Professional Documents

Culture Documents

Precast Box Culvert Methodology

Precast Box Culvert Methodology

Uploaded by

ram kumarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Precast Box Culvert Methodology

Precast Box Culvert Methodology

Uploaded by

ram kumarCopyright:

Available Formats

Four Laning of Bakhtiyarpur-Mokama Section of NH-31 from

Km 153+300 To Km 197+900 (Design Chainage) and (Existing

Chainage Km 153+300 To Km 204+741 of NH-31) in the State of

Bihar on EPC Mode.

METHODOLOGY FOR CONSTRUCTION OF

PRECAST RCC BOX CULVERT

CLIENT

SUPERVISION CONSULTANT

CONTRACTOR:

BSCPL Infrastructure Ltd.

__________________________________________________________________________________

Page 1 of 8

Construction Methodology for Precast RCC Box Culvert NH-31

Submitted by: BSCPL Infrastructure Ltd

WORKING METHODOLOGY – CONST. OF PRECAST RCC BOX CULVERT

TABLE OF CONTENTS

S. No. Description of Title Page No.

1.0 Purpose 3

2.0 Scope 3

3.0 Definitions 3

4.0 Code References 3

5.0 Responsibilities 4

6.0 Details of Plant, Equipment and 5

Machinery

7.0 Material 5-6

7.1 Reinforcement steel

7.2 Cement

7.3 Course Aggregate

7.4 Fine aggregate

7.5 Others Material

8.0 Segment Constructions 6-8

Methodology

9.0 Segment Inspections & Testing 8

Process.

10.0 Segment Documentation 8

Requirements:

11.0 Segment Safety & Environmental 8

Requirements:

WORK METHODOLOGY

For (Precast) Box Culvert

1.0 PURPOSE:

The purpose of this Segment Quality Plan for Box Culvert is to provide

details of the Construction Methodology, Quality Control System,

Procedures and Safety & Environment Management Plans to be adopted

by BSCPL INFRASTRUCTURE LIMITED.

Page 2 of 8

Construction Methodology for Precast RCC Box Culvert NH-31

2.0 SCOPE:

The Scope of this Segment Quality Plan covers the following activities:

The construction of Box Culvert shall be done in accordance with the

approved drawings and Technical Specifications, and NHAI Guidelines.

3.0 DEFINITIONS:

The words like contract, Contractor, Engineer, Drawing, Employer,

Government, Works, Worksite used in this Work Methodology shall be

considered to have the same meaning as understood from the definitions

of these terms given in the General conditions of the contract.

4.0 CODE REFERENCES:

(i) Volume III of Technical Specifications.

(ii) NHAI Guidelines.

5.0 RESPONSIBILITIES:

Responsible personnel for execution of the Segment of Box Culvert are

as per the following Responsibilities Matrix:

Sl. Responsible Personnel for

Activity Remarks

No. Performing Checking/Verifying Approval

Sampling of QC Engr./Lab

01 Lab-In-charge Engineer

Materials Tech.

Testing of

02 Samples & Lab Technician QC Engineer Engineer

Approval

Cutting,

Bending & Casting Yard

03 Structure In-charge Engineer

Tying of Eng./Supervisor

reinforcement

Fixing &

Casting Yard

04 supporting of Structure In-charge Engineer

Eng./Supervisor

Frame work

Equipment

Production of Dept.

QC Engr./Lab

05 Concrete from Lab In-charge Engineer responsible

Tech.

Batching Plant to provide

infrastructure

06 Placing of Casting Yard Structure In-charge Engineer

Page 3 of 8

Construction Methodology for Precast RCC Box Culvert NH-31

Concrete Eng./Supervisor

De-shuttering Casting Yard

07 Structure In-charge Engineer

Work Eng./Supervisor

Transportation Equipment

of Precast Box Site Dept.

