Professional Documents

Culture Documents

MaintenanceOfIndUnits2019V001 Industrial Units

MaintenanceOfIndUnits2019V001 Industrial Units

Uploaded by

Miguel Angel Flores MojicaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MaintenanceOfIndUnits2019V001 Industrial Units

MaintenanceOfIndUnits2019V001 Industrial Units

Uploaded by

Miguel Angel Flores MojicaCopyright:

Available Formats

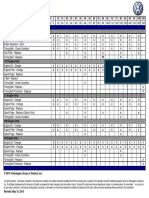

Maintenance Schedule Of Industry Compressors

(Including Dry Gases)

Incl. Maintenance kit (MK): a1 ab1 a1 abc1 a1 ab1 a1 abc1 abcd1 abcde1

in Maintenance and testing works depending on time**: annually 2 years 3 years 4 years 5 years 6 years 7 years 8 years 16 years 32 years

MK: Maintenance and testing works depending on operating hours**: 1,000hrs 2,000hrs 3,000hrs 4,000hrs 5,000hrs 6,000hrs 7,000hrs 8,000hrs 16,000hrs 32,000hrs

* ACD – to be maintained and checked (separate kit available!) x x x x x x x x x x

Anti vibration elements – function to be checked (exchange if damaged) x x x x x x x

* Anti vibration elements – to be exchanged x x x

d1 Connecting-rod and upper bearings (K28.xx) – to be exchanged As required x x

* Coolant – to be exchanged x x x

Coolant level – to be checked and filled up if necessary (liquid cooled units) x x x x x x x

Cylinders, piston and piston rings – to be checked for wearing x x

d1 Cylinders, piston and piston rings – to be exchanged (exch. in combination only) As required x x

* Direct clutch (if mounted) – to be exchanged x x x

e1 Driving gear or crank shaft, main bearings and slide bearings – to be exchanged x

Electrical motor – to be lubricated (if lubricating nipples available) x x x x x x x x x x

Electrical terminal clamps – to be checked for strength x x x x x x x x x x

Emergency button – function to be checked (if mounted) x x x x x x x x x x

Fan blades – to be checked x x x x x x x x x x

* Fan blades – to be exchanged Every 10 years

* Filter cartridge, molecular sieve and desiccant – to be exchanged As required / According to saturation

* Final separator filter cartridge – to be exchanged x x x x x x x x x x

Fittings to be fixed according to torque load x x x x x x x x x x

Functional testing, final inspection, test run x x x x x x x x x x

a1 Intake filter – to be exchanged x x x x x x x x x x

Intermediate pressures (all stages) and oil pressure - to be checked x x x x x x x x x x

Leak test and general visual inspection of unit x x x x x x x x x x

* Oil (mineral) – to be exchanged x x x x x x x x x x

* Oil (synthetic) – to be exchanged x x x x x x

a1 Oil filter cartridge – to be exchanged x x x x x x x x x x

Oil injection nozzle – function to be checked and cleaned (exchange if damaged) x x x x x x x

*Not included in maintenance kit a/b/c. To be ordered separately. Maintenance between 16 years till 32 years / 16,000hrs till 32,000hrs similar to the previous intervals.

**Maintenance and testing works according to interval whatever comes first (time OR operating hours).

BAUER KOMPRESSOREN GmbH Stäblistraße 8 81477 München

Edition 01.2019 V001 Tel.: 089/78049-0, Fax: 089/78049-167

page 1 / 2

Maintenance Schedule Of Industry Compressors

(Including Dry Gases)

Incl. Maintenance kit (MK): a1 ab1 a1 abc1 a1 ab1 a1 abc1 abcd1 abcde1

in Maintenance and testing works depending on time**: annually 2 years 3 years 4 years 5 years 6 years 7 years 8 years 16 years 32 years

MK: Maintenance and testing works depending on operating hours**: 1,000hrs 2,000hrs 3,000hrs 4,000hrs 5,000hrs 6,000hrs 7,000hrs 8,000hrs 16,000hrs 32,000hrs

* Oil injection nozzle – to be exchanged x x x

Piston and sleeve assembly – to be checked x x x x

b1 Piston and sleeve assembly – to be exchanged x x x x x x

Pressure gauges – to be checked for function and precision x x x x x x x x x x

Pressure hoses/hoses - to be checked for tightness and damages (exch. if necessary) Every 6 months

