Professional Documents

Culture Documents

04 Vetotop CX534 - 141221 JO

04 Vetotop CX534 - 141221 JO

Uploaded by

assala HaddadOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

04 Vetotop CX534 - 141221 JO

04 Vetotop CX534 - 141221 JO

Uploaded by

assala HaddadCopyright:

Available Formats

Construction Materials Product Data Sheet

Vetotop CX534

Premixed 20 to 100 mm thick

conventional cementitious mortar.

Uses

u Cost-effective cavity filling in non-structural

areas.

u Non-structural backing mortar.

u Filling around underfloor heating installations

and mechanical fittings.

u As a bedding mortar for granite and marble.

Product Description

Vetotop CX534 is a single component cementitious backing mortar composed of hydraulic binders, silica sand, and

selected aggregates. It is supplied in bulk as a dry pumpable powder ready to use on-site, once mixed it will form a

mortar applied by trowel in thicknesses between 20 and 100 mm.

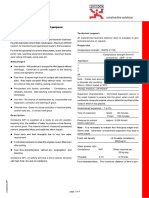

Advantages Technical Data

u Factory-controlled pre-blend ensures

Vetotop CX534 Typical Values

consistently high quality.

Appearance Grey & White Powder

u Suitable for Middle East harsh weather Max Aggregate size (mm) 2.8 mm

Technical Data Sheet -Vetotop CX534

conditions. Application thickness 20 - 100 mm

u Easy application enabling high productivity Wet density (Kg/Liter) 2.0 approx.

through pumps and horizontal mixers. Open time @ 25ºC 45 min approx.

u Easy to break and refurbish backing to install Adjustability 10-15 minutes

additional piping and mechanical fittings. Setting time 3-5 hours

Compressive Strength

u Excellent workability. 10 N/mm² approx.

@ 28 days (ASTM C109)

u Replaces conventional site-batched mortars. Flexural Strength

> 2.0 N/mm2 @ 28 Days

ASTM C348

u Applied on horizontal damp compacted sand

Bond Strength

and cementitious substrates while providing > 0.2 N/mm2 @ 28 Days

good adhesion. EN 1015 - 12

u It contains a special additive that reduces friction All values are at standard lab conditions at 25ºC

and prolongs the lifespan of the equipment.

Design Criteria Standards Compliance

Vetotop CX534 is designed for pumping machine (HM h ASTM C 150

24) application. It contains a special shrinkage control h ASTM C 207

additive that provides good adhesion. The product is

available in grey and white color and can be applied in h ASTM C 136

thickness from 2 to 10 cm.

Product Data Sheet Construction Materials

Usage Instructions Packaging & Coverage

Surface Preparation Product Pack Size Yield

Substrate should be sound, clean, free from loose Vetotop CX534 50 kg bag 0.5 - 0.6 Ltr / Kg

material, grease, laitance, dirt curing compound, etc. Stated consumption data are for general guidance.

Before Vetotop CX534 application, wet the entire Actual consumption depends on the nature of

surfaces with clean potable water, and the surface substrate, method of application, and wastage.

should look damp at the time of application.

Shelf Life & Storage

Smooth Concrete Surfaces

Vetotop CX534 has a shelf life of 12 months provided

Apply Vetobond PB433 or Vetobond EB430 as a primer it is stored clear of ground in a dry and shaded place

coat or prepare the horizontal substrate by chopping below 35ºC.

or chiseling.

Mixing Health & Safety

For manual mixing, add to the mixing container 9.25 - Vetotop CX534 is highly alkaline; therefore, avoid direct

10 liters of water to each 50kg bag of Vetotop CX534. contact with eyes or skin. Vetobond PB434 is a latex

Add the powder to the water and mix with a mechanical emulsion; it is recommended to use protective gloves

mixer or low-speed electric drill fitted with a suitable and goggles during application.

paddle for 3-4 minutes until achieving a uniform, lump- Any skin contact should be washed with plenty

free consistency. amount of water. In case of eye irritation, immediately

For application using HM 24 mixing & pumping wash with a copious amount of clean cold water. Seek

machine, the water flow rate should be 300-500 Lit/ medical advice.

hour. Use the mixed material within 1 hour. Vetotop CX534 is non-flammable.

