Professional Documents

Culture Documents

Prox td001 - en P

Prox td001 - en P

Uploaded by

OETINCA OETINCACopyright:

Available Formats

You might also like

- Pundit 6 ManualDocument11 pagesPundit 6 ManualJuan David GonzalezNo ratings yet

- G1314A VWD Reference Manual PDFDocument250 pagesG1314A VWD Reference Manual PDFdriveNo ratings yet

- Vibrating Wire PiezometerDocument4 pagesVibrating Wire Piezometers pradhanNo ratings yet

- Management Information System of EDCLDocument47 pagesManagement Information System of EDCLAbir MohammadNo ratings yet

- Pi Bu Zonas CutáneasDocument4 pagesPi Bu Zonas CutáneasjjseguinNo ratings yet

- Field Devices - Analytical: Log oDocument20 pagesField Devices - Analytical: Log oSebastian OsellaNo ratings yet

- 1443 Series Accelerometers Specifications: Technical DataDocument60 pages1443 Series Accelerometers Specifications: Technical Datasschoudhury.squaremNo ratings yet

- Datasheet - Mass Flow MeterDocument6 pagesDatasheet - Mass Flow Metergalih santosoNo ratings yet

- SCOUT140EX Vibration Data Collector Datasheet 323330 PDFDocument9 pagesSCOUT140EX Vibration Data Collector Datasheet 323330 PDFShouqi ErmanNo ratings yet

- TranspondersDocument11 pagesTransponderskhalidNo ratings yet

- In Depth Look at UltrasonicTransducersDocument52 pagesIn Depth Look at UltrasonicTransducersGrafton MontgomeryNo ratings yet

- Data Sheet R-SeriesV RDV Analog 552135 ENDocument18 pagesData Sheet R-SeriesV RDV Analog 552135 ENdylancottrill.the84groupNo ratings yet

- PMT Hps 4493 HPS BRO QSonic PlusDocument8 pagesPMT Hps 4493 HPS BRO QSonic PlusmmilovanmNo ratings yet

- Frequently Asked Questions: tSEN-190Document1 pageFrequently Asked Questions: tSEN-190Venkat DeepakNo ratings yet

- Agilent Technologies 1141A Differential Probe and 1142A Probe Control and PowerDocument90 pagesAgilent Technologies 1141A Differential Probe and 1142A Probe Control and PowerRuggero RamponeNo ratings yet

- Title Journal 3 PDFDocument8 pagesTitle Journal 3 PDFSAMENo ratings yet

- 8GE02 0e Active Antennas For RadiomonitoringDocument35 pages8GE02 0e Active Antennas For RadiomonitoringMostafa hdghNo ratings yet

- Analog SDK Users Manual v18Document4 pagesAnalog SDK Users Manual v18undywcpeqwfstbqwrgNo ratings yet

- S STARA112 E Orion StarA112 Conductivity MeterDocument2 pagesS STARA112 E Orion StarA112 Conductivity MeteralexmontellNo ratings yet

- Opa4277 EpDocument23 pagesOpa4277 EpaidilazmaNo ratings yet

- Quality Performance Reputation 2 - Year Limited Warranty: Multi-Frequency Digital Line TracerDocument8 pagesQuality Performance Reputation 2 - Year Limited Warranty: Multi-Frequency Digital Line Tracerlogistica 902No ratings yet

- Product Data Sheet 1057 Triple Channel Transmitter Rosemount en 69226Document16 pagesProduct Data Sheet 1057 Triple Channel Transmitter Rosemount en 69226Paul HotiuNo ratings yet

- Bobina de Rogowski - KEVCR 24 BA2 - 1VLM000801 Rev.-, enDocument10 pagesBobina de Rogowski - KEVCR 24 BA2 - 1VLM000801 Rev.-, enluciano.alburguettiNo ratings yet

- SV - 03678 - en - Na 2Document16 pagesSV - 03678 - en - Na 2eduardodluffy268No ratings yet

- Control Engineering and AutomationDocument2 pagesControl Engineering and AutomationaltanshnetNo ratings yet

- Active Monopole Antennas Operation ManualualDocument15 pagesActive Monopole Antennas Operation Manualualmid_cycloneNo ratings yet

- Es60 26 ND9000 SMC ValmetDocument20 pagesEs60 26 ND9000 SMC ValmetJosé Angel ZabaletaNo ratings yet

- TW8800) 05.14.12 - ReaderDocument16 pagesTW8800) 05.14.12 - ReaderJavier iimareNo ratings yet

- DS0047 - HSENS-CC - EN - A4 CompressedDocument2 pagesDS0047 - HSENS-CC - EN - A4 CompressedAnish PalNo ratings yet

- PA Probe Catalog en 201304Document24 pagesPA Probe Catalog en 201304Durgamadhaba Mishra100% (2)

- PA Probe Catalog en 201308Document24 pagesPA Probe Catalog en 201308Alvaro Alexis Mendoza PradaNo ratings yet

- A1369 DatasheetDocument22 pagesA1369 Datasheetconaco.tecnologiaNo ratings yet

- Service Case With Test Unit For Pro-Portional Valves and Their Control ElectronicsDocument8 pagesService Case With Test Unit For Pro-Portional Valves and Their Control ElectronicsАлександр БулдыгинNo ratings yet

- Features & Benefits Description: Product Name Product Type Marking Ordering Code PackageDocument20 pagesFeatures & Benefits Description: Product Name Product Type Marking Ordering Code PackageFurkan Berk KayaNo ratings yet

- Capacitive Proximity SensorsDocument22 pagesCapacitive Proximity SensorsYahia NassarNo ratings yet

- Burkert 8793Document31 pagesBurkert 8793Flavio nascimentoNo ratings yet

- lm567c 4Document27 pageslm567c 4Adin BagindutNo ratings yet

- Vibrating Wire Pressure CellDocument4 pagesVibrating Wire Pressure Cells pradhanNo ratings yet

- Modulo Sensores AnalogosDocument4 pagesModulo Sensores AnalogosJUAN FELIPE CARMONA DEOSSANo ratings yet

- 1131A User's GuideDocument68 pages1131A User's GuideMichael TecofskyNo ratings yet

- Instruction - KECA 80 C184Document9 pagesInstruction - KECA 80 C184David MendozaNo ratings yet

- TMP451Document42 pagesTMP451Giulliana NietoNo ratings yet

- Model Paxlcl - Pax Lite Current Loop Meter: C Us Listed Us ListedDocument8 pagesModel Paxlcl - Pax Lite Current Loop Meter: C Us Listed Us ListedSURESHNo ratings yet

- Power-Supply-Control Ac en 5216-4462-92 v0101Document4 pagesPower-Supply-Control Ac en 5216-4462-92 v0101Garry RFNo ratings yet

- CTN0007 Magneto Resistive SensorsDocument4 pagesCTN0007 Magneto Resistive SensorsYuregir TNo ratings yet

- Pgr-8800 Arc-Flash RelayDocument6 pagesPgr-8800 Arc-Flash RelayvikasmikkuNo ratings yet

- Rohde Schwarz Power Electronics Fly en - 3608 5893 32 - v0100Document7 pagesRohde Schwarz Power Electronics Fly en - 3608 5893 32 - v0100lepinay OlivierNo ratings yet

- Upload 00064874 1653551341842Document17 pagesUpload 00064874 1653551341842Karl SturausNo ratings yet

- Simple Loop Automatic TunerDocument16 pagesSimple Loop Automatic TunerIngo KnitoNo ratings yet

- ABB AX400 ConductivityDocument12 pagesABB AX400 ConductivityNazrul IslamNo ratings yet

- Solar PanalDocument5 pagesSolar PanalShankar SwamiNo ratings yet

- Ad8672 EpDocument8 pagesAd8672 EpEdwin Exequiel Quintanilla PinedaNo ratings yet

- Esser 808623 Esserbus Alarm Transponder DatasheetDocument1 pageEsser 808623 Esserbus Alarm Transponder DatasheetkhalidNo ratings yet

- BODAS Pressure Sensor PR4: RE 95156/2021-02-24 Replaces: 2020-11-24Document32 pagesBODAS Pressure Sensor PR4: RE 95156/2021-02-24 Replaces: 2020-11-24Vinod HegdeNo ratings yet

- HR Wallingford-009 - Wave - GaugeDocument2 pagesHR Wallingford-009 - Wave - GaugeSutanto HadiNo ratings yet

- Espectrofotómetro Unico 2100Document51 pagesEspectrofotómetro Unico 2100Jocelyn Gallardo50% (2)

- Duct Smoke Detector For Special Applications: Models Available 2151Document4 pagesDuct Smoke Detector For Special Applications: Models Available 2151Argile-assholeNo ratings yet

- Sensepoint XCD Gas Detector Technical ManualDocument70 pagesSensepoint XCD Gas Detector Technical ManualYugandhar YuguNo ratings yet

- Pss 6-1a4aDocument24 pagesPss 6-1a4aFernando MéndezNo ratings yet

- FSP-951T-SELFT Intelligent Photoelectric and Temperature Self-Test Smoke SensorDocument4 pagesFSP-951T-SELFT Intelligent Photoelectric and Temperature Self-Test Smoke SensorDinaNo ratings yet

- 85106-90 (E) (1) Young AnemometerDocument16 pages85106-90 (E) (1) Young AnemometerakhilNo ratings yet

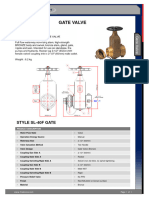

- Gate Valve: Style Sl-40F GateDocument1 pageGate Valve: Style Sl-40F GateOETINCA OETINCANo ratings yet

- Racer Evo BrochureDocument17 pagesRacer Evo BrochureOETINCA OETINCANo ratings yet

- TEG CertificateDocument1 pageTEG CertificateOETINCA OETINCA100% (1)

- Teg MSDSDocument4 pagesTeg MSDSOETINCA OETINCANo ratings yet

- Item 17 - 3J - CDSDocument1 pageItem 17 - 3J - CDSOETINCA OETINCANo ratings yet

- 6f84db380d88275a4cf962d81db9488bDocument1 page6f84db380d88275a4cf962d81db9488bOETINCA OETINCANo ratings yet

- 285 - 2285 - 100143 PartsDocument2 pages285 - 2285 - 100143 PartsOETINCA OETINCANo ratings yet

- Shandong Pulisi Chemical Co.,Ltd.: WWW - Sdpulisi.cnDocument1 pageShandong Pulisi Chemical Co.,Ltd.: WWW - Sdpulisi.cnOETINCA OETINCANo ratings yet

- Item 1 - 8H Woods - 8H Sure Flex Hytrel SleeveDocument1 pageItem 1 - 8H Woods - 8H Sure Flex Hytrel SleeveOETINCA OETINCANo ratings yet

- DATASHEET - Monoethanolamine MEADocument1 pageDATASHEET - Monoethanolamine MEAOETINCA OETINCANo ratings yet

- CATALOG - Monoethanolamine MEADocument2 pagesCATALOG - Monoethanolamine MEAOETINCA OETINCANo ratings yet

