Professional Documents

Culture Documents

COP 0209-1 Dry Film Thickness Measurements - December 2002

COP 0209-1 Dry Film Thickness Measurements - December 2002

Uploaded by

huycongvu0 ratings0% found this document useful (0 votes)

18 views2 pagesThis document provides guidelines for measuring dry film thickness (DFT) to ensure coatings meet specifications. It addresses:

1) DFT measurements are essential to check coating thickness and lifetime, and influence material costs.

2) Magnetic or electromagnetic gauges are commonly used to non-destructively measure DFT along with visual inspection.

3) Gauges must be properly adjusted according to specifications, such as on a smooth plate or abrasive-blasted surface, before taking measurements.

4) Guidelines are provided on how to take measurements based on substrate roughness, specified thickness, and adjusting measurements based on roughness deviations.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides guidelines for measuring dry film thickness (DFT) to ensure coatings meet specifications. It addresses:

1) DFT measurements are essential to check coating thickness and lifetime, and influence material costs.

2) Magnetic or electromagnetic gauges are commonly used to non-destructively measure DFT along with visual inspection.

3) Gauges must be properly adjusted according to specifications, such as on a smooth plate or abrasive-blasted surface, before taking measurements.

4) Guidelines are provided on how to take measurements based on substrate roughness, specified thickness, and adjusting measurements based on roughness deviations.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

18 views2 pagesCOP 0209-1 Dry Film Thickness Measurements - December 2002

COP 0209-1 Dry Film Thickness Measurements - December 2002

Uploaded by

huycongvuThis document provides guidelines for measuring dry film thickness (DFT) to ensure coatings meet specifications. It addresses:

1) DFT measurements are essential to check coating thickness and lifetime, and influence material costs.

2) Magnetic or electromagnetic gauges are commonly used to non-destructively measure DFT along with visual inspection.

3) Gauges must be properly adjusted according to specifications, such as on a smooth plate or abrasive-blasted surface, before taking measurements.

4) Guidelines are provided on how to take measurements based on substrate roughness, specified thickness, and adjusting measurements based on roughness deviations.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

HEMPEL Code of Practice

Code of

Practice

HEMPEL'S

Code of Practice No. 0209-1

Dry film thickness measurements

What to use when:

Dry film thickness pr coat and in

HEMPEL’S Painting Specifications

total for the coating system specified

are based on practical experience

are essential parts of the painting

and assume that check of

specification.

DFT-compliance follows the

They have influence on the protective procedures stated in this Code of

lifetime of the coating, but also have Practice.

a significant influence on how much

However if customers specifications

paint is needed and thus the cost of

state one of the references given

the coating system.

below, requirements in this reference

Measurement of dry film thickness must be observed.

(DFT) is normally non-destructive

and easy to carry out with magnetic How to adjust the dft-gauge:

or electromagnetic gauges. Together

A plate of smooth, clean metallic

with the visual appearance of the

substrate of the same kind as the

applied coating DFT is the primary

construction is to be used for

check of compliance with the

adjustment. Ordinary steel, high

painting specification.

strength ordinary steel and low

The most modern types of gauges alloyed steel are considered the

can hold a lot of measurements, and same substrate.

they can be adjusted in various ways.

The size of the plate should be

This has led to several opinions -

minimum 30 x 30 x 3 mm, except

even national and international

for constructions of lower thickness

standards - about how to adjust

than 3 mm. In this case the

them: On smooth plate? or on the

thickness of the adjustment plate

rough, abrasive blasted surface?, and

should be the same as for the

how?

construction within ± 0.2 mm.

Before carrying out dry film thick- The temperature during adjustment

ness measurements, it is therefore should be at or near to that

imperative that the directions as prevailing during the taking of the

stated in the specification are fully readings/ measurements.

understood and followed.

z How shall the dft-gauge be References:

adjusted? Various international references are

z How many measurements to take, available. Some of these are:

and where? EN ISO 2808:1999, Paints and

z How to interpretate the measure- varnishes - Determination of film

ments and how to decide? thickness.

These issues must have been prEN ISO 19840:2002, Measurement

clarified before the practical and acceptance criteria for, the dry film

inspection is initiated. thickness on rough surfaces.

SSPC-PA 2: Measurement of Dry Paint

Thickness with Magnetic Gages.