08 Culvert From Engineer/Site Site Engineer Engineer responsible

Casting Yard to Supervisor to provide

work place infrastructure

Ground Site Engineer,/QC

09 Site Engineer Engineer

preparation Engineer

Alignment and

10 Surveyor Section In charge Engineer

Level Checking

Clearance to

Section In Section In charge

11 release/final Engineer

charge QA/QC Engineer

approval

Rectification of

Non- Section In Section In charge

12 Engineer

Conforming charge QA/QC Engineer

works

6.0 Plant & Equipments.

The following sets of equipment as necessary for the planned progress

shall be deployed:-

1) Concrete Batching plant

2) Concrete Millar

3) Vibrator

4) Crane

5) Trailer

6) Excavator

7) Dumper

7.0 Materials:

7.1. Reinforcement Steel

The Reinforcement Steel (HYSD-Fe 500 Grade) shall be procured from

manufacturers directly. The Reinforcement bars shall be subject to all

necessary tests. The bars shall be procured and stacked in central stack

yard. The stacking shall be done in such a way that bars do not come in

contact with soil.

7.2 Cement

Page 4 of 8

Construction Methodology for Precast RCC Box Culvert NH-31

a. It is proposed to use Ordinary Portland Cement of 43 Grade. The cement

shall be procured from reputed manufactures in bags of 50 kg. Each or

bulk. The cement shall be stocked at raised platform in covered Cement

Godown to protect it from moisture, sun and rain etc. The consumption of

cement shall be done on first-in-first-out basis.

b. Testing of cement shall be done on regular basis to ensure quality as per

requirement.

7.3 Coarse Aggregates

a. Coarse Aggregates shall be of clean, hard strong, dense, non-porous

crushed stone of specified gradation. Initially the aggregates shall be

purchased from market and later these shall be produced from Crusher

setup for the project.

b. The aggregate shall be tested for all physical properties before

incorporation in work.

7.4 Sand/Fine Aggregates

a. The Fine Aggregate shall consist of clean, hard, strong and durable pieces

o crushed stone or natural sand from river bed. It shall be tested for

Fineness Modulus, Silt Content, etc.before using in the works.

7.5 Other materials

a. Associated materials and consumables like water for concrete works,

binding wire and cover blocks for reinforcement works, supports, nails

and shuttering oil for formwork, tools and tackles shall be arranged and

checked for conformance to good engineering and accepted standards.

b. Concrete admixture-used as super –plasticizers:

Concrete Admixtures shall be obtained only from the established

manufactures with proven track record, quality assurance and testing of

concrete.

8.0 Segment Construction Methodology

8.1 Concrete Design Mix (ISI0262-1982, IS SP-23-1982) and IS 456-

Page 5 of 8

Construction Methodology for Precast RCC Box Culvert NH-31

1978/2000):

8.2 Well before proposed start for RCC works, Mix Design for M-30 grades

of concrete to be used in works shall be conducted in Field Laboratory

as per approved Technical Specifications. The Mix Design shall be

conducted in the presence of Consultant/Client’s representatives. The

Design Mix results shall be submitted to Consultant for approval.

8.3 Bar Bending schedule shall be prepared for each Segment structure and

reinforcement, steel shall be cut bent at centralized reinforcement yard

and shall conform to the dimensions and shapes as given in the approved

Bar Bending schedules.

8.4 The bars shall be placed in accordance with the drawings and cross bars

shall be tied together with binding wires at every intersection.

8.5 Appropriate cover between the formwork and bars shall be provided as

per the requirement by placing cover blocks. Necessary spacer bars,

chairs, etc shall be provided to fix the reinforcement firmly to its correct

position.

8.6 Overlaps in main reinforcement shall be provided as per technical

requirements and care shall be taken that overlaps are staggered to avoid

weak construction zone.

8.7 The Form work shall be made of Structural Steel with standardized plates

& other formworks. The scaffolding material shall be of standard in

nature and shall be of MS pipes, jacks etc.

8.8 Placement of shuttering shall be done manually or with help of crane and

care shall be taken that there are no weak joints from where the concrete

slurry can leak.

8.9 In order to prevent sticking of concrete to shuttering plates, coating on

shuttering plates shall be done with shuttering oil of approved quality.

8.10 After placement of reinforcement, formwork of side walls haunches shall

be done so that concrete structure of required shape, line, level and

Page 6 of 8

Construction Methodology for Precast RCC Box Culvert NH-31

dimensions is achieved and remains within the specified tolerances.

