Professional Documents

Culture Documents

VSK LS

VSK LS

Uploaded by

Trịnh Đức HạnhOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VSK LS

VSK LS

Uploaded by

Trịnh Đức HạnhCopyright:

Available Formats

YOUR PARTNER WORLDWIDE

VSK

Special tools for grinding conical valve seats

DN 8-300 mm (¼-12”)

VSK tools facilitate the quick repair of conical sealing faces on all shut-off and control valves with

nominal diameter 8-300 mm.

VSK tools prove their strength everywhere where fast valve repair and economy are required:

Wide-ranging use:

in conventional power stations, nuclear power stations,

refurbishment companies, refineries, chemical plant, shipyards,

sugar mills, paper mills, on ships, by valve manufacturers and

many others.

Long life due to the use of:

- high-quality materials

- powerful drives

- wear-resistant tools

- stable light-weight design

Use independent of:

- width and hardness of sealing faces to be machined

- installation position of fitting (horizontal, vertical)

- type of fitting

Due to its low weight

- easy handling

- hand-held operation

- fast setting up

EFCO VSK Tools

An impressive Concept

Simple handling

Low weight

One-man operation

Wear-resistant tools

Good price/performance ratio

High profitability and efficiency

Optimum material removal due to use of high-quality abrasives

Simple fitting of tools

Safe centring using centring cone or rim chuck, thus centred

machining

Hard grinding cones to which the abrasive is attached ensure precise

angular geometry

THE PREMIUM-PRODUCTS – MADE BY EFCO – MADE IN GERMANY

VSK Specifications

VSK-1 VSK-2 VSK-3 VSK-4 VSK-5

DN (mm) 8-50 (¼”-2”) 8-65 (¼”-2.5”) 8-100 (¼”-4”) 8-150 (¼”-6”) 80-300 (3”-12”)

Drive electric 230/110 V, 50/60Hz or pneumatic 6-7 bar

Standard seating 30° (2x15°), 40° (2x20°), 60° (2x30°), 75 (2x37,5), 90° (2x45°)

angle (other angles on request)

Standard seating angle

Jaw chuck Jaw chuck

with guide tube with guide tube

or or

Centring Centring

cone cone

Tool holder Tool holder

Grinding cone Grinding cone

Abrasive

Clamping nut Abrasive

Mounting screw

The EFCO VSK tools, as do all EFCO products, provide

a complete repair system.

It is possible to combine various angles and sizes into a

complete tool set as per your specification.

Subject to technical change.

EFCO Maschinenbau GmbH – Valve repair and testing equipment

08/2009 – 02

Otto-Brenner-Straße 5 – 7 D - 52353 Düren Phone: +49-(0)2421-989-0 Fax: +49-(0)2421-86260

info@efco-dueren.de sales@efco-dueren.de www.efco-dueren.com

Agencies in many countries

THE PREMIUM-PRODUCTS – MADE BY EFCO – MADE IN GERMANY

YOUR PARTNER WORLDWIDE

LS

Tools for the machining of pipe ends with 140°metallic

lenticular gaskets

(to BASF and DIN 2696)

DN 8 – 200 mm (3/8”-8”)

EFCO-LS with guide bush

Precise special guides provide for completely centred

machining of the sealing face.

Guide bushes are used for small nominal diameters.

Even for large diameters, our special jaw chucks

enable precise guiding of the grinding tool.

Our EFCO-LS tools are supplied complete with guide

bush or rim chuck and an extensive assortment of

various abrasive cloths in a plastic carry case.

EFCO-LS with jaw chuck

Subject to technical change.

