131 pagesManuals XRN-6410DB4XRN-6410B4XRN-3210B4 230411 ENaparichithudooNo ratings yet

- Lenovo Tab 3-10 HMM en v1.0 201510 PDFDocument103 pagesLenovo Tab 3-10 HMM en v1.0 201510 PDFAlexis PerezNo ratings yet

- Tgn01 Guidance On The Selection Use Maintenance and Inspection of Retractable Type Fall ArrestorsDocument8 pagesTgn01 Guidance On The Selection Use Maintenance and Inspection of Retractable Type Fall ArrestorsandrewhwNo ratings yet

- UNI T UTD2102 User ManualDocument65 pagesUNI T UTD2102 User ManualPetr KratkyNo ratings yet

- User Instruction Manual Adjust-A-Net Personnel Net SystemDocument8 pagesUser Instruction Manual Adjust-A-Net Personnel Net SystemTiago FernandesNo ratings yet

- HiSpeed FXi Operator ManualDocument258 pagesHiSpeed FXi Operator Manualnery castroNo ratings yet

- 2-120 2-240 Models: Federal Signal Corporation'SDocument35 pages2-120 2-240 Models: Federal Signal Corporation'SSabino M RomeroNo ratings yet

- IS_FCDocument24 pagesIS_FCkris nonsoNo ratings yet

- Video Intercom D Series Door Station Quick Start Guide - V1.3.0 - 20160116Document51 pagesVideo Intercom D Series Door Station Quick Start Guide - V1.3.0 - 20160116David QuijadaNo ratings yet

- Uas Owners Manual Xa Extraction ArmDocument16 pagesUas Owners Manual Xa Extraction ArmThamilselvan VengatasalamNo ratings yet

- Installer Instructions: WWW - Etnice.co - ZaDocument20 pagesInstaller Instructions: WWW - Etnice.co - ZaJack SmithNo ratings yet

- X3158 - enUS - 3158 - U Type IOM - 112420Document32 pagesX3158 - enUS - 3158 - U Type IOM - 112420Edson MirandaNo ratings yet

- In-Sight 7000 Series Vision System Installation ManualDocument42 pagesIn-Sight 7000 Series Vision System Installation ManualjglunaNo ratings yet

- 19 Personal Fall Protection: Travel-Restraint Systems Fall-Arrest SystemsDocument6 pages19 Personal Fall Protection: Travel-Restraint Systems Fall-Arrest SystemsStill SatNo ratings yet

- Ultrakey Plus: Installation and User GuideDocument74 pagesUltrakey Plus: Installation and User GuideGilmer Vásquez PérezNo ratings yet

- Network Bullet Camera: Quick Start GuideDocument28 pagesNetwork Bullet Camera: Quick Start GuideR&L Multisistemas PanamaNo ratings yet

- Lenovo Ideapad S100 Hardware Maintenance Manual (English)Document79 pagesLenovo Ideapad S100 Hardware Maintenance Manual (English)isa'No ratings yet

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesFrom EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesRating: 5 out of 5 stars5/5 (1)

- Stealth Protocols - Using Phone to Create Feedback Loops in Closed Surveillance Systems: Stealth Protocols, #1From EverandStealth Protocols - Using Phone to Create Feedback Loops in Closed Surveillance Systems: Stealth Protocols, #1No ratings yet

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsFrom EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsNo ratings yet

- RoofSafe Anchor Instruction ManualDocument16 pagesRoofSafe Anchor Instruction Manualefrain bulaNo ratings yet

- Uni16 UIMDocument15 pagesUni16 UIMefrain bulaNo ratings yet

- Free Fall Space Calculator Issue 1Document1 pageFree Fall Space Calculator Issue 1efrain bulaNo ratings yet

- 5400 South 122 East Avenue Tulsa, OK 74146 1-800-879-8000: Hilti, IncDocument14 pages5400 South 122 East Avenue Tulsa, OK 74146 1-800-879-8000: Hilti, Incefrain bulaNo ratings yet

- Re 500Document16 pagesRe 500efrain bulaNo ratings yet

- Engineered Anchor Range BrochureDocument4 pagesEngineered Anchor Range Brochureefrain bulaNo ratings yet

- FT Equipos de Escape Respiración Honeywell Herracruz Sa.Document2 pagesFT Equipos de Escape Respiración Honeywell Herracruz Sa.efrain bulaNo ratings yet

- SRP 229 - Brochure - PD-SAR FamilyDocument6 pagesSRP 229 - Brochure - PD-SAR Familyefrain bulaNo ratings yet

- IperDocument3 pagesIperefrain bulaNo ratings yet

- 1498048898-Patrol - Declaration of ConformityDocument1 page1498048898-Patrol - Declaration of Conformityefrain bulaNo ratings yet

- Modelo LTXDocument2 pagesModelo LTXefrain bulaNo ratings yet

- B313426-Spec-Sheet HonrtDocument2 pagesB313426-Spec-Sheet Honrtefrain bulaNo ratings yet

