Professional Documents

Culture Documents

Geringhoff Harvest Bulletin 1 - 2

Geringhoff Harvest Bulletin 1 - 2

Uploaded by

alecandro_90Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Geringhoff Harvest Bulletin 1 - 2

Geringhoff Harvest Bulletin 1 - 2

Uploaded by

alecandro_90Copyright:

Available Formats

Follow the guidelines below to optimize your harvest header for maximum yield retention.

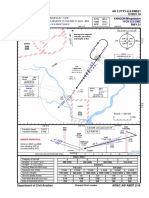

Header Angle X [°] mm

Y - Rota Disc RD

inch” Comment X [°]

Y - NorthStar NS

mm inch” Comment

Setting measured for working angle of the cornheader 17 - - 17 325 12.80 Too flat to

Note!: The base must be close to horizontal! Too flat to

18 - - 18 328 13.31 run properly

run properly

19 - - 19 351 13.82

Center of miter gearbox cover

20 352 13.86 Remove Sta- 20 364 14.33

21 364 14.35 tionary Knife 21 376 14.82 Standard

22 377 14.84 22 389 15.31 Setting

23 389 15.33 Standard 23 401 15.81

24 402 15.83 Setting 24 414 16.30

y – Height

Angle from Center 25 414 16.30 25 426 16.77

X of miter gearbox

from ground

26 426 16.78 26 438 17.24 Too Steep

Skids approximately

Skids 1” 1”

approximately above

abovethe

theground

ground Too Steep

27 438 17.26 27 450 17.72

Y – Rota Disc RD Y - North Star NS

Check

X [°] mmhead

inch for

'' proper

Remark angle X [°] using an''angleRemark

mm inch finder tool or smart phone Angle Finder app. If angle finder tool is not

availalable, use the

17 - -

chart

too flat angel above to determine

17 325 12,80

the angle of the head and set to proper working angle.

too flat angel for a

good function

18 - - for a good 18 338 13,31

function

19 - - 19 351 13,82

Other Items to Check

20 352 13,86 20 364 14,33

only possible

21 364 14,35 without 21 376 14,82

stubble cutter

22 377 14,84 22 389 15,31 standard setting

•

23 Check

389 Auger Height. Set

15,33 23 at

4011 -15,81

1.25 inches above auger • Factory recommended speed for your head

24 trough.

402 15,83Set clearance between 24 414 auger flighting and

16,30 with no load at high idle:

25

stripper

414 16,30

bar .25” - .75”25for426

standard setting

optimum

16,77

performance.

too steep angel - RD - 700 - 750 RPM

• Check all knives for proper clearance. - NS - 750 - 800 RPM

26 426 16,78 26 438 17,24 for a good

function

27 438 17,26 27 450 17,72

- RD - .5mm between knife roll and stationary knife

- NS - .5mm at the rear of knife rolls, and 1 - 2 mm

spacing at the front

Service Hotline: (888) 721-1340

Harvest 2014

Dear Geringhoff Owner,

Harvest time is just around the corner with some of you

having already started. Periodic maintenance is a key

ingredient to having a safe and trouble free harvest

experience. Our dedicated field support staff travels the

country during the harvest season assisting dealers with

your service and operating questions.

Following the simple checklist on the back of this card

will be the first step towards a safe, profitable and trouble

free harvest season. Feel free to contact our field support

staff for additional assistance at any time during your

harvest season.

Sincerely,

Geringhoff Support Staff

Be sure to perform these simple maintenance procedures to

ensure your harvest goes smoothly.

Check grease in crown gear box (PTO drive line) - in

lower position - bottom check plug.

Check grease in miter gear box - center check plug

Row unit gear boxes - oil at proper level

Grease row units - 3 zerks/row on Rota Disc model,

2 zerks/row on Northstar model

Grease PTO shafts and bearing connection

Auger chain drive - check for proper tension and

alignment on sprockets

Check and adjust stationary knives

(Rota Disc model only)

Ensure all safety shields are in place

Check functionality of Headsight control (if equipped)

Oil gathering chains with chain lube provided, after

and prior to storage

Following harvest be sure to perform these same

procedures and thoroughly clean your equipment

prior to storage

Enjoy your Geringhoff products!