EFCO Maschinenbau GmbH – Valve repair and testing equipment

07/2009 – 01

Otto-Brenner-Straße 5 – 7 D - 52353 Düren Phone: +49-(0)2421-989-0 Fax: +49-(0)2421-86260

info@efco-dueren.de sales@efco-dueren.de www.efco-dueren.com

Agencies in many countries

THE PREMIUM-PRODUCTS – MADE BY EFCO – MADE IN GERMANY

You might also like

- Conectores de Modulo de Control de Spark 2008 Mtor 1.0Document3 pagesConectores de Modulo de Control de Spark 2008 Mtor 1.0Gladys Pumayalli100% (3)

- Air Torque Full Catalogue en PDFDocument105 pagesAir Torque Full Catalogue en PDFBass Mullen100% (2)

- Seat ExeoDocument15 pagesSeat ExeoCosmin Mihai KiritaNo ratings yet

- E 08 Prospekt Serie SL WebDocument4 pagesE 08 Prospekt Serie SL Webกล้วย มาแล้วจ้าNo ratings yet

- Universal Connector Element - BredentDocument6 pagesUniversal Connector Element - Bredentjohndoe21roNo ratings yet

- Product Overview: Valves Actuators Automation TechnologyDocument36 pagesProduct Overview: Valves Actuators Automation TechnologyBrion Bara IndonesiaNo ratings yet

- Simple, Accurate, Good Value: F-Tool Product LineDocument56 pagesSimple, Accurate, Good Value: F-Tool Product Lineantonioc8719No ratings yet

- Sinowon - Katalog Projektory Pomiarowe - 2015 ENDocument16 pagesSinowon - Katalog Projektory Pomiarowe - 2015 END.T.No ratings yet

- Biegen Engl PDFDocument3 pagesBiegen Engl PDFLucian LeonteNo ratings yet

- ARCELOR CATALOG TechnicalDocument47 pagesARCELOR CATALOG TechnicalRadu MateiNo ratings yet

- Tough Crushing: Smooth OperatingDocument16 pagesTough Crushing: Smooth OperatingManuel GagnoNo ratings yet

- 1 773 Lifeline-Manual R03 2020-1Document30 pages1 773 Lifeline-Manual R03 2020-1Anonymous ggRTHDKe6No ratings yet

- ProfilDocument18 pagesProfilAnonymous 6EW2MsFbkNo ratings yet

- Seal DesignDocument307 pagesSeal DesignAshishNo ratings yet

- Industrial High Frequency Grinding With FEIN.Document6 pagesIndustrial High Frequency Grinding With FEIN.RameetNo ratings yet

- Heald Frame Brochure PDFDocument8 pagesHeald Frame Brochure PDFPame AlejandraNo ratings yet

- MB8 Automatic Sheet Metal Press Brake Bending Machine With DA56S SystemDocument8 pagesMB8 Automatic Sheet Metal Press Brake Bending Machine With DA56S SystemryneleeNo ratings yet

- PT Promecam Tools 1801 ENGDocument45 pagesPT Promecam Tools 1801 ENGpressbraketoolsNo ratings yet

- DownloadDocument28 pagesDownloadmoonstarNo ratings yet

- Hidrolik Kirici Sarf Malzeme KataloguDocument132 pagesHidrolik Kirici Sarf Malzeme KataloguÇkta FıfiNo ratings yet

- Comet Portables and Mobile Catalog v5Document11 pagesComet Portables and Mobile Catalog v5Hyujeii MceNo ratings yet

- Vtec - Grinding and Lapping - ORBIT - 0101 - V1Document3 pagesVtec - Grinding and Lapping - ORBIT - 0101 - V1Hugo AbreuNo ratings yet

- KKT e 48209Document48 pagesKKT e 48209royroverNo ratings yet

- Brochure Roofing-Sarnamatic-681 enDocument6 pagesBrochure Roofing-Sarnamatic-681 enDoni AgusmanNo ratings yet

- Fro Bro Vs247317 EngDocument4 pagesFro Bro Vs247317 EngvonipkoNo ratings yet

- KniikkaDocument15 pagesKniikkasundyaNo ratings yet

- Famat - Waterworks Valves Catalogue 2019 enDocument64 pagesFamat - Waterworks Valves Catalogue 2019 enAHSAN GGCNo ratings yet

- CUT - 200 300 400 MS SP - ENDocument24 pagesCUT - 200 300 400 MS SP - ENMoustaffaNo ratings yet

- Schroder Brochure - PowerBend - Professional - ENDocument12 pagesSchroder Brochure - PowerBend - Professional - ENIlian AvramovNo ratings yet

