Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

9 viewsPilecap Design

Pilecap Design

Uploaded by

Amier ThaqifCopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You might also like

- Recommended Practice For Glass Fiber Reinforced Co PDFDocument104 pagesRecommended Practice For Glass Fiber Reinforced Co PDFvikram50% (2)

- Column Foundation ConnectionDocument3 pagesColumn Foundation Connectionmdelacua2No ratings yet

- Pile Retaining Wall - With Wind..Document6 pagesPile Retaining Wall - With Wind..epe civilNo ratings yet

- Pile Cap DesignDocument35 pagesPile Cap Designعصام السامرائي100% (2)

- SAE J434 1986 Automotive Ductile Iron Castings Nodular Iron CastingsDocument10 pagesSAE J434 1986 Automotive Ductile Iron Castings Nodular Iron Castingsvinicius_bacellarNo ratings yet

- 3.0 One Way SlabDocument20 pages3.0 One Way SlabAbhishek HulloliNo ratings yet

- Corbel DesignDocument3 pagesCorbel DesignLim EcNo ratings yet

- Pile RectifyingDocument2 pagesPile RectifyingAnonymous O404LiV4CNo ratings yet

- Pile Cap of CrystalDocument19 pagesPile Cap of CrystalPriyank MotivarasNo ratings yet

- BEAMDESIGN XLSMDocument4 pagesBEAMDESIGN XLSMSaurabh PednekarNo ratings yet

- Hinge Connection Design: A Reference CodeDocument3 pagesHinge Connection Design: A Reference CodeGaurav BhabadNo ratings yet

- Sloped FootingDocument19 pagesSloped FootingBala ChandarNo ratings yet

- Crack Width Calculation: MaterialsDocument2 pagesCrack Width Calculation: MaterialsIrfan AliNo ratings yet

- Column Splice 356 x368x129 Column - WeldDocument4 pagesColumn Splice 356 x368x129 Column - WeldNiraj Shinde100% (1)

- 508x10 CHSDocument8 pages508x10 CHSMuhammad BilalNo ratings yet

- Design of Square Footing F2Document18 pagesDesign of Square Footing F2Mohammed Sumer100% (1)

- Combined FootingsDocument17 pagesCombined FootingsLove SemsemNo ratings yet

- Design of Double Pilecap: Design For Axial Load and MomentDocument16 pagesDesign of Double Pilecap: Design For Axial Load and MomentMidhun BabuNo ratings yet

- Bolt Punching Block Shear AnchorageDocument3 pagesBolt Punching Block Shear AnchorageChangHangWingNo ratings yet

- Pilecap Design EC2 (1) (Autosaved) (Strut and Tie Method)Document25 pagesPilecap Design EC2 (1) (Autosaved) (Strut and Tie Method)Thaung Myint OoNo ratings yet

- Retaining WallDocument34 pagesRetaining WallDavirson Ajah100% (1)

- Slab Bridge DesignDocument25 pagesSlab Bridge DesignEngineeri TadiyosNo ratings yet

- 4-Base Plate - Pin ConnectionDocument3 pages4-Base Plate - Pin ConnectionMUTHUKKUMARAMNo ratings yet

- Rafter To Column Top Connection Design Given DataDocument10 pagesRafter To Column Top Connection Design Given DataSafi Zabihullah SafiNo ratings yet

- Hollow Section Connection Using BoltDocument4 pagesHollow Section Connection Using Boltikanyu79No ratings yet

- Spreadsheets To BS 8110etc: The Concrete CentreDocument10 pagesSpreadsheets To BS 8110etc: The Concrete Centrerajusk24No ratings yet

- Design Detail For RCC One Way SlabDocument18 pagesDesign Detail For RCC One Way SlabWanda BeasleyNo ratings yet

- Footing f8Document4 pagesFooting f8ravi4paperNo ratings yet

- Abutment A1 On Counterfort Wall - 03.07.2020 1.04 PMDocument34 pagesAbutment A1 On Counterfort Wall - 03.07.2020 1.04 PMVikas KushwahaNo ratings yet

- Analysis of 6 Pile Group - Pg6 MX Design Data: Load Case Joint No MZ X Grid Mark Y Sum Column Plinth Beam ZDocument14 pagesAnalysis of 6 Pile Group - Pg6 MX Design Data: Load Case Joint No MZ X Grid Mark Y Sum Column Plinth Beam ZAnonymous JUn5jis0No ratings yet