- Butyl Mercaptan TertDocument1 pageButyl Mercaptan TertOETINCA OETINCANo ratings yet

- mx8030 Probe July 2021 Rev GDocument3 pagesmx8030 Probe July 2021 Rev GOETINCA OETINCANo ratings yet

- Model E-5vDocument1 pageModel E-5vOETINCA OETINCANo ratings yet

- PlasticsDocument6 pagesPlasticsOETINCA OETINCANo ratings yet

- PicnicDocument6 pagesPicnicOETINCA OETINCANo ratings yet

- KOMAKINO1 - 43643 - 1493201559720 - Kammprofile-TechData-ENKAMMPROFILE GASKETDocument4 pagesKOMAKINO1 - 43643 - 1493201559720 - Kammprofile-TechData-ENKAMMPROFILE GASKETguojun sunNo ratings yet

- Maps of Consciousness Yi King TarotDocument171 pagesMaps of Consciousness Yi King TarotRichard Hansoul100% (7)

- If I Had A Million Dollars EssayDocument4 pagesIf I Had A Million Dollars Essaygejjavbaf100% (2)

- Food and FarmingDocument38 pagesFood and FarmingKevin LlorenteNo ratings yet

- Proteomic Landscape Presents Cues For Vegetative To Reproductive Transition in MangoDocument7 pagesProteomic Landscape Presents Cues For Vegetative To Reproductive Transition in MangoShailendra RajanNo ratings yet

- Employment Document Folder ListsDocument90 pagesEmployment Document Folder ListsIsna FauziahNo ratings yet

- Railway Accounting: Indian Railway Accounts ServiceDocument5 pagesRailway Accounting: Indian Railway Accounts ServiceAbhijeet AsthanaNo ratings yet

- GENED 200 ItemsDocument235 pagesGENED 200 ItemsBRIAN100% (1)

- 2022 Fuenzalida Et Al 2022 New Records OfgigantolaelapswolffsohniDocument10 pages2022 Fuenzalida Et Al 2022 New Records OfgigantolaelapswolffsohniCarlos LandaetaNo ratings yet

- AAADocument12 pagesAAAMisael CamposanoNo ratings yet

- Appendix G Construction Inspection Checklists and Asbuilt CertificationsDocument30 pagesAppendix G Construction Inspection Checklists and Asbuilt CertificationsMehdi RezougNo ratings yet

- Flowers For Algernon ThesisDocument6 pagesFlowers For Algernon Thesiss0kuzej0byn2100% (2)

- Migraine - National StudyDocument2 pagesMigraine - National StudyMagdallinaNo ratings yet

- Suzumar Boat Engine PackagesDocument7 pagesSuzumar Boat Engine PackagesmarkoNo ratings yet

- Hawthorne ExperimentsDocument14 pagesHawthorne ExperimentsShalini SharmaNo ratings yet

- 1000 English Collocations EbookDocument128 pages1000 English Collocations EbookHerdeiro DicaprioNo ratings yet

- EpitheliumDocument48 pagesEpitheliumdrpankaj28100% (1)

- Aero Piston Engine Module SyllabusDocument21 pagesAero Piston Engine Module Syllabussuubi KimbowaNo ratings yet

- Carbon and Its Compounds Revision SheetDocument2 pagesCarbon and Its Compounds Revision Sheetyashvibhatia5No ratings yet

- Prosecutor v. FurundzijaDocument1 pageProsecutor v. Furundzijacrlstinaaa100% (1)

- Abdikamalov Xodjabay Ismamutovich, Najimov Paraxat Ibrayimovich, Abstract. The Article Discusses The Importance and Necessity of PhysicalDocument7 pagesAbdikamalov Xodjabay Ismamutovich, Najimov Paraxat Ibrayimovich, Abstract. The Article Discusses The Importance and Necessity of PhysicalNurnazar PirnazarovNo ratings yet

- Escalator Switches AdjustmentDocument6 pagesEscalator Switches AdjustmentSANAL KUMAR SNo ratings yet

- NIM: 2440007043 Nama: Ni Putu Young Yenyuo A Mata Kuliah: Accounting For Business Dosen: Herlin Tundjung SetijaningsihDocument5 pagesNIM: 2440007043 Nama: Ni Putu Young Yenyuo A Mata Kuliah: Accounting For Business Dosen: Herlin Tundjung SetijaningsihiyeNo ratings yet

- Chiari ExerciseDocument3 pagesChiari ExercisesoliverosteopathyNo ratings yet

- Radiation HazardDocument27 pagesRadiation Hazardlelu ojhaNo ratings yet

- Far Eastern Polytechnic College: Republic of The Philippines Region Iv-A Calabarzon City Schools Division of DasmariñasDocument2 pagesFar Eastern Polytechnic College: Republic of The Philippines Region Iv-A Calabarzon City Schools Division of DasmariñasJed CahinusayanNo ratings yet

- SITREP NUMBER 62 As of 29 January 2020 1100HDocument67 pagesSITREP NUMBER 62 As of 29 January 2020 1100HEdison ManaloNo ratings yet

- CP SYSTEM - DESIGN DOCUMENT (Rev.01)Document46 pagesCP SYSTEM - DESIGN DOCUMENT (Rev.01)suman ghosh100% (1)

Prox td001 - en P

Prox td001 - en P

Uploaded by

OETINCA OETINCAOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Prox td001 - en P

Prox td001 - en P

Uploaded by

OETINCA OETINCACopyright:

Available Formats

Technical Data

Original Instructions

Inductive Proximity Sensor Specifications

Bulletin Numbers 802PR, 871C, 871D, 871F, 871FM, 871L, 871P, 871R, 871T, 871TM, 871TS, 871Z, 871ZC, 871ZT, 872C, 872L

Topic Page Topic Page

Summary of Changes 2 Ring Sensors

Inductive Proximity Sensors Basics 5 871R Ring Style 141

Applications 15 Inductive Proximity Accessories

Tubular Sensors Banking Screw Adapters 143

871C Special Purpose 17 Conduit Adapters 144

871T Stainless Steel Barrel 30 Mounting Brackets

871TM All Stainless Steel 36 Tubular Proximity Sensors 145

871TS Food and Beverage 59 Can Sensor Proximity Sensors 150

871Z Weld Field Immune 61 VersaCube Sensors 150

871ZT Weld Field Immune 65 VersaCube Proximity Sensors (Limit Switch Style) 151

872C WorldProx General Purpose 73 PTFE Cover for VersaCube 151

Rectangular Sensors PTFE End Caps for Tubular Proximity Sensors 152

802PR Limit Switch Style 89 Plastic Deflecting Caps for Tubular Proximity Sensors 152

871F Block, Flat Pack, and Puck Style 100 Mounting Nuts for Tubular Proximity Sensors 153

871FM Mini Flat Pack Style 112 Lock Washers for Tubular Proximity Sensors 155

871L and 872L Limit Switch Style 118 Spacer Kits 155

871P Can Sensors 122 Torque Charts 157

871P VersaCube Multi-position 125

Cylinder Sensors

871D Cylinder Positioning 133

871D WorldClamp 137

Inductive Proximity Sensor Specifications Technical Data

Summary of Changes

This publication contains the following new or updated information. This list includes substantive updates only and is not intended to reflect

all changes.

Topic Page

Added product selection tables for all products Throughout manual

Added Inductive Proximity Sensors Basics section 5

Added Applications section 15

Added 871TS smooth barrel cat. nos. 59

Updated dimension in Table 8 78

Added 872C WorldProx 4-wire DC Complementary Output section 80

Added 872C WorldProx 2-wire AC section 82

Added 872C WorldProx 2-wire AC — Extended Sensing section 84

Added 872C WorldProx 2-wire AC/DC section 86

Added 872C WorldProx 2-wire AC/DC Relay Output section 88

Updated 871F 3-wire DC Weld Field Immune Rectangular Sensors section title 107

Added Factor-1 Equal Sensing to 871P VersaCube 4-wire DC Rectangular Sensors specifications table 129

Updated 871P VersaCube 2-wire AC/DC Rectangular Sensors section title 131

Added Inductive Proximity Accessories section 143

2 Rockwell Automation Publication PROX-TD001J-EN-P - August 2020

Technical Definitions and Terminology

Term Definition Term Definition

Portion of the sensor from which the electromagnetic field Operating Distance, 0…81% of the rated operating distance for inductive

Active Face Assured proximity switches.

or ultrasonic pulse emanates.

Operating Distance, The

The approach of the target with its center maintained on operating distance that the manufacturer specifies and

Axial Approach is used as a reference value. Also known as nominal sensing

the reference axis. Rated distance.

(N.O. & N.C.) A proximity sensor that features both normally

Complementary The sensor switches the load to the positive terminal.

open and normally closed outputs, which can be used

Outputs PNP Connect the load between the sensor output and negative

simultaneously.

terminal. See Figure 3 on page 4.

Suggested multiplication factors that take variations in the

target material composition into account. When figuring Output which can be changed from N.O. to N.C. or N.C. to

Correction Factors actual Programmable

Output (N.O. or N.C.) N.O.

sensing distance, multiply this factor with the by way of a switch or jumper wire. Also known as

nominal sensing distance. selectable output.

Current The current consumed by the proximity switch when the The variation of the effective operating distance that is

Consumption output device is in the off condition. measured at room temperature and constant supply

Repeatability voltage. It is expressed as a percentage of the sensing

Material that causes a decrease in the strength of the distance.

Damping Material electromagnetic or electrical field that the sensing coil is

produces. The voltage across the sensor output while energized and

Residual Voltage carrying maximum load current.

Differential Travel The distance between the operating point and the release

(Hysteresis) point. See Hysteresis. The sum of the time needed for a string of electronic

Response Time circuits to translate a change in light into a change of

Sensor that has two outputs, which can be complementary output status.

Dual Output or of one type (that is, two N.O. or two N.C.).

A circuit that uses a diode to avoid damage to the control in

Reverse Polarity

Effective Operating The operating distance of an individual proximity switch case the polarity of the power supply is accidentally

measured at stated temperature, voltage, and mounting Protection

Distance (Sr) reversed.

condition.

The variance between peak-to-peak values in DC voltage. It

An undesired change in the state of the output of the Ripple

False Pulse is expressed in percentage of rated voltage.

proximity switch that lasts for more than 2 milliseconds.

Sensing Distance The distance at which an approaching target activates

A shielded proximity sensor that can be flush mounted in (changes state of) the proximity output.

Flush Mounting metal up to the plane of the active sensing face.

The sensing range is the distance within which the sensor

The area around the proximity switch that must be kept free Sensing Range detects a target under fluctuations of temperature and

Free Zone from any damping material. voltage.

The difference, in percentage (%), of the nominal sensing Sensor that can be flush mounted in metal up to the plane of

distance between the operate (switch ON) and release point Shielded the active sensing face. See Figure 1 on page 4.

(switch OFF) when the target is moving away from the

Hysteresis Short Circuit Sensor that is protected from damage when a shorted

sensors active face. Without sufficient hysteresis, a

proximity sensor “chatters” (continuously switch on and off) Protection (SCP) condition exists for an indefinite or defined period.

when significant vibration is applied to the target or sensor. Sinking See NPN.

