Professional Documents

Culture Documents

Technical Notes and Specifications: Front End Cylinder, Bush - Eye (Spherical Bearing)

Technical Notes and Specifications: Front End Cylinder, Bush - Eye (Spherical Bearing)

Uploaded by

Eddy OrtegaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Notes and Specifications: Front End Cylinder, Bush - Eye (Spherical Bearing)

Technical Notes and Specifications: Front End Cylinder, Bush - Eye (Spherical Bearing)

Uploaded by

Eddy OrtegaCopyright:

Available Formats

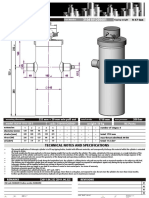

Front end cylinder, bush - eye (spherical bearing) Part Number 4312801694001 Tipping weight 46-85 ton

SR5 40

6

60

50

192

1438 ±5

G1

300

52.5

54

240

mounting dimension 1438 mm + 20 mm min pull out total stroke 4330 mm max pressure 200 bar

model: HFB 4330 169 4 code: 4312801694001 weight: 203 kg HS Penta

extension 1 2 3 4 - - - - - -- -- number of stages: 4

diameter [mm] 169 149 129 111 -- -- -- -- -- -- --

stroke [mm] 1075 1080 1085 1090 -- -- -- -- -- -- -- total: 4330 mm

thrust [kN] 449 349 261 194 -- -- -- -- -- -- -- max thrust admitted: 224 kN

oil [dm³] 24.1 18.8 14.2 10.5 -- -- -- -- -- -- -- total: 67.6 dm³

TECHNICAL NOTES AND SPECIFICATIONS

• The normal application of telescopic cylinder is to lift up tipping bodies, loaded with different materials, and consequently discharge this material whilst the cylinder is extended

all along its stroke.

• The body weight plus the max payload are the max tipping weight that can be raised by the cylinder. This value, calculated at the max pressure, is a rough indication of the

tipping power of the cylinder and must be used as a first criteria for the selection of the cylinder. The real tipping mass can only be calculated by the design engineer of the

dump truck, and must take into account the geometry of the dump body and operating conditions. Never exceed the maximum thrust.

• Never exceed maximum pressure.

• The cylinder has been designed for loads along the longitudinal axis: the cylinder is a lifting device only and may not be used as structural member or be subject to side load.

• Chrome coating type CRN (40 h corrosion test ISO 9227-rating 9 ISO 10289 / minimum thickness: 15 µm) on rod stage Ø111.

• H.S.PENTA warranty does not apply to any kind of corrosion of coated or non-coated parts. See terms of warranty.

• Maximum extension speed less than 0.2 m/s.

• Hydraulic oil temperature admitted between -40°C and +100°C.

• In case the cylinders must be stored, do not remove the package. Store them in a dry place, not exposed to rain. Do not store the cylinders for more than 6 (six) months.

• Further specifications see mounting instructions, hydraulic oil specification sheet, user & maintenance manual.

REMARKS [2012.02.22] [2012.04.12] REVISIONS

Last stage Ø111 chromed (Elemento terminale Ø111 cromato) 2012.04.12 - Modificata boccola da Ø55 a Ø52.5 01

02

03

04

Alberto Cavina Modulo " Figurino" - 2008.10.27 Andrea Ricci

2012.04.12 15:34:23 +02'00' 2012.04.13 08:15:21 +

02'00'

Sono l'autore di questo Ho rivisto questo

Firma non verificata documento. Firma non verificata documento.