- Brosur - Fume Hood DuoDocument4 pagesBrosur - Fume Hood DuoNiezhaNo ratings yet

- Power Bend Pro EngDocument36 pagesPower Bend Pro EngmarcoNo ratings yet

- Welding News 2016-II ENG LowDocument16 pagesWelding News 2016-II ENG Lowtekstep7No ratings yet

- Sunriseiw IronworkersDocument26 pagesSunriseiw IronworkersjvictorvrNo ratings yet

- Precitool Cat FRDocument44 pagesPrecitool Cat FRRohan KulkarniNo ratings yet

- Kessler BRO PK1002 Kessler Spindel H Line A4 en V2-5 WEBDocument16 pagesKessler BRO PK1002 Kessler Spindel H Line A4 en V2-5 WEBCRISENTENANo ratings yet

- Single Spring SealsDocument128 pagesSingle Spring SealsicingrockNo ratings yet

- Siemens Sentron BuswayDocument2 pagesSiemens Sentron Buswayduyan1987No ratings yet

- Stauff Press Spr-Prc-Poc en 03-2016Document6 pagesStauff Press Spr-Prc-Poc en 03-2016onlymotieNo ratings yet

- EMCO Medical Technology 01Document8 pagesEMCO Medical Technology 01bakry50002000No ratings yet

- SCITEQ Universal Testing Machines 2020Document7 pagesSCITEQ Universal Testing Machines 2020taylontovarNo ratings yet

- T622 Rigid-Scopes en IV06GB4Document8 pagesT622 Rigid-Scopes en IV06GB4Bill MeeladerNo ratings yet

- EDM ErosionadoraDocument8 pagesEDM ErosionadoraEuler VilcaNo ratings yet

- PVC Cable TrayDocument24 pagesPVC Cable TrayDavidNo ratings yet

- Baumer EIL580 BR EN 1301 11101195 LRDocument8 pagesBaumer EIL580 BR EN 1301 11101195 LRAlessandro CotroneoNo ratings yet

- Micro Technology en WebDocument12 pagesMicro Technology en WebIlya FuksmanNo ratings yet

- Wpas Directional SpeakerDocument20 pagesWpas Directional Speakervictor perezNo ratings yet

- Omsco Drillpipe CatalogueDocument24 pagesOmsco Drillpipe Cataloguerwinmill100% (3)

- Pm0uk Dmu Evo Series PDF DataDocument32 pagesPm0uk Dmu Evo Series PDF Datamail2jyothishdsNo ratings yet

- 01EDH English 0816Document10 pages01EDH English 0816karthikeyan1992No ratings yet

- Series Abo 300: DN 50 - DN 600 (2" - 24") PN 10Document12 pagesSeries Abo 300: DN 50 - DN 600 (2" - 24") PN 10Vignesh NadimuthuNo ratings yet

- Corona & Plasma: For ExtrusionDocument8 pagesCorona & Plasma: For ExtrusionHuy Tuan QuachNo ratings yet

- GENOS L2000 L3000 e OEG E - 1 - 100 - Aug2017 - PDFDocument13 pagesGENOS L2000 L3000 e OEG E - 1 - 100 - Aug2017 - PDFنعيم سعيدNo ratings yet

- A V C T: Utomatic Ertical OIL ONGDocument2 pagesA V C T: Utomatic Ertical OIL ONGDejanNo ratings yet

- Multi Head ExtrusionDocument12 pagesMulti Head Extrusionsuoya14No ratings yet

- Singlemultiplelimitswitches TecknicDocument18 pagesSinglemultiplelimitswitches Tecknicchidambaram kasiNo ratings yet

- CFC Usen PDFDocument436 pagesCFC Usen PDFpiping1522No ratings yet

- Trilogy of Connectors: Basic Principles and Connector Design ExplanationsFrom EverandTrilogy of Connectors: Basic Principles and Connector Design ExplanationsRating: 5 out of 5 stars5/5 (1)