An output that is optically separated from the input and Sourcing See PNP.

Isolated Output other output and independent of the other output to a

specified level. The maximum number of times per second the sensor can

Switching change state (ON and OFF) usually expressed in Hertz (Hz).

Maximum rated voltage between isolated outputs or input Frequency

Isolation Voltage As measured in DIN EN 50010.

and output.

Target Object that activates the sensor.

Lateral Approach The approach of the target perpendicular to the reference

axis. Three-Wire An AC or DC proximity sensor with three leads, two of which

Proximity Switch supply power and a third that switches the load.

Current that flows through the output when the output is in

Two-Wire Proximity Aseries

Leakage Current an “off” condition or de-energized. This current is necessary proximity sensor that switches a load that is connected in

to supply power to the electronics of the sensor. to the power supply. Power for the proximity switch is

Switch always obtained through the load.

LED (Light-emitting Semi-conductor that generates monochromatic light when

current flows in the conductive direction. An LED is the Sensors that have longer sensing distances and a wider

Diode) Unshielded magnetic field but are sensitive to surrounding metal. See

standard light source for most photoelectric sensors.

Figure 1 on page 4.

Maximum Inrush The maximum current level at which the proximity sensor

Current can be operated for a short time. Voltage Drop The maximum voltage drop across a conducting sensor.

Maximum Load The maximum current level at which the proximity sensor Weld Field The ability of a sensor not to false trigger in the presence of

Current can be continuously operated. Immunity (WFI) strong electromagnetic fields.

Minimum Load The minimum amount of current required by the sensor to

Current maintain reliable operation.

Nonferrous Metal Any metal that does not contain iron.

Normally Closed Output opens when an object is detected in the active

(N.C.) switching area. See Figure 2 on page 4.

Normally Open Output closes when an object is detected in the active

(N.O.) switching area. See Figure 2 on page 4.

The sensor switches the load to the negative terminal.

NPN Connect the load between the sensor output and positive

terminal. See Figure 3 on page 4.

Rockwell Automation Publication PROX-TD001J-EN-P - August 2020 3

Technical Definitions and Terminology

Figure 1 - Shielded and Unshielded Figure 4 - Voltage Symbols

DC AC/DC AC

Figure 5 - Connectors

Shielded Unshielded

2 1

3 4

Figure 2 - Normally Open and Normally Closed

4-pin Micro 4-pin Mini

Normally Open (N.O.) Normally Closed (N.C.)

1 1

2 3 2 3

Figure 3 - NPN and PNP

3-pin Micro 3-pin Mini

+

Figure 6 - LED

Load

Out

--

NPN

Out

Load

--

PNP

4 Rockwell Automation Publication PROX-TD001J-EN-P - August 2020

Inductive Proximity Sensors Basics

The following information describes the application of inductive proximity sensors.

Principles of Operation Target Correction Factors

To determine the sensing distance for materials other than the

standard mild steel, a correction factor is used. The composition of

Coil Oscillator Trigger Output

Circuit Circuit

the target has a large effect on sensing distance of inductive

proximity sensors. If a target constructed from one of the materials

Inductive proximity sensors are designed to operate by generating that are listed in Table 1 on page 5 is used, multiply the nominal

an electromagnetic field and detecting the eddy current losses that sensing distance by the correction factor that is listed to determine

are generated when ferrous and nonferrous metal target objects the nominal sensing distance for that target. Ferrous-selective

enter the field. The sensor consists of a coil on a ferrite core, an sensors do not detect brass, aluminum, or copper, while nonferrous

oscillator, a trigger-signal level detector, and an output circuit. As a selective sensors do not detect steel or ferrous-type stainless

metal object advances into the field, eddy currents are induced in steels.

the target. The result is a loss of energy and a smaller amplitude of

oscillation. The detector circuit then recognizes a specific change The correction factors that are listed in Table 1 on page 5 can be

in amplitude and generates a signal that turns the solid-state used as a general guideline. Common materials and their specific

output “ON” or “OFF.” correction factors are listed on each product specification page.

Oscillator Response

(Nominal Sensing Range) x (Correction Factor) = Sensing Range

Table 1 - Correction Factors

Approximate

Target Material Correction Factor

Mild Steel 1.0

Output Voltage

Stainless Steel 0.85

On Releasing Level Brass 0.50

Operating Level

Aluminum 0.45

Output Copper 0.40

Off Off

A metal target that approaches an inductive proximity sensor absorbs

energy the oscillator generates. When the target is in close range, the The size and shape of the target can also affect the sensing

energy drain stops the oscillator and changes the output state. distance. Use the following as a general guideline when correcting

for the size and shape of a target:

• Flat targets are preferable

Standard Target • Rounded targets can reduce the sensing distance

• Nonferrous materials usually reduce the sensing distance for

Target all-metal sensing models

• Targets smaller than the sensing face typically reduce the

sensing distance

Proximity Switch

• Targets larger than the sensing face can increase the

Motion Active Face

1 mm

sensing distance

Direction

• Foils can increase the sensing distance

The active face of an inductive proximity switch is the surface

where a high-frequency electro-magnetic field emerges.

A standard target is a mild steel square, 1 mm (0.04 in.) thick, with

side lengths equal to the diameter of the active face or three times

the nominal switching distance, whichever is greater.

Rockwell Automation Publication PROX-TD001J-EN-P - August 2020 5

Inductive Proximity Sensors Basics

Hysteresis (Differential Travel) Ripple

The difference between the operate and release points is called Ripple is the alternating voltage that is superimposed on the DC

hysteresis or differential travel. The amount of target travel that is voltage (peak-to-peak) in percent (%).

required for release after operation must be accounted for when

you select target and sensor locations. Hysteresis is required to For the operation of DC voltage switches, a filtered DC voltage with

help prevent chattering (turning on and off rapidly) when the sensor a ripple of 10% maximum is required (according to DIN 41755).

is subjected to shock and vibration or when the target is stationary U

at the nominal sensing distance.

Uuss

Vibration amplitudes must be smaller than the hysteresis band to Ud

avoid chatter.

t

Target

Motion Direction

Switch Point

When Leaving

Switch Point

Hysteresis

Mounting Considerations for Weld Field

When Operating

Approaching Distance Immune Proximity Sensors

Proximity

Reliable operation is dependent on the strength of the magnetic

Switch

field and the distance between the current line and the sensor.

Figure 7 - Perpendicular Mounting to the Current Line

Current Line

Switching Frequency

The switching frequency is the maximum speed at which a sensor r

delivers discrete individual pulses as the target enters and leaves Sensor

the sensing field. This value is always dependent on target size,

distance from sensing face, speed of target, and switch type. This Magnetic Field

value indicates the maximum possible number of switching Figure 8 - Parallel Mounting to the Current Line

operations per second. IEC 60947-5-2 specifies the measuring Sensor

method for determining switching frequency with standard targets.

d

Proximity Switch Current Line

Motion

Direction

Targets of

Fe 360 or A570

2xm Sn Grade 36

m 2

Nonmagnetic and nonconducting material

m=d

6 Rockwell Automation Publication PROX-TD001J-EN-P - August 2020

Inductive Proximity Sensors Basics

Use the following chart or formulas to determine the spacing Parallel Connected Sensors

requirements between the current line and proximity sensor. Select

a distance that falls within the safe zone. Sensors can be connected in parallel to energize a load. To

• H = I/2pr determine the maximum allowable number of sensors for an

• B = H/0.796 application, the sum of the maximum leakage current of the

• Gauss - 10*B sensors that are connected in parallel must be less than the

maximum OFF-state current of the load device.

where:

ATTENTION: Care must be taken when designing

I = welding current (in kA) parallel proximity circuits. If too much leakage

current flows into the load it can cause the solid-

H = field strength (in kA/m) state input to change state or a small relay not to

B = flux (in mT) drop out. Sensors that are connected in parallel do

r = distance between sensor and current carrying lines (in m) not provide a higher load current capability.

50

Figure 11 - Wiring Diagram for Parallel Connected Current Sink

40 Sensors (NPN)

Current ( l ) [kA]

+ -

30

V DC

20 Safe Zone

+ -

10 Load

0

0 10 20 30 40 50

(0.5) (1.0) (1.5) (2.0) (2.5)

Distance from Current Line (r) [mm (in.)]

Figure 12 - Wiring Diagram for Parallel Connected Current Source

Sensors (PNP)

Series Connected Sensors +

V DC

-

+ -

Sensors can be connected in series with a load. For proper Load

operation, the load voltage must be less than or equal to the

minimum supply voltage minus the voltage drops across the series-

connected proximity sensors.

Figure 9 - Wiring Diagram for Series Connected Current Sink

Sensors (NPN) Add diode as shown to each output to maintain

individual output indicator function.

+ -

V DC Figure 13 - Wiring Diagram for Parallel Connected AC Sensors

L1 L2

V AC

+ -

Load R

R Load

Figure 10 - Wiring Diagram for Series Connected Current Source

Sensors (PNP)

+ - Add R in series with sensor to maintain

minimum voltage when sensor is switching.

V DC

+ -

Load

Rockwell Automation Publication PROX-TD001J-EN-P - August 2020 7

Inductive Proximity Sensors Basics

TTL Wiring Shielded vs. Unshielded Inductive Sensors

( + ) 10…30V DC

Shielded construction includes a metal band which surrounds the

(+) 5V

Brown ferrite core and coil arrangement. Unshielded sensors do not have

Black this metal band.

TTL

Sink

Blue Figure 14 - Shielded Sensor

(-) Common

(-)

GND

( + ) 10…30V DC Metal Metal

Shield Shield

TTL

Source

(-)

Ferrite Core

(-) 5V GND Shielded construction includes a metal

band which surrounds the ferrite core and

coil arrangement.

ATTENTION: When using sourcing outputs, ground Figure 15 - Unshielded Sensor

must be floating and cannot be common, or short

circuit results.

Ferrite Core

Unshielded sensors do not have

this metal band.

8 Rockwell Automation Publication PROX-TD001J-EN-P - August 2020

Inductive Proximity Sensors Basics

Spacing Between Shielded Sensors (Flush-mountable) and Nearby Metal Surfaces

Shielded proximity sensors allow the electro-magnetic field to be concentrated to the front of the sensor face. Shielded construction allows

the proximity to be mounted flush in surrounding metal without causing a false trigger.

Tubular Style

Figure 16 - Tubular Style Figure 17 - Tubular Style Extended Figure 18 - Tubular-style Long-range

Sensing (872C) Sensing (872C)

d d d

3 Sn

3 Sn ≥ 3d

3 Sn 3 Sn

3d d

2d

6 Sn 5d

d = diameter or width of active sensing face

d = diameter or width of active sensing face

Sn = nominal sensing distance d = diameter or width of active sensing face

Sn = nominal sensing distance Housing Diameter Dimension X

[mm (in.)] [mm (in.)]