16/12/2002 ed.1 EMi -1- Code of Practice 1

HEMPEL Code of Practice

Code of Practice No. 0209-1

DRY FILM THICKNESS MEASUREMENTS

The recommendations given below are HEMPEL recommendations.

Other recommendations exist, see References overleaf .

What is a reading/measurement:

A reading/measurement is the value displayed when the probe is placed on the

coated substrate.

How to take the measurements:

The surface roughness of the substrate must have been checked using an ISO 8503-1

or similar comparator and recorded/reported prior to the measurements.

The coat/coating to be measured must be sufficiently hard dry to resist the

indentation of gauge’s probe.

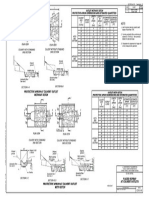

Table 1: Possible situations

Condition of Specified How to take the Comments

substrate film measurement

thickness

Roughness Dry film Place the probe on the Compensation for

within interval thickness coated surface and take roughness has already been

specified in the 30 micron the reading/ done in the HEMPEL

HEMPEL or above. measurement Painting Specification.

Painting

Specification.

Roughness Dry film A separate smooth panel Mainly used for pre-

within interval thickness must be coated together fabrication/ shopprimers .

specified in the below with the object. Measured values to be

HEMPEL 30 micron Take the reading compared to specified DFT

Painting /measurement on this (rough surface) multiplied

Specification panel. by factor indicated in table

2 below.

Roughness Dry film Place the probe on the Measured values to be

more coarse thickness coated surface and take compared to specified DFT

than specified 30 micron the reading/ after adding to the latter

in the HEMPEL or above measurement.. the figure indicated in table

Painting 3 below..

Specification

Table 2: Relative adjustment Table 3: Relative adjustment figure for

factor for dft’s below 30 micron: deviation in roughness:

Surface Rz = 75 Rz = 40 Smooth Surface Specified: Actual: Specified: Actual:

roughness micron micron roughness Fine Medium Medium Coarse

Factor 1,66 1,33 1 add micron 10 15

Where, and how many measurements to take, and how to decide?:

If a sampling plan is specified in the painting specification, follow this. Otherwise as

judged necessary in order to make a proper recommendation.

Measurements taken should be noted down and reported. As a minimum: Number of

measurements, average value and minimum and maximum reading.

16/12/2002 ed.1 EMi -2- Code of Practice 2

You might also like

- Astm D4414-2001 PDFDocument3 pagesAstm D4414-2001 PDFkishor150688100% (5)

- ASTM F2296 Lamination Test MethodsDocument5 pagesASTM F2296 Lamination Test MethodsGerven MonteNo ratings yet

- SSPC-PA 2 (2004) - Measurement of DFT With Magnetic Gages PDFDocument11 pagesSSPC-PA 2 (2004) - Measurement of DFT With Magnetic Gages PDFkhuramilyas100% (1)

- D1474Document5 pagesD1474hdanyealNo ratings yet

- JV3-160SP Mechanical Drawing V1.01 PDFDocument56 pagesJV3-160SP Mechanical Drawing V1.01 PDFErnestoNo ratings yet

- DFT RulesDocument4 pagesDFT RulesSalahuddin Farooqui100% (1)

- ASTM D7091-05 DFT of Non Magnetic Coatings To Ferrous MetalsDocument7 pagesASTM D7091-05 DFT of Non Magnetic Coatings To Ferrous MetalsChris Parkinson100% (1)

- Dulux Powder Technical Advice Brochure Dry Film Thickness WEB 09 20Document3 pagesDulux Powder Technical Advice Brochure Dry Film Thickness WEB 09 20Nurma DiinnaaNo ratings yet

- Astm C664 10Document3 pagesAstm C664 10turbio15No ratings yet

- Nondestructive Measurement of Dry Film Thickness of Nonmagnetic Coatings Applied To Ferrous Metals and Nonmagnetic, Nonconductive Coatings Applied To Non-Ferrous MetalsDocument11 pagesNondestructive Measurement of Dry Film Thickness of Nonmagnetic Coatings Applied To Ferrous Metals and Nonmagnetic, Nonconductive Coatings Applied To Non-Ferrous MetalsIvan AlanizNo ratings yet