You might also like

- TNG Release Notes 502Document14 pagesTNG Release Notes 502alecandro_90No ratings yet

- SR22 ChecklistDocument74 pagesSR22 Checklistpatrouilledeafrance100% (1)

- The Solex 28/34 Cisac Z10 Carburettor (As Used On The 300 Series With The B172K Engine)Document16 pagesThe Solex 28/34 Cisac Z10 Carburettor (As Used On The 300 Series With The B172K Engine)İlker ÖndeşNo ratings yet

- Drawing CombingDocument29 pagesDrawing CombingShoaib ArifNo ratings yet

- Diferencial Delantero 44 46000 RockwellDocument4 pagesDiferencial Delantero 44 46000 RockwellDaniel Marin MoralesNo ratings yet

- 13728-014R1 Abreviated Checklist PDFDocument82 pages13728-014R1 Abreviated Checklist PDFfelipesansNo ratings yet

- Fire Hose Reel DimensionDocument1 pageFire Hose Reel DimensionChristianNo ratings yet

- It Should Be Less Than R /3 or 10mDocument5 pagesIt Should Be Less Than R /3 or 10mMawan BentzNo ratings yet

- Swaraj PTL Tractor PumpDocument25 pagesSwaraj PTL Tractor PumpKarthikVijayNo ratings yet

- 7kN JackDocument2 pages7kN JackNguyen Quoc KhanhNo ratings yet

- AnchoringDocument34 pagesAnchoringFedor Koretko100% (2)

- WSSS Ad2 109Document1 pageWSSS Ad2 109Chan Ze YuanNo ratings yet

- E CatalogDocument24 pagesE Cataloghary.dedeharyadiNo ratings yet

- UntitledDocument1 pageUntitledargmsfNo ratings yet

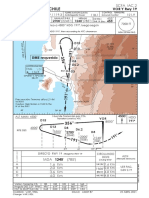

- Fact - Ils Z RW 19 - Ils-02 10may2007Document1 pageFact - Ils Z RW 19 - Ils-02 10may2007EegullNo ratings yet

- RCCen53 Column Design - Password RemoveDocument1 pageRCCen53 Column Design - Password RemoveStephen KokoNo ratings yet

- 8 5-FX56sDocument4 pages8 5-FX56snappyNo ratings yet

- 1.3 G Code List: Code Group Description ModalDocument2 pages1.3 G Code List: Code Group Description ModalFelipe CanabarroNo ratings yet

- Model Silverstitcher: Box StitcherDocument32 pagesModel Silverstitcher: Box StitcherEnrique DelgadoNo ratings yet

- FICHA TECNICA HYSTER E80-120xn-Tech-GuideDocument8 pagesFICHA TECNICA HYSTER E80-120xn-Tech-Guideblurhe2023No ratings yet

- CRV07 Service Manual CH 7 PDFDocument78 pagesCRV07 Service Manual CH 7 PDFPaoloPinardNo ratings yet

- SRA100/166/210/166L/120EL: World Class Speed RobotDocument2 pagesSRA100/166/210/166L/120EL: World Class Speed RobotXanti Zabala Da RosaNo ratings yet

- JR TDocument20 pagesJR TDan FuentesNo ratings yet

- 国际39M混凝土泵车卖点介绍Specification & Advantages of SYG39Document30 pages国际39M混凝土泵车卖点介绍Specification & Advantages of SYG39Alex MazaNo ratings yet

- Suspension: Front and Rear SuspensionDocument34 pagesSuspension: Front and Rear Suspensioncarlosm6669No ratings yet

- Runner Blocks Slimline, Steel Version: Runner Block SNS R1622Document2 pagesRunner Blocks Slimline, Steel Version: Runner Block SNS R1622Leonardo AlexNo ratings yet

- 8rxEM en TableTop, MatTop, Multiflex Chain Engineering ManualDocument276 pages8rxEM en TableTop, MatTop, Multiflex Chain Engineering ManualandriNo ratings yet

- Ad 2.Vynt-Dvor/Dme16 10 NOV 16 AIP Myanmar: Aerodrome Elev - FT TWR 118.7 APP 119.7Document1 pageAd 2.Vynt-Dvor/Dme16 10 NOV 16 AIP Myanmar: Aerodrome Elev - FT TWR 118.7 APP 119.7shan ma layNo ratings yet

- Katalog Rexnord Engineering Manual MatTop and TableTop Chain - Issue 3Document272 pagesKatalog Rexnord Engineering Manual MatTop and TableTop Chain - Issue 3controlsatsmarthomeNo ratings yet

- Scfa Iac 2Document1 pageScfa Iac 2Carlos EduardoNo ratings yet

- Ils Z Rwy10 CatDocument1 pageIls Z Rwy10 CatDante RussiaNo ratings yet

- S2-Maintenance Ocr Si YapıldıDocument40 pagesS2-Maintenance Ocr Si YapıldıÖzerAdıgüzelNo ratings yet