- BASEPLT9Document27 pagesBASEPLT9Homero Silva100% (3)

- Bharat Heavy Plate & Vessels Limited - VisakhapatnamDocument8 pagesBharat Heavy Plate & Vessels Limited - VisakhapatnamRama Subramanyam ManepalliNo ratings yet

- Project Designed By: Date: Client CPG Trang 9/11/2017 Code BS8110:1997 Checked By: Revision: JOB BKT 1Document2 pagesProject Designed By: Date: Client CPG Trang 9/11/2017 Code BS8110:1997 Checked By: Revision: JOB BKT 1Sơn Nguyễn-LêNo ratings yet

- Isolated Footing (ACI)Document4 pagesIsolated Footing (ACI)Boubakeur FerkousNo ratings yet

- Proposed Development: Lucia Njahira Waiganjo Ruiru Kiambu County PW 1 TW - 285Document15 pagesProposed Development: Lucia Njahira Waiganjo Ruiru Kiambu County PW 1 TW - 285patrick chegeNo ratings yet

- 150mm Thick FloorDocument11 pages150mm Thick FloorAnil UdaleNo ratings yet

- TCC11 Element DesignDocument9 pagesTCC11 Element DesignMario Sajulga Dela CuadraNo ratings yet

- Corbel DesignDocument2 pagesCorbel Designsidiq7No ratings yet

- Design of Purlin BeamsDocument5 pagesDesign of Purlin BeamsSanchal ShirkeNo ratings yet

- Chequer Platform-Flat Bar Design - L 1.112m - SDL 10kpaDocument1 pageChequer Platform-Flat Bar Design - L 1.112m - SDL 10kpaGOHNo ratings yet

- Made Date Sheet AR 17-Jul-11 1 Check Date Rev. MKI 17-Jul-11 0 PROJECT TITLE: Minhal Crowne Plaza Location: RiyadhDocument6 pagesMade Date Sheet AR 17-Jul-11 1 Check Date Rev. MKI 17-Jul-11 0 PROJECT TITLE: Minhal Crowne Plaza Location: Riyadhsidiq7No ratings yet

- Design of Pile CapDocument3 pagesDesign of Pile Capabhi aroteNo ratings yet

- Gording & TreckstangDocument10 pagesGording & TreckstangHendra CenNo ratings yet

- PreStressed Slab Design-2017-V1.0Document8 pagesPreStressed Slab Design-2017-V1.0maherelabdNo ratings yet

- Pile Cap-4 PileDocument2 pagesPile Cap-4 Pilecnt_chanddanNo ratings yet

- Beam - Capacity Check - SumanDocument4 pagesBeam - Capacity Check - Sumansuman_civilNo ratings yet

- RC Beam Analysis & Design (En1992-1) : TEDDS Calculation Version 2.0.03Document5 pagesRC Beam Analysis & Design (En1992-1) : TEDDS Calculation Version 2.0.03Natasha WyneNo ratings yet

- Boundray Wall Design Data Ganj BasodaDocument6 pagesBoundray Wall Design Data Ganj BasodaShubham KhareNo ratings yet

- Loads: Short Column With Axial LoadingDocument5 pagesLoads: Short Column With Axial LoadingMohd AftabNo ratings yet

- Design of Aluminium Window Frame:: REFER: IS 8147 - (1976)Document6 pagesDesign of Aluminium Window Frame:: REFER: IS 8147 - (1976)kamalxdNo ratings yet

- Raft Smr2 SubgrDocument22 pagesRaft Smr2 Subgrsivaraju1100% (1)

- Slab DesignDocument3 pagesSlab DesignMagdy BakryNo ratings yet

- Punching Shear StandardDocument4 pagesPunching Shear StandardjanethNo ratings yet

- T0516-Eco Sanctuary CPL 23-Feb-16 LYJ RC 250 850 1500: Design Calculation For Pilecap 2Rc250Document2 pagesT0516-Eco Sanctuary CPL 23-Feb-16 LYJ RC 250 850 1500: Design Calculation For Pilecap 2Rc250Tj TanNo ratings yet

