Professional Documents

Culture Documents

Allumunium Foil Manufacturing Processed

Allumunium Foil Manufacturing Processed

Uploaded by

jerry0 ratings0% found this document useful (0 votes)

13 views3 pagesAluminum foil is produced through a multi-step process beginning with mining bauxite ore. The ore is refined into alumina powder then smelted into liquid aluminum. The liquid metal is cast into ingots and rolled into thin sheets. The sheets undergo cold rolling, annealing to improve flexibility, and further rolling until the desired thickness is reached. The foil is cut and may receive surface treatments before quality testing and packaging for distribution.

Original Description:

Manufactured processed of Allumunium Foil

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAluminum foil is produced through a multi-step process beginning with mining bauxite ore. The ore is refined into alumina powder then smelted into liquid aluminum. The liquid metal is cast into ingots and rolled into thin sheets. The sheets undergo cold rolling, annealing to improve flexibility, and further rolling until the desired thickness is reached. The foil is cut and may receive surface treatments before quality testing and packaging for distribution.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

13 views3 pagesAllumunium Foil Manufacturing Processed

Allumunium Foil Manufacturing Processed

Uploaded by

jerryAluminum foil is produced through a multi-step process beginning with mining bauxite ore. The ore is refined into alumina powder then smelted into liquid aluminum. The liquid metal is cast into ingots and rolled into thin sheets. The sheets undergo cold rolling, annealing to improve flexibility, and further rolling until the desired thickness is reached. The foil is cut and may receive surface treatments before quality testing and packaging for distribution.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

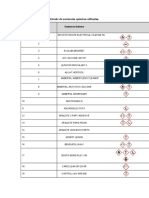

Allumunium Foil Manufacturing Processed

Aluminum foil is a versatile product that is widely used for various

purposes, including food packaging, insulation, and cooking. The

process of manufacturing aluminum foil involves several steps after

the mining and extraction of aluminum from its ore, bauxite. Here's an

overview of the process:

Mining and refining: Bauxite, the primary source of aluminum, is

mined from the earth and refined to obtain alumina (aluminum oxide)

through the Bayer process. Alumina is a white powder.

Smelting: Alumina is then smelted in a furnace, typically using the Hall-

Héroult process, which involves passing an electric current through a

molten mixture of alumina and cryolite (a compound that lowers the

melting point). This process separates the aluminum from the oxygen,

producing liquid aluminum.

Continuous casting: The liquid aluminum is poured into large molds to

create ingots or billets. These ingots are then rolled into thin sheets

known as coils.

Rolling: The coils are sent through a series of rolling mills that

progressively reduce the thickness of the aluminum. This process is

called cold rolling and is typically done at room temperature. The

rolling can be repeated several times to achieve the desired thickness.

Jerry 1908 9 July 2023

Annealing: After cold rolling, the aluminum is annealed by heating it

to a specific temperature and then allowing it to cool slowly. Annealing

improves the foil's flexibility and makes it less prone to tearing.

Finishing: The annealed aluminum is then rolled even thinner and

passed through more sets of rollers to achieve the desired thickness.

This final rolling is known as foil rolling.

Slitting and cutting: The rolled aluminum is slit into narrower strips and

cut into appropriate lengths, depending on the desired width and

length of the aluminum foil.

Annealing (again): The foil may undergo another round of annealing to

further enhance its flexibility and remove any residual stress.

Surface treatment: The foil may undergo surface treatment processes

such as lubrication or coating to improve its performance in specific

applications. For example, a lubricant coating can be applied to

enhance the foil's ease of use during food packaging.

Quality control and packaging: The aluminum foil undergoes rigorous

quality control checks to ensure it meets the required specifications.

After passing the quality control tests, the foil is packaged and

prepared for distribution and sale.

Jerry 1908 9 July 2023

It's worth noting that the specific processes and technologies used

may vary slightly between different manufacturers, but the overall

steps involved in aluminum foil production generally follow this

outline.

