Professional Documents

Culture Documents

WQT Form (ASME) 04-23

WQT Form (ASME) 04-23

Uploaded by

hanz bermejoCopyright:

Available Formats

You might also like

- Welding Procedure Specification FormatDocument3 pagesWelding Procedure Specification FormatAnonymous 4e7GNjzGW100% (1)

- AWS Maintenance-of-Welder-Certification-Form (01-2023)Document1 pageAWS Maintenance-of-Welder-Certification-Form (01-2023)hanz bermejoNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- PQR Is7307Document1 pagePQR Is7307Tridib Dey100% (1)

- WPS and PQRDocument4 pagesWPS and PQRdandiar1No ratings yet

- A Seminar Report On Rover Mission .1Document23 pagesA Seminar Report On Rover Mission .1monster gaming100% (1)

- I-Ready Multiply Whole NumbersDocument6 pagesI-Ready Multiply Whole Numbersapi-28514220150% (4)

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaNo ratings yet

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- P91 ProfileDocument6 pagesP91 ProfilesrinivasanNo ratings yet

- Radiographic Testing: Inspection ReportDocument2 pagesRadiographic Testing: Inspection Reportsuria qaqcNo ratings yet

- Birla Copper WPS For Tube To Tubesheet Welding MOC - CSDocument2 pagesBirla Copper WPS For Tube To Tubesheet Welding MOC - CSJitu Padhiyar PadhiyarNo ratings yet

- Indt QCP RT HJ 05NDocument14 pagesIndt QCP RT HJ 05NAsad Bin Ala QatariNo ratings yet

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- Preliminary Welding Procedure Specification (PWPS)Document1 pagePreliminary Welding Procedure Specification (PWPS)AzriNo ratings yet

- WPS SampleDocument182 pagesWPS Sampleaymenfr23No ratings yet

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDocument2 pagesASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaNo ratings yet

- PQR TipsDocument4 pagesPQR TipsWaqas WaqasNo ratings yet

- Juta Bumi Kapital Sdn. BHD: Doc. No. Revision NoDocument2 pagesJuta Bumi Kapital Sdn. BHD: Doc. No. Revision NoSong Kiet ChooNo ratings yet

- Welding Procedure Specification For GTAW & GMAWDocument4 pagesWelding Procedure Specification For GTAW & GMAWanh thoNo ratings yet

- WPS Qualify To DNV-OS-C401 - SampleDocument12 pagesWPS Qualify To DNV-OS-C401 - SampleBien NguyenDuyNo ratings yet

- WPQT FormatDocument176 pagesWPQT FormatRafiqKu50% (2)

- Dimension Check & Fit Up Inspection Report (Piping)Document1 pageDimension Check & Fit Up Inspection Report (Piping)ZaidiNo ratings yet

- Dokumen - Tips Wqt-FormatDocument2 pagesDokumen - Tips Wqt-FormatMr Pie100% (1)

- PQR - PipeDocument3 pagesPQR - PipeAdvanced Quality Centre AQC100% (1)

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium WeldingMohammed MusaNo ratings yet

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- Welding Electrode Selection Table - Piping StudyDocument1 pageWelding Electrode Selection Table - Piping StudySujay AsukarNo ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad Pathan100% (1)

- WPS ListDocument2 pagesWPS ListAdeel OmerNo ratings yet

- QW 483Document2 pagesQW 483delta lab sangliNo ratings yet

- Wps For Smaw06-001 (Pipe 6g CS)Document10 pagesWps For Smaw06-001 (Pipe 6g CS)walitedisonNo ratings yet

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 pagesCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNo ratings yet

- ASME 9 - CalculatorDocument2 pagesASME 9 - CalculatorEmel Besir100% (1)

- Asme Ix 2013 PTDocument1 pageAsme Ix 2013 PTRonel John Rodriguez CustodioNo ratings yet

- PQR Asme Template EDITABLEDocument6 pagesPQR Asme Template EDITABLErcpretoriusNo ratings yet