* Pressure hoses / hoses – to be exchanged Every 6 years

* Pressure relief valve – to be checked (order maintenance kit if necessary) x x x x x x x x x x

Pressure sensors - to be checked (if available) x x x x x x x x x x

Pressure switches and pressure relief valve settings – to be checked x x x x x x x x x x

Pressure vessel – to be checked (according to PED-Pressure Equipment Directive) x

* Pressure vessel – to be exchanged after reaching maximum amount of load cycles According to PED

Pressure vessel, recording of working hrs and load cycles–to be controlled visually x x x x x x x x x x

Reporting, test sticker to be attached x x x x x x x x x x

* Safety valves - to be checked (no tests possible SV have to be exchanged) x x x x x x x x x x

a1 Seals and o-rings acc. to maintenance kit – to be exchanged x x x x x x x x x x

c1 Seals and o-rings acc. to maintenance kit – to be exchanged x x x x

Separator, drain of condensate collector - to be cleaned and checked for damages x x x x x x x x x x

Suction- and pressure valves - to be checked (all stages) x x x x

b1 Suction- and pressure valves – to be exchanged (all stages) x x x x x x

Temperature sensors - to be checked (if available) x x x x

V-belt - to be checked x x x x x x

* V-belt – to be exchanged x x x x

Water pressure of cooling unit – to be checked (liquid cooled units) x x x x x x x x x x

*Not included in maintenance kit a/b/c. To be ordered separately. Maintenance between 16 years till 32 years / 16,000hrs till 32,000hrs similar to the previous intervals.

**Maintenance and testing works according to interval whatever comes first (time OR operating hours).

BAUER KOMPRESSOREN GmbH Stäblistraße 8 81477 München

Edition 01.2019 V001 Tel.: 089/78049-0, Fax: 089/78049-167

page 2 / 2

You might also like

- MCM Diagrama Electronico Detroit Diesel Serie 60 Ddec VIDocument1 pageMCM Diagrama Electronico Detroit Diesel Serie 60 Ddec VIJohn MkCito KI91% (70)

- 003 Hilight v5+ KHD Pne SN Pe2270532Document108 pages003 Hilight v5+ KHD Pne SN Pe2270532Mr dirinNo ratings yet

- Scania Generator Maintenance Interval: Daily Interval (Hours) Minimum R S M L L XLDocument3 pagesScania Generator Maintenance Interval: Daily Interval (Hours) Minimum R S M L L XLramsey2220% (1)

- York Chiller Log SheetDocument4 pagesYork Chiller Log SheetEngr Fazal AkbarNo ratings yet

- Summary of API 16AR Repair / Remanufacturing Production Service LevelDocument1 pageSummary of API 16AR Repair / Remanufacturing Production Service LevelSameer OmarNo ratings yet

- Kubota - Diesel Motors-Basico PDFDocument29 pagesKubota - Diesel Motors-Basico PDFRolando BobadillaNo ratings yet

- Manual - Piaggio MP3 300 Yourban Ie RL NRL EN PDFDocument342 pagesManual - Piaggio MP3 300 Yourban Ie RL NRL EN PDFValera NikitinNo ratings yet

- Maintenance Schedule Bauer CompressorsDocument1 pageMaintenance Schedule Bauer CompressorsCristel_DC100% (3)

- Standard Service Oil Injected Compressor Atlas CopcoDocument1 pageStandard Service Oil Injected Compressor Atlas CopcoAhmad FauzieNo ratings yet

- Equipment GA132 75 Bar (W) PackDocument1 pageEquipment GA132 75 Bar (W) Packsurendra SinghNo ratings yet

- Kilometers: 2001 Volkswagen Maintenance Schedule by Miles / KilometersDocument2 pagesKilometers: 2001 Volkswagen Maintenance Schedule by Miles / KilometersaleksandarlaskovNo ratings yet

- VW Maintenance Cards 2000 - 5!10!10Document2 pagesVW Maintenance Cards 2000 - 5!10!10Samuel BohnNo ratings yet