You might also like

- Cat 3304 3306 Industrial Marine Service ManualDocument827 pagesCat 3304 3306 Industrial Marine Service Manualruss mathis100% (35)

- Nissan Y61 Engine MechanicalDocument65 pagesNissan Y61 Engine Mechanicalblumng100% (2)

- Scania DC13 - Industrial Engine - PDF Installation ManualDocument39 pagesScania DC13 - Industrial Engine - PDF Installation ManualGem RNo ratings yet

- Repair Manual ZF GearboxDocument69 pagesRepair Manual ZF Gearboxjann100% (1)

- Surface Grinding Machine CPMDocument48 pagesSurface Grinding Machine CPMSamer SalibaNo ratings yet

- ED4W L Series OriginalmanualDocument44 pagesED4W L Series OriginalmanualKester OssaiNo ratings yet

- BOWIN SERVICE MANUAL (Ceiling LED) PDFDocument28 pagesBOWIN SERVICE MANUAL (Ceiling LED) PDFCarolina Diaz MurillasNo ratings yet

- Cilindro Penta Hydraulic PowerDocument1 pageCilindro Penta Hydraulic PowerUniversity FilesNo ratings yet

- Manual Skoda Octavia - Gearbox m5 002Document94 pagesManual Skoda Octavia - Gearbox m5 002Cornea Horatiu Sebastian100% (1)

- 16760910-KP6MEAOM-Komatsu S6d170e-2 Sa6d170-2 Saa6d170-2 Shop ManualDocument344 pages16760910-KP6MEAOM-Komatsu S6d170e-2 Sa6d170-2 Saa6d170-2 Shop Manualravinder.singh91968No ratings yet

- Transsmicion Mitsubishi Montero f5mr1-f55mr2Document12 pagesTranssmicion Mitsubishi Montero f5mr1-f55mr2Miguel ruizNo ratings yet

- A Polyhydron Group Company: DescriptionDocument2 pagesA Polyhydron Group Company: DescriptionRenjithSivaNo ratings yet

- 18 Engine Lubrication - Unimog 435 Workshop ManualDocument30 pages18 Engine Lubrication - Unimog 435 Workshop ManualJuan JapNo ratings yet

- Gts Binotto RuDocument1 pageGts Binotto RuDeivis CedeñoNo ratings yet

- Tightening TorqueDocument8 pagesTightening TorqueGaurav MaithilNo ratings yet

- Nissanqd32engineservicemanual 160831215636Document108 pagesNissanqd32engineservicemanual 160831215636Miguel GomezNo ratings yet

- TSPG - Engine Tools 2-139 A 2-220 PDFDocument82 pagesTSPG - Engine Tools 2-139 A 2-220 PDFAKshay100% (1)

- 6D1l 9Document1 page6D1l 9Jasm LiuNo ratings yet

- SCANIA Suspension BT200 Work DescDocument32 pagesSCANIA Suspension BT200 Work DescHeri Suryo0% (1)

- User'S Manul: 3Gp Series Steam Boiler Feed PumpDocument25 pagesUser'S Manul: 3Gp Series Steam Boiler Feed PumpEdinsonUribeTorresNo ratings yet

- 01 4TNV98T-ZCSTY 规格参数表-英文Document4 pages01 4TNV98T-ZCSTY 规格参数表-英文Eric CNo ratings yet

- 20 Cooling - Unimog 435 Workshop ManualDocument20 pages20 Cooling - Unimog 435 Workshop ManualJuan JapNo ratings yet

- Partie 2Document45 pagesPartie 2Alain GARNIERNo ratings yet

- SBB365 Drum BrakeDocument8 pagesSBB365 Drum BrakerodrigomessiasNo ratings yet

- Lit2323 r7 Ch400b Parts ListDocument28 pagesLit2323 r7 Ch400b Parts ListRoman cupulNo ratings yet

- Drain Transmission Oil From Torque Converter PDFDocument1 pageDrain Transmission Oil From Torque Converter PDFLance LundbergNo ratings yet

- HGS HSM SL 20 007 - Adjustment of Valve ClearanceDocument66 pagesHGS HSM SL 20 007 - Adjustment of Valve Clearanceajshsu5682No ratings yet

- List of Critical Spare Part BCMDocument26 pagesList of Critical Spare Part BCMPMA creationsNo ratings yet

- 0.75kW - 1750rpmDocument1 page0.75kW - 1750rpmanush_swaminathanNo ratings yet

- Clutch: Clutch 21A Clutch Overhaul 21 BDocument12 pagesClutch: Clutch 21A Clutch Overhaul 21 BRolly CebanesNo ratings yet