6.5 (0.26) 1 (0.04)

12 (0.47) 2 (0.08)

18 (0.71) 4 (0.16)

30 (1.18) 6 (0.24)

Limit Switch Style

Figure 19 - Limit Switch Style (871L/872L) Figure 20 - Limit Switch Style (802PR)

d

d

d

1.3d (1)

d d d = diam

(1) Cata

802P

2d 1.8d

d = diameter or width of active sensing face d = diameter or width of active sensing face

Rockwell Automation Publication PROX-TD001J-EN-P - August 2020 9

Inductive Proximity Sensors Basics

Flat Pack Style Cube Style

Figure 21 - Flat Pack Style (871F) Figure 23 - 871P VersaCube® — 2- & 3-Wire

Active Face d d d d

Active Face

d = diameter or width of active sensing

Figure 22 - Miniature Flat Pack Style (871FM)

d

d

d = diameter or width of active sensing d

Figure 24 - 871P VersaCube — 4-Wire

Metal-free clear zone required

3 Sn

(1…4 mm) on sensor sides

with surrounding metal on four sides

Sn = nominal sensing distance

d

d

d d = diameter or width of active sensing face

Surrounding Metal-free

Opening

Metal Number of Clear Zone

Orientation Required (Each

Thickness Sides Side)

[mm (in.)] [mm (in.)]

[mm (in.)]

44 x 44

<3 (0.12) 4 4 (0.16)

Front sensing (1.73 x 1.73)

face with 40 x 40

3 (0.12) 1, 2, or 3 None

bracket on (1.57 x 1.57)

back 41 x 41

≥3 (0.12) 4 1 (0.04)

(1.61 x 1.61

Figure 25 - Spacing Between Opposing Sensors

Active Face

d = diameter or width of

active sensing face

3d

10 Rockwell Automation Publication PROX-TD001J-EN-P - August 2020

Inductive Proximity Sensors Basics

Spacing Between Unshielded Sensors (Nonflush-mountable) and Nearby Metal Surfaces

Longer sensing distances can be obtained by using an unshielded sensor. Unshielded proximity sensors require a metal-free zone around

the sensing face. Metal immediately opposite the sensing face must be no closer than three times the rated nominal sensing distance of the

sensor.

Tubular Style Limit Switch Style

Figure 26 - Tubular Style Figure 29 - Limit Switch Style (871L and 872L)

0.4d

≥ 3d

3d d 3 Sn

d

4d

d = diameter or width of active sensing face

d = diameter or width of active sensing face

Sn = nominal sensing distance 4d

4d

Figure 30 - Limit Switch Style (802PR)

Figure 27 - Tubular-style Extended Sensing (872C) 0.4d

3 Sn 3 Sn

d

d 0.4d

d = diameter or width of active sensing face

d = diameter or width of active sensing face 1.5d

Sn = nominal sensing distance

6 Sn

Flat Pack Style

Figure 28 - Tubular-style Long Range Sensing (872C)

Figure 31 - Flat Pack Style (871F)

≥ 3d

3 Sn Active Face

3d d

d 4d d d

X

d = diameter or width of

active sensing face

d = diameter or width of active sensing face Figure 32 - Miniature Flat Pack Style (871FM)

Sn = nominal sensing distance

Side View

(amount of overhang)

6 Sn

0.5L

Housing Diameter Dimension X

[mm (in.)] [mm (in.)]

8 (0.31) 8 (0.31) L

12 (0.47) 13 (0.51) 6 Sn

Sn = nominal sensing distance

18 (0.71) 20 (0.79)

30 (1.18) 35 (1.38)

Rockwell Automation Publication PROX-TD001J-EN-P - August 2020 11

Inductive Proximity Sensors Basics

Cube Style Figure 35 - Spacing Between Sensors

0.75d

Figure 33 - 871P VersaCube — 2- & 3-Wire

Active Face

4d (1) d d

0.75d

d

4d d = diameter or width of active sensing

0.75d d face

Figure 36 - Spacing Between Opposing Sensors

Active Face

d

4d

d

d

d

0.75d

0.75d 6d 0.75d

d = diameter or width of active sensing face

Sn = nominal sensing distance

(1) 3d for weld field immune

Figure 34 - 871P VersaCube — 4-Wire

Metal

15 (0.59)

Sensor Face

Front Sensing Face 15 (0.59)

Sensor Face

Metal

Side Sensing Face

Surrounding Metal Number of Metal-free Clear

Thickness [mm Orientation Zone (Each Side)

Sides

(in.)] [mm (in.)]

Front sensing face

with bracket on 15 (0.59) protrusion

back

1

Side sensing face 15 (0.59)

3 (0.12) with bracket on (1)

back protrusion

Front sensing face

2, 3, or 4 with bracket on 30 (1.18) protrusion

back

(1) Sensing distance deviation can be up to -15%.

12 Rockwell Automation Publication PROX-TD001J-EN-P - August 2020

Inductive Proximity Sensors Basics

Spacing for 871TM 3-Wire DC Long Range Sensors

Figure 37 - Shielded Sensors Figure 38 - Unshielded Sensors

X Y W X

Metal-free Metal-free

zone zone

Sensing Y

Z face

Sensing

face Z

Support

Support

Sensor Diameter Dimension [mm (in.)]

[mm (in.)] W X Y Z

Sensor Diameter Dimension [mm (in.)] • Aluminum: 9 (0.35)

[mm (in.)] X Y Z • Steel: 14 (0.55)

8 (0.31) 18 (0.71) 60 (2.36) 18 (0.71)

8 (0.31) 6 (0.24) 22 (0.87) 9 (0.35) • Brass: 10 (0.39)

• Stainless Steel: 13 (0.51)

12 (0.47) 12 (0.47) 50 (1.97) 18 (0.71)

• Aluminum: 13 (0.51)

18 (0.71) 25 (0.98) 50 (1.97) 30 (1.18) • Steel: 21 (0.83)

30 (1.18) 45 (1.77) 110 (4.33) 60 (2.36) 12 (0.47) 12 (0.47) 50 (1.97) 18 (0.71)

• Brass: 14 (0.55)

• Stainless Steel: 20 (0.79)

• Aluminum: 22 (0.87)

• Steel: 36 (1.42)

18 (0.71) 25 (0.98) 50 (1.97) 30 (1.18)

• Brass: 22 (0.87)

• Stainless Steel: 43 (1.69)

• Aluminum: 31 (1.22)

• Steel: 17 (0.67)

30 (1.18) 45 (1.77) 110 (4.33) 60 (2.36)

• Brass: 34 (1.34)

• Stainless Steel: 17 (0.67)

Rockwell Automation Publication PROX-TD001J-EN-P - August 2020 13

Inductive Proximity Sensors Basics

Spacing for 871FM Miniature Metal Flat Pack Sensors

D

A

E

Sensor Dimension [mm (in.)]

[WxLxH in mm (in.)] A B C D E

20x32x8 (0.79x1.26x0.31) shielded, 24 (0.94) 24 (0.94) 20 (0.79) 20 (0.79) 48 (1.89)

7 (0.28) sensing

30x52x14 (1.18x2.05x0.55) shielded, 45 (1.77) 45 (0.79) 30 (1.18) 30 (1.18) 90 (3.54)

10 (0.39) sensing

14 Rockwell Automation Publication PROX-TD001J-EN-P - August 2020

Applications

Figure 39 - Machine Tools Figure 43 - Wood Industry Figure 47 - Can Tops

Capacitive Proximity Inductive

Sensor Proximity

Lathe Sensor

Tool Wood

Chuck Inductive

Proximity

Inductive

Sensor

Proximity

Sensor

Saw Blade Returns for

Inductive Another Cut Figure 48 - Food Industry

Proximity Inductive

Sensor Proximity

Figure 44 - Conveyor Belts Sensor

Figure 40 - Plating Line Metal Parts

Bottle

Inductive

Proximity Cap

Sensor

Metal

Can

Inductive

Proximity

Sensor Conveyor

Inductive

Proximity Figure 45 - Petroleum Industry — Conveyor

Sensor Valve Position

Handwheel Acts as Target

Figure 49 - Stainless Steel Sheet Welder

Figure 41 - Plating Line A 871TM

Inductive Proximity

Sensor for Horizontal

B 871TM

Trigger Position Detection

871Z Hole to

Identify Weld

Work to be - (Cathode)

Dipped Insulation

+ (Anode) 871Z

A: Open Valve Indicator

B: Closed Valve Indicator

Inductive

Proximity Figure 46 shows an inductive proximity

Sensors for Figure 50 - On Line Parts Sorting

Vertical Position sensor being used to detect a foil

Detection

seasoning bag inside of a cardboard

Figure 42 - Grinding Machines container. Bad

Good

Figure 46 - Foil Seasoning Bag

- DETAIL -

3/4 in. Dia.

7/16 in.

1/2 in.

872C

1 in.

7/8 in. Dia.

Inductive

Proximity Figure 51 - Railroad Yard Position Sensing

Sensor

Inductive

Proximity Figure 47 shows a ferrous-selective

Sensor

inductive proximity sensor being used to

sort ferrous and nonferrous can tops. Inductive

Proximity

Sensors

Rockwell Automation Publication PROX-TD001J-EN-P - August 2020 15

Applications

Figure 52 - Coolant Resistant Sensing Figure 57 - Control Presence of Mild Steel Bars in Grate Welding

871TM

Coolant

+ (Anode)

871Z

Check Parallelism

of Transversal Bar

with WFI Control

- (Cathode)

Figure 53 - Up and Downslope Control of Continuous Tube Welder

871P

Transformers

871Z

and 871Z 871Z

Rectifiers

Look for Position

of Steel Bar

with WFI Control

+ (Anode)

Insulation Figure 58 - Elevator Positioning

- (Cathode)

Downslope

Sensor Proximity

Rail Guide

Sensor

871P Target

Upslope

Pressure

Sensor

Roll 871P

Figure 54 - Nut Placement on Transformer 2nd Floor

871Z

871Z

Target

Transformer

Figure 55 - Closed Barrier Indicator

1st Floor

Rockwell Automation produces rail-guide inductive proximity

sensors for the positioning of elevator cars. These sensors offer

871TM Indicates increased accuracy and longer life when compared to typical

When Barrier Is

Closed mechanical switches. They are a cost-effective solution for

lowering your repair costs and downtime. Contact your local

Rockwell Automation sales office or Allen-Bradley distributor for a

Figure 56 - Detect Presence of Bushing in Piston proximity sensor that is tailored to your requirements.