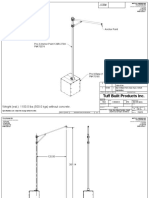

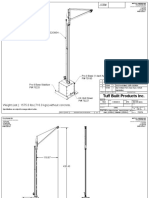

- Tuff Built Products Inc.: Anchor PointDocument2 pagesTuff Built Products Inc.: Anchor Pointefrain bulaNo ratings yet

- Rotho Blaas Munkakotelzet 2022Document77 pagesRotho Blaas Munkakotelzet 2022efrain bulaNo ratings yet

- Fall Protection With Freedom: Robust Functional DiscreetDocument12 pagesFall Protection With Freedom: Robust Functional Discreetefrain bulaNo ratings yet

- Tuff Built Products Inc.: Pro-9 Mast, 120R-132/385H PT# 70349Document2 pagesTuff Built Products Inc.: Pro-9 Mast, 120R-132/385H PT# 70349efrain bulaNo ratings yet

- VGJT 32Document2 pagesVGJT 32efrain bulaNo ratings yet

- Thellp - Iraup: Certificate of ConformanceDocument3 pagesThellp - Iraup: Certificate of Conformanceefrain bulaNo ratings yet

- Coral Triangle PhiDocument105 pagesCoral Triangle PhiDenny Boy MochranNo ratings yet

- The 12 Elements of An Information Security Policy - Reader ViewDocument7 pagesThe 12 Elements of An Information Security Policy - Reader ViewHoney DhaliwalNo ratings yet

- Supplemental Math High School G 7 4rth QDocument8 pagesSupplemental Math High School G 7 4rth QdapitomaryjoyNo ratings yet

- Diagnostic ExampleDocument17 pagesDiagnostic Exampleapi-296055206No ratings yet

- Compaction Trends Shale CleanSands Gulf of MexicoDocument8 pagesCompaction Trends Shale CleanSands Gulf of MexicoAfonso ElvaNo ratings yet

- Direct To FCE WorksheetsDocument64 pagesDirect To FCE WorksheetsElena MelenoiDe100% (2)

- Tutorial Letter 203/2/2017: General Chemistry 1BDocument18 pagesTutorial Letter 203/2/2017: General Chemistry 1BLeigh MakanNo ratings yet

- How To Connect A Laptop To A ProjectorDocument87 pagesHow To Connect A Laptop To A ProjectorPurificacion, AnabeaNo ratings yet

- Notes For Chemistry PracticalsDocument32 pagesNotes For Chemistry Practicalsj0ntj2ivjyNo ratings yet

- Kondensasi Aldol Silang PDFDocument7 pagesKondensasi Aldol Silang PDFRiska Elya VenilitaNo ratings yet

- AGRIC43 Unit03Document10 pagesAGRIC43 Unit03Maria Lourdes samontinaNo ratings yet

- Full Ebook of Daily Routines To Jump Start Math Class Elementary School 1St Edition John J Sangiovanni 2 Online PDF All ChapterDocument24 pagesFull Ebook of Daily Routines To Jump Start Math Class Elementary School 1St Edition John J Sangiovanni 2 Online PDF All Chapterandereabat100% (4)

- Aba For Slps Bcba AutismoDocument48 pagesAba For Slps Bcba AutismoRafael AlvesNo ratings yet

- Obo Commissioning 9Document75 pagesObo Commissioning 998257002No ratings yet

- 2252-Article Text-3992-1-10-20190421Document22 pages2252-Article Text-3992-1-10-20190421Etab BarakatNo ratings yet

- Web Pages With MVC3 and Razor SyntaxDocument282 pagesWeb Pages With MVC3 and Razor Syntaxozamaro100% (1)

- Lagos Audit Manual - Part OneDocument83 pagesLagos Audit Manual - Part OneAndy WynneNo ratings yet

- Research On Moment of Inertia Measurement Method2019Document7 pagesResearch On Moment of Inertia Measurement Method2019ait oubella marouaneNo ratings yet

- Fsı Analysis For Helix StrakesDocument22 pagesFsı Analysis For Helix StrakestalhaNo ratings yet

- Ringwood Pha 1Document167 pagesRingwood Pha 1api-608967166No ratings yet

- Spring 2024 - CS610 - 2Document2 pagesSpring 2024 - CS610 - 2Shahmir Ali MughalNo ratings yet

- The 7 Habits of Highly Effective People Covey en 3515Document5 pagesThe 7 Habits of Highly Effective People Covey en 3515tania_986550485100% (1)

- Eirseptember 2018Document2,927 pagesEirseptember 2018IvyNo ratings yet

- Safety Plan 2023Document4 pagesSafety Plan 2023Raphy BrionesNo ratings yet

- Be Electronics and Telecommunication Engineering Semester 6 2022 November Cellular Networks CN Pattern 2019Document2 pagesBe Electronics and Telecommunication Engineering Semester 6 2022 November Cellular Networks CN Pattern 2019micekeyNo ratings yet

- Maintenance ScheduleDocument12 pagesMaintenance ScheduleVanHoangNo ratings yet

- Agriculture AhmedabadDocument33 pagesAgriculture AhmedabadKrupam Thetenders.com100% (1)

- Song Review Ysabelle CuevasDocument4 pagesSong Review Ysabelle Cuevasnurul amaliaNo ratings yet