- Astm G12Document2 pagesAstm G12Jairo Arroyo100% (1)

- Through Thick and Thin Some ObservationsDocument10 pagesThrough Thick and Thin Some ObservationsAhmed hafezNo ratings yet

- Through Thick and Thin Some ObservationsDocument10 pagesThrough Thick and Thin Some ObservationsDavid RodriguesNo ratings yet

- D 1400 - 94 Rde0mdatotq - PDFDocument3 pagesD 1400 - 94 Rde0mdatotq - PDFCharlie DukeNo ratings yet

- Measurement of Dry Film Thickness of Protective Coating Systems by Destructive, Cross-Sectioning MeansDocument6 pagesMeasurement of Dry Film Thickness of Protective Coating Systems by Destructive, Cross-Sectioning MeansAlvaro Iparraguirre NavarroNo ratings yet

- ASTM D4414 - Measur. Wet Film Thickness by GagesDocument3 pagesASTM D4414 - Measur. Wet Film Thickness by GagesMarlon Villarreal100% (1)

- Astm D4414Document3 pagesAstm D4414kashif ehsanNo ratings yet

- Astm D2967.20571 PDFDocument3 pagesAstm D2967.20571 PDFMariano Emir Garcia OdriozolaNo ratings yet

- Methods of Sampling and Test For Paints, Varnishes and Related ProductsDocument7 pagesMethods of Sampling and Test For Paints, Varnishes and Related ProductsAravind B PatilNo ratings yet

- DFT StandardsDocument42 pagesDFT StandardsDandy Adrianto100% (2)

- Astm D7378.4648Document5 pagesAstm D7378.4648xochihua4986No ratings yet

- 234 D7091 344Document7 pages234 D7091 344Ivan AlanizNo ratings yet

- Loadcell and Strain GaugesDocument10 pagesLoadcell and Strain Gaugesshubham develakarNo ratings yet

- Attachment 1 SSPC-PA2Document6 pagesAttachment 1 SSPC-PA2Tudor MoraruNo ratings yet

- Nondestructive Measurement of Film Thickness of Pipeline Coatings On SteelDocument2 pagesNondestructive Measurement of Film Thickness of Pipeline Coatings On SteelGul Hassan AkhunzadaNo ratings yet

- F 2226 - 03 Rjiymjy - PDFDocument6 pagesF 2226 - 03 Rjiymjy - PDFHernan MartNo ratings yet

- Evaluation of Gloss or Sheen Uniformity: Standard Test Method ForDocument3 pagesEvaluation of Gloss or Sheen Uniformity: Standard Test Method ForMariana Rodriguez IbarraNo ratings yet

- Dry Film Thickness Measurements How Many Are EnoughDocument11 pagesDry Film Thickness Measurements How Many Are EnoughMuhammad TantowiNo ratings yet

- D522Document5 pagesD522Jeremy Toh100% (1)

- Sspc-Pa9 1311669483Document5 pagesSspc-Pa9 1311669483mrreach100% (1)

- F 92 - 93 R03 - Rjky PDFDocument4 pagesF 92 - 93 R03 - Rjky PDFGiorgos SiorentasNo ratings yet

- Astm D6132-08 PDFDocument4 pagesAstm D6132-08 PDFdang2172014100% (4)

- ASTM D6132 Measurement of Coating Thickness by UTDocument3 pagesASTM D6132 Measurement of Coating Thickness by UTViswanath SreepadaNo ratings yet

- D 2967 - 02 - Rdi5njctmdiDocument3 pagesD 2967 - 02 - Rdi5njctmdiEmre DalgicNo ratings yet

- Comparison-of-SSPC-PA2-and-ISO 19840Document6 pagesComparison-of-SSPC-PA2-and-ISO 19840Ahmad FazriNo ratings yet

- ASTM D 1186 Pelicula SecaDocument3 pagesASTM D 1186 Pelicula SecaFelipe montana100% (1)

- Calculating Pavement Macrotexture Mean Profile Depth: Standard Practice ForDocument4 pagesCalculating Pavement Macrotexture Mean Profile Depth: Standard Practice Forjorgesilva84No ratings yet

- D522-21 ElongaciónDocument5 pagesD522-21 ElongaciónDaniela TovarNo ratings yet

- Thickness of Paper and Paperboard: Standard Test Method ForDocument3 pagesThickness of Paper and Paperboard: Standard Test Method ForcucurucucuNo ratings yet

