Professional Documents

Culture Documents

1.10 Preliminary Process Flow Chart

1.10 Preliminary Process Flow Chart

Uploaded by

Amirhossein Ghadiri0 ratings0% found this document useful (0 votes)

49 views1 pageThe document discusses three topics:

1) Creating a preliminary process flow chart based on the bill of materials and product assumptions to describe the anticipated manufacturing process.

2) Identifying special product and process characteristics from customer requirements, reliability goals, process characteristics, and similar part FMEAs.

3) Developing a Product Assurance Plan to translate design goals into requirements based on customer needs, including outlining program requirements, identifying reliability goals, assessing risk factors, and using FMEA to develop preliminary engineering requirements.

Original Description:

Original Title

20140923234325 22

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses three topics:

1) Creating a preliminary process flow chart based on the bill of materials and product assumptions to describe the anticipated manufacturing process.

2) Identifying special product and process characteristics from customer requirements, reliability goals, process characteristics, and similar part FMEAs.

3) Developing a Product Assurance Plan to translate design goals into requirements based on customer needs, including outlining program requirements, identifying reliability goals, assessing risk factors, and using FMEA to develop preliminary engineering requirements.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

49 views1 page1.10 Preliminary Process Flow Chart

1.10 Preliminary Process Flow Chart

Uploaded by

Amirhossein GhadiriThe document discusses three topics:

1) Creating a preliminary process flow chart based on the bill of materials and product assumptions to describe the anticipated manufacturing process.

2) Identifying special product and process characteristics from customer requirements, reliability goals, process characteristics, and similar part FMEAs.

3) Developing a Product Assurance Plan to translate design goals into requirements based on customer needs, including outlining program requirements, identifying reliability goals, assessing risk factors, and using FMEA to develop preliminary engineering requirements.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

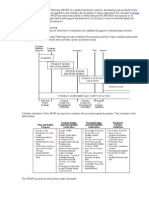

1.

10 Preliminary Process Flow

Chart

The anticipated manufacturing process should be described using a process

flow chart developed from the preliminary bill of material and

product/process assumptions.

1.11 Preliminary Identification

of Special Product and

Process Characteristics

Special product and process characteristics are identified by the customer in

addition to those selected by the organization through knowledge of the

product and process. Examples of input to identification of special

characteristics include:

• Product assumptions based on the analysis of customer needs and

expectations.

• Identification of reliability goals and requirements.

• Identification of special process characteristics from the anticipated

manufacturing process.

• Similar part FMEAs.

1.12 Product Assurance Plan

The Product Assurance Plan translates design goals into design

requirements and is based on customer needs and expectations. This

manual does not require a specific method for preparing a Product

Assurance Plan. The Product Assurance Plan can be developed in any

format understood by the organization and should include:

• Outlining of program requirements.

• Identification of reliability, durability, and apportionment/allocation goals

and/or requirements.

• Assessment of new technology, complexity, materials, application,

environment, packaging, service, and manufacturing requirements, or any

other factor that may place the program at risk.

• Use of Failure Mode and Effects Analysis (FMEA).

• Development of preliminary engineering requirements.

You might also like

- Internal Audit Checklist New Product Dev.Document10 pagesInternal Audit Checklist New Product Dev.dhir.ankur100% (3)

- APQP & Control Plan Training - Presentation Slides - Working TemplateDocument149 pagesAPQP & Control Plan Training - Presentation Slides - Working TemplateTeeva Battumalai100% (3)

- AS9100 9145 - Guidance PDFDocument20 pagesAS9100 9145 - Guidance PDF44abcNo ratings yet

- P 830 Design DevelopmentDocument7 pagesP 830 Design DevelopmentTamara Johnson-Pariag100% (1)

- Plan and Define ProgramDocument22 pagesPlan and Define ProgramScrashtheleader PkmGo100% (1)