- T0516-Eco Sanctuary CPL 23-Feb-16 LYJ RC 250 850 2300: Design Calculation For Pilecap 3Rc250Document3 pagesT0516-Eco Sanctuary CPL 23-Feb-16 LYJ RC 250 850 2300: Design Calculation For Pilecap 3Rc250Tj TanNo ratings yet

- T0516-Eco Sanctuary CPL 23-Feb-16 LYJ RC 250 850 3000: Design Calculation For Pilecap 4Rc250Document2 pagesT0516-Eco Sanctuary CPL 23-Feb-16 LYJ RC 250 850 3000: Design Calculation For Pilecap 4Rc250Tj TanNo ratings yet

- T0516-Eco Sanctuary CPL 23-Feb-16 LYJ RC 250 850 2800: Design Calculation For Pilecap 4Rc250Document2 pagesT0516-Eco Sanctuary CPL 23-Feb-16 LYJ RC 250 850 2800: Design Calculation For Pilecap 4Rc250Tj TanNo ratings yet

- CSE519 - Beam Design - 2 - TrialDocument2 pagesCSE519 - Beam Design - 2 - TrialTik HonNo ratings yet

- Job: 200, Nawala Road, Narahenpita Colombo - 05, Sri Lanka. Tel: 2808835 To 44 Fax: 2808846 & 47Document55 pagesJob: 200, Nawala Road, Narahenpita Colombo - 05, Sri Lanka. Tel: 2808835 To 44 Fax: 2808846 & 47Shamitha KanchanaNo ratings yet

- Pile Cap 8P-PC6Document6 pagesPile Cap 8P-PC6balaji gmscNo ratings yet

- Design of Eccentric Isolated Footing With Strap Beam: NMM Per Meter RunDocument3 pagesDesign of Eccentric Isolated Footing With Strap Beam: NMM Per Meter RunBishal ShresthaNo ratings yet

- Design Check For Plunge in Column: Project: Belfield Tunnel Location: M&E4 Date: 4/13/2020 Description: 2 LevelsDocument1 pageDesign Check For Plunge in Column: Project: Belfield Tunnel Location: M&E4 Date: 4/13/2020 Description: 2 LevelsGerards ChinNo ratings yet

- Top Bar Slab CheckingDocument6 pagesTop Bar Slab CheckingJamie MartinezNo ratings yet

- InterpolatedDocument9 pagesInterpolatedJamie MartinezNo ratings yet

- Beam Design Beam No Design Data: CompressionDocument8 pagesBeam Design Beam No Design Data: CompressionJamie MartinezNo ratings yet

- Spacing CheckDocument1 pageSpacing CheckJamie MartinezNo ratings yet

- Slides-pdf-ACEM-Supervision-Bored Piles-5 Sept 19Document82 pagesSlides-pdf-ACEM-Supervision-Bored Piles-5 Sept 19Jamie Martinez100% (1)

- Form QT5Document2 pagesForm QT5Jamie MartinezNo ratings yet

- Profile PROCA (New)Document44 pagesProfile PROCA (New)Jamie MartinezNo ratings yet

- KH 3153 Geoteknik 2 Geoslope Tutorial 2009Document8 pagesKH 3153 Geoteknik 2 Geoslope Tutorial 2009Jamie MartinezNo ratings yet

- Waste Segregation System - FinalDocument20 pagesWaste Segregation System - FinalAgraj KhadkaNo ratings yet

- (Eng) ASTM D3846-08 Standard Test Method For In-Plane Shear Strength of Reinforced PlasticsDocument3 pages(Eng) ASTM D3846-08 Standard Test Method For In-Plane Shear Strength of Reinforced Plasticsjaehoon.ahnNo ratings yet

- Nelcote E-718 Epoxy Prepreg, 7781 E-Glass ReinforcedDocument5 pagesNelcote E-718 Epoxy Prepreg, 7781 E-Glass ReinforcedjackNo ratings yet

- TutorialDocument3 pagesTutorialAzhan SuddleNo ratings yet

- Solutions For Practice Problems ElectronicsDocument7 pagesSolutions For Practice Problems ElectronicsRobNo ratings yet

- ECE6450L6-Rapid Thermal ProcessingDocument11 pagesECE6450L6-Rapid Thermal ProcessingSweetie EngNo ratings yet

- Courses DescriptionDocument8 pagesCourses Descriptionjanatfaili1No ratings yet

- Insta-Blak 333 Blackening BrochureDocument8 pagesInsta-Blak 333 Blackening BrochureLuuThiThuyDuongNo ratings yet