Necessary staging, scaffolding and temporary supports shall be provided

to the main shuttering so that the formwork is capable of withstanding all

ramming and vibrating pressures while placement of concrete is carried

out. The false work for shuttering shall be done in accordance to the

technical requirements/specifications.

8.11 The Concrete shall be produced as per approved Mix Designs.

8.12 Admixtures such for concrete may be used with exceeding specified limit

prescribed by the manufacturers, as the selection of appropriate concrete

admixtures is an integral part of the mix design.

8.13 The production of concrete shall be done with Concrete Batching and

Mixing plant of 30 cum/hour and shall be transported though transit

mixers and placed at the casting yard work site.

8.14 Transportation of concrete shall be done in transit Mixers.

8.15 Appropriate number of labors shall be engaged to lay concrete and

vibrators shall be used to have a uniform, homogeneous and compacted

surface. Concrete shall not be freely dropped into place from a height

exceeding 1.5m to avoid segregation of material.

9.0 Segment Inspections and Testing Process:

All the Inspection and Testing requirements for various activities in the

present segment will be carried out as per relevant NHAI Specification &

Article-11 of Contract Agreement.

10.0 Segment Documentation Requirements:

The following general documents/records shall be kept maintained as per

relevant applicable BSCPL Infrastructure Limited Quality Management

Procedures:

1) Construction Schedules for the Segment

2) NHAI and other Technical Specifications including relevant

IS/BS/ASTM Codes

3) Field memos/notes/complaints etc including action taken status

Page 7 of 8

Construction Methodology for Precast RCC Box Culvert NH-31

4) Product Non-conformance Reports etc.

All the above document/records shall be maintained at appropriate

locations with proper and defined filing system, which can be identified

& traceable.

11.0 Segment Safety & Environmental Requirements:

Hazard Identification, Risk assessment and Risk control measures for

each and every activities and sub-activities involved in the present

Segment shall be identified and necessary action plan shall be initiated.

Environmental Aspects and Impacts associated with various activities and

sub-activities involved in the present segment and their mitigation/control

measures shall be identified and necessary measures shall be initiated.

Page 8 of 8

Construction Methodology for Precast RCC Box Culvert NH-31

You might also like

- Motivation Letter: TH TH TH THDocument1 pageMotivation Letter: TH TH TH THDolzMaGiCzNo ratings yet

- Steel Structure ErectionDocument33 pagesSteel Structure ErectionAhmed ImranNo ratings yet

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- MARJAN INCREMENT PROGRAM Installation of Steel Support and Gratings For TR AreaDocument10 pagesMARJAN INCREMENT PROGRAM Installation of Steel Support and Gratings For TR AreaFaraaz MohammedNo ratings yet

- ConsultantsDocument26 pagesConsultantsvenkat6No ratings yet

- TataElxsi Vs LTTS Investyadnya 20210607Document74 pagesTataElxsi Vs LTTS Investyadnya 20210607Financial WisdomNo ratings yet

- Company ProfileDocument9 pagesCompany ProfileRajat MehtaNo ratings yet

- Methodology: CD WORKS: BOX, SLAB & PIPE CulvertDocument8 pagesMethodology: CD WORKS: BOX, SLAB & PIPE CulvertjitendraNo ratings yet

- DLC Rectification Methodology - Nagpur Mumbai R0Document10 pagesDLC Rectification Methodology - Nagpur Mumbai R0Ganesh Kumar TulabandulaNo ratings yet

- Methodology For Emb With Pond AshDocument10 pagesMethodology For Emb With Pond Ashjitendra100% (4)

- Cast-In-Situ Bored Piling Works by ConventionalMethod1Document11 pagesCast-In-Situ Bored Piling Works by ConventionalMethod1jitendraNo ratings yet

- Box Girder MethodologyDocument11 pagesBox Girder Methodologyrks.nh119dNo ratings yet

- A MTL Pro 000 38673 CDocument21 pagesA MTL Pro 000 38673 CHussein Adnan FneishNo ratings yet