Re-tempering is allowed between 60 and 90 minutes

for one time only.

Additional Information

Saveto manufactures a wide range of construction

Application chemicals and specialty products for various

Apply Vetotop CX534 in a single layer to the desired applications divided into the following product groups:

thickness using HM 24 machine. Rod or screed to a u Waterproofing Systems.

uniform thickness immediately, then follow with the

u Concrete Repairs & Grouts.

Technical Data Sheet -Vetotop CX534

tiles’ installation. To ensure better coverage, increase

the thickness and firmly press on the tile squeezing u Flooring Systems.

the excess out. For better adhesion, you can use the

Saveto product Vetobond PB434. Call Saveto technical u Wall & Facade Systems.

engineer for advice. u Sealants and Joints.

Curing u Renders & Finishes.

Cure Vetotop CX534 by spraying water on the tiles’ u Plasters & Masonry.

surfaces before grouting for 2-3 days. During hot & dry u Tile adhesives & Grouts.

conditions, allow curing for a minimum of 5 days..

u Primers & Ancillary Products.

Cleaning

u Thermal Insulation Systems.

Clean tools with water promptly before material

hardens. Hardened material can be mechanically u Protective Coatings.

removed. u Accessories.

For further information on these products and systems

kindly check our website or contact your local Saveto

representative.

LEGAL DISCLAIMER

Saveto endeavors to ensure that any advice, recommendations, information it may give is accurate and correct. It cannot accept any lia-

bility either directly or indirectly arising from the use of its products because it has no direct or continuous control over where or how its

products are applied, whether or not following any advice, specification, recommendation, or information given by us. Saveto has the right

to change any of the technical datasheets’ specifications upon its discretion without prior notification.

Hard copies of TDSs are printed once or twice a year. Our technical data sheets are continuously updated as per R&D improvements and

new 3rd party testing; kindly refer to our website for the latest updated TDSs.

Ref No.: G3-CF004-05-21 JO www.saveto.com

You might also like

- Graphic Design Learn It, Do ItDocument606 pagesGraphic Design Learn It, Do ItVishwajit Gosavi100% (4)

- 753-826 - Cheyenne Service Manual - Pa-31t Cheyenne - Cheyenne II, Pa-31t1 Cheyenne I - Ia, Pa-31t2 Cheyenne II XLDocument8 pages753-826 - Cheyenne Service Manual - Pa-31t Cheyenne - Cheyenne II, Pa-31t1 Cheyenne I - Ia, Pa-31t2 Cheyenne II XLGustavo HofstatterNo ratings yet

- Emcekrete EP: High Performance Self-Leveling Epoxy GroutDocument2 pagesEmcekrete EP: High Performance Self-Leveling Epoxy Groutwilian liNo ratings yet

- The Application of PUR Hotmelt Adhesive As Sealant For Washing MachineDocument4 pagesThe Application of PUR Hotmelt Adhesive As Sealant For Washing MachinePankaj Choure100% (1)

- Mid Century Modern Furniture Shop Drawings Techniques For Making 29 ProjectsDocument178 pagesMid Century Modern Furniture Shop Drawings Techniques For Making 29 ProjectsFery Novianto100% (4)

- TDS Conbextra GP3 IndiaDocument4 pagesTDS Conbextra GP3 IndiaashishroshanNo ratings yet

- Product Submittal - MasterSeal 730 UVSDocument66 pagesProduct Submittal - MasterSeal 730 UVSTrầnDuyNo ratings yet

- Elastoseal EPDM Tanking SystemDocument8 pagesElastoseal EPDM Tanking SystemStephen100% (1)

- Gurit-SP Resin Infusion PresentationDocument19 pagesGurit-SP Resin Infusion PresentationEdgar Real ViúlaNo ratings yet