- 2010 Prius Maintenance Schedule (Canadian, Based On Owner's Manual Supplement)Document1 page2010 Prius Maintenance Schedule (Canadian, Based On Owner's Manual Supplement)Raihan GrimuflihinNo ratings yet

- Atlas Copco Xrvs 476 Manual (050 054)Document5 pagesAtlas Copco Xrvs 476 Manual (050 054)joseNo ratings yet

- VW-2004 Schedule ManualDocument3 pagesVW-2004 Schedule Manualanyone331No ratings yet

- O2 - Service Check List Ver.20170830Document1 pageO2 - Service Check List Ver.20170830Shau WilliamNo ratings yet

- Energy Saving Techniques Applicablity Matrix - (2022-23)Document6 pagesEnergy Saving Techniques Applicablity Matrix - (2022-23)Mohamedsameer ANo ratings yet

- EC COMM Note No 001j Setting Access RightsDocument35 pagesEC COMM Note No 001j Setting Access Rightsmanu_el_3No ratings yet

- D528 Maintenance Schedule - Xls Maintenance ScheduleDocument1 pageD528 Maintenance Schedule - Xls Maintenance ScheduleDPNo ratings yet

- HL Owners Manual 2021Document2 pagesHL Owners Manual 2021Dutchie169No ratings yet

- Preventative Maintenance Activity A B C D E: Type of Visit For Each Specific Year, Running Hours Per Year 8000 HRSDocument1 pagePreventative Maintenance Activity A B C D E: Type of Visit For Each Specific Year, Running Hours Per Year 8000 HRSSeif AlbaghdadyNo ratings yet

- 160.81-MR1 (Log Sheet)Document4 pages160.81-MR1 (Log Sheet)dhcastanoNo ratings yet

- CTAS Reefer System Parameters 7.4.9Document1 pageCTAS Reefer System Parameters 7.4.9mvasquez2011No ratings yet

- D358 Maintenance Schedule - Xls Maintenance ScheduleDocument1 pageD358 Maintenance Schedule - Xls Maintenance ScheduleDPNo ratings yet

- Table of Access Rights SPPA-T3000 Before PAC After PAC: Valid For SW Release(s) : 07.2.11.xx User-Roles User-RolesDocument1 pageTable of Access Rights SPPA-T3000 Before PAC After PAC: Valid For SW Release(s) : 07.2.11.xx User-Roles User-Rolesmanu_el_3No ratings yet

- Basic Barrier Maintenance Guide: Tasks Hydraulic ElectricDocument2 pagesBasic Barrier Maintenance Guide: Tasks Hydraulic Electricbaguspermana7No ratings yet

- CC, Eos, Golf, GTI, Tiguan, Touareg, Jetta Models, Golf Wagon, and Beetle ModelsDocument6 pagesCC, Eos, Golf, GTI, Tiguan, Touareg, Jetta Models, Golf Wagon, and Beetle ModelsjuliancajiaoNo ratings yet

- 2 Stroke Maintenance SchedulesDocument3 pages2 Stroke Maintenance SchedulesGeo PalNo ratings yet

- Variable Frequency DrivesDocument6 pagesVariable Frequency DrivesMohammed Sayeeduddin100% (1)

- Philips Floor Care Repair FlowDocument17 pagesPhilips Floor Care Repair FlowMonete FlorinNo ratings yet

- UNIT DRILLING TOP DRIVE SERVICE MANUALDocument102 pagesUNIT DRILLING TOP DRIVE SERVICE MANUALjulioramcaNo ratings yet

- ... An Energy-Saving Approach To Your Service Needs..Document4 pages... An Energy-Saving Approach To Your Service Needs..Robert sherrodNo ratings yet

- DG Maintenance PlanDocument2 pagesDG Maintenance PlanYasir Mehmood100% (1)

- 160 54-MR1 PDFDocument1 page160 54-MR1 PDFghilesNo ratings yet

- Repair Options FOR 950G/H/M Wheel LoadersDocument2 pagesRepair Options FOR 950G/H/M Wheel LoadersАдыль БабировNo ratings yet

- Part Remplacment Transmission Overhaul ScheduleDocument2 pagesPart Remplacment Transmission Overhaul ScheduleamineNo ratings yet

- 2012 Passat MaintenanceDocument3 pages2012 Passat Maintenanceoctavio araujoNo ratings yet