- Inspection Test Plan For Concrete Blinding Work: Approved Method StatementDocument2 pagesInspection Test Plan For Concrete Blinding Work: Approved Method StatementDan SarmientoNo ratings yet

- Method Statement For Post Anchor BoltsDocument13 pagesMethod Statement For Post Anchor BoltsAhmed ImranNo ratings yet

- Method Statement - Grouting of Segmental Lining Green LineDocument82 pagesMethod Statement - Grouting of Segmental Lining Green Linegeology01100% (1)

- 2024-01-25 - KERN Company PresentationDocument28 pages2024-01-25 - KERN Company PresentationAnonymous U7GlQH3No ratings yet

- Design QualificationDocument17 pagesDesign QualificationNur Nabi RashedNo ratings yet

- Ms For Di Above Ground 01Document22 pagesMs For Di Above Ground 01VibinNo ratings yet

- Structural Fabrication and Installation ProcedureDocument7 pagesStructural Fabrication and Installation ProcedureMuhammad IrsyadiNo ratings yet

- SQP-CD Works (Pipe Culverts (18-10-04) .Document8 pagesSQP-CD Works (Pipe Culverts (18-10-04) .jitendraNo ratings yet

- 014 - G.I Duct, Accessories and FittingsDocument14 pages014 - G.I Duct, Accessories and FittingsJomy JohnyNo ratings yet

- Nilesh Sutradhar - Feb24 2Document5 pagesNilesh Sutradhar - Feb24 2Nilesh SutradharNo ratings yet

- Lps 01 Hti MST Me 007 GRP Water TankDocument12 pagesLps 01 Hti MST Me 007 GRP Water TankJomy JohnyNo ratings yet

- LPS-01-HTI-MST-EL-005 - Point WiringDocument11 pagesLPS-01-HTI-MST-EL-005 - Point WiringJomy JohnyNo ratings yet

- MS For Embeddded Items in Concrete WorksDocument5 pagesMS For Embeddded Items in Concrete Worksnazim7No ratings yet

- BMS-05 Earthworks (SH)Document13 pagesBMS-05 Earthworks (SH)Mohamed GamalNo ratings yet

- 05 C&S WMS at Super Structure (RC Work)Document10 pages05 C&S WMS at Super Structure (RC Work)Aldi mubaroqNo ratings yet

- Ms For Di Underground Pipes 01Document25 pagesMs For Di Underground Pipes 01VibinNo ratings yet

- QAP FinalDocument6 pagesQAP FinalANSHUMAN KUMARNo ratings yet

- A Con Pro 000 38658 BDocument13 pagesA Con Pro 000 38658 BHussein Adnan FneishNo ratings yet

- Ask - Wo-22.2672-Method-Swc-004 - Work Method Concrete Wall Rev.03Document14 pagesAsk - Wo-22.2672-Method-Swc-004 - Work Method Concrete Wall Rev.03air separation unit plant swadaya ciptaNo ratings yet

- CP11Document9 pagesCP11Bharat KhandekarNo ratings yet

- Work Method Statement Paiting Work For Steel Structure, Piping Work, Cable TrayDocument9 pagesWork Method Statement Paiting Work For Steel Structure, Piping Work, Cable TrayHồng Trung DươngNo ratings yet

- Mechanical (Projects)Document7 pagesMechanical (Projects)Nilesh SutradharNo ratings yet

- CP05-03-MMC-MST-ELE-0026 Testing & Commissioning For Structure Cabling SystemDocument47 pagesCP05-03-MMC-MST-ELE-0026 Testing & Commissioning For Structure Cabling SystemMohamed AshrafNo ratings yet

- Db02 - PPT - PRM 13 Oct 2023Document10 pagesDb02 - PPT - PRM 13 Oct 2023amjad31may74No ratings yet

- MST-M-0058 Pre Action SystemDocument10 pagesMST-M-0058 Pre Action SystemJERINNo ratings yet