- NACA TN 3169 RoshkoDocument30 pagesNACA TN 3169 RoshkodickysilitongaNo ratings yet

- Mold CoatingDocument36 pagesMold Coatingsandeep100% (1)

- Aditya Dubey: Division: B URN: 2022-B-25102004Document16 pagesAditya Dubey: Division: B URN: 2022-B-25102004Aditya DubeyNo ratings yet

- HybridizationDocument21 pagesHybridizationpinehas nguluNo ratings yet

- Mixing of Ams 3025 Type IDocument3 pagesMixing of Ams 3025 Type ISatinder BhatiaNo ratings yet

- DefoamersDocument21 pagesDefoamersKaustubh Dhabale100% (1)

- Charles, 2008Document76 pagesCharles, 2008Jose G. Cueva CardeñaNo ratings yet

- MCQs Suface Tension & Interficial TensionDocument15 pagesMCQs Suface Tension & Interficial Tensionmukul sidhque100% (1)

- 3D Elasticity TheoryDocument6 pages3D Elasticity TheorySaurabh PednekarNo ratings yet

- 05 CT Jee-Pc As 29-12-2022Document4 pages05 CT Jee-Pc As 29-12-2022Bolly TubeNo ratings yet

- Photo DiodeDocument5 pagesPhoto DiodeNoble SharmaNo ratings yet

- Design Note For Retaining WallDocument127 pagesDesign Note For Retaining WallbijendraNo ratings yet

- Introduction 1Document34 pagesIntroduction 1KASHIF USMAN L1S16MSME0003No ratings yet

- Introduction To Reservoir EngineeringDocument28 pagesIntroduction To Reservoir EngineeringChijioke Zion OkabieNo ratings yet

- Tensile TestDocument9 pagesTensile Testonkod1No ratings yet

- CHAPTER 13 NanoworldDocument11 pagesCHAPTER 13 NanoworldRussel Labog50% (2)

- Newzeland Pav - Design ManualDocument64 pagesNewzeland Pav - Design ManualvijaydandageNo ratings yet

- Plastic Solar Cells Report Part 2Document32 pagesPlastic Solar Cells Report Part 2IRSHAD PNo ratings yet

- Chapter 3Document80 pagesChapter 3Ezzati AzizNo ratings yet

- NPL Report Mat 93: JULY 2020Document57 pagesNPL Report Mat 93: JULY 2020Volca CmmNo ratings yet

Pilecap Design

Pilecap Design

Uploaded by

Amier Thaqif0 ratings0% found this document useful (0 votes)

9 views2 pagesCopyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

0 ratings0% found this document useful (0 votes)

9 views2 pagesPilecap Design

Pilecap Design

Uploaded by

Amier ThaqifCopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

You are on page 1of 2

KUMPULAN JURUTERA PERUNDING Project title: INTANA RIA 3 Sheet No:

239 A-C Jalan Bandar 13, Melawati Metro Job No.

Ulu Klang 53100 Kuala Lumpur Part of structure : PILECAP Designed by Kong

Date:

PILECAP MARKING 2 P

Design data

Column loading (Ns) = 500 kN

Ultimate column load (Nu = 1.5 x Ns) = 750 kN

Pile size (square or circular) = 150 mm

Column dimension A = 225 mm

Column dimension B = 225 mm

Size of pile cap X = 910 mm

Size of pile cap Y = 600 mm

Depth of pilecap = 525 mm

Concrete cover = 150 mm

Concrete grade (fcu) = 25 N/mm2

Steel grade (fy) = 460 N/mm3

Unfactored load per pile (S.L.) = 250 kN

Factored load per pile (U.L) = 375 kN

No of piles in group = 2 nos.