- Davco Grout 280 ECO - BROCHURE - 2 PDFDocument2 pagesDavco Grout 280 ECO - BROCHURE - 2 PDFbenjaminNo ratings yet

- SPF 1K - MDU4075 Clear Coat - WBF 19 - 26 PDFDocument2 pagesSPF 1K - MDU4075 Clear Coat - WBF 19 - 26 PDFsriatul2006100% (1)

- (PDS) Nitoproof RS (Green Label)Document3 pages(PDS) Nitoproof RS (Green Label)Hendra WahyuNo ratings yet

- 01 Vetotop CL530 - 141221 JODocument2 pages01 Vetotop CL530 - 141221 JOassala HaddadNo ratings yet

- Masterflow 810: Non-Shrink, Precision Cementitious Grout For Use in General Civil Engineering WorksDocument2 pagesMasterflow 810: Non-Shrink, Precision Cementitious Grout For Use in General Civil Engineering WorksPradeep KumaraNo ratings yet

- TDS Conbextra GP1 India PDFDocument4 pagesTDS Conbextra GP1 India PDFvikash singh tomarNo ratings yet

- Conbextra atDocument4 pagesConbextra atsathishbe5No ratings yet

- UltraTech Powergrout NS2Document2 pagesUltraTech Powergrout NS2Savalia HardikNo ratings yet

- TDS - MasterPolyheed 8320Document2 pagesTDS - MasterPolyheed 8320Taposh Paul100% (2)

- Concrete Plant: Atlasindustries - inDocument15 pagesConcrete Plant: Atlasindustries - innew2trackNo ratings yet

- Poxeecote-D: High - Build Epoxy CoatingDocument2 pagesPoxeecote-D: High - Build Epoxy CoatingSibgathullahNo ratings yet

- Fosroc Nitoflor TF120 UB: Constructive SolutionsDocument4 pagesFosroc Nitoflor TF120 UB: Constructive SolutionstalatzahoorNo ratings yet

- Basf Masterbrace 2200 Tds PDFDocument2 pagesBasf Masterbrace 2200 Tds PDFkrishna dhageNo ratings yet

- Mondeco ExoticDocument2 pagesMondeco ExoticatrijoshiNo ratings yet

- Damp FreeDocument3 pagesDamp FreeblaqhaqarNo ratings yet

- Mondeco SplashDocument2 pagesMondeco SplashatrijoshiNo ratings yet

- Mondeco MirrazzoDocument2 pagesMondeco MirrazzoatrijoshiNo ratings yet

- ESTOP TDS - Estogard CS Lining R002.i.21Document2 pagesESTOP TDS - Estogard CS Lining R002.i.21Dewi OktoraNo ratings yet

- Nitoproof 600PF: Hydrocarbon Free, Liquid Applied Elastomeric One Coat Waterproofing Membrane UsesDocument2 pagesNitoproof 600PF: Hydrocarbon Free, Liquid Applied Elastomeric One Coat Waterproofing Membrane UsesKishore Nayak kNo ratings yet

- PACTOBond SBR-DatasheetDocument2 pagesPACTOBond SBR-DatasheethidiNo ratings yet

- Comparison Between Delta Terraxx R and DraincellDocument6 pagesComparison Between Delta Terraxx R and DraincellManoj HarikishanNo ratings yet

- BL-BGD186-22-BL-BGD 186 Intelligent Krebs Stormer Viscometer 180719 PDFDocument12 pagesBL-BGD186-22-BL-BGD 186 Intelligent Krebs Stormer Viscometer 180719 PDFJesùs EscalonaNo ratings yet

- 3 TekniFloor LDPDocument2 pages3 TekniFloor LDPAndy100% (1)

- JR WR240 en 1011 Lo-1Document12 pagesJR WR240 en 1011 Lo-1TUNAS ADITYA PUTRANo ratings yet

- Cartaspers PSM PDFDocument4 pagesCartaspers PSM PDFLUIS XVNo ratings yet

- Schlosser-Pfeiffer Variant EnglischDocument8 pagesSchlosser-Pfeiffer Variant EnglischHESSGROUPNo ratings yet