- WEP For Concrete BIGMDocument12 pagesWEP For Concrete BIGMpalashNo ratings yet

- Cgk063-Rfa-mos-m-xxx - Soil & Waste Water Underground Pipe Installation (r.1)Document39 pagesCgk063-Rfa-mos-m-xxx - Soil & Waste Water Underground Pipe Installation (r.1)diki anggriawanNo ratings yet

- Cgk063-Rfa-mos-m-xxx - Waste Water-Sewerage & Sanitary Fixture Underground Pipe InstallationDocument35 pagesCgk063-Rfa-mos-m-xxx - Waste Water-Sewerage & Sanitary Fixture Underground Pipe Installationdiki anggriawanNo ratings yet

- Work Method Statement For Sub Structure Works: (Pile Cap)Document9 pagesWork Method Statement For Sub Structure Works: (Pile Cap)AlbawaviNo ratings yet

- Work Method Statement For Sub Structure Works: (Pile Cap)Document9 pagesWork Method Statement For Sub Structure Works: (Pile Cap)Rufahniyah LizhaNo ratings yet

- 1) Method Statement For FORMWORK STEEL & CONCRETE WORKDocument7 pages1) Method Statement For FORMWORK STEEL & CONCRETE WORKMukesh PrajapatNo ratings yet

- P603 - Commissioning StrategyDocument12 pagesP603 - Commissioning StrategyFernando SantosNo ratings yet

- Method of Statement Rev02 PDFDocument44 pagesMethod of Statement Rev02 PDFBadhur ZamanNo ratings yet

- Method Statement FOR Roof Waterproofing Works: Revision RecordDocument18 pagesMethod Statement FOR Roof Waterproofing Works: Revision RecordYash Sharma100% (6)

- SD05wi1 Structural Inspection WorkpackDocument22 pagesSD05wi1 Structural Inspection WorkpackidrisNo ratings yet

- Method Statement For Concrete WorksDocument25 pagesMethod Statement For Concrete WorksqsNo ratings yet

- Communication ProtocolDocument2 pagesCommunication ProtocolMohammed AffrozeNo ratings yet

- Fabrication, Supply, Erection, Installation and Commissioning of Non Regenerative Type Demineralisation Plant and Online Polishing PlantDocument40 pagesFabrication, Supply, Erection, Installation and Commissioning of Non Regenerative Type Demineralisation Plant and Online Polishing Plantmangal deo pathakNo ratings yet

- MethodologyDocument8 pagesMethodologyBalbir SharmaNo ratings yet

- Procedure For As-Built DrawingDocument736 pagesProcedure For As-Built DrawingSmith SuwanNo ratings yet

- Underck Insulation MSTDocument8 pagesUnderck Insulation MSTmahesh naikNo ratings yet

- 01 Work Repair ProcedureDocument17 pages01 Work Repair ProcedureAnonymous sQ1toMHD100% (2)

- 01 Work Repair Procedure PDFDocument17 pages01 Work Repair Procedure PDFZul HafizNo ratings yet

- ASK - WO-22.2672-METHOD-SWC-001 - 1 Method Statement of Architecture WorkDocument13 pagesASK - WO-22.2672-METHOD-SWC-001 - 1 Method Statement of Architecture Workair separation unit plant swadaya ciptaNo ratings yet

- MES - Construction Quality Manual - Rev - 0Document55 pagesMES - Construction Quality Manual - Rev - 0Ishaan ThakerNo ratings yet

- CPD KCC (Ons) T 3301Document30 pagesCPD KCC (Ons) T 3301khurram ijazNo ratings yet

- Posorja Multipurpose Terminal Terminal Works: High-Mast and CCTV Poles InstallationDocument5 pagesPosorja Multipurpose Terminal Terminal Works: High-Mast and CCTV Poles Installationhz135874No ratings yet

- Boc India Limited: Cryogenic Nitrogen Plant Bharat Oman Refineries Ltd. Engineers India Ltd. BOC India Ltd. Bina (M.P.)Document6 pagesBoc India Limited: Cryogenic Nitrogen Plant Bharat Oman Refineries Ltd. Engineers India Ltd. BOC India Ltd. Bina (M.P.)aceengineering08No ratings yet