- 1 ApqpDocument30 pages1 ApqpVIPIN YADAVNo ratings yet

- 7 1 PDFDocument3 pages7 1 PDFnice guyNo ratings yet

- APQP-Training MaterialDocument39 pagesAPQP-Training MaterialthsukeshsinghNo ratings yet

- SDLC TrainingDocument10 pagesSDLC Trainingsiddu1008patilNo ratings yet

- Apqp 23 Elements What Is APQP 23 Elements?: 1. Customer OrderDocument7 pagesApqp 23 Elements What Is APQP 23 Elements?: 1. Customer OrderAdrian Alcorta100% (1)

- Fusion Applications Deep Dive Setup For Supply Chain Management: Product Information ManagementDocument29 pagesFusion Applications Deep Dive Setup For Supply Chain Management: Product Information ManagementAnshuman Gahlot100% (2)

- All Tools in OneDocument38 pagesAll Tools in Oneom_3334No ratings yet

- 9 8.3 Design and DevelopmentDocument23 pages9 8.3 Design and DevelopmentprashantNo ratings yet

- APQP Process Training (In-Depth)Document142 pagesAPQP Process Training (In-Depth)Sunil67% (3)

- 05.quality MGTDocument32 pages05.quality MGTsycb2xktn4100% (1)

- Week 1 and 2 IntroductionDocument41 pagesWeek 1 and 2 IntroductionNaima GhulamMNo ratings yet

- APQPDocument33 pagesAPQPAtul SURVENo ratings yet

- Supplier APQP Process Training (In-Depth)Document142 pagesSupplier APQP Process Training (In-Depth)mihai1976mihaiNo ratings yet

- Unit 5 Quality ManagementDocument7 pagesUnit 5 Quality ManagementKezzy KayNo ratings yet

- QAP 4.0 - Design Control - Rev B (G) PDFDocument13 pagesQAP 4.0 - Design Control - Rev B (G) PDFPrakash TiwariNo ratings yet

- JISC QA PolicyDocument8 pagesJISC QA PolicyJo-Sharon UdohNo ratings yet

- 05 Project Scope Management Updated 6th PMBOOKDocument115 pages05 Project Scope Management Updated 6th PMBOOKMohammad Irshad AlamNo ratings yet

- EDP 3 Product DevelopmentDocument15 pagesEDP 3 Product DevelopmentatulkirarNo ratings yet

- Supplier APQP Process Training in DepthDocument142 pagesSupplier APQP Process Training in DepthMarcelo TeixeiraNo ratings yet

- AIAG VDA DFMEA TrainingDocument68 pagesAIAG VDA DFMEA TrainingAtul SURVE100% (2)

- Advanced Product Quality PlanningDocument2 pagesAdvanced Product Quality PlanningSanjay BaidNo ratings yet

- Product Design and DevelopmentDocument13 pagesProduct Design and DevelopmentGeorgiana BusuiocNo ratings yet

- Preliminary Design in Quality Control and Quality AssuranceDocument4 pagesPreliminary Design in Quality Control and Quality Assuranceayashwanth289No ratings yet

- ISO TS 16949 2009 RequirementsDocument22 pagesISO TS 16949 2009 RequirementsAshishNo ratings yet

- ITIDAT0182A Develop Macros and Templates For Clients Using Standard ProductsDocument4 pagesITIDAT0182A Develop Macros and Templates For Clients Using Standard ProductsShedeen McKenzieNo ratings yet

- Chapter 13 - Designing For Quality: PTTE 434 Jim Wixson - InstructorDocument72 pagesChapter 13 - Designing For Quality: PTTE 434 Jim Wixson - InstructorPrabhat SharmaNo ratings yet

- SR&S 5Document23 pagesSR&S 5xinova6613No ratings yet

- DEV-PR-01 Procedure For APQPDocument4 pagesDEV-PR-01 Procedure For APQPcghodake1No ratings yet