- Uploads Media Document BAC Rigging-VXI RVXIv15ENDocument28 pagesUploads Media Document BAC Rigging-VXI RVXIv15ENsidsaleemNo ratings yet

- P&G SowDocument4 pagesP&G SowsigmaintipurnamaNo ratings yet

- Maintenance ScheduleDocument2 pagesMaintenance ScheduleScott MercerNo ratings yet

- Service ScheduleDocument5 pagesService Scheduleronare6613No ratings yet

- Steam Turbine Generator UnitDocument2 pagesSteam Turbine Generator UnitYogesh kumarNo ratings yet

- VW 2009 MaintenanceDocument3 pagesVW 2009 MaintenancejdchavesNo ratings yet

- Golf Variant Technical SheetDocument1 pageGolf Variant Technical SheetScribdTranslationsNo ratings yet

- DBV - 30X - List of Errors and How To Handle The Errors During CalibrationDocument2 pagesDBV - 30X - List of Errors and How To Handle The Errors During CalibrationГеннадий ЧашницкийNo ratings yet

- 1.3 Maintenance Schedule: GeneralDocument2 pages1.3 Maintenance Schedule: GeneralÉder Oliveira NicolletiNo ratings yet

- 2-Stroke Rotax Maintenance Schedule: Cylinder Head Temperature (Reading at Spark Plug Seat) : CHTDocument1 page2-Stroke Rotax Maintenance Schedule: Cylinder Head Temperature (Reading at Spark Plug Seat) : CHTLeonardo PachecoNo ratings yet

- AEXQ0370Document4 pagesAEXQ0370liva rakotondrasoaNo ratings yet

- Diagnostic Test Chart Transformers Reactors Regulators-IEEE STD 62-1995Document2 pagesDiagnostic Test Chart Transformers Reactors Regulators-IEEE STD 62-1995GualadrakeNo ratings yet

- O&m Logs PDFDocument3 pagesO&m Logs PDFMuhammad azeemNo ratings yet

- Bac - VXC - Operating and Maintenance InstructionsDocument36 pagesBac - VXC - Operating and Maintenance InstructionsLuis Alejandro VásquezNo ratings yet

- ML1812R Maintenance ScheduleDocument6 pagesML1812R Maintenance ScheduleGioeNo ratings yet

- BAC Maintenance-VXI MVXIv17EN-SADocument34 pagesBAC Maintenance-VXI MVXIv17EN-SAEurotech Tra TranNo ratings yet

- Cleaning and Repair Boiler and Shoot Blower Scope of Works and SupplyDocument1 pageCleaning and Repair Boiler and Shoot Blower Scope of Works and SupplydharwinNo ratings yet

- Vxi 9Document38 pagesVxi 9Ritche Lim BragaisNo ratings yet

- Yacht Annual Maintenance ListDocument2 pagesYacht Annual Maintenance ListCapt. Cole SislerNo ratings yet

- Amp200 300Document9 pagesAmp200 300Daniel PinheiroNo ratings yet

- 232 Service Schedule1 02Document3 pages232 Service Schedule1 02madetnNo ratings yet

- Harley-Davidson: and Buell Service IntervalsDocument16 pagesHarley-Davidson: and Buell Service IntervalsPeluzitaNo ratings yet

- VT0 Open Cooling Towers VT1 Open Cooling Tower: Operating and Maintenance InstructionsDocument34 pagesVT0 Open Cooling Towers VT1 Open Cooling Tower: Operating and Maintenance InstructionsoussNo ratings yet

- Secure: ITSM Feature List & Comparison With Other VendorsDocument3 pagesSecure: ITSM Feature List & Comparison With Other VendorsDhanish KhnNo ratings yet

- Series: Equipment and Options (A 309)Document4 pagesSeries: Equipment and Options (A 309)madiNo ratings yet

- 2006 HD Buell Service IntervalsDocument12 pages2006 HD Buell Service IntervalsAdrián CasarrubiasNo ratings yet

- MVT35H-E3 Instruction Manual and Parts ListDocument158 pagesMVT35H-E3 Instruction Manual and Parts ListMiguel Angel Flores MojicaNo ratings yet

- Manual Disco DuroDocument32 pagesManual Disco DuroMiguel Angel Flores MojicaNo ratings yet