- Masterflow 648 v2 PDFDocument2 pagesMasterflow 648 v2 PDFSunny RohillaNo ratings yet

- Drfixit Torchshield PDFDocument4 pagesDrfixit Torchshield PDFshashiNo ratings yet

- BentoniteDocument4 pagesBentoniteSihanu SubasinghaNo ratings yet

- Revc FinalDocument12 pagesRevc FinalHasan KamalNo ratings yet

- Emcephob LE enDocument2 pagesEmcephob LE enpetronela.12No ratings yet

- N-Dril HT PlusDocument1 pageN-Dril HT PluspaimanNo ratings yet

- TDS - Pulmix 4033Document1 pageTDS - Pulmix 4033dipen royNo ratings yet

- Terokal 5089-EN PDFDocument2 pagesTerokal 5089-EN PDFLuis Velasquez SilvaNo ratings yet

- 09 - TDS - Masterflow 928T PDFDocument5 pages09 - TDS - Masterflow 928T PDFGibbs PerNo ratings yet

- Kuap Block Clamp BroushorDocument8 pagesKuap Block Clamp BroushorAyman B. ManaseerNo ratings yet

- Technical Bulletin: Three Bond 2217HDocument3 pagesTechnical Bulletin: Three Bond 2217HbehzadNo ratings yet

- Technical Data Sheet: Constab® Af 00240 PP (Former: AF 0240 PP) Antifog MasterbatchDocument1 pageTechnical Data Sheet: Constab® Af 00240 PP (Former: AF 0240 PP) Antifog MasterbatchmohammedNo ratings yet

- ConcreteDocument3 pagesConcreteTran DtrungNo ratings yet

- JOINLEADER 880 Weatherproof Silicone Sealant TDSDocument5 pagesJOINLEADER 880 Weatherproof Silicone Sealant TDSdasaNo ratings yet

- Superthermolay App PL / MT: DescriptionDocument2 pagesSuperthermolay App PL / MT: DescriptionTarun80No ratings yet

- 101 DR Fixit Pidiproof LW+Document2 pages101 DR Fixit Pidiproof LW+beshnu garanaikNo ratings yet

- Proto Copy Finale DraeteDocument60 pagesProto Copy Finale DraeteAjinkya MoreNo ratings yet

- Nitoproof 600PFDocument3 pagesNitoproof 600PFshyamsundar_ceNo ratings yet

- CONCRESIVE 2200 - v1Document2 pagesCONCRESIVE 2200 - v1VaishamNo ratings yet

- Liquid Applied Waterproofing - ProtectowrapDocument3 pagesLiquid Applied Waterproofing - ProtectowrapYndia SorianoNo ratings yet

- Instruction Manual: Permeability Plugging TesterDocument27 pagesInstruction Manual: Permeability Plugging TesterDukilson PersyNo ratings yet

- KrytonDocument4 pagesKrytonProject Manager IIT Kanpur CPWDNo ratings yet

- Secutec Binder Ds UkDocument2 pagesSecutec Binder Ds UkSuresh RaoNo ratings yet

- Membrane Filter Tester Instruction Manual: Part No. 396460 Rev. BDocument23 pagesMembrane Filter Tester Instruction Manual: Part No. 396460 Rev. BWajid NizamiNo ratings yet

- Instruction Manual: Roller Oven With Programmable Timer and Circulating Fan, 5 RollerDocument20 pagesInstruction Manual: Roller Oven With Programmable Timer and Circulating Fan, 5 RollerLuis Gomez JimenezNo ratings yet

- Ductility of BitumenDocument4 pagesDuctility of BitumenArpita MulikNo ratings yet

- 14 Vetogrout CG510 - Group 170821Document2 pages14 Vetogrout CG510 - Group 170821faisal dildarNo ratings yet

- (PDS) Conbextra STDDocument3 pages(PDS) Conbextra STDPritha DasNo ratings yet

- Key Notes: Tile Shower AssemblyDocument1 pageKey Notes: Tile Shower AssemblyHeriberto Yau BNo ratings yet