872C

A = Sensing Path

16 Rockwell Automation Publication PROX-TD001J-EN-P - August 2020

Tubular Sensors

871C 2-wire AC Full Featured Tubular Sensors

Specifications

Attribute 12 mm Diameter 18 mm and 30 mm Diameter

Load Current 5…200 mA 5…250 mA

Inrush Current (one cycle) ≤2 A ≤4 A

Leakage Current ≤1.9 mA at 120V AC

Operating Voltage 20…250V AC

Voltage Drop ≤10V at 5…200 mA ≤10V at 5…250 mA

871C Cable Style Repeatability ≤10% at constant temperature

18 mm and 30 mm Dia. Hysteresis 10% typical

False pulse, transient noise, short False pulse, transient noise, short

Protection Type circuit, overload (trigger at 250 mA circuit, overload (trigger at 320 mA

typical) typical)

Certifications UL Listed, CSA Certified, and CE Marked for all applicable directives

Enclosure Type Rating NEMA 1, 2, 3, 3R, 4, 4X, 6, 6P, 12, 13; IP67 (IEC529)

Housing Material Plastic face, threaded nickel-plated brass barrel

• Cable: 2 m (6.5 ft) length, 2-conductor PVC

Connection Type • Quick-disconnect: 3-pin AC micro, 3-pin mini

• Red: Output energized/short circuit (flashing)

Status Indicator

871C Mini Quick-disconnect Style • Green: Power

12 mm, 18 mm, and 30 mm Dia. Operating Temperature -25…+70 °C (-13…+158 °F)

Shock 30 g (1.06 oz), 11 ms

Vibration 55 Hz, 1 mm (0.04 in.) amplitude, 3 planes

Correction Factors

Target Material Correction Factors

Steel 1.0

871C AC Micro Quick-disconnect Style

12 mm, 18 mm, and 30 mm Dia. Stainless Steel 0.9

Brass 0.5

Aluminum 0.45

Copper 0.4

Product Selection

Barrel Diameter Nominal Sensing Output Switching Cat. No.

Shielded

[mm (in.)] Distance [mm (in.)] Configuration Frequency [Hz] Cable Style Mini QD Style AC Micro QD Style

N.O. 30 871C-A2N12-A2 871C-A2N12-N3 871C-A2N12-R3

12 (0.47) 2 (0.08) Yes

N.C. 20 871C-A2C12-A2 871C-A2C12-N3 871C-A2C12-R3

N.O. 30 871C-A5N18-A2 871C-A5N18-N3 871C-A5N18-R3

18 (0.71) 5 (0.20) Yes

N.C. 20 871C-A5C18-A2 871C-A5C18-N3 871C-A5C18-R3

N.O. 30 871C-A10N30-A2 871C-A10N30-N3 871C-A10N30-R3

30 (1.18) 10 (0.39) Yes

N.C. 20 871C-A10C30-A2 871C-A10C30-N3 871C-A10C30-R3

Recommended Standard QD Cordset (-6F = 1.8 m [6 ft], -2 = 2 m [6.5 ft]) 889N-F3AFC-6F 889R-F3ECA-2

Rockwell Automation Publication PROX-TD001J-EN-P - August 2020 17

Tubular Sensors

Approximate Dimensions Wiring Diagrams

Cable Style Normally Open Normally Closed

2 Status Brown Brown

Indicators

2 m (6.5 ft) Blue Load Blue Load

Green/Yellow Green/Yellow

A C B

D IMPORTANT Load can be switched

to brown wire.

Dimensions are shown in mm (in.).

Thread Size Shielded

A B C D

M12 x 1 Yes 12.0 (0.47) 78.99 (3.11) 47.24 (1.86)

M18 x 1 Yes 18.0 (0.71) 74.68 (2.94) 61.6 (2.43) 0.8 (0.03)

M30 X 1.5 Yes 30.0 (1.18) 77.52 (3.05) 64.31 (2.53)

Mini QD Style Normally Open or Normally Closed

Ground

2 Status A IMPORTANT • No ground wire on

Indicators

D

12 mm. Attach housing to

1

2 3

ground.

C

• Load can be switched to

B

pin 3.

Load

7/8-16-UN-2A

Dimensions are shown in mm (in.).

Thread Size

A B C

M12 x 1 12.0 (0.47) 93.45 (3.68) 46.08 (1.81)

M18 x 1 18.0 (0.71) 75.82 (2.99) 53.9 (2.12)

M30 X 1.5 30.0 (1.18) 86.66 (3.41) 64.31 (2.53)

AC Micro QD Style Normally Open or Normally Closed

Ground

A IMPORTANT • No ground wire on

1

2 Status D 2 3 Load 12 mm. Attach housing to

Indicators ground.

C • Load can be switched to

B pin 2.

1/2-20 UNF-2A

Dimensions are shown in mm (in.).

Thread Size

A B C

M12 x 1 12.0 (0.47) 90.42 (3.56) 46.99 (1.85)

M18 x 1 18.0 (0.71) 83.54 (3.29) 61.6 (2.43)

M30 X 1.5 30.0 (1.18) 86.00 (3.39) 64.31 (2.53)

18 Rockwell Automation Publication PROX-TD001J-EN-P - August 2020

Tubular Sensors

871C 2-wire AC Plastic Barrel Tubular Sensors

Specifications

Attribute 18 mm Diameter 30 mm Diameter

Load Current ≤180 mA ≤300 mA

Inrush Current (one cycle) ≤1 A ≤3 A

Leakage Current ≤1.7 mA

871C Cable Style Operating Voltage 24…250V AC

18 mm and 30 mm Dia.

Voltage Drop ≤11V

Hysteresis ≤20% typical

Protection Type Transient noise

Certifications CE Marked for all applicable directives

Enclosure Type Rating NEMA 1, 2, 3, 4, 4X, 12, 13; IP67 (IEC529)

Housing Material Plastic face and threaded barrel

Connection Type Cable: 2 m (6.5 ft) length, 2-conductor PVC

Status Indicator Red: Output energized

Operating Temperature -25…+55 °C (-13…+131 °F)

Shock 30 g (1.06 oz), 11 ms

Vibration 55 Hz, 1 mm (0.039 in.) amplitude, 3 planes

Correction Factors

Target Material Correction Factors

Steel 1.0

Stainless Steel 0.7…0.8

Brass 0.4…0.5

Aluminum 0.3…0.4

Copper 0.3…0.4

Product Selection

Barrel Diameter Nominal Sensing Distance Cat. No.

Shielded Output Configuration Switching Frequency [Hz]

[mm (in.)] [mm (in.)] Cable Style

N.O. 871C-C5S18

5 (0.20) Yes

N.C. 871C-D5S18

18 (0.71)

N.O. 871C-C8R18

8 (0.31) No

N.C. 8 871C-D8R18

10 (0.39) Yes N.O. 871C-C10S30

30 (1.18) N.O. 871C-C15R30

15 (0.59) No

N.C. 871C-D15R30

Rockwell Automation Publication PROX-TD001J-EN-P - August 2020 19

Tubular Sensors

Approximate Dimensions Wiring Diagrams

Cable Style Normally Open Normally Closed

Status Black Black

Indicator

Blue Load Blue

Load

2 m (6.5 ft)

C B IMPORTANT Load can be switched to

A

black wire.

D

Dimensions are shown in mm (in.).

Thread Size Shielded

A B C D

Yes

M18x 1 18.0 (0.71)

No(1)

81.0 (3.19) 61.0 (2.40) 2.0 (0.08)

Yes

M30 X 1.5 30.0 (1.18)

No (1)

(1) Unshielded proximity sensors require a metal-free zone around the sensing face. Any metal immediately opposite the sensing face must be no closer than three times the rated nominal

sensing distance of the sensor.

20 Rockwell Automation Publication PROX-TD001J-EN-P - August 2020

Tubular Sensors

871C Analog Output, 3-wire DC Tubular Sensors

Specifications

Attribute 12 mm Diameter 18 mm Diameter 30 mm Diameter

Analog Output 0…10V Sourcing

Load Current 5 mA

Operating Voltage 18…30V DC

Repeatability ≤1%

871C Cable Style Ripple 10%

12 mm, 18 mm, and 30 mm Dia. Slew Speed 1.0 V/ms 0.7 V/ms 0.1 V/ms

∆ Output/∆ Distance 0.25 mm/V 0.375 mm/V 0.875 mm/V

Linearity Tolerance 6.25%

Temperature Drift ±0.3V

Protection Type Transient noise, reverse polarity, short circuit, and overload

Certifications CE Marked for all applicable directives

Enclosure Type Rating NEMA 1, 2, 3, 4, 12, 13; IP67 (IEC529)

Housing Material Nickel-plated brass barrel, plastic face (PBT)

Connection Type Cable: 2 m (6.5 ft) length, 3-conductor PVC

Status Indicator None

Operating Temperature -25…+70 °C (-13…+158 °F)

Shock 30 g (1.06 oz), 11 ms

Vibration 55 Hz, 1 mm amplitude, 3 planes

Correction Factors

Target Material Correction Factors

Steel 1.0

Stainless Steel 0.7…0.8

Brass 0.4…0.5

Aluminum 0.3…0.4

Copper 0.2…0.3

Product Selection

Barrel Diameter Linear Sensing Distance Cat. No.

Shielded Output Configuration Switching Frequency [Hz]

[mm (in.)] [mm (in.)] Cable Style

12 (0.47) 0.5…2.5 (0.02…0.10) Yes 100 871C-D3AP12-E2

18 (0.71) 1…4 (0.04…0.16) Yes 100 871C-D4AP18-E2

Analog Voltage PNP

1…9 (0.04…0.35) Yes 400 871C-D9AP30-E2

30 (1.18)

7…14 (0.27…0.55) No 30 871C-D14AP30-E2

Rockwell Automation Publication PROX-TD001J-EN-P - August 2020 21

Tubular Sensors

Approximate Dimensions

Dimensions are shown in mm (in.).

Thread Size

A B C D

12 mm 12.0 (0.47)

2 m (6.5 ft) 58.0 (2.28)

18 mm 18 (0.71) 81.0 (3.15) 12 (0.47)

A C B

30 mm 30.0 (1.18) 70 (2.75)

D

Wiring Diagrams

12 mm Diameter 18 mm Diameter 30 mm Diameter

+ Brown + Brown + Brown

Analog Analog Analog

Black Black Black

Load 18…30V DC Load 18…30V DC Load 18…30V DC

I - Blue I - Blue I - Blue

Nominal Output

12 mm Diameter 18 mm Diameter 30 mm Diameter

9V 9V

9V

0.375 mm/V 0.875 mm/V

0.25 mm/V

Output

Output

Output

1V 1V

1V

1 mm 4 mm 7 mm 14 mm

0.5 mm 2.5 mm

Distance to Target Distance to Target

Distance to Target

22 Rockwell Automation Publication PROX-TD001J-EN-P - August 2020

Tubular Sensors

871C 2-wire NAMUR Intrinsically Safe, Cable Style Tubular Sensors

Specifications

Attribute 8 mm, 12 mm, 18 mm, and 30 mm Diameter

Output Type NAMUR (conforms to DIN 19 234)

Load Current, Nom. <1 mA (target present), >3 mA (target absent)

Operating Voltage 5…15V DC (8.2V DC nom., Ri = 1 kohm, DIN 19 234)

Ripple 5%

Repeatability <10%

871C NAMUR Cable Style Hysteresis 10% typical

8 mm, 12 mm, 18 mm, and 30 mm Dia, Protection Type (Realized in Amplifier) Reverse polarity, false pulse, transient noise, short circuit, and overload

FM Approved:

• Class I, II, III; Divisions 1, 2; Groups A, B, C, D, E, F, G

Certifications • Class I; Zone 0, 1, 2; Groups IIC, IIB, IIA; T6; CSA Certified

• Class I, II, III; Divisions 1, 2; Groups A, B, C, D, E, F, G

• Class I; Zone 0, 1, 2; Groups IIC, IIB, IIA; CE Marked for all applicable directives

Enclosure Type Rating NEMA 4, IP67 (IEC529)

Housing Material Nickel-plated brass barrel, plastic face

Connection Type • Cable: 2 m (6.5 ft) length, 2-conductor #22 AWG PVC

• Quick-disconnect: 4-pin micro style

Status Indicator None

871C NAMUR Micro Quick-disconnect Style Operating Temperature -25…+60 °C (-13…+140 °F)

8 mm, 12 mm, 18 mm, and 30 mm Dia. Shock 30 g (1.06 oz), 11 ms

Vibration 55 Hz, 1 mm amplitude, 3 plane

Entity Parameters Correction Factors

Sensor Barrier Target Material Correction Factors

Vmax 16V ≥ Vt Steel 1.0

ATTENTION: Imax 60 mA ≥ lt Stainless Steel 0.7…0.8

Operating parameters must be Cl 150 nF ≤ Ca Brass 0.4…0.5

adhered to. Ll 200 µH ≤ La Aluminum 0.3…0.4

Copper 0.2…0.3

Product Selection

Barrel Diameter Nominal Sensing Distance Switching Frequency Cat. No.