- Abrasive Materials For Industrial Valve Grinding - LarsLap®Document9 pagesAbrasive Materials For Industrial Valve Grinding - LarsLap®Trịnh Đức HạnhNo ratings yet

- Truong Thi Thuy Trang - 98 - DH GTVTDocument1 pageTruong Thi Thuy Trang - 98 - DH GTVTTrịnh Đức HạnhNo ratings yet

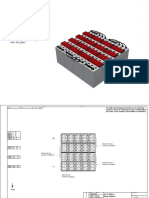

- Ni-Cd Battery 96 Cells UP1M 48 1 X ESGL2-1500 STD 2 Tier 2 Step RackDocument4 pagesNi-Cd Battery 96 Cells UP1M 48 1 X ESGL2-1500 STD 2 Tier 2 Step RackTrịnh Đức HạnhNo ratings yet

- Ni-Cd Battery 170 Cells UP1L 325 1 X ESGL3-3450 STD 2 Tier 3 Step RackDocument4 pagesNi-Cd Battery 170 Cells UP1L 325 1 X ESGL3-3450 STD 2 Tier 3 Step RackTrịnh Đức HạnhNo ratings yet

- Ni-Cd Battery 40 Cells SBLE 300 1 X ESGL2-1200 STD 2 Tier 2 Step RackDocument4 pagesNi-Cd Battery 40 Cells SBLE 300 1 X ESGL2-1200 STD 2 Tier 2 Step RackTrịnh Đức HạnhNo ratings yet

- Ni-Cd Battery 40 Cells SBLE 300 1 X ESGL2-1200 STD 2 Tier 2 Step RackDocument4 pagesNi-Cd Battery 40 Cells SBLE 300 1 X ESGL2-1200 STD 2 Tier 2 Step RackTrịnh Đức HạnhNo ratings yet

- P 28may21 Trinh Duc A SYS 00001Document4 pagesP 28may21 Trinh Duc A SYS 00001Trịnh Đức HạnhNo ratings yet

- Back To Basics - Pump Specific Speed and Suction Specific Speed - WaterWorldDocument7 pagesBack To Basics - Pump Specific Speed and Suction Specific Speed - WaterWorldTrịnh Đức HạnhNo ratings yet

- P 17may21 Trinh Duc A SYS 00001Document4 pagesP 17may21 Trinh Duc A SYS 00001Trịnh Đức HạnhNo ratings yet

- P 04aug21 Trinh Duc A SYS 00001Document4 pagesP 04aug21 Trinh Duc A SYS 00001Trịnh Đức HạnhNo ratings yet

- Ni-Cd Battery 20 Cells UP1L 800 1 Tier 4 Rows: Customer Information Ref1: P - 29jun21 - Trinh Duc - A Ref2: SYS - 00001Document4 pagesNi-Cd Battery 20 Cells UP1L 800 1 Tier 4 Rows: Customer Information Ref1: P - 29jun21 - Trinh Duc - A Ref2: SYS - 00001Trịnh Đức HạnhNo ratings yet

- Ni-Cd Battery 180 Cells SBLE 300 1 X ESGL4-2700 STD 2 Tier 4 Step RackDocument4 pagesNi-Cd Battery 180 Cells SBLE 300 1 X ESGL4-2700 STD 2 Tier 4 Step RackTrịnh Đức HạnhNo ratings yet

- P 08sep21 Trinh Duc A SYS 00001Document4 pagesP 08sep21 Trinh Duc A SYS 00001Trịnh Đức HạnhNo ratings yet

- How To Find The Best Efficiency Point For Your Pump - All Pumps BlogDocument3 pagesHow To Find The Best Efficiency Point For Your Pump - All Pumps BlogTrịnh Đức HạnhNo ratings yet

- Specific Speed (NS) Definition - Pump Terms - Intro To PumpsDocument3 pagesSpecific Speed (NS) Definition - Pump Terms - Intro To PumpsTrịnh Đức HạnhNo ratings yet

- 1769 Compact Power Supplies, Expansion Cables, and End CapsDocument1 page1769 Compact Power Supplies, Expansion Cables, and End CapsTrịnh Đức HạnhNo ratings yet