- Double Pitch SprocketDocument17 pagesDouble Pitch SprocketArmor MachineryNo ratings yet

- Scfa Iac 1Document1 pageScfa Iac 1Carlos EduardoNo ratings yet

- Diferencial RT461 para Cat RM-250CDocument5 pagesDiferencial RT461 para Cat RM-250CMarcoBrenesNo ratings yet

- Profile Sheet C5-Cushion CrownDocument4 pagesProfile Sheet C5-Cushion CrownLuis Alberto Rivas GarciaNo ratings yet

- Elevation of Beam Section Before Cutting and WeldingDocument1 pageElevation of Beam Section Before Cutting and WeldingMartin ScottNo ratings yet

- Lawn Tractors: Brand & Model Price Overall Score Test Results FeaturesDocument54 pagesLawn Tractors: Brand & Model Price Overall Score Test Results FeaturesJ DNo ratings yet

- Technical Guide S135-155FT SERIESDocument6 pagesTechnical Guide S135-155FT SERIESSaldañaNo ratings yet

- One Tough Animal One Tough Animal: Vibratory Roller AttachmentDocument2 pagesOne Tough Animal One Tough Animal: Vibratory Roller AttachmentAldo RuizNo ratings yet

- SBRP Ndb-Rwy-18 Iac 20210715Document1 pageSBRP Ndb-Rwy-18 Iac 20210715Wilson NovaesNo ratings yet

- Airport InformationDocument11 pagesAirport InformationSeyi WilliamsNo ratings yet

- Lec5 Machining 2019Document87 pagesLec5 Machining 2019ED 405No ratings yet

- Gun Drill Sharpening Fixture - LIT-079Document2 pagesGun Drill Sharpening Fixture - LIT-079Ron Biggs100% (1)

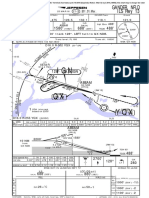

- Gander, NFLD ILS Rwy 13 Cyqx/Yqx: .Eff.31.MarDocument1 pageGander, NFLD ILS Rwy 13 Cyqx/Yqx: .Eff.31.MarYuri AlexanderNo ratings yet

- MGP Z DD - EU SMC PneumaticDocument97 pagesMGP Z DD - EU SMC PneumaticFatih BahşiNo ratings yet

- Vyyy Ilsdme21 Airac 2016 02 PDFDocument1 pageVyyy Ilsdme21 Airac 2016 02 PDFWIN MINNo ratings yet

- Naa347hj (LC-01) Machine CapabilityDocument2 pagesNaa347hj (LC-01) Machine CapabilityJagadesh PNo ratings yet

- Bridgestone Truck Tire DataBookDocument122 pagesBridgestone Truck Tire DataBookfikereNo ratings yet

- User Manual: CNC RouterDocument31 pagesUser Manual: CNC RouterPIXIDOUNo ratings yet

- Makita N1900B UGDocument12 pagesMakita N1900B UGnorthpolebcsNo ratings yet

- Generatordatenblatt Marelli MJB200SA4 PDFDocument4 pagesGeneratordatenblatt Marelli MJB200SA4 PDFtjiangNo ratings yet

- Kent USA KTM 3S 3VS 3VK 3VKF 4VKF Knee Mill Operation ManualDocument59 pagesKent USA KTM 3S 3VS 3VK 3VKF 4VKF Knee Mill Operation ManualYoga RahadianNo ratings yet

- 0.75kW - 1750rpmDocument1 page0.75kW - 1750rpmanush_swaminathanNo ratings yet

- Gravity Wall Calculator TADocument13 pagesGravity Wall Calculator TAAdibowoWicaksonoNo ratings yet

- Bosch Rexroth Runner Blocks Type 1622 CatalogDocument4 pagesBosch Rexroth Runner Blocks Type 1622 CatalogBudy GedhaBlackNo ratings yet

- Chains F09Document1 pageChains F09chmatias3No ratings yet

- sharePointMarketingProductsapplicationsToolsandaccessoriesProduct ManualsMirka DEOS 230V.pdf 3Document208 pagessharePointMarketingProductsapplicationsToolsandaccessoriesProduct ManualsMirka DEOS 230V.pdf 3jmcNo ratings yet

- 18284-c Std. Table Assy, ManualDocument1 page18284-c Std. Table Assy, Manualgregorymw9No ratings yet