Shielded Output Configuration

[mm (in.)] [mm (in.)] [Hz] Cable Style Micro QD Style

1 (0.03) Yes 2000 871C-DH1M8-A2 871C-DH1M8-D4

8 (0.31)

2 (0.08) No 1000 871C-DH2M8-A2 871C-DH2M8-D4

2 (0.08) Yes 2000 871C-DH2M12-A2 871C-DH2M12-D4

12 (0.47)

4 (0.16) No NAMUR 1000 871C-DH4M12-A2 871C-DH4M12-D4

5 (0.20) Yes (conforms to DIN 19 234) 1000 871C-DH5M18-A2 871C-DH5M18-D4

18 (0.71)

8 (0.31) No 500 871C-DH8M18-A2 871C-DH8M18-D4

10 (0.39) Yes 500 871C-DH10M30-A2 871C-DH10M30-D4

30 (1.18)

15 (0.59) No 300 871C-DH15M30-A2 871C-DH15M30-D4

Recommended cordset: 2 m (6.5 ft) 4-pin DC micro (straight) 889D-F4AC-2

IMPORTANT The sensor output conforms to NAMUR specification (DIN 19 234) when used with Cat. Nos. 937TH-DISAR-DC2, 937TS-

DISAR-KD2, 937TS-DISAR-KF2, or 937TH-DISAT-DC Intrinsically Safe Output Switch Amplifier. Installation must be in

accordance with the National Electrical Code, ANSI/ISA RP12.6, or per other regulations by authority having jurisdiction

over the installation site as appropriate.

Rockwell Automation Publication PROX-TD001J-EN-P - August 2020 23

Tubular Sensors

Approximate Dimensions Wiring Diagrams

Cable Style

Brown +

To NAMUR

2 m (6.5 ft)

Galvanic Isolator

Blue

--

A C B

D

Dimensions are shown in mm (in.).

Thread Size Shielded

A B C

Yes —

M8 X1 8.0 (0.31)

No 5.0 (0.20)

Yes —

M12 X 1 12.0 (0.47) 30.0 (1.18)

No 6.0 (0.24)

Yes —

M18 X 1 18.0 (0.71)

No 8.0 (0.31)

Yes —

M30 X 1.5 30.0 (1.18) 40.0 (1.57)

No 12.0 (0.47

Micro QD Style Normally Open

PNP (Sourcing)

A

D 2 1 +

3 4

To NAMUR

C Galvanic Isolator

B --

M12 x 1

Dimensions are shown in mm (in.).

Thread Size Shielded

A B C D

Yes 28.0 (1.10) —

M8 X1 8.0 (0.31)

No 23.0 (0.91) 5.0 (0.20)

Yes 30.0 (1.18) —

M12 X 1 12 (0.47) 50.0 (1.97)

No 24.0 (0.94) 6.0 (0.24)

Yes 30.0 (1.18) —

M18 X 1 18.0 (0.71)

No 22.0 (0.87) 8.0 (0.31)

Yes 40.0 (1.57) —

M30 X 1.5 30.0 (1.36) 60.0 (2.36)

No 28.0 (1.10) 12.0 (0.47)

Block Diagram

Relay Output Transistor Output

937TH-DISAR-DC2 937TH-DISAT-DC2

Dual Channel Dual Channel

1+ 5 1+ 5

2 - 6 2 - 6

3+ 7 3+ 7

4 - 8 4 - 8

Switch Switch

Settings Settings

S1 I S1 I

- 10

- 10

S2 I S2 I

S3 I U 9 S3 I U 9

+ +

S4 I Err S4 I Err

DIN Rail Connections DIN Rail Connections

24 Rockwell Automation Publication PROX-TD001J-EN-P - August 2020

Tubular Sensors

871C 3-wire DC Mini Tubular Sensors

Specifications

3 mm Smooth Barrel and 4 mm Smooth Barrel and

Attribute

4 mm Threaded Barrel 5 mm Threaded Barrel

Environmental

871C NAMUR Cable Style Operating Environment NEMA 1, 2, 3, 4, 12, 13 IP67 (IEC 529)

8 mm, 12 mm, 18 mm, and 30 mm Operating Temperature -25…+70 °C (-13…+158 °F)

Vibration 55 Hz, 1 mm amplitude, 3 planes

Shock 30 g (1.06 oz), 11 ms

Electrical

Load Current ≤ 100 mA <200 mA

Leakage Current ≤ 0.1 mA

871C NAMUR Micro Quick-disconnect Style

8 mm, 12 mm, 18 mm, and 30 mm Operating Voltage 10…30V DC

Voltage Drop ≤ 2V

Repeatability ≤ 5%

Hysteresis 10% typical

Protection Type False pulse, transient noise, reverse polarity, and short circuit

871C NAMUR Micro Quick-disconnect Style IO-Link (Enabled on Normally Open, PNP Models Only)

8 mm, 12 mm, 18 mm, and 30 mm Protocol IO-Link V1.0

Interface Type IO-Link

Mode COM 2 (38.4 kBd)

Cycle Time 1 10.4 ms, minimum

SIO (standard I/O) Supported (pin 4 for either IO-Link or standard I/O)

Mechanical

Housing Material Small threaded or smooth stainless steel barrel, polyester face

871C NAMUR Micro Quick-disconnect Style Status Indicator Yellow: Output energized

8 mm, 12 mm, 18 mm, and 30 mm Status Indicator (IO-Link Mode) Solid yellow: Sensor in IO-Link mode

Connection Type Pico™ QD (M8), 2 m (6.6 ft) cable, pico with lead

Correction Factors

4 mm Diameter 5 mm Diameter

Sensor Type/ 3 mm Diameter Smooth Smooth or Threaded Smooth or Threaded

Target Material

871C NAMUR Micro Quick-disconnect Style 0.6 mm Sr 1.0 mm Sr 0.8 mm Sr 1.5 mm Sr 1 mm Sr 1.5 mm Sr

8 mm, 12 mm, 18 mm, and 30 mm Steel 1 1 1 1 1 1

Copper 0.5 0.45 0.45 0.4 0.45 0.4

Aluminum 0.55 0.5 0.5 0.4 0.5 0.4

Brass 0.65 0.6 0.55 0.5 0.55 0.5

Stainless Steel 304 0.8 0.8 0.8 0.75 0.8 0.75

Rockwell Automation Publication PROX-TD001J-EN-P - August 2020 25

Tubular Sensors

Product Selection

Barrel Nominal Sensing Switching Cat. No.

Barrel Type Output

Diameter Distance [mm Shielded Frequency

[mm (in.)] Configuration Cable Style Pico™ QD Style Pico with Lead Style

[mm (in.)] (in.)] [Hz]

NPN 871C-DM1NN3-E2 — 871C-DM1NN3-AP3

0.6 (0.02) 5000

PNP 871C-DM1NP3-E2 — 871C-DM1NP3-AP3

3 (0.12) Smooth

NPN 871C-MM1NN3-E2 — 871C-MM1NN3-AP3

1 (0.04) 3000

PNP 871C-MM1NP3-E2 — 871C-MM1NP3-AP3

NPN 871C-D1NN4-E2 — 871C-D1NN4-AP3

0.8 (0.03) 5000

PNP 871C-D1NP4-E2 — 871C-D1NP4-AP3

Threaded

NPN 871C-M1NN4-E2 — 871C-M1NN4-AP3

1 (0.04) 3000

PNP 871C-M1NP4-E2 — 871C-M1NP4-AP3

4 (0.16) Yes N.O.

NPN 871C-DM1NN4-E2 871C-DM1NN4-P3 —

0.8 (0.03) 5000

PNP 871C-DM1NP4-E2 871C-DM1NP4-P3 871C-DM1NP4-AP3

Smooth

NPN 871C-MM2NN4-E2 871C-MM2NN4-P3 —

1.5 (0.06) 3000

PNP 871C-MM2NP4-E2 871C-MM2NP4-P3 —

NPN 871C-D1NN5-E2 871C-D1NN5-P3 —

1 (0.04) 5000

PNP 871C-D1NP5-E2 871C-D1NP5-P3 —

5 (0.20) Threaded

NPN 871C-M2NN5-E2 871C-M2NN5-P3 —

1.5 (0.06) 3000

PNP 871C-M2NP5-E2 871C-M2NP5-P3 —

Recommended Standard QD Cordset (-2 = 2 m [6.5 ft]) 889P-F3AB-2

Approximate Dimensions Wiring Diagrams

Cable Style Normally Open

NPN (Sinking) PNP (Sourcing)

Status + -- + --

Indicator Status 10…30V DC 10…30V DC

Indicator Brown + --

Brown

2 m (6.5 ft) + -- Load

B 2 m (6.5 ft) Blue Black

Load

C Black

A B Blue

A

Dimensions are shown in mm (in.).

Smooth Diameter Thread Size Shielded

A B C

3.0 — 3.0 (0.12) 22.0 (0.87) —

Yes

4.0 — 4.0 (0.16) 25.0 (0.98) —

4.0 M4 X 0.5 4.0 (0.16) 22.0 (0.87) 19.0 (0.75)

Yes

5.0 M5 X 0.5 5.0 (0.20) 25.0 (0.98) 20.0 (0.79)

26 Rockwell Automation Publication PROX-TD001J-EN-P - August 2020

Tubular Sensors

Approximate Dimensions Wiring Diagrams

Pico QD Style Normally Open

Status Status PNP (Sourcing) NPN (Sinking)

Indicator A Indicator A

+ --

4 Load Load 4

1 3 -- + 1 3

C C

+ 10…30V DC -- + 10…30V DC --

B B

Smooth Threaded

Dimensions are shown in mm (in.).