- Clutch HSG 9200 4WDDocument2 pagesClutch HSG 9200 4WDBrianNo ratings yet

- 21B Clutch OverhaulDocument8 pages21B Clutch OverhaulRolly CebanesNo ratings yet

- Radial Piston Hydraulic Motor Hägglunds Cab: Re 15354, Edition: 12 2016, Bosch Rexroth AbDocument44 pagesRadial Piston Hydraulic Motor Hägglunds Cab: Re 15354, Edition: 12 2016, Bosch Rexroth Abjose salvadorNo ratings yet

- Especificaciones Zapatas D3GDocument4 pagesEspecificaciones Zapatas D3GJose YatoNo ratings yet

- D4114ZG3B Engine Parts Catalog CLG614Document85 pagesD4114ZG3B Engine Parts Catalog CLG614Abas AbasariNo ratings yet

- Fuso PDFDocument5,804 pagesFuso PDFAlvin Siew Wai50% (2)

- Manual de Servicio FUSO FE, FG, FH, FK, FM, 1996-2001 - Parte1 - 1Document232 pagesManual de Servicio FUSO FE, FG, FH, FK, FM, 1996-2001 - Parte1 - 1Brian VilchisNo ratings yet

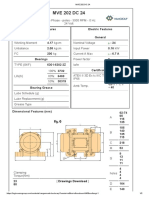

- MVE 202 DC 24: Drawings DownloadDocument2 pagesMVE 202 DC 24: Drawings DownloadAmol SarinNo ratings yet

- Engine Assembly - Dismantle and Assemble (Engine Removed) (21 134 8)Document30 pagesEngine Assembly - Dismantle and Assemble (Engine Removed) (21 134 8)judas1432No ratings yet

- Reductor Gripper 120TDocument1 pageReductor Gripper 120TgustavoaponteunoNo ratings yet

- Tech Data C6.6Document62 pagesTech Data C6.6Andrey100% (2)

- Volvo D 20 d24 Service Manual 1983Document8 pagesVolvo D 20 d24 Service Manual 1983sadie100% (62)

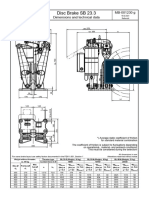

- Dellner Bubenzer SB 23.3Document2 pagesDellner Bubenzer SB 23.3AKA jeanNo ratings yet

- Service Manual Deutz Dde 2012Document172 pagesService Manual Deutz Dde 2012Oscar Tello100% (2)

- Cat Helimax 2016 Esp 1Document74 pagesCat Helimax 2016 Esp 1HKM IngenierosNo ratings yet

- Group 27 Rear Axle: 1. Wheel Hub and Brake Drum 2. Reduction and Differential 3. Limited Slip DifferentialDocument84 pagesGroup 27 Rear Axle: 1. Wheel Hub and Brake Drum 2. Reduction and Differential 3. Limited Slip DifferentialNeoGaraNo ratings yet

- Toro 38180 Snowthrower Parts CatalogDocument16 pagesToro 38180 Snowthrower Parts CatalogDanNo ratings yet

- Disassembling and Reassembling Diesel Engine Turbocharger Based On The Manufacturer's ManualDocument21 pagesDisassembling and Reassembling Diesel Engine Turbocharger Based On The Manufacturer's ManualChriscarl De LimaNo ratings yet

- Re91008 04-05Document16 pagesRe91008 04-05Rafał DworakNo ratings yet

- Mshe 112 002 - C4Document18 pagesMshe 112 002 - C4Automan IntertradeNo ratings yet

- Catalogue Wheel Track and Pump Drives - Protetto PDFDocument1 pageCatalogue Wheel Track and Pump Drives - Protetto PDFkaribean007No ratings yet

- Type 06198: Overflow ValvesDocument2 pagesType 06198: Overflow ValvesabdulfetahNo ratings yet