- Easy Tips For Drawing Eyes - Art RocketDocument12 pagesEasy Tips For Drawing Eyes - Art RocketTammy Blackwell-Keith67% (6)

- National Museum of Fine ArtsDocument10 pagesNational Museum of Fine ArtsKrista Joy PetalioNo ratings yet

- Contemporary Indian Art: Module - 3Document11 pagesContemporary Indian Art: Module - 318ufaa044 18ufaa044No ratings yet

- Popfold 001vaultboy (Updated)Document4 pagesPopfold 001vaultboy (Updated)Grisha Kovalchuk100% (1)

- Dama y Caballero - 2023Document107 pagesDama y Caballero - 2023efeerrecholula18No ratings yet

- 300nb Fire Water Line - BEEL - 071953Document2 pages300nb Fire Water Line - BEEL - 071953irshadiiitNo ratings yet

- A Color Wheel Consisting of Primary - ZahraDocument12 pagesA Color Wheel Consisting of Primary - Zahrazahrabncdxb100% (1)

- The Art of Pencil Drawing PDFDocument164 pagesThe Art of Pencil Drawing PDFTử Uyển100% (10)

- History of RealismDocument2 pagesHistory of RealismPearl ArcamoNo ratings yet

- Fernando AmorsoloDocument45 pagesFernando AmorsoloTimothy CaragNo ratings yet

- Plants As Architectural Framework and of Aesthetic Value in Jordan Landscape Home GardensDocument11 pagesPlants As Architectural Framework and of Aesthetic Value in Jordan Landscape Home Gardensibrahim mohammedNo ratings yet

- Nanu HouseDocument43 pagesNanu HouseSUHANI VERMANo ratings yet

- FL WrightDocument20 pagesFL Wrightarpitvyas67100% (1)

- Grade 7 - Arts First Quarter SY 2020-2021: Mrs. Nemia P. Macabingkil Mapeh TeacherDocument32 pagesGrade 7 - Arts First Quarter SY 2020-2021: Mrs. Nemia P. Macabingkil Mapeh Teachernemia macabingkilNo ratings yet

- 2019 TapiesDocument16 pages2019 TapiesToby J Lloyd-JonesNo ratings yet

- Wassily Kandinsky BiographyDocument4 pagesWassily Kandinsky BiographyveekshiNo ratings yet

- Coraline EngDocument8 pagesCoraline EngVictória Mendes100% (2)

- Marilou Acosta - Learning Sheet Number 2-CONTEMPORARY ARTSDocument2 pagesMarilou Acosta - Learning Sheet Number 2-CONTEMPORARY ARTSMariel AcostaNo ratings yet

- TLE 6 PPT Q4 - Methods of Enhancing Decorating Bamboo, Wood, and Metal ProductsDocument86 pagesTLE 6 PPT Q4 - Methods of Enhancing Decorating Bamboo, Wood, and Metal ProductsMaureen VillacobaNo ratings yet

- POST MODERN ARCHITECTURE Prof KhaledDocument15 pagesPOST MODERN ARCHITECTURE Prof KhaledMariam MansourNo ratings yet

- Common Defects in PlasterDocument2 pagesCommon Defects in PlasterDesmond VlietstraNo ratings yet

- MZ Rice SalesSheetDocument4 pagesMZ Rice SalesSheetCerio DuroNo ratings yet

- 1 Cultural DimensionsDocument20 pages1 Cultural DimensionsIulianaioana SicaruNo ratings yet

- CPAR-LESSON 9-Contemporary ArchitectureDocument58 pagesCPAR-LESSON 9-Contemporary ArchitectureJana MiaNo ratings yet

- Scott Giarnese: ObjectiveDocument2 pagesScott Giarnese: Objectiveapi-26788570No ratings yet

- Lesson 4: Painting: Chapter 2: Media and Processes in Visual ArtsDocument32 pagesLesson 4: Painting: Chapter 2: Media and Processes in Visual ArtsJessa CancinoNo ratings yet