Jerry 1908 9 July 2023

You might also like

- Metallic Transmutations by Acetic Acid Primo DinaDocument5 pagesMetallic Transmutations by Acetic Acid Primo Dinamunishahuja17No ratings yet

- Concrete Curing PlanDocument2 pagesConcrete Curing PlanazhustuddyingNo ratings yet

- Aluminum - Group No. 7 - Reporting in Meeng325 - 3BDocument11 pagesAluminum - Group No. 7 - Reporting in Meeng325 - 3BTrisha Mae BelmonteNo ratings yet

- FLLDocument10 pagesFLLFikaduNo ratings yet

- AluminumDocument10 pagesAluminumAnushka KulkarniNo ratings yet

- Fabrication and ApplicationDocument8 pagesFabrication and Application000No ratings yet

- 10 Aluminium Foil in Packaging - SBDocument40 pages10 Aluminium Foil in Packaging - SBSiddharth Saxena67% (3)

- Foil Making 3Document26 pagesFoil Making 3Gupta SuyashNo ratings yet

- Aluminium in Building ConstructionDocument18 pagesAluminium in Building ConstructionRithas Mohammad PKNo ratings yet

- ALUMINIUM FinalDocument18 pagesALUMINIUM FinalRamya shree kNo ratings yet

- Aluminium: Submitted by Group 1Document21 pagesAluminium: Submitted by Group 1Nidhi MehtaNo ratings yet

- Aluminium ExtrusionDocument2 pagesAluminium ExtrusionJithu AANo ratings yet

- AluminiumDocument20 pagesAluminiumANKITA BAJPAINo ratings yet

- (Processing, Properties and Applications) : Cooper Kollie Lackay (40447)Document17 pages(Processing, Properties and Applications) : Cooper Kollie Lackay (40447)Rolando d'HellemmesNo ratings yet

- Aluminum Recyclimg AssignmentDocument5 pagesAluminum Recyclimg AssignmentAhmed MughalNo ratings yet

- Aluminium Alloys and Its ManufacturingDocument8 pagesAluminium Alloys and Its ManufacturingthanhnguyenhhvnNo ratings yet

- Aluminizing by (08MT3012 & 08MT1030) Atanu & ManojDocument24 pagesAluminizing by (08MT3012 & 08MT1030) Atanu & ManojAtanu KumarNo ratings yet

- Aleaciones de Aluminio MarinoDocument4 pagesAleaciones de Aluminio MarinoreurriNo ratings yet

- Standard Profile Catalogue Oct 2012 Master FINAL Interactive CorrectedDocument72 pagesStandard Profile Catalogue Oct 2012 Master FINAL Interactive CorrectedMa ArullandhuNo ratings yet

- Aluminium Prices in IndiaDocument12 pagesAluminium Prices in IndiaKumar Chandan JhaNo ratings yet

- Aluminium & Steel Book Mai SeDocument3 pagesAluminium & Steel Book Mai SeJatin TilwaniNo ratings yet

- Aluminum FoilDocument19 pagesAluminum Foilvijay2020No ratings yet

- Aluminium PDFDocument325 pagesAluminium PDFDeepakNo ratings yet

- Aluminium Castings PDFDocument4 pagesAluminium Castings PDFpalsettyNo ratings yet

- Classification of Bricks: Course Title: Building and Finished MaterialsDocument10 pagesClassification of Bricks: Course Title: Building and Finished MaterialsasadNo ratings yet

- Department of Metallurgy and Materials Engineering Complex Engineering Problem Physical Metallurgy-II Dr. Imtiaz Ali SoomroDocument11 pagesDepartment of Metallurgy and Materials Engineering Complex Engineering Problem Physical Metallurgy-II Dr. Imtiaz Ali SoomroAli SoomroNo ratings yet

- Aluminum Extrusion ProcessDocument4 pagesAluminum Extrusion Processswarna raviNo ratings yet

- Wispeco Aluminium ProfilesDocument22 pagesWispeco Aluminium ProfilesPatrick153No ratings yet