- Tipo Argano / Winch Type: The Dimensions Shown Can Be Used As ReferenceDocument10 pagesTipo Argano / Winch Type: The Dimensions Shown Can Be Used As ReferencePaolo StablumNo ratings yet

- Kpz-Cylinder Compact PN 0822 392 304-Page 43Document89 pagesKpz-Cylinder Compact PN 0822 392 304-Page 43Jamin SmtpngNo ratings yet

- Alpha Series - Front End Cylinder With Single Eye: FE A129-3-03880-001-K1600 Item No. Tipping Weight 43 - 59 Ton 70544230Document2 pagesAlpha Series - Front End Cylinder With Single Eye: FE A129-3-03880-001-K1600 Item No. Tipping Weight 43 - 59 Ton 70544230NurdinNo ratings yet

- Permanent Magnet Brake. PMB SeriesDocument8 pagesPermanent Magnet Brake. PMB SeriesAshok BhatNo ratings yet

- Hystea: TransmissionDocument33 pagesHystea: TransmissionMelwyn FernandesNo ratings yet

- 11B PDFDocument54 pages11B PDFCao LanNo ratings yet

- Catalogo Itap InglesDocument13 pagesCatalogo Itap InglesJarlissonmartinsNo ratings yet

- Duq1 184e PDFDocument5 pagesDuq1 184e PDFRajiv RanjanNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- 1 Replacement Hydraulic PartsDocument52 pages1 Replacement Hydraulic PartsEddy Ortega100% (3)

- ABER Catalogue EspañolDocument70 pagesABER Catalogue EspañolEddy OrtegaNo ratings yet

- 9 Aluminum Gear PumpDocument10 pages9 Aluminum Gear PumpEddy OrtegaNo ratings yet

- US Seal MFG Catalog 2015Document218 pagesUS Seal MFG Catalog 2015Eddy OrtegaNo ratings yet

- DanfossPartNumbers NEWDocument902 pagesDanfossPartNumbers NEWEddy Ortega0% (1)

- Catalogo HydratechDocument21 pagesCatalogo HydratechEddy OrtegaNo ratings yet

- B Series: Pumps and MotorsDocument13 pagesB Series: Pumps and MotorsEddy OrtegaNo ratings yet

- Bomba de Pistones Sauer Danfoss Serie 40Document44 pagesBomba de Pistones Sauer Danfoss Serie 40Eddy Ortega100% (2)

- Transit Mixer Axial Piston Motor: Size 070/084/089Document27 pagesTransit Mixer Axial Piston Motor: Size 070/084/089Eddy OrtegaNo ratings yet

- Integrated Fittings: Combination Valves Flow ControlsDocument32 pagesIntegrated Fittings: Combination Valves Flow ControlsEddy OrtegaNo ratings yet

- Valves: Truck Valves Ball ValvesDocument78 pagesValves: Truck Valves Ball ValvesEddy OrtegaNo ratings yet

- Parts Book P20-P50/51-P75/76-P315 Gear Pumps and Motors: Distributor ProgramDocument37 pagesParts Book P20-P50/51-P75/76-P315 Gear Pumps and Motors: Distributor ProgramEddy OrtegaNo ratings yet

- 1708FP-BLK: Downloaded From Manuals Search EngineDocument2 pages1708FP-BLK: Downloaded From Manuals Search EngineEddy OrtegaNo ratings yet

- PVG 048 065 075 100 & 130 PumpDocument32 pagesPVG 048 065 075 100 & 130 PumpEddy OrtegaNo ratings yet

- Mac Formatting ElCapDocument7 pagesMac Formatting ElCapJC SardiniaNo ratings yet

- Assessment of Capital Budgeting Technique in Evaluating The Profitability of Manufacturing Firm With Reference To SME in RajasthanDocument5 pagesAssessment of Capital Budgeting Technique in Evaluating The Profitability of Manufacturing Firm With Reference To SME in RajasthanSunita MishraNo ratings yet

