Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

14 viewsLOCKWASHER

LOCKWASHER

Uploaded by

俞悅Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5824)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Mother's ListDocument3 pagesMother's List俞悅No ratings yet

- Daily Grand Past ResultDocument21 pagesDaily Grand Past Result俞悅No ratings yet

- Personalized Mortgage ReportDocument2 pagesPersonalized Mortgage Report俞悅No ratings yet

- SOLIDWORKS Ds Javelin Training CatalogueDocument20 pagesSOLIDWORKS Ds Javelin Training Catalogue俞悅No ratings yet

- DIN 76-Part3Document4 pagesDIN 76-Part3俞悅100% (1)

- Din 127Document3 pagesDin 127俞悅No ratings yet

- Ansi - Asq Z1.4-2003 (R2013)Document48 pagesAnsi - Asq Z1.4-2003 (R2013)俞悅No ratings yet

- Asme Y14.6-2001 (R2007)Document27 pagesAsme Y14.6-2001 (R2007)Oleg Ushakov75% (4)

- HCDocument163 pagesHC俞悅No ratings yet

- RBC - Printable VersionDocument6 pagesRBC - Printable Version俞悅No ratings yet

- 003 - 1271 - RulesDocument33 pages003 - 1271 - Rules俞悅No ratings yet

- Asq Quality Press Book CatalogDocument57 pagesAsq Quality Press Book Catalog俞悅No ratings yet

LOCKWASHER

LOCKWASHER

Uploaded by

俞悅0 ratings0% found this document useful (0 votes)

14 views3 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

14 views3 pagesLOCKWASHER

LOCKWASHER

Uploaded by

俞悅Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 3

|

|

a

SECTION 2.10 SPECIFICATIONS FOR SPRING WASHERS" ®

— 1967 —

2.10.1 GENERAL SCOPE (1967)

‘These specifications prescribe the physical properties intended for the material of the spring washers

purchased and state in detail the method of testing for providing their fulfillment

2.10.2 MATERIAL (1967)

Material for spring washers shall be of steel, manufactured by the electrie furnace, open-hearth, basic oxygen

or erueible process.

2.10.3 METHOD OF TESTING (1967)

‘Test specimens shall be interposed between the platens of a compression machine of approved design,

equipped with a deflection recorder calibrated to 0.001 inch and located so that readings are recorded from

approximately the center of the platens, and shall be subjected to the preliminary load of 20,000 Ib three

successive times, the washer each time being completely released to its free height.

2.10.4 MECHANICAL STRENGTH AND DUCTILITY (1967)

a. After application of the preliminary loads, the washer shall again be compressed to test load in Col. 2 of

‘Table 2-19 and the load shall be released by opening the platens through the preseribed distance,

Col. 3, for respective sizes of spring washers for bolts in Col. 1. A reactive spring pressure of not less

than the limits of the loads in Col. 4 shall then be required

b. Ductility shall be determined by twisting one end of a finished spring washer through 90 degrees

without sign of fracture, while the other end is held securely in a vise, as follows:

(1) Fasten one-fourth of the length of the coll from one end between the jaws of a vise.

(2) Grip one-fourth of the length of the evil from the other end between the jaws of a wrench.

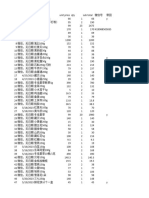

Table 2-13. Washer Strength Test

Spring Washers for | Platens Released | pyinimum Reactive

Bolt Diameter plied Load | from Loads by | “ Spring Pressure

Pounds Distances se

Inches reer Pounds

% TE 7,500

% 0.035 2,500

r 0080 5,000

We 0.080 5,000

Ts 0.030 5,000

Ts 0.080 5,000

1 these specifications have been prepared and are recommended for the ute of reeds purchasing spring washers, This recommendation

(of these specifications, however. doesnot imply any recommendation for or against the use of spring weshers, Reapproved with

sions 1987

ferences, Vol 3, 1993, pp 638,822; Vol 49, 1948, pp 978, 61; Vo 64, 1953, pp 1180, 1434; Vol 62, 1961, pp 687,952; Vol.64,

1963, pp. 499, 690; Vol 65, 1967, p 400

4278 ‘AREA Manual for Railway Engineering

Specifications

ee eo,

(8) Rotate the wrench, thus causing the end of the coil to deseribe a circle about the middle point of the

coil as a center so that open ends of washer shall pass each other

© Spring washers shall be heat-treated by oil quenching and tempering.