- 26march - Method Statement For The Pouring of Concrete Floor Slab (Segment Plant)Document27 pages26march - Method Statement For The Pouring of Concrete Floor Slab (Segment Plant)know netNo ratings yet

- Mec531 Course Outline 2017 - NursalbiahDocument10 pagesMec531 Course Outline 2017 - Nursalbiahkhairi_mohammadNo ratings yet

- Nbs Technical Note 1325Document496 pagesNbs Technical Note 1325Daniel Felipe Parias AnayaNo ratings yet

- Tor For Electrical Underground Services - 135 MW - With Table of ContentsDocument26 pagesTor For Electrical Underground Services - 135 MW - With Table of Contentsshanks263No ratings yet

- Jobs For NICMAR Alumni (Responses)Document6 pagesJobs For NICMAR Alumni (Responses)Tushar DoshiNo ratings yet

- Eric RFIDocument25 pagesEric RFIYeshitilaNo ratings yet

- Job Vacancies: 1. Environmental OfficerDocument2 pagesJob Vacancies: 1. Environmental OfficerAzani OmarNo ratings yet

- SMEC - Capstone Project - TemplateDocument17 pagesSMEC - Capstone Project - TemplateSPAMNo ratings yet

- Site Suitability Report C14Xh/Cllag: Ranelagh GardensDocument121 pagesSite Suitability Report C14Xh/Cllag: Ranelagh Gardensinfo1639No ratings yet

- Obsolescence Study Control SystemDocument45 pagesObsolescence Study Control Systemmgkvpr100% (1)

- Cover LetterDocument1 pageCover LetterJafri JaafarNo ratings yet

- Sample of A Statement of Purpose (Sop)Document2 pagesSample of A Statement of Purpose (Sop)adiG48 AtdiG48No ratings yet

- Power Link Module For LD 800PDocument4 pagesPower Link Module For LD 800PSarah FrazierNo ratings yet

- 2051Document1 page2051zaheerNo ratings yet

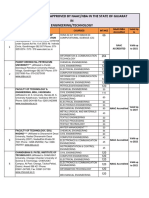

- List of The Institute Approved by Naac/Nba in The State of Gujarat IN Engineering/TechnologyDocument3 pagesList of The Institute Approved by Naac/Nba in The State of Gujarat IN Engineering/TechnologyMeet MakwanaNo ratings yet

- Show ImgDocument68 pagesShow ImgpradeepNo ratings yet

- 08 DRG - Protection SLD 220kV SarigamDocument1 page08 DRG - Protection SLD 220kV SarigamAmarjit Kulkarni100% (1)

- Seismic Design of Steel DeckDocument42 pagesSeismic Design of Steel Decksmartman35No ratings yet

- Plantrun Oee CalculatorDocument2 pagesPlantrun Oee CalculatorYogesh SharmaNo ratings yet

- Load Testing of Static Modular Aluminium ScaffoldDocument33 pagesLoad Testing of Static Modular Aluminium ScaffoldReda ElawadyNo ratings yet

- PTDF 2017 2018 DetailsDocument8 pagesPTDF 2017 2018 DetailsAdeniji OlusegunNo ratings yet

- Prestressed Concrete - 1 IntroductionDocument21 pagesPrestressed Concrete - 1 Introduction4493464No ratings yet

- Bridge Procedures and Design GuideDocument89 pagesBridge Procedures and Design Guideyhsza100% (1)

- AE 157A - Soil and Water Conservation Eng'G - SyllabusDocument11 pagesAE 157A - Soil and Water Conservation Eng'G - Syllabusallyson minaNo ratings yet

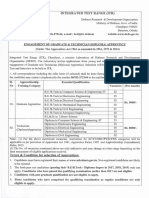

- DRDO 2019 Jobs Latest Recruitment of 116 Apprentice VacanciesDocument2 pagesDRDO 2019 Jobs Latest Recruitment of 116 Apprentice VacanciessudvsuxvsjdNo ratings yet

- TE AICTE 2018 Final TIME TABLE Exam. Nov-Dec.2022Document6 pagesTE AICTE 2018 Final TIME TABLE Exam. Nov-Dec.2022Harshal PatilNo ratings yet