- Reports - QAQC - R0Document10 pagesReports - QAQC - R0talupurumNo ratings yet

- Welding Procedure Specification (WPS) : N.A N.ADocument1 pageWelding Procedure Specification (WPS) : N.A N.AMajdi Jerbi100% (1)

- PQR - 152Document3 pagesPQR - 152MAT-LIONNo ratings yet

- Electrode Backing RegisterDocument4 pagesElectrode Backing RegisterSimbu Arasan100% (1)

- Welding Procedure Specification (WPS) : Asme Boiler and Pressure Vessel Code - Section Ix - Qw-482Document2 pagesWelding Procedure Specification (WPS) : Asme Boiler and Pressure Vessel Code - Section Ix - Qw-482Edwin Romero100% (2)

- FM-IN-02 Monorail CHECKLISTDocument3 pagesFM-IN-02 Monorail CHECKLISTishfaq100% (1)

- wps63 PDFDocument4 pageswps63 PDFErick HoganNo ratings yet

- QA-R-04 - Visual Inspection ReportDocument1 pageQA-R-04 - Visual Inspection ReportvinothNo ratings yet

- Technofibre International SDN BHD: Welder Qualification Test Reord (WQT)Document1 pageTechnofibre International SDN BHD: Welder Qualification Test Reord (WQT)dandiar1100% (1)

- EFR-190719-PQR-01 - Shell Vertical-Horizontal PDFDocument11 pagesEFR-190719-PQR-01 - Shell Vertical-Horizontal PDFIonut FloricaNo ratings yet

- QW-483 BlankDocument2 pagesQW-483 BlankCraftyBob100% (1)

- WPS E6013+e7018Document2 pagesWPS E6013+e7018Anvesh Vaddi100% (1)

- Wps Aws d1.1 Ss400 To Ss400 Gmaw-RevDocument2 pagesWps Aws d1.1 Ss400 To Ss400 Gmaw-RevAnonymous zfC1zo9C100% (2)

- WPS Pipe 08'' SHD 40 SMAW REV02Document2 pagesWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejNo ratings yet

- QW-484A (WPQ) GTAW 4MM FilletDocument2 pagesQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- Welding Proposed Pwps For Our Jubail WorkDocument2 pagesWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- 57 PQRDocument13 pages57 PQRAbdul Tri Hamdani Hamdani100% (1)

- WPS002 312Document2 pagesWPS002 312proxywarNo ratings yet

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- ASME IX Sample WPS GTAW SMAWDocument1 pageASME IX Sample WPS GTAW SMAWDeepak ShrivastavNo ratings yet

- WQT Form (AWS D1.1) 04-23Document1 pageWQT Form (AWS D1.1) 04-23hanz bermejoNo ratings yet

- 6gr Smaw WQTR - F. Edilo (Sn-189)Document1 page6gr Smaw WQTR - F. Edilo (Sn-189)hanz bermejoNo ratings yet

- Toaz - Info Welding Procedure Specification Format PRDocument3 pagesToaz - Info Welding Procedure Specification Format PRKarim ZahranNo ratings yet

- Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001Document2 pagesWelding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001neerajNo ratings yet

- Welding-Joining-InstructionsDocument1 pageWelding-Joining-Instructionshanz bermejoNo ratings yet

- Son WPS 262 WQTDocument1 pageSon WPS 262 WQThanz bermejoNo ratings yet

- N-7018-2.5mm-64210048 (F18)Document1 pageN-7018-2.5mm-64210048 (F18)hanz bermejoNo ratings yet

- SR Al WPS 011 BWDocument2 pagesSR Al WPS 011 BWhanz bermejoNo ratings yet

- PWPS Image 1 1024x1024Document1 pagePWPS Image 1 1024x1024hanz bermejoNo ratings yet

- C. 6GR Test Schedule (Mar. 13, 2023)Document1 pageC. 6GR Test Schedule (Mar. 13, 2023)hanz bermejoNo ratings yet

- JRY 02