- ASTM D 1186 - Pintura PDFDocument3 pagesASTM D 1186 - Pintura PDFVicente Francisco Caballero100% (2)

- ASTM - D3359 Adherencia PDFDocument7 pagesASTM - D3359 Adherencia PDFPracticante 20% (1)

- Guia para La Medición de Espesores SSPC - PA2Document11 pagesGuia para La Medición de Espesores SSPC - PA2robertabarreiroNo ratings yet

- Paint Application Specification No. 2: SSPC: The Society For Protective CoatingsDocument12 pagesPaint Application Specification No. 2: SSPC: The Society For Protective CoatingsEdgar Sanchez ChamizoNo ratings yet

- D 1186 - 93 PDFDocument5 pagesD 1186 - 93 PDFanon_896116749No ratings yet

- Measurement of Wet Film Thickness of Organic Coatings: Standard Test Methods ForDocument4 pagesMeasurement of Wet Film Thickness of Organic Coatings: Standard Test Methods ForAlvaro Iparraguirre NavarroNo ratings yet

- TP913Document5 pagesTP913jmpateiro1985No ratings yet

- SSPC Pa2Document11 pagesSSPC Pa2Nageswara Rao BavisettyNo ratings yet

- 809 PDFDocument11 pages809 PDFDEE RBNo ratings yet

- TP913 Coating Thickness CheckDocument5 pagesTP913 Coating Thickness CheckShahril ZainulNo ratings yet

- Astm D2967.20571Document3 pagesAstm D2967.20571FCTNo ratings yet

- Tgn03 (1) DFT MeasurementDocument12 pagesTgn03 (1) DFT MeasurementFPA InspectorNo ratings yet

- ASTM D 3359 - 97 Standard Test Methods For Measuring Adhesion by Tape Test PDFDocument7 pagesASTM D 3359 - 97 Standard Test Methods For Measuring Adhesion by Tape Test PDFAlfredoNo ratings yet

- Measurement of Wet Film Thickness of Organic Coatings: Standard Test Methods ForDocument4 pagesMeasurement of Wet Film Thickness of Organic Coatings: Standard Test Methods FordavidfonsecaNo ratings yet

- Instruction Manual - Dial Thickness Gauge Kit How Replica Tape WorksDocument6 pagesInstruction Manual - Dial Thickness Gauge Kit How Replica Tape Worksmusaismail8863No ratings yet

- D 1400 - 94 Rde0mdatukve PDFDocument4 pagesD 1400 - 94 Rde0mdatukve PDFCharlie DukeNo ratings yet

- Mar Resistance of Organic Coatings: Standard Test Method ForDocument3 pagesMar Resistance of Organic Coatings: Standard Test Method Formit uotNo ratings yet

- Mathematical Analysis of Quasi-Simultaneous Laser Welding on PolymersFrom EverandMathematical Analysis of Quasi-Simultaneous Laser Welding on PolymersNo ratings yet

- Buried Steel PipeDocument163 pagesBuried Steel PipehuycongvuNo ratings yet

- COP 0006-1 Pul-Off Testing - September 2000Document2 pagesCOP 0006-1 Pul-Off Testing - September 2000huycongvuNo ratings yet

- COP 96.11 Brush Application - May 1997Document2 pagesCOP 96.11 Brush Application - May 1997huycongvuNo ratings yet

- COP 96.12 Roller Application - May 1997Document2 pagesCOP 96.12 Roller Application - May 1997huycongvuNo ratings yet

- COP 0004-1 Stripe Coating - March 2000Document2 pagesCOP 0004-1 Stripe Coating - March 2000huycongvuNo ratings yet

- COP 96.03 Preparation of Wood - May 1997Document2 pagesCOP 96.03 Preparation of Wood - May 1997huycongvuNo ratings yet

- Carbozinc 858 PDSDocument4 pagesCarbozinc 858 PDShuycongvuNo ratings yet

- Welding SymbolsDocument8 pagesWelding SymbolsRaoFarhan100% (1)

- Automatic Transfer Switch ATS104DMSDocument2 pagesAutomatic Transfer Switch ATS104DMSJabir QuadriNo ratings yet