Spacing x from c.g. = 225 mm

Spacing y from c.g. = 0 mm

S of distance from column face x-x = 0.11 m

S of distance from column face y-y = 0 m

Nos of piles along axis X-X = 1

Nos of piles along axis Y-Y = 0

Checking Bending Moment

Moment Mxx = 41.25 kNm

d = D - c - f/2 = 365 mm

k = M/bd2fcu = 0.0206 < 0.156

z = lever arm = 346.75 mm

Ast = M / 0.87 fy z = 297 mm2

Nominal steel 0.13%bh = 410 mm2

Ast required = 410 mm2

Use 4 T 12

Ast provided = 452 mm2

spacing = 163 mm c/c

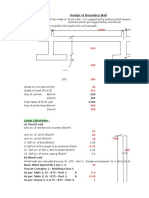

Moment Myy = 0.00 kNm

d = D - c - f - f/2 = 345 mm

k = M/bd2fcu = 0.0000 < 0.156

z = lever arm = 327.75 mm

Ast = M / 0.87 fy z = 0 mm2

Nominal steel 0.13%bh = 621 mm2

Ast required = 621 mm2

Use 6 T 12

KUMPULAN JURUTERA PERUNDING Project title: INTANA RIA 3 Sheet No:

239 A-C Jalan Bandar 13, Melawati Metro Job No.

Ulu Klang 53100 Kuala Lumpur Part of structure : PILECAP Designed by Kong

Date:

Ast provided = 679 mm2

spacing = 160 mm c/c

Checking normal shear

Assume critical section occur at distance "av"

measured at face of column (Axis x-x and y-y)

Axis x-x Axis y-y

100 Asprov / bd = 0.21 0.22

vc = 0.79(100As/bd)1/3(400/d)1/4/1.25 = 0.38 0.39 N/mm2

v = V/bd = 1.71 0.00 N/mm2

av = 67.50 1.00 mm

Enchanced shear = 2d x vc / av = 4.13 287.31

Shear is ok. Shear is ok.

Checking punching shear

Critical perimeter (from face of col) = 900 mm

Critical punching shear area = 328,500 mm2

Punching shear stress = force/area = 2.28 < 4.00

Allowable punching shear stress

= 0.8*fcu^0.5 N/mm2

Loop bars

Min area of steel for loop bars = 170 mm2

(25% of Asprov)

Use 2 T 12

Ast provided = 226 mm2

spacing = 185 mm c/c

You might also like

- Recommended Practice For Glass Fiber Reinforced Co PDFDocument104 pagesRecommended Practice For Glass Fiber Reinforced Co PDFvikram50% (2)

- Column Foundation ConnectionDocument3 pagesColumn Foundation Connectionmdelacua2No ratings yet

- Pile Retaining Wall - With Wind..Document6 pagesPile Retaining Wall - With Wind..epe civilNo ratings yet

- Pile Cap DesignDocument35 pagesPile Cap Designعصام السامرائي100% (2)

- SAE J434 1986 Automotive Ductile Iron Castings Nodular Iron CastingsDocument10 pagesSAE J434 1986 Automotive Ductile Iron Castings Nodular Iron Castingsvinicius_bacellarNo ratings yet

- 3.0 One Way SlabDocument20 pages3.0 One Way SlabAbhishek HulloliNo ratings yet

- Corbel DesignDocument3 pagesCorbel DesignLim EcNo ratings yet

- Pile RectifyingDocument2 pagesPile RectifyingAnonymous O404LiV4CNo ratings yet

- Pile Cap of CrystalDocument19 pagesPile Cap of CrystalPriyank MotivarasNo ratings yet

- BEAMDESIGN XLSMDocument4 pagesBEAMDESIGN XLSMSaurabh PednekarNo ratings yet

- Hinge Connection Design: A Reference CodeDocument3 pagesHinge Connection Design: A Reference CodeGaurav BhabadNo ratings yet

- Sloped FootingDocument19 pagesSloped FootingBala ChandarNo ratings yet

- Crack Width Calculation: MaterialsDocument2 pagesCrack Width Calculation: MaterialsIrfan AliNo ratings yet

- Column Splice 356 x368x129 Column - WeldDocument4 pagesColumn Splice 356 x368x129 Column - WeldNiraj Shinde100% (1)

- 508x10 CHSDocument8 pages508x10 CHSMuhammad BilalNo ratings yet

- Design of Square Footing F2Document18 pagesDesign of Square Footing F2Mohammed Sumer100% (1)

- Combined FootingsDocument17 pagesCombined FootingsLove SemsemNo ratings yet

- Design of Double Pilecap: Design For Axial Load and MomentDocument16 pagesDesign of Double Pilecap: Design For Axial Load and MomentMidhun BabuNo ratings yet

- Bolt Punching Block Shear AnchorageDocument3 pagesBolt Punching Block Shear AnchorageChangHangWingNo ratings yet