- Motor PLL - 2232Document4 pagesMotor PLL - 2232Rouni AñazcoNo ratings yet

- Input Data: ITB 44 3 U 54.26 D60 132B5 SZSX M1 7.5kW 4p 3ph 60Hz T1Document4 pagesInput Data: ITB 44 3 U 54.26 D60 132B5 SZSX M1 7.5kW 4p 3ph 60Hz T1Eduardo CamNo ratings yet

- MathsTraks: Geometry: A Collection of Blackline Masters for ages 11-14From EverandMathsTraks: Geometry: A Collection of Blackline Masters for ages 11-14No ratings yet

- 02 - Posicionar-eje-Horizontal - 001 - KUKA Positioners ENDocument5 pages02 - Posicionar-eje-Horizontal - 001 - KUKA Positioners ENalecandro_90No ratings yet

- Fig. A Fig. B Fig. CDocument1 pageFig. A Fig. B Fig. Calecandro_90No ratings yet

- V BeltsDocument3 pagesV Beltsalecandro_90No ratings yet

- Sca3000 Demo Kit User ManualDocument21 pagesSca3000 Demo Kit User Manualalecandro_90No ratings yet

- An00008642930101 000201Document4 pagesAn00008642930101 000201alecandro_90No ratings yet

- P 1 Acf 3 J 9 J 0 R 2 CT 23 LHG 7 Be 77 V 2Document8 pagesP 1 Acf 3 J 9 J 0 R 2 CT 23 LHG 7 Be 77 V 2alecandro_90No ratings yet

- Toradex & NXP - AI Vision Starter Kit - Solution Brief - FINALDocument2 pagesToradex & NXP - AI Vision Starter Kit - Solution Brief - FINALalecandro_90No ratings yet

- Sllu 158Document15 pagesSllu 158alecandro_90No ratings yet

- VBB4449 SpecificationDocument3 pagesVBB4449 Specificationalecandro_90No ratings yet

- CAT 2023 Laser AmadaDocument35 pagesCAT 2023 Laser Amadaalecandro_90No ratings yet

- Total Solution For Gear MachiningDocument12 pagesTotal Solution For Gear Machiningalecandro_90No ratings yet

- ESPRIT EDGE - Release - Notes - 2023 - 1Document20 pagesESPRIT EDGE - Release - Notes - 2023 - 1alecandro_9050% (2)

- RIVKLE Blindnietmuttern Edelstahl Senkkopf Rundschaft Offen enDocument2 pagesRIVKLE Blindnietmuttern Edelstahl Senkkopf Rundschaft Offen enalecandro_90No ratings yet

- Gearpro eDocument1 pageGearpro ealecandro_90No ratings yet

- Messprotokoll Gear Pro BevelDocument2 pagesMessprotokoll Gear Pro Bevelalecandro_90No ratings yet

- Spna 088Document14 pagesSpna 088alecandro_90No ratings yet

- Marvell Phys Transceivers Alaska 88e1548 88e1548p Product Brief 2015 08Document2 pagesMarvell Phys Transceivers Alaska 88e1548 88e1548p Product Brief 2015 08alecandro_90No ratings yet

- DPRNTDocument4 pagesDPRNTalecandro_90No ratings yet

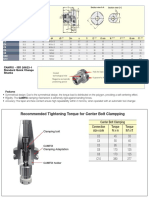

- Tooling Form A Zak SDocument11 pagesTooling Form A Zak Salecandro_90No ratings yet

- Typical Applications: Radial Adjustment (Off-Center Drilling)Document1 pageTypical Applications: Radial Adjustment (Off-Center Drilling)alecandro_90No ratings yet

- PD.02.22 Release NotesDocument14 pagesPD.02.22 Release Notesalecandro_90No ratings yet

- Bevel Gear BlanksDocument3 pagesBevel Gear Blanksalecandro_90No ratings yet

- WenzelDocument4 pagesWenzelalecandro_90No ratings yet

- Camfix Std.Document1 pageCamfix Std.alecandro_90No ratings yet

- 1.EIMA 2022 ProgrammeDocument7 pages1.EIMA 2022 Programmealecandro_90No ratings yet

- AMADA MIYACHI To Newly Release ML-6811C / ML-6810C Fiber Laser WeldersDocument3 pagesAMADA MIYACHI To Newly Release ML-6811C / ML-6810C Fiber Laser Weldersalecandro_90No ratings yet

- Release Notes MTB 4.4Document1 pageRelease Notes MTB 4.4alecandro_90No ratings yet

- DHI ASM202 Fingerprint-Enrollment-Reader Users-Manual V1.0.0Document14 pagesDHI ASM202 Fingerprint-Enrollment-Reader Users-Manual V1.0.0alecandro_90No ratings yet