- Nirma: UniversityDocument2 pagesNirma: UniversityBHENSDADIYA KEVIN PRABHULALNo ratings yet

- PracResearch2 Grade-12 Q4 Mod5 Data-Collection-Presentation-and-Analysis Version4Document59 pagesPracResearch2 Grade-12 Q4 Mod5 Data-Collection-Presentation-and-Analysis Version4MichiOdevilasNo ratings yet

- XT Series BrochureDocument4 pagesXT Series BrochureErick MendezNo ratings yet

- Minor Project II Guidelines 070920Document7 pagesMinor Project II Guidelines 070920Sandesh PaithaneNo ratings yet

- RulebookDocument8 pagesRulebookEren KoyunoğluNo ratings yet

- Monthly Questions (February) (E-Math)Document48 pagesMonthly Questions (February) (E-Math)Wei Ting ChuiNo ratings yet

- Monorail Hoist SystemDocument17 pagesMonorail Hoist SystemypatelsNo ratings yet

- Technical Information On How The Planning Run Works: ContentsDocument50 pagesTechnical Information On How The Planning Run Works: ContentsMárcio NascimentoNo ratings yet

- Buenavista Central Elementary SchoolDocument2 pagesBuenavista Central Elementary Schoolanon_108827268No ratings yet

- CC 2Document43 pagesCC 2iamsabaalyNo ratings yet

- UntitledDocument168 pagesUntitledjerald mendesNo ratings yet

- Aa - Mindray BS-120 BS-200 Bs200e-Cldl PDFDocument1 pageAa - Mindray BS-120 BS-200 Bs200e-Cldl PDFFlorelia VazquezNo ratings yet

- S111 EN 12 Aluminium Standard Inclinometric CasingDocument4 pagesS111 EN 12 Aluminium Standard Inclinometric CasingIrwan DarmawanNo ratings yet

- Incident Investigation ProcedureDocument35 pagesIncident Investigation ProcedureAnonymous yCpjZF1rF100% (3)

- CS0005873Document1 pageCS0005873heryantoNo ratings yet

- Legitimacy TheoryDocument6 pagesLegitimacy TheoryFakoyede OluwapamilerinNo ratings yet

- Supermarket CSR 07 Holly WatermanDocument213 pagesSupermarket CSR 07 Holly WatermanRaja Imran KhanNo ratings yet

- Manzo Food and Cocktail MenuDocument2 pagesManzo Food and Cocktail MenuNell CaseyNo ratings yet

- The Art of Designing Ductile Concrete in The Past 50 Years: The Impact of The PCA Book and Mete A. Sozen, Part 1Document6 pagesThe Art of Designing Ductile Concrete in The Past 50 Years: The Impact of The PCA Book and Mete A. Sozen, Part 1masteriragaNo ratings yet

- Permit-To-Work - General Electrical (Under 1000 Volts) : ANNEX 16.1.6Document3 pagesPermit-To-Work - General Electrical (Under 1000 Volts) : ANNEX 16.1.6RihardsNo ratings yet

- Provisional Seniority Lists - LDC UDC and Sr. Clerk-01012024Document21 pagesProvisional Seniority Lists - LDC UDC and Sr. Clerk-01012024shubham patilNo ratings yet

- 89 Aristorod Rev4 ER120S GDocument2 pages89 Aristorod Rev4 ER120S Grusf123No ratings yet

- MelEye - CatalogDocument4 pagesMelEye - CatalogChinmay GhoshNo ratings yet

- React JsDocument15 pagesReact JsAtom AtomNo ratings yet

- PVC Coated Steel Wire Rope 2020Document1 pagePVC Coated Steel Wire Rope 2020ELZEKKIWIRENo ratings yet

- CIO VP Director IT in Detroit MI Resume Remi DiesbourgDocument2 pagesCIO VP Director IT in Detroit MI Resume Remi DiesbourgRemi DiesbourgNo ratings yet

- Philips Automatic Hand SanitaizerDocument24 pagesPhilips Automatic Hand SanitaizerAjith9410No ratings yet