- Pilecap Design EC2 (1) (Autosaved) (Strut and Tie Method)Document25 pagesPilecap Design EC2 (1) (Autosaved) (Strut and Tie Method)Thaung Myint OoNo ratings yet

- Retaining WallDocument34 pagesRetaining WallDavirson Ajah100% (1)

- Slab Bridge DesignDocument25 pagesSlab Bridge DesignEngineeri TadiyosNo ratings yet

- 4-Base Plate - Pin ConnectionDocument3 pages4-Base Plate - Pin ConnectionMUTHUKKUMARAMNo ratings yet

- Rafter To Column Top Connection Design Given DataDocument10 pagesRafter To Column Top Connection Design Given DataSafi Zabihullah SafiNo ratings yet

- Hollow Section Connection Using BoltDocument4 pagesHollow Section Connection Using Boltikanyu79No ratings yet

- Spreadsheets To BS 8110etc: The Concrete CentreDocument10 pagesSpreadsheets To BS 8110etc: The Concrete Centrerajusk24No ratings yet

- Design Detail For RCC One Way SlabDocument18 pagesDesign Detail For RCC One Way SlabWanda BeasleyNo ratings yet

- Footing f8Document4 pagesFooting f8ravi4paperNo ratings yet

- Abutment A1 On Counterfort Wall - 03.07.2020 1.04 PMDocument34 pagesAbutment A1 On Counterfort Wall - 03.07.2020 1.04 PMVikas KushwahaNo ratings yet

- Analysis of 6 Pile Group - Pg6 MX Design Data: Load Case Joint No MZ X Grid Mark Y Sum Column Plinth Beam ZDocument14 pagesAnalysis of 6 Pile Group - Pg6 MX Design Data: Load Case Joint No MZ X Grid Mark Y Sum Column Plinth Beam ZAnonymous JUn5jis0No ratings yet

- BASEPLT9Document27 pagesBASEPLT9Homero Silva100% (3)

- Bharat Heavy Plate & Vessels Limited - VisakhapatnamDocument8 pagesBharat Heavy Plate & Vessels Limited - VisakhapatnamRama Subramanyam ManepalliNo ratings yet

- Project Designed By: Date: Client CPG Trang 9/11/2017 Code BS8110:1997 Checked By: Revision: JOB BKT 1Document2 pagesProject Designed By: Date: Client CPG Trang 9/11/2017 Code BS8110:1997 Checked By: Revision: JOB BKT 1Sơn Nguyễn-LêNo ratings yet

- Isolated Footing (ACI)Document4 pagesIsolated Footing (ACI)Boubakeur FerkousNo ratings yet

- Proposed Development: Lucia Njahira Waiganjo Ruiru Kiambu County PW 1 TW - 285Document15 pagesProposed Development: Lucia Njahira Waiganjo Ruiru Kiambu County PW 1 TW - 285patrick chegeNo ratings yet

- 150mm Thick FloorDocument11 pages150mm Thick FloorAnil UdaleNo ratings yet

- TCC11 Element DesignDocument9 pagesTCC11 Element DesignMario Sajulga Dela CuadraNo ratings yet

- Corbel DesignDocument2 pagesCorbel Designsidiq7No ratings yet

- Design of Purlin BeamsDocument5 pagesDesign of Purlin BeamsSanchal ShirkeNo ratings yet

- Chequer Platform-Flat Bar Design - L 1.112m - SDL 10kpaDocument1 pageChequer Platform-Flat Bar Design - L 1.112m - SDL 10kpaGOHNo ratings yet

- Made Date Sheet AR 17-Jul-11 1 Check Date Rev. MKI 17-Jul-11 0 PROJECT TITLE: Minhal Crowne Plaza Location: RiyadhDocument6 pagesMade Date Sheet AR 17-Jul-11 1 Check Date Rev. MKI 17-Jul-11 0 PROJECT TITLE: Minhal Crowne Plaza Location: Riyadhsidiq7No ratings yet

- Design of Pile CapDocument3 pagesDesign of Pile Capabhi aroteNo ratings yet

- Gording & TreckstangDocument10 pagesGording & TreckstangHendra CenNo ratings yet

- PreStressed Slab Design-2017-V1.0Document8 pagesPreStressed Slab Design-2017-V1.0maherelabdNo ratings yet