- Aluminium RollingDocument5 pagesAluminium RollingChetna BarochiyakalolaNo ratings yet

- Module 3 AluminiumDocument34 pagesModule 3 Aluminiumalbatroos earlybirdNo ratings yet

- Aluminium IngotDocument2 pagesAluminium IngotSoumya BoseNo ratings yet

- Aluminium RecyclingDocument9 pagesAluminium RecyclingannbennNo ratings yet

- Aluminium Alloys: Engineering Materials CE1304Document19 pagesAluminium Alloys: Engineering Materials CE1304Madhumita KumarNo ratings yet

- Boc Welding Consumables-AluminiumDocument15 pagesBoc Welding Consumables-AluminiumClaudia MmsNo ratings yet

- Bhagwan Mahavir College of Architecture: Sub: Building Material Construction Sem 3Document56 pagesBhagwan Mahavir College of Architecture: Sub: Building Material Construction Sem 3Yousif HusseinNo ratings yet

- Research Note On Aluminium Alloy Property PDFDocument80 pagesResearch Note On Aluminium Alloy Property PDFpenghzNo ratings yet

- Aluminium CastingDocument5 pagesAluminium CastingBalaji RajaNo ratings yet

- Tool and MoldDocument4 pagesTool and MoldWilmar MattesNo ratings yet

- Aluminium ForgingDocument7 pagesAluminium Forgingbusinessdevelopment.corpNo ratings yet

- Affect of Elements On SteelDocument82 pagesAffect of Elements On SteelAditya PratapNo ratings yet

- Aluminium: Chris Grover & Fabian Reeves WhymarkDocument11 pagesAluminium: Chris Grover & Fabian Reeves WhymarkPlymouth3DDesignNo ratings yet

- 1586858195metallization ProcessDocument2 pages1586858195metallization ProcessNoah Oluwatoyin AderiyikeNo ratings yet

- Pre Fabricated AluminiumDocument6 pagesPre Fabricated AluminiumMahalakshmi R NairNo ratings yet

- Architectural Catalogue RenukootDocument103 pagesArchitectural Catalogue Renukootprchoudharykp100% (2)

- EngineDocument2 pagesEngineFuner AndrishNo ratings yet

- Aluminum As Alloy and DeoxidantDocument5 pagesAluminum As Alloy and DeoxidantlarryjhNo ratings yet

- Aluminium Roofing SheetsDocument2 pagesAluminium Roofing SheetsDotan NutodNo ratings yet

- Aluminium: Special Commodity ReportDocument10 pagesAluminium: Special Commodity ReporttejaskopardeNo ratings yet

- Aluminium AlloyDocument22 pagesAluminium AlloyAashish Gharde0% (1)

- 6.2.Non ferrous metalsDocument60 pages6.2.Non ferrous metalslaurielleNo ratings yet

- AluminaDocument5 pagesAluminaehsannasiri100% (1)

- ASM Subject Guide - AluminumDocument5 pagesASM Subject Guide - AluminumBlueOneGaussNo ratings yet

- Aluminium (Al) - Forms Casting BasedDocument13 pagesAluminium (Al) - Forms Casting BasedSansar PanchalNo ratings yet

- 5 Aluminium RecyclingDocument4 pages5 Aluminium Recyclinggosaye desalegn50% (2)

- Aluminum Electrical Conductor HandbookDocument365 pagesAluminum Electrical Conductor Handbookprem100% (4)

- How Aluminium Alloys Are ProducedDocument4 pagesHow Aluminium Alloys Are Producedمحمد نجارNo ratings yet

- Worksheet9_20MT30019Document9 pagesWorksheet9_20MT30019productNo ratings yet

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkFrom EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNo ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- 411 InternshipDocument33 pages411 Internshipnamith58075807No ratings yet

- Hercules Structural Systems Pvt. LTDDocument5 pagesHercules Structural Systems Pvt. LTDNeeraj SinghNo ratings yet