2.10.5 PROPORTION OF TESTS (1967)

a. Tests shall be made of 3 specimens selected by the inspector at random from each lot of 15,000 finished

spring washers for bolts less than 1 inch in diameter or from each lot of 10,000 finished spring washers

for bolts 1 inch or more in diameter. ‘The 8 test specimens from eaeh lot or fraction thereof shall be

tested for reactive pressure and ductility, and if all specimens meet the specification requirements the

lot will be accepted.

b. If Lof the 9 test specimens should fail, 2 more specimens shall be selected from the same lot and if both

‘meet the specification requirements the lot will be accepted, If] or both fail the lot will be rejected,

© If2 of the first 3 specimens selected from a lot should fail, all the washers from that lot shall be

rejected

2.10.6 REHEAT TREATMENT (1967)

a. If the results of the physical tests do not conform to the requirements specified, the manufacturer may

reheat-treat each lot, but not more than 3 additional times, unless authorized by the purchaser, and

retests shall be made as specified in Paragraph 2.10.5

b. No lot which has failed to pass the tests shall be offered for further test until after the spring washers

in that lot have been retreated

2.10.7 UNIFORMITY OF STOCK (1967)

Uniformity in size of steel stock used in making spring washers and the dimensions around which the spiral

is coiled are desirable In cross section the faces of the finished spring washer which bear against the joint bar

and the nut must be parallel.

2.10.8 PERMANENT SET (1967)

Previous to offering any lot of spring washers for inspection, each individual piece shall have been subjected

as a part of the routine manufacturing process to shock or pressure sufficient to cause permanent set and any

individual pieces defective through seams, quenching cracks, ete., shall be discarded.

2.10.9 FINISH (1967)

All finished pieces must be clean, smooth, without burrs or rough edges, of uniform size, with well-shaped

symmetrical coil and cross section, free from injurious mechanical defects, and be finished in a first class,

workmanlike manner.

2.10.10 PACKING (1967)

‘The finished spring washers shall be packed in securely hooped kegs or well fastened boxes. Containers shall

be left open until the inspection is completed

"S195 ava Ray Engrg Aasoctan

AREA Manual for Railway Engineering 42-79

Rail

2.10.11 : BRANDING (1967)

a. Identification will be by the manufacturer's marks

b. Spring washers shall be individually marked for identification.

¢ Containers shall be marked as follows:

(2) Name of manufacturer

(2) Size of spring washer (bolt size over thread, width and thickness).

(3) Number of spring washers.

2.10.12 DEFECT FOUND AFTER DELIVERY (1953)

‘Spring washers to the extent of 5%, or more of the order which show injurious defects subsequent to their

acceptance at the place of manufacture or sale will be rejected and returned to the manufacturer who must

pay the freight charges both ways, and replace the defective spring washers with new ones, fulfilling the

requirements of the specifications.

2.10.13 PLACE OF TESTS (1953)

All tests and inspection shall be so conducted as not to interfere unnecessarily with the operation of the mill,

‘and shall be made st the place of the manufacturer prior to shipment.

2.10.14 ACCESS TO WORKS (1953)

Inspectors representing the purchaser shall have free entry to the works of the manufacturers at all times

while the contract is being executed, and shall have all reasonable facilities afforded them by the

manufacturer to satisfy them that the spring washers are furnished in accordance with the terms of these

specifications

4-2-80 AREA Manual for Railway Engineering

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5824)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Mother's ListDocument3 pagesMother's List俞悅No ratings yet

- Daily Grand Past ResultDocument21 pagesDaily Grand Past Result俞悅No ratings yet

- Personalized Mortgage ReportDocument2 pagesPersonalized Mortgage Report俞悅No ratings yet

- SOLIDWORKS Ds Javelin Training CatalogueDocument20 pagesSOLIDWORKS Ds Javelin Training Catalogue俞悅No ratings yet

- DIN 76-Part3Document4 pagesDIN 76-Part3俞悅100% (1)

- Din 127Document3 pagesDin 127俞悅No ratings yet

- Ansi - Asq Z1.4-2003 (R2013)Document48 pagesAnsi - Asq Z1.4-2003 (R2013)俞悅No ratings yet

- Asme Y14.6-2001 (R2007)Document27 pagesAsme Y14.6-2001 (R2007)Oleg Ushakov75% (4)

- HCDocument163 pagesHC俞悅No ratings yet

- RBC - Printable VersionDocument6 pagesRBC - Printable Version俞悅No ratings yet

- 003 - 1271 - RulesDocument33 pages003 - 1271 - Rules俞悅No ratings yet

- Asq Quality Press Book CatalogDocument57 pagesAsq Quality Press Book Catalog俞悅No ratings yet