- Yale Assure Install TemplateDocument1 pageYale Assure Install Templatealecandro_90No ratings yet

- 2014 Nissan Leaf Service Repair Manual (Brake System)Document531 pages2014 Nissan Leaf Service Repair Manual (Brake System)Engr Ko Victor100% (1)

- Stack Car Parking SystemDocument27 pagesStack Car Parking Systemapollo.jiyoNo ratings yet

- 250 KVA DG Set EstimateDocument2 pages250 KVA DG Set EstimateProject Engineer ElectricalNo ratings yet

- 9736 1 3 - Im-Clm1,2,3-En-10 03Document87 pages9736 1 3 - Im-Clm1,2,3-En-10 03Jeremy ShaneNo ratings yet

- Clio Brochure 2013Document20 pagesClio Brochure 2013Douglas FisherNo ratings yet

- Hydraulic Caliper Disc Brakes SF Series: Pintsch BubenzerDocument6 pagesHydraulic Caliper Disc Brakes SF Series: Pintsch BubenzeryoyoNo ratings yet

- ALP Cultivator Users-GuideDocument27 pagesALP Cultivator Users-GuidePașala Mihai LucianNo ratings yet

- 7 Safety InstructionDocument57 pages7 Safety Instructionbelaye bekeleNo ratings yet

- Het Asb 097Document13 pagesHet Asb 097Proar Aeronaves e Revisões Ltda. OficinaNo ratings yet

- Restriction of Air Inlet and ExhaustDocument3 pagesRestriction of Air Inlet and ExhaustHugo CiprianiNo ratings yet

- Product Training: Rigid Dump Truck (RDT) TR45: TR60: TR70: TR100Document3 pagesProduct Training: Rigid Dump Truck (RDT) TR45: TR60: TR70: TR100Bassie100% (2)

- MTLQ-L MAGNUM Owner's Manual - E-GB - TL203-19-03-00Document57 pagesMTLQ-L MAGNUM Owner's Manual - E-GB - TL203-19-03-00Lucas MaldonadoNo ratings yet

- 4TNV98-ZNVS (MC80B - Ferticel)Document28 pages4TNV98-ZNVS (MC80B - Ferticel)pecasplh02No ratings yet

- Audi A5 Users Manual 310334Document58 pagesAudi A5 Users Manual 310334julianNo ratings yet

- Sbe 1L24Document2 pagesSbe 1L24akeel.backup92No ratings yet

- Multimetro Automotriz UNI-T UT107-operation ManualDocument64 pagesMultimetro Automotriz UNI-T UT107-operation Manualjorge_pinzon_70No ratings yet

- Wba3d31070j549204-Bimmer Work PDFDocument4 pagesWba3d31070j549204-Bimmer Work PDFStevan AritonovicNo ratings yet

- Tute 07 Traffic Loading & Pavement DesignDocument2 pagesTute 07 Traffic Loading & Pavement Designyu yanNo ratings yet

- Rtad 085Document84 pagesRtad 085Omar Piña100% (1)

- Relay Loc LCR 200Document40 pagesRelay Loc LCR 200Yannick de WalqueNo ratings yet

- Fault Code P1830 (Controlled Manual Gearbox ECU)Document2 pagesFault Code P1830 (Controlled Manual Gearbox ECU)thierry.fifieldoutlook.comNo ratings yet

- Lum mp3 300 Yourban RLNRL 2011Document98 pagesLum mp3 300 Yourban RLNRL 2011om syNo ratings yet

- 2014 Rockshox Suspension Fork Oil Air and Coil ChartsDocument5 pages2014 Rockshox Suspension Fork Oil Air and Coil ChartsJosip.kNo ratings yet

- Nol Nog Modulating Data SheetDocument4 pagesNol Nog Modulating Data Sheetkikokiko KarimNo ratings yet

- 2506C-E15TAG1 ElectropaK PN1845 PDFDocument2 pages2506C-E15TAG1 ElectropaK PN1845 PDFCarlos Rincon0% (1)

- Fls0.1 SW Flex Ecu Obd BenchDocument911 pagesFls0.1 SW Flex Ecu Obd BenchHamza HamliNo ratings yet

- XCMG XC948 Wheel Loader Operation and Maintenance ManualDocument296 pagesXCMG XC948 Wheel Loader Operation and Maintenance ManualSyeed Asif AliNo ratings yet

- Power You Can Depend On: Introduction - Impact WrenchesDocument8 pagesPower You Can Depend On: Introduction - Impact Wrenchesjoker63000No ratings yet