Smooth Diameter Thread Size Shielded

A B C

4.0 — 4.0 (0.16) 38.0 (1.50) 19.0 (0.74)

Yes

5.0 M5 X 0.5 5.0 (0.20) 38.0 (1.50) 23.0 (0.90)

Pico with Lead Style Normally Open

Smooth 152 Threaded 152 PNP (Sourcing) NPN (Sinking)

Status (6.0) Status (6.0)

Indicator Indicator + --

4 Load Load 4

1 3 -- + 1 3

B C

A A B

+ 10…30V DC -- + 10…30V DC --

Dimensions are shown in mm (in.).

Smooth Diameter Shielded

A B C

3.0 3.0 (0.1) 22.0 (0.87) —

Yes

4.0 4.0 (0.16) 22.0 (0.87) 19.0 (0.74)

Rockwell Automation Publication PROX-TD001J-EN-P - August 2020 27

Tubular Sensors

871C 3-wire DC Extended Temperature Tubular Sensors

Specifications

Attribute 12 mm, 18 mm, and 30 mm Diameter

Load Current 1…200 mA

Leakage Current ≤10 μA

Operating Voltage 10…30V DC

Voltage Drop ≤2.4V

Repeatability ≤10%

871C Cable Style

Hysteresis ≤15% typical

12 mm, 18 mm, and 30 mm Dia.

Protection Type False pulse, transient noise, reverse polarity, short circuit, and overload

Certifications CE Marked for all applicable directives

Enclosure Type Rating NEMA 1, 2, 3, 4, 12, 13; IP67 (IEC529)

Housing Material Threaded nickel-plated brass barrel, plastic face

• Cable: 2 m (6.5 ft) length, 3-conductor PUR

Connection Type

• Quick-disconnect: 4-pin M12 micro style

Status Indicator Orange: Output Energized

Operating Temperature -40…+100 °C (-40…+212 °F)

Shock 30 g (1.06 oz), 11 ms

Vibration 55 Hz, 1 mm amplitude, 3 planes

871C DC M12 Micro Quick-disconnect Style

12 mm, 18 mm, and 30 mm Dia.

Correction Factors

Target Material Correction Factors

Steel 1.0

Stainless Steel 0.9

Brass 0.5

Aluminum 0.45

Copper 0.4

Product Selection

Barrel Diameter Nominal Sensing Distance Switching Frequency Cat. No.

Shielded Output Configuration

[mm (in.)] [mm (in.)] [Hz] Cable Style Micro QD Style

2 (0.08) Yes 2000 871C-DT2NP12-U2 871C-DT2NP12-D4

12 (0.47) N.O. PNP

4 (0.16) No 1000 871C-DT4NP12-U2 871C-DT4NP12-D4

5 (0.20) Yes 1000 871C-DT5NP18-U2 871C-DT5NP18-D4

18 (0.71) N.O. PNP

8 (0.31) No 500 871C-DT8NP18-U2 871C-DT8NP18-D4

10 (0.39) Yes 500 871C-DT10NP30-U2 871C-DT10NP30-D4

30 (1.18) N.O. PNP

15 (0.59) No 300 871C-DT15NP30-U2 871C-DT15NP30-D4

Recommended cordset: 2 m (6.5 ft) 889D-F4AC-2

28 Rockwell Automation Publication PROX-TD001J-EN-P - August 2020

Tubular Sensors

Approximate Dimensions Wiring Diagrams

Cable Style Normally Open

+

PNP (Sourcing) --

Status

Indicator 10…30V DC

Brown + --

2 m (6.5 ft) Black Load

Blue

C

A B

Dimensions are shown in mm (in.).

Thread Size Shielded

A B C D

Yes 40.0 (1.57) —

M12 X 1 12.0 (0.47)

No 34.0 (1.34) 6.0 (0.24)

Yes 40.0 (1.57) —

M18 X 1 18.0 (0.71) 40.0 (1.57)

No 32.0 (1.26) 8.0 (0.31)

Yes 40.0 (1.57) —

M30 X 1.5 30.0 (1.18)

No 28.0 (1.12) 12 (0.47)

M12 Micro QD Style Normally Open PNP (Sourcing)

A

Status 2 1

D

Indicator 3 4

C

B Load

-- +

M12 x 1

10…30V DC

-- +

Dimensions are shown in mm (in.).

Thread Size Shielded

A B C D

Yes 40.0 (1.57) —

M12 X 1 12.0 (0.47)

No 34.0 (1.34) 6.0 (0.24)

Yes 40.0 (1.57) —

M18 X 1 18.0 (0.71) 60.0 (2.36)

No 32.0 (1.26) 8.0 (0.31)

Yes 40.0 (1.57) —

M30 X 1.5 30.0 (1.18)

No 28.0 (1.12) 12 (0.47)

Rockwell Automation Publication PROX-TD001J-EN-P - August 2020 29

Tubular Sensors

871T 3-wire DC Stainless Steel Barrel Tubular Sensors

Specifications

Attribute 12 mm Diameter 18 mm Diameter

Load Current ≤300 mA ≤400 mA

Leakage Current ≤10 μA

Operating Voltage 10…30V DC

Voltage Drop ≤1V

Repeatability ≤10%

871C Cable Style

12 mm and 18 mm Dia. Hysteresis ≤10% typical

Protection Type False pulse, transient noise, reverse polarity, short circuit, and overload

Certifications UL Listed, CSA Certified, and CE Marked for all applicable directives

Enclosure Type Rating NEMA 1, 2, 3, 4, 12 and 13; IP67 (IEC529)

Housing Material Stainless Steel 303 barrel, plastic face

• Cable: 3 m (10 ft) length, 3-conductor PVC

Connections

• Quick-disconnect: 4-pin mini style

Status Indicator Red: output energized

Operating Temperature -40…+70 °C (-40…+158 °F)

871C Mini Quick-disconnect Style

18 mm Dia.

Correction Factors

Target Material Correction Factors

Steel 1.0

Stainless Steel 0.7…0.9

Brass 0.3…0.5

Aluminum 0.3…0.4

Copper 0.3…0.4

Product Selection

Barrel Diameter Nominal Sensing Distance Output Switching Frequency Cat. No.

Shielded

[mm (in.)] [mm (in.)] Configuration [Hz] Cable Style Mini QD Style

NPN 871T-R2A12 —

2 (0.08) Yes N.O. 2000

PNP 871T-L2A12 —

12 (0.47)

NPN 871T-R4B12 —

4 (0.16) No N.O. 1000

PNP 871T-L4B12 —

NPN 871T-R5A18 871T-R5J18

5 (0.20) Yes N.O. 1000

PNP 871T-L5A18 871T-L5J18

18 (0.71)

NPN 871T-R8B18 871T-R8K18

8 (0.31) No N.O. 500

PNP 871T-L8B18 871T-L8K18

Recommended Standard QD Cordset (-6F = 1.8 m [6 ft], -2 = 2 m [6.5 ft]) 889N-F4AFC-6F

30 Rockwell Automation Publication PROX-TD001J-EN-P - August 2020

Tubular Sensors

Approximate Dimensions Wiring Diagrams

Cable Style Normally Open

Status NPN (Sinking) +

PNP (Sourcing) --

Indicator + --

10…30V DC 10…30V DC

Brown Brown + --

3 m (9.8 ft) + -- Blue Black Load

Load Black

Blue

C B

A

Dimensions are shown in mm (in.).

Thread Size Shielded

A B (Max) C (Min) D (Max)

Yes 53.8 (2.12) 0.8 (0.03)

M12 X 1 12.0 (0.47) 80.0 (23.15)

No 46.5 (1.83) 8.1 (0.32)

Yes 81.5 (3.21) 55.6 (2.19) 0.8 (0.03)

M18 X 1 18.0 (0.71)

No 81.3 (3.20) 43.7 (1.72) 12.3 (0.48)

Mini QD Style Normally Open

NPN (Sinking) PNP (Sourcing)

A

-- +

Status 1 4 Load Load 1 4

Indicator D + -- 2 3

2 3

-- 10…30V DC + -- 10…30V DC +

C

7/8-16-UN-2A B

Dimensions are shown in mm (in.).

Thread Size Shielded

A B (Max) C (Min) D (Max)

Yes 51.9 (2.04) 0.8 (0.03)

M18 X 1 18.0 (0.71) 96.9 (3.81)

No 40.4 (1.59) 12.3 (0.48)

Rockwell Automation Publication PROX-TD001J-EN-P - August 2020 31

Tubular Sensors

871T 2-wire AC Stainless Steel Barrel Tubular Sensors

Specifications

Attribute 12 mm Diameter 18 mm Diameter

Load Current ≤300 mA ≤500 mA

Inrush Current (one cycle) ≤3 A ≤5 A

Leakage Current ≤1.5 mA

Operating Voltage 20…132V AC

871T Cable Style Voltage Drop 6.5V AC at 500 mA, 10V AC at 20 mA (RMS)

12 mm and 18 mm Dia. Repeatability ≤10%

Hysteresis ≤10% typical

Protection Type False pulse, transient noise

Certifications UL Listed, CSA Certified, and CE Marked for all applicable directives

Enclosure Type Rating NEMA 1, 2, 3, 4, 12 and 13; IP67 (IEC529)

Housing Material Stainless steel 303 barrel, plastic face

• Cable: 3 m (10 ft) length, 12 mm

Connection Type 2 conductor PVC, 18 mm

3 conductor PVC

871T Mini Quick Disconnect Style • Quick-disconnect: 3-pin mini style

18 mm Dia. Status Indicator Red: Output Energized

Operating Temperature -40…+70 °C (-40…+158 °F)

Shock 30 g (1.06 oz), 11 ms

Vibration 55 Hz, 1 mm amplitude, 3 planes

Correction Factors

Target Material Correction Factors

Steel 1.0

Stainless Steel 0.7…0.9

Brass 0.3…0.5

Aluminum 0.3…0.4

Copper 0.3…0.4

Product Selection

Barrel Diameter Nominal Sensing Distance Switching Frequency Cat. No.

Shielded Output Configuration

[mm (in.)] [mm (in.)] [Hz] Cable Style Mini QD Style

2 (0.08) Yes 871T-G2A12 —

N.O.

4 (0.16) No 871T-G4B12 —

12 (0.47)

2 (0.08) Yes 871T-H2A12 —

N.C.

4 (0.16) No 871T-H4B12 —

50

5 (0.20) Yes 871T-G5A18 871T-G5J18

N.O.

8 (0.31) No 871T-G8B18 871T-G8K18

18 (0.71)

5 (0.20) Yes 871T-H5A18 871T-H5J18

N.C.

8 (0.31) No 871T-H8B18 871T-H8K18

Recommended Standard QD Cordset (-6F = 1.8 m [6 ft], -2 = 2 m [6.5 ft]) 889N-F3AFC-6F

32 Rockwell Automation Publication PROX-TD001J-EN-P - August 2020

Tubular Sensors

Approximate Dimensions Wiring Diagrams

Cable Style Normally Open Normally Closed

Status Brown Brown

Indicator

Blue Load Blue Load

3 m (9.8 ft)

Green Green

C B

A

IMPORTANT No green wire on

D 12 mm. Attach

housing to ground.

Dimensions are shown in mm (in.).