- Title: Use of Geometrical & Dimensional Tolerances, & Surface Finish Symbol in Machine Component DrawingDocument25 pagesTitle: Use of Geometrical & Dimensional Tolerances, & Surface Finish Symbol in Machine Component DrawingRAHUL KADLAG55% (11)

- ESET 212 LECTURE - Week 7Document41 pagesESET 212 LECTURE - Week 7eglits4170No ratings yet

- 8 Infrared Drying: November 2006Document17 pages8 Infrared Drying: November 2006satish kumarNo ratings yet

- Velocium Announcement From Hittite Oct 2007Document4 pagesVelocium Announcement From Hittite Oct 2007fleksNo ratings yet

- GIMP Tutorial 2 - Graffiti PDFDocument6 pagesGIMP Tutorial 2 - Graffiti PDFRicardo MorilloNo ratings yet

- Process Sizing Criteria: PlantDocument38 pagesProcess Sizing Criteria: Plantwylie01100% (1)

- Lesson06 PDFDocument4 pagesLesson06 PDFUrooj HasanNo ratings yet

- Module2 Session3 FinalDocument21 pagesModule2 Session3 FinalPapillon BlancNo ratings yet

- DIY Bike GeneratorDocument17 pagesDIY Bike GeneratorMarius Danila100% (1)

- Detail Approved For UseDocument1 pageDetail Approved For UseLeticia Karine Sanches BritoNo ratings yet

- A Unified Theory of Wear For Ultra-High Molecular Weight Polyethylene in Multi-Directional SlidingDocument10 pagesA Unified Theory of Wear For Ultra-High Molecular Weight Polyethylene in Multi-Directional SlidingJosé santanaNo ratings yet

- IQ Math Virtual Floating Point Engine For DSPDocument20 pagesIQ Math Virtual Floating Point Engine For DSPVinh TranNo ratings yet

- Pangilinan, Floor and Roof PlanDocument7 pagesPangilinan, Floor and Roof PlanKoryne Escauriaga PangilinanNo ratings yet

- WallsDocument26 pagesWallsdeependraNo ratings yet

- Hysol EA 9330: Epoxy Paste AdhesiveDocument5 pagesHysol EA 9330: Epoxy Paste AdhesiveFernando GarzonNo ratings yet

- Answers For 6.6: 6.6 Skill Practice 1. 12.) ) 13. 14. 15. 16. 17. 18. 19. A-B. S CDocument4 pagesAnswers For 6.6: 6.6 Skill Practice 1. 12.) ) 13. 14. 15. 16. 17. 18. 19. A-B. S CsisikaNo ratings yet

- E39529013 s5520hc s5500hcv s5520hct Tps r19Document190 pagesE39529013 s5520hc s5500hcv s5520hct Tps r19spacnavNo ratings yet

- Quiz 2 KTCDocument2 pagesQuiz 2 KTCacurvz2005No ratings yet

- Spesfikasi PM Mindray - uMEC 12A AdvanceDocument1 pageSpesfikasi PM Mindray - uMEC 12A AdvanceIwan LuthfiNo ratings yet

- EST TH 1 October 2018Document21 pagesEST TH 1 October 2018becy welbaNo ratings yet

- Autopilot Paid MethodDocument3 pagesAutopilot Paid MethodMarg CenterNo ratings yet

- Tutorial Four-TutorialDocument4 pagesTutorial Four-Tutorialhagt813No ratings yet

- Sony Kdl-55ex505 Kdl-60ex505 Chassis Az1-L Rev.1 SMDocument50 pagesSony Kdl-55ex505 Kdl-60ex505 Chassis Az1-L Rev.1 SMRogerio BarsottiNo ratings yet

- 4049-9 Owom gr02 TM 2017Document165 pages4049-9 Owom gr02 TM 2017KAYE MARIE MOLINANo ratings yet

- SC MCQsDocument12 pagesSC MCQsGanesh Singh100% (1)

- SIMPLE DC GeneratorDocument7 pagesSIMPLE DC GeneratorDavies MasumbaNo ratings yet

- Full Download Problem Solving With C 10th Edition Savitch Test BankDocument32 pagesFull Download Problem Solving With C 10th Edition Savitch Test Bankarrowcornet0100% (34)