- Maximum Allowable Stress Values ASME Pressure Vessel CodeDocument1 pageMaximum Allowable Stress Values ASME Pressure Vessel CodeBill HNo ratings yet

- Research ProposalDocument5 pagesResearch ProposalHyellamada DanielNo ratings yet

- HazmatDocument9 pagesHazmategarciachNo ratings yet

- Konfigurasi Elektron Kulit KLMNDocument2 pagesKonfigurasi Elektron Kulit KLMNFendy Shirah50% (8)

- Boilers and Steam Systems ..BoeDocument151 pagesBoilers and Steam Systems ..BoeMV AmohanAKarthicK100% (2)

- Polymer Practice ProblemsDocument11 pagesPolymer Practice ProblemspolypolyyNo ratings yet

- Preparations of Tetraamminecopper IIDocument13 pagesPreparations of Tetraamminecopper IIJOHANA ARAUZNo ratings yet

- Cellulose Fibers, RegeneratedDocument39 pagesCellulose Fibers, Regeneratedyemresimsek100% (1)

- General Chemistry 2 Quarter 2-Week 1 (Module 2) Types of Intermolecular Forces Pre-TestDocument4 pagesGeneral Chemistry 2 Quarter 2-Week 1 (Module 2) Types of Intermolecular Forces Pre-TestDexter John Delos SantosNo ratings yet

- Sistem Selubung BangunanDocument114 pagesSistem Selubung BangunanFirdha LudviaNo ratings yet

- Reinforced Concrete Beam Design (Nzs 3101-95)Document4 pagesReinforced Concrete Beam Design (Nzs 3101-95)aev65No ratings yet

- Procedure For Piping Hydrostatic Pressure Test - 15124-MS-M-006 Rev-1Document17 pagesProcedure For Piping Hydrostatic Pressure Test - 15124-MS-M-006 Rev-1Midhun K Chandrabose100% (3)

- Chem PlanDocument9 pagesChem PlanadNo ratings yet

- Reinforced Concrete Frank ColumbusDocument194 pagesReinforced Concrete Frank ColumbusKamilly100% (3)

- MERCK - Catalogue PDFDocument156 pagesMERCK - Catalogue PDFCorina StanculescuNo ratings yet

- Fire Safety During HOLIDAYS - SMDocument45 pagesFire Safety During HOLIDAYS - SMBfp Dos Tuguegarao CagayanNo ratings yet

- User Manual HYCD-282-282ADocument16 pagesUser Manual HYCD-282-282ALuis GutierrezNo ratings yet

- Chapter - 5 Minerals and Energy ResourcesDocument23 pagesChapter - 5 Minerals and Energy ResourcesRohan PatelNo ratings yet

- N35UH Grade Neodymium Magnets DataDocument1 pageN35UH Grade Neodymium Magnets DataSteve HsuNo ratings yet

- Description Packaging Shelf Life CoverageDocument2 pagesDescription Packaging Shelf Life Coveragejet toledoNo ratings yet

- Ahmedna (2000)Document11 pagesAhmedna (2000)Jean RisquezNo ratings yet

- Duration-2hours Total Marks-118: Questions On Electric FieldsDocument16 pagesDuration-2hours Total Marks-118: Questions On Electric Fieldsgaffar kadirNo ratings yet

- Universal Columns (UC), Buckling Resistance Moment With S355 Moment Capacity and Buckling Resistance MomentDocument12 pagesUniversal Columns (UC), Buckling Resistance Moment With S355 Moment Capacity and Buckling Resistance MomentAlok MehtaNo ratings yet

- P-QAC-PRO-200-38257 QCP For Cleaning, Gauging and HydrotestingDocument48 pagesP-QAC-PRO-200-38257 QCP For Cleaning, Gauging and HydrotestingBadi100% (1)

- FM-200 DesignDocument48 pagesFM-200 DesignMimi MimiNo ratings yet

- Tile Adhesive Standards and Their Relevance For Tile InstallationDocument6 pagesTile Adhesive Standards and Their Relevance For Tile InstallationAhmadAlsekaweNo ratings yet