- CD1670-02 - Quadron Pump ControlDocument1 pageCD1670-02 - Quadron Pump ControlMiguel Angel Flores MojicaNo ratings yet

- CD1176-05 - Quadron Stepper Board SchematicDocument1 pageCD1176-05 - Quadron Stepper Board SchematicMiguel Angel Flores MojicaNo ratings yet

- Checklist 08 Ship Equipment Maintenance Plan S-8917-MD Main Engine Performance DataDocument1 pageChecklist 08 Ship Equipment Maintenance Plan S-8917-MD Main Engine Performance DataJezrell JaravataNo ratings yet

- Technical Data: @perkinsDocument2 pagesTechnical Data: @perkinsOGNo ratings yet

- Paket Engine Yzm Garage: Paket Tune Up Harian Touring Rp. 3.900.000 Largeframe 150 - 172 CCDocument4 pagesPaket Engine Yzm Garage: Paket Tune Up Harian Touring Rp. 3.900.000 Largeframe 150 - 172 CCMuhammad Attohar Ibnu RafiNo ratings yet

- SU Carburatores - LandRoverDocument24 pagesSU Carburatores - LandRoverChevronelleNo ratings yet

- Scorpio - Mahindra Herramientas PDFDocument169 pagesScorpio - Mahindra Herramientas PDFMarcelo MendozaNo ratings yet

- John Deere CodesDocument2 pagesJohn Deere CodesScribdTranslationsNo ratings yet

- Parts LS650 PDFDocument87 pagesParts LS650 PDFUlysses del AGuilaNo ratings yet

- Cat 303.5Document600 pagesCat 303.5Diego MontenegroNo ratings yet

- 4 5902085539233794318Document366 pages4 5902085539233794318Angel Jesús Agapito Cortez100% (6)

- 6 Stroke EngineDocument16 pages6 Stroke EngineKongala Vamsi KrishnaNo ratings yet

- Engine Rebuild Spec - C SeriesDocument6 pagesEngine Rebuild Spec - C SeriesWoley Reagan RobertNo ratings yet

- RVR 2011 20L PDFDocument99 pagesRVR 2011 20L PDFnicolas sanatanaNo ratings yet

- 3 - SFG15T EngineDocument61 pages3 - SFG15T EngineFausto TrentiniNo ratings yet

- 6M33G825/5 Powerkit Engine Datasheet: RatingsDocument4 pages6M33G825/5 Powerkit Engine Datasheet: RatingsKarim Ahmed KhodjaNo ratings yet

- Autoteam Edition No. 1Document32 pagesAutoteam Edition No. 1EdinIndiraHuseinagicNo ratings yet

- End Sem Question PaperDocument3 pagesEnd Sem Question PaperAyesha IshuNo ratings yet

- Workshop Manual Deutz VolvoDocument28 pagesWorkshop Manual Deutz VolvoMarcelo Daniel Gonzalez LLanosNo ratings yet

- Vector8 PDFDocument206 pagesVector8 PDFgluykNo ratings yet

- Crank CamshaftDocument20 pagesCrank CamshaftM. AguiarNo ratings yet

- M46 Motor (MMC046)Document112 pagesM46 Motor (MMC046)g alves100% (1)

- The Muncaster Steam-Engine Models: 5-Vertical Stationary EnginesDocument3 pagesThe Muncaster Steam-Engine Models: 5-Vertical Stationary EnginesАлексей МоисеевNo ratings yet

- Monster 620 (2002)Document102 pagesMonster 620 (2002)Yuri FabresNo ratings yet

- Catalogue Mitsubishi 6D24TCDocument2 pagesCatalogue Mitsubishi 6D24TCRangga SetaNo ratings yet

- GE Turbine n1 n2 PercentDocument10 pagesGE Turbine n1 n2 PercentYukihira SoumaNo ratings yet

- HARTZELL P9EA - Rev17 PIPER PA30Document9 pagesHARTZELL P9EA - Rev17 PIPER PA30Enrique F. Zamalloa LeonNo ratings yet

- Service Bulletin - (TR 0178 08 6228) Indicator Valve LocationDocument2 pagesService Bulletin - (TR 0178 08 6228) Indicator Valve Locationps_visjehotmailcomNo ratings yet