Thread Size Shielded

A B (Max) C (Min) D (Max)

Yes 53.8 (2.12) 0.8 (0.03)

M12 X 1 12.0 (0.47) 80.0 (23.15)

No 46.5 (1.83) 8.1 (0.32)

Yes 81.5 (3.21) 55.6 (2.19) 0.8 (0.03)

M18 X 1 18.0 (0.71)

No 81.3 (3.20) 43.7 (1.72) 12.3 (0.48)

Mini QD Style Normally Open or Normally Closed

Ground

A

Status

Indicator D 1

2 3

C

Load

7/8-16-UN-2A B

IMPORTANT Load can be switched to pin 3.

Dimensions are shown in mm (in.).

Thread Size Shielded

A B (Max) C (Min) D (Max)

Yes 51.9 (2.04) 0.8 (0.03)

M18 X 1 18.0 (0.71) 96.9 (3.81)

No 40.4 (1.59) 12.3 (0.48)

Rockwell Automation Publication PROX-TD001J-EN-P - August 2020 33

Tubular Sensors

871T 4-wire AC Ferrous Selective

Specifications

Attribute 18 mm Diameter

Load Current ≤500 mA

Inrush Current (one Cycle) ≤5 A

Supply Current (minimum) 5 mA

Leakage Current ≤1.7 mA

871T Cable Style Operating Voltage 20…132V AC

18 mm Dia.

• N.O. output: 6.5V AC at 500 mA, 10V AC at 20 mA (RMS)

Voltage Drop

• N.C. output: 1.7V AC at 500 mA (RMS)

Isolation Voltage 800V AC (output to output); 1500V AC (output to housing)

Repeatability ≤10%

Hysteresis ≤10% typical

Protection Type False pulse, transient noise

Certifications CE Marked for all applicable directives

Enclosure Type Rating NEMA 3, 4, 12 and 13; IP67 (IEC529)

871T Mini Quick-disconnect Style Housing Material Stainless steel face and threaded barrel

18 mm DIa. • Cable: 3.6 m (12 ft) length, 5-conductor PVC

Connections

• Quick-disconnect: 5-pin mini style

• Red: Output energized

Status Indicator • Green: Power

Operating Temperature 0…70 °C (32…158 °F)

Correction Factors

Target Material Correction Factors

Steel 1.0

Stainless Steel (1) 0.8…1.1

Brass 0.0

Aluminum 0.0

Copper 0.0

(1) Stainless steel 10% contains carbon.

Product Selection

Barrel Diameter Nominal Sensing Distance Switching Frequency Cat. No.

Shielded Output Configuration

[mm (in.)] [mm (in.)] [Hz] Cable Style Mini QD 5-pin Style

18 (0.71) 5 (0.20) Yes N.O. and N.C. 10 871T-A5A18FE-12 871T-A5J18FE

Recommended Standard QD Cordset (-6F = 1.8 m [6 ft]) 889N-F5AFC-6F

34 Rockwell Automation Publication PROX-TD001J-EN-P - August 2020

Tubular Sensors

Approximate Dimensions Wiring Diagrams

Cable Style Complementary Normally Open or Normally Closed

White

Status A N.O. Output

Indicators D

Black

Load

7/8-16UN-2A Orange Load

N.C. Output

C Green

Red

B

IMPORTANT • N.O. output must be wired for operation. N.C.

output is optional.

3.6 m • N.O. load can be switched to white wire.

(12 ft)

• N.C. load can be switched to red wire.

Dimensions are shown in mm (in.).

Thread Size

A B (Max) C (Min) D (Max)

M18 X 1 18.0 (0.71) 101.6 (4.00) 50.8 (2.00) 20.3 (0.80)

Mini QD Style Normally Open or Normally Closed

N.O. Output

2 Status A 1 5 Load

Indicators Load 2

3

4

N.C. Output

D

C

B

7/8-16-UN-2A IMPORTANT • N.O. output must be wired for operation. N.C.

output is optional.

• N.O. load can be switched to pin 1.

• N.C. load can be switched to pin 4.

Dimensions are shown in mm (in.).

Thread Size

A B (Max) C (Min) D (Max)

M18 X 1 18.0 (0.71) 101.6 (4.00) 50.8 (2.00) 20.3 (0.80)

Rockwell Automation Publication PROX-TD001J-EN-P - August 2020 35

Tubular Sensors

871TM 3-wire DC Short Barrel Tubular Sensors

Specifications

Attribute 12 mm, 18 mm, and 30 mm Diameter

Load Current ≤200 mA

Capacitive Load ≤1 µF

Leakage Current ≤10 μA

Operating Voltage 10…30V DC

Voltage Drop ≤1V DC at 200 mA

871TM Cable Style Repeatability ≤10% at constant temperature

12 mm, 18 mm, and 30 mm Dia. Hysteresis 10% typical

False pulse, transient noise, reverse polarity, short circuit (trigger at 340 mA

Protection Type

typical), overload

Certifications UL Listed, CSA Certified, and CE Marked for all applicable directives

NEMA 1, 2, 3, 3R, 4, 4X, 6, 6P, 12, 13 IP67 (IEC529) all models; 1200 psi (8270 kPa)

Enclosure Type Rating washdown; ToughLink™ and micro connector versions are also rated IP69K

(IEC 529)

Housing Material Stainless steel face and threaded barrel

• Cable: 2 m (6.5 ft) length, A2 - 3-conductor PVC,

Connection Type C2 - 3-conductor #22 AWG-ToughLink, H2 - 3-conductor #18 AWG ToughLink

871TM Mini Quick Disconnect Style • Quick-disconnect: 4-pin mini style, 4-pin M12 micro style

12 mm, 18 mm, and 30 mm Dia. • Red: Output Energized

Indicator Status Indicators • Green: Power/Short Circuit (flashing)—18 mm models only

Operating Temperature -25…+70 °C (-13…+158 °F)

Shock 30 g (1.06 oz), 11 ms

Vibration 55 Hz, 1 mm amplitude, 3 planes

Correction Factors

Target Material Correction Factors

Steel 1.0

Stainless Steel 0.9…1.0

Brass 0.3…0.5

Aluminum 0.1…0.4

871TM DC Micro Quick Disconnect Style Aluminum (≤0.02 Thick) 0.9…1.1

12 mm, 18 mm, and 30 mm Dia.

Copper 0.1…0.2

36 Rockwell Automation Publication PROX-TD001J-EN-P - August 2020

Tubular Sensors

Product Selection

Nominal Cat. No.

Barrel Switching

Sensing Output

Diameter Shielded Frequency

Distance Configuration PVC Cable ToughLink Cable Mini QD Style M12 Micro QD Style

[mm (in.)] [Hz]

[mm (in.)]

NPN 871TM-DH2NN12-A2 871TM-DH2NN12-C2 871TM-DH2NN12-N4 871TM-DH2NN12-D4

2 (0.08) Yes N.O. 75

PNP 871TM-DH2NP12-A2 871TM-DH2NP12-C2 871TM-DH2NP12-N4 871TM-DH2NP12-D4

NPN 871TM-DH4NN12-A2 871TM-DH4NN12-C2 871TM-DH4NN12-N4 871TM-DH4NN12-D4

4 (0.16) No N.O. 70

PNP 871TM-DH4NP12-A2 871TM-DH4NP12-C2 871TM-DH4NP12-N4 871TM-DH4NP12-D4

12 (0.47)

NPN 871TM-DH2CN12-A2 871TM-DH2CN12-C2 871TM-DH2CN12-N4 871TM-DH2CN12-D4

2 (0.08) Yes N.C. 75

PNP 871TM-DH2CP12-A2 871TM-DH2CP12-C2 871TM-DH2CP12-N4 871TM-DH2CP12-D4

NPN 871TM-DH4CN12-A2 871TM-DH4CN12-C2 871TM-DH4CN12-N4 871TM-DH4CN12-D4

4 (0.16) No N.C. 70

PNP 871TM-DH4CP12-A2 871TM-DH4CP12-C2 871TM-DH4CP12-N4 871TM-DH4CP12-D4

NPN 871TM-DH5NN18-A2 871TM-DH5NN18-H2 871TM-DH5NN18-N4 871TM-DH5NN18-D4

5 (0.20) Yes N.O. 60

PNP 871TM-DH5NP18-A2 871TM-DH5NP18-H2 871TM-DH5NP18-N4 871TM-DH5NP18-D4

NPN 871TM-DH8NN18-A2 871TM-DH8NN18-H2 871TM-DH8NN18-N4 871TM-DH8NN18-D4

8 (0.31) No N.O. 40

PNP 871TM-DH8NP18-A2 871TM-DH8NP18-H2 871TM-DH8NP18-N4 871TM-DH8NP18-D4

18 (0.71)

NPN 871TM-DH5CN18-A2 871TM-DH5CN18-H2 871TM-DH5CN18-N4 871TM-DH5CN18-D4

5 (0.20) Yes N.C. 60

PNP 871TM-DH5CP18-A2 871TM-DH5CP18-H2 871TM-DH5CP18-N4 871TM-DH5CP18-D4

NPN 871TM-DH8CN18-A2 871TM-DH8CN18-H2 871TM-DH8CN18-N4 871TM-DH8CN18-D4

8 (0.31) No N.C. 40

PNP 871TM-DH8CP18-A2 871TM-DH8CP18-H2 871TM-DH8CP18-N4 871TM-DH8CP18-D4

NPN 871TM-DH10NN30-A2 871TM-DH10NN30-H2 871TM-DH10NN30-N4 871TM-DH10NN30-D4

10 (0.39) Yes N.O. 40

PNP 871TM-DH10NP30-A2 871TM-DH10NP30-H2 871TM-DH10NP30-N4 871TM-DH10NP30-D4

NPN 871TM-DH15NN30-A2 871TM-DH15NN30-H2 871TM-DH15NN30-N4 871TM-DH15NN30-D4

15 (0.59) No N.O. 30

PNP 871TM-DH15NP30-A2 871TM-DH15NP30-H2 871TM-DH15NP30-N4 871TM-DH15NP30-D4

30 (1.18)

NPN 871TM-DH10CN30-A2 871TM-DH10CN30-H2 871TM-DH10CN30-N4 871TM-DH10CN30-D4

10 (0.39) Yes N.C. 40

PNP 871TM-DH10CP30-A2 871TM-DH10CP30-H2 871TM-DH10CP30-N4 871TM-DH10CP30-D4

NPN 871TM-DH15CN30-A2 871TM-DH15CN30-H2 871TM-DH15CN30-N4 871TM-DH15CN30-D4

15 (0.59) No N.C. 30

PNP 871TM-DH15CP30-A2 871TM-DH15CP30-H2 871TM-DH15CP30-N4 871TM-DH15CP30-D4

Recommended standard QD cordset (-6F = 1.8 m [6 ft], -2 = 2 m [6.5 ft]) 889N-F4AFC-6F 889D-F4AC-2

Rockwell Automation Publication PROX-TD001J-EN-P - August 2020 37

Tubular Sensors

Approximate Dimensions Wiring Diagrams

Cable Style Normally Open Normally Closed

Status NPN (Sinking) PNP (Sourcing) NPN (Sinking) PNP (Sourcing)