- FMC ManDocument208 pagesFMC ManrafaelldalpraNo ratings yet

- Automated Wall Production LineDocument4 pagesAutomated Wall Production LineCici GonzalesNo ratings yet

- Matlab Tutorial: Getting StartedDocument25 pagesMatlab Tutorial: Getting StartedGITAM UNIVERISTYNo ratings yet

- Heat Exchanger Design, Arthur PDocument2 pagesHeat Exchanger Design, Arthur PPutra Safuan Ariff0% (2)

- Plan Dee Studios Ingenieria Mecanic ADocument1 pagePlan Dee Studios Ingenieria Mecanic ARafael AvilaNo ratings yet

- Do Loop: ExplanationDocument4 pagesDo Loop: ExplanationshanapotzNo ratings yet

- Spe 88491 MS PDFDocument7 pagesSpe 88491 MS PDFBruni MartinezNo ratings yet

- Git Hub PDF Cheat SheetDocument2 pagesGit Hub PDF Cheat SheetasdkuvheriugbzjNo ratings yet

- Daag To Lirf b737Document76 pagesDaag To Lirf b737Abdel Hafid LahrecheNo ratings yet

- Raspberry Pi CNC Machine - 8 Steps (With Pictures)Document12 pagesRaspberry Pi CNC Machine - 8 Steps (With Pictures)Everton Klinger Sousa SilvaNo ratings yet

- 1756-Pm008 Logix5000 Ladder DiagramDocument20 pages1756-Pm008 Logix5000 Ladder DiagramAnojan BalaNo ratings yet

- 966F Series II and Electrical System 970F Wheel LoadersDocument2 pages966F Series II and Electrical System 970F Wheel Loadersdinny blanco rojasNo ratings yet

- NotifierDocument32 pagesNotifierRaviNo ratings yet

- KM Epm D CBL General - F03Document24 pagesKM Epm D CBL General - F03Rajeeb MohammedNo ratings yet

- Fire Protection, Fire Detection and Fire ExtinctionDocument15 pagesFire Protection, Fire Detection and Fire Extinctionrbnsn927053No ratings yet

- Physics Formula Sheet PDFDocument4 pagesPhysics Formula Sheet PDFSuneel KumarsinghNo ratings yet

- Ip Class 12 Black Bindid CorrectDocument221 pagesIp Class 12 Black Bindid CorrectTarun royNo ratings yet

- ATV600 Getting Started en EAV63253 03Document4 pagesATV600 Getting Started en EAV63253 03Pustinjak SaharicNo ratings yet

- Standard ADA Locations and Information of Door Hardware DiagramDocument1 pageStandard ADA Locations and Information of Door Hardware DiagramEmily Jamieson BoydNo ratings yet

- Lenovo Z500 DatasheetDocument2 pagesLenovo Z500 DatasheetMahendra KammaNo ratings yet

- Warman Mcu 350 Masbate Philippines Case Study DuplicateDocument2 pagesWarman Mcu 350 Masbate Philippines Case Study DuplicateBJ AbelaNo ratings yet

- SANFLO PE Manholes CatalogDocument12 pagesSANFLO PE Manholes CataloganandNo ratings yet

- Amc Banking 2012 5 For Dynamics Ax 2012 User GuideDocument75 pagesAmc Banking 2012 5 For Dynamics Ax 2012 User GuideTố Quyên NguyễnNo ratings yet

- Sambu: Engineering & Construction Co.,LtdDocument28 pagesSambu: Engineering & Construction Co.,LtdTanushree MishraNo ratings yet

- Valery P. Dmitriyev - Elasticity and ElectromagnetismDocument10 pagesValery P. Dmitriyev - Elasticity and Electromagnetism939392No ratings yet

- Method StatementDocument7 pagesMethod StatementBhargav BbvsNo ratings yet

- Ninglu BW-508Document23 pagesNinglu BW-508John QwerNo ratings yet

- BS 00848-4 1997 Iso 13351 1996 (En) PDFDocument16 pagesBS 00848-4 1997 Iso 13351 1996 (En) PDFMahendran MNo ratings yet