- Pile Cap-4 PileDocument2 pagesPile Cap-4 Pilecnt_chanddanNo ratings yet

- Beam - Capacity Check - SumanDocument4 pagesBeam - Capacity Check - Sumansuman_civilNo ratings yet

- RC Beam Analysis & Design (En1992-1) : TEDDS Calculation Version 2.0.03Document5 pagesRC Beam Analysis & Design (En1992-1) : TEDDS Calculation Version 2.0.03Natasha WyneNo ratings yet

- Boundray Wall Design Data Ganj BasodaDocument6 pagesBoundray Wall Design Data Ganj BasodaShubham KhareNo ratings yet

- Loads: Short Column With Axial LoadingDocument5 pagesLoads: Short Column With Axial LoadingMohd AftabNo ratings yet

- Design of Aluminium Window Frame:: REFER: IS 8147 - (1976)Document6 pagesDesign of Aluminium Window Frame:: REFER: IS 8147 - (1976)kamalxdNo ratings yet

- Raft Smr2 SubgrDocument22 pagesRaft Smr2 Subgrsivaraju1100% (1)

- Slab DesignDocument3 pagesSlab DesignMagdy BakryNo ratings yet

- Punching Shear StandardDocument4 pagesPunching Shear StandardjanethNo ratings yet

- T0516-Eco Sanctuary CPL 23-Feb-16 LYJ RC 250 850 1500: Design Calculation For Pilecap 2Rc250Document2 pagesT0516-Eco Sanctuary CPL 23-Feb-16 LYJ RC 250 850 1500: Design Calculation For Pilecap 2Rc250Tj TanNo ratings yet

- T0516-Eco Sanctuary CPL 23-Feb-16 LYJ RC 250 850 2300: Design Calculation For Pilecap 3Rc250Document3 pagesT0516-Eco Sanctuary CPL 23-Feb-16 LYJ RC 250 850 2300: Design Calculation For Pilecap 3Rc250Tj TanNo ratings yet

- T0516-Eco Sanctuary CPL 23-Feb-16 LYJ RC 250 850 3000: Design Calculation For Pilecap 4Rc250Document2 pagesT0516-Eco Sanctuary CPL 23-Feb-16 LYJ RC 250 850 3000: Design Calculation For Pilecap 4Rc250Tj TanNo ratings yet

- T0516-Eco Sanctuary CPL 23-Feb-16 LYJ RC 250 850 2800: Design Calculation For Pilecap 4Rc250Document2 pagesT0516-Eco Sanctuary CPL 23-Feb-16 LYJ RC 250 850 2800: Design Calculation For Pilecap 4Rc250Tj TanNo ratings yet

- CSE519 - Beam Design - 2 - TrialDocument2 pagesCSE519 - Beam Design - 2 - TrialTik HonNo ratings yet

- Job: 200, Nawala Road, Narahenpita Colombo - 05, Sri Lanka. Tel: 2808835 To 44 Fax: 2808846 & 47Document55 pagesJob: 200, Nawala Road, Narahenpita Colombo - 05, Sri Lanka. Tel: 2808835 To 44 Fax: 2808846 & 47Shamitha KanchanaNo ratings yet

- Pile Cap 8P-PC6Document6 pagesPile Cap 8P-PC6balaji gmscNo ratings yet

- Design of Eccentric Isolated Footing With Strap Beam: NMM Per Meter RunDocument3 pagesDesign of Eccentric Isolated Footing With Strap Beam: NMM Per Meter RunBishal ShresthaNo ratings yet

- Design Check For Plunge in Column: Project: Belfield Tunnel Location: M&E4 Date: 4/13/2020 Description: 2 LevelsDocument1 pageDesign Check For Plunge in Column: Project: Belfield Tunnel Location: M&E4 Date: 4/13/2020 Description: 2 LevelsGerards ChinNo ratings yet

- Top Bar Slab CheckingDocument6 pagesTop Bar Slab CheckingJamie MartinezNo ratings yet

- InterpolatedDocument9 pagesInterpolatedJamie MartinezNo ratings yet

- Beam Design Beam No Design Data: CompressionDocument8 pagesBeam Design Beam No Design Data: CompressionJamie MartinezNo ratings yet