- PocketGuideDocument62 pagesPocketGuideIvanNo ratings yet

- APQPDocument3 pagesAPQPSherazi MujtabaNo ratings yet

- PPAP Awareness TrainingDocument28 pagesPPAP Awareness TrainingneerajrdxNo ratings yet

- What Is QFDDocument7 pagesWhat Is QFDAkhilesh YadavNo ratings yet

- M K P L: Anajemen Ualitas Erangkat UnakDocument20 pagesM K P L: Anajemen Ualitas Erangkat UnakLinda RupturNo ratings yet

- Lecture 1Document34 pagesLecture 1roomigillani26No ratings yet

- Basic Concepts of Software QualityDocument41 pagesBasic Concepts of Software QualityBalaram PapanaNo ratings yet

- PUCIT - Lec2 PDFDocument28 pagesPUCIT - Lec2 PDFMOHAMMAD HARISNo ratings yet

- APQP - Core Tools of QualityDocument108 pagesAPQP - Core Tools of Qualitykiran kumar psNo ratings yet

- SOP Module 1-1Document7 pagesSOP Module 1-1Aniket ParateNo ratings yet

- Apqp & PpapDocument63 pagesApqp & Ppapjd4u100% (1)

- Day2 Concepts of QualityDocument57 pagesDay2 Concepts of QualityPaul StarkNo ratings yet

- 08 Quality 25010 II PDFDocument66 pages08 Quality 25010 II PDFSimeon Cainday III100% (2)

- Ch24 Quality Management PDFDocument74 pagesCh24 Quality Management PDFxenesNo ratings yet

- Chapter 6 Design For Quality & Product ExcellenceDocument32 pagesChapter 6 Design For Quality & Product ExcellenceKhazandra Nicole CudapasNo ratings yet

- TQM ToolsDocument29 pagesTQM Toolsविवेक शर्माNo ratings yet

- Unit2 Product AssuranceDocument42 pagesUnit2 Product AssuranceJigar ShahNo ratings yet

- Lý Thuyết Kiểm Định Chất Lượng Phần Mềm - 2. Quality Assurance - Quality EngineeringDocument35 pagesLý Thuyết Kiểm Định Chất Lượng Phần Mềm - 2. Quality Assurance - Quality Engineeringgzzgzz5xNo ratings yet

- Aqpaxi Phase 2.rev13Document7 pagesAqpaxi Phase 2.rev13Isabel SierraNo ratings yet

- Design and Development ISODocument7 pagesDesign and Development ISObrenda smith100% (1)

- Fundamentals of Product Quality Planning: Organize The TeamDocument1 pageFundamentals of Product Quality Planning: Organize The TeamAmirhossein GhadiriNo ratings yet

- Chapter 14 - Quality ConceptsDocument4 pagesChapter 14 - Quality ConceptsSan Lizas AirenNo ratings yet

- Es-Unit 3 Edlc-Iii EeeDocument45 pagesEs-Unit 3 Edlc-Iii EeepriyadarshniNo ratings yet

- Paper ReliabilityDocument6 pagesPaper ReliabilitySebastian TrujilloNo ratings yet

- 1 SDLCDocument16 pages1 SDLCmanjiri510No ratings yet

- Product Quality Planning Timing ChartDocument1 pageProduct Quality Planning Timing ChartAmirhossein GhadiriNo ratings yet

- 1.1.1 Market ResearchDocument1 page1.1.1 Market ResearchAmirhossein GhadiriNo ratings yet

- 1.4 Product/Process AssumptionsDocument1 page1.4 Product/Process AssumptionsAmirhossein GhadiriNo ratings yet

- Product Quality Planning Timing ChartDocument1 pageProduct Quality Planning Timing ChartAmirhossein GhadiriNo ratings yet

- Concern ResolutionDocument1 pageConcern ResolutionAmirhossein GhadiriNo ratings yet

- 1.1 Voice of The Customer: InputsDocument1 page1.1 Voice of The Customer: InputsAmirhossein GhadiriNo ratings yet