- Spacing CheckDocument1 pageSpacing CheckJamie MartinezNo ratings yet

- Slides-pdf-ACEM-Supervision-Bored Piles-5 Sept 19Document82 pagesSlides-pdf-ACEM-Supervision-Bored Piles-5 Sept 19Jamie Martinez100% (1)

- Form QT5Document2 pagesForm QT5Jamie MartinezNo ratings yet

- Profile PROCA (New)Document44 pagesProfile PROCA (New)Jamie MartinezNo ratings yet

- KH 3153 Geoteknik 2 Geoslope Tutorial 2009Document8 pagesKH 3153 Geoteknik 2 Geoslope Tutorial 2009Jamie MartinezNo ratings yet

- Waste Segregation System - FinalDocument20 pagesWaste Segregation System - FinalAgraj KhadkaNo ratings yet

- (Eng) ASTM D3846-08 Standard Test Method For In-Plane Shear Strength of Reinforced PlasticsDocument3 pages(Eng) ASTM D3846-08 Standard Test Method For In-Plane Shear Strength of Reinforced Plasticsjaehoon.ahnNo ratings yet

- Nelcote E-718 Epoxy Prepreg, 7781 E-Glass ReinforcedDocument5 pagesNelcote E-718 Epoxy Prepreg, 7781 E-Glass ReinforcedjackNo ratings yet

- TutorialDocument3 pagesTutorialAzhan SuddleNo ratings yet

- Solutions For Practice Problems ElectronicsDocument7 pagesSolutions For Practice Problems ElectronicsRobNo ratings yet

- ECE6450L6-Rapid Thermal ProcessingDocument11 pagesECE6450L6-Rapid Thermal ProcessingSweetie EngNo ratings yet

- Courses DescriptionDocument8 pagesCourses Descriptionjanatfaili1No ratings yet

- Insta-Blak 333 Blackening BrochureDocument8 pagesInsta-Blak 333 Blackening BrochureLuuThiThuyDuongNo ratings yet

- NACA TN 3169 RoshkoDocument30 pagesNACA TN 3169 RoshkodickysilitongaNo ratings yet

- Mold CoatingDocument36 pagesMold Coatingsandeep100% (1)

- Aditya Dubey: Division: B URN: 2022-B-25102004Document16 pagesAditya Dubey: Division: B URN: 2022-B-25102004Aditya DubeyNo ratings yet

- HybridizationDocument21 pagesHybridizationpinehas nguluNo ratings yet

- Mixing of Ams 3025 Type IDocument3 pagesMixing of Ams 3025 Type ISatinder BhatiaNo ratings yet

- DefoamersDocument21 pagesDefoamersKaustubh Dhabale100% (1)

- Charles, 2008Document76 pagesCharles, 2008Jose G. Cueva CardeñaNo ratings yet

- MCQs Suface Tension & Interficial TensionDocument15 pagesMCQs Suface Tension & Interficial Tensionmukul sidhque100% (1)

- 3D Elasticity TheoryDocument6 pages3D Elasticity TheorySaurabh PednekarNo ratings yet

- 05 CT Jee-Pc As 29-12-2022Document4 pages05 CT Jee-Pc As 29-12-2022Bolly TubeNo ratings yet

- Photo DiodeDocument5 pagesPhoto DiodeNoble SharmaNo ratings yet

- Design Note For Retaining WallDocument127 pagesDesign Note For Retaining WallbijendraNo ratings yet

- Introduction 1Document34 pagesIntroduction 1KASHIF USMAN L1S16MSME0003No ratings yet

- Introduction To Reservoir EngineeringDocument28 pagesIntroduction To Reservoir EngineeringChijioke Zion OkabieNo ratings yet

- Tensile TestDocument9 pagesTensile Testonkod1No ratings yet

- CHAPTER 13 NanoworldDocument11 pagesCHAPTER 13 NanoworldRussel Labog50% (2)

- Newzeland Pav - Design ManualDocument64 pagesNewzeland Pav - Design ManualvijaydandageNo ratings yet

- Plastic Solar Cells Report Part 2Document32 pagesPlastic Solar Cells Report Part 2IRSHAD PNo ratings yet

- Chapter 3Document80 pagesChapter 3Ezzati AzizNo ratings yet

- NPL Report Mat 93: JULY 2020Document57 pagesNPL Report Mat 93: JULY 2020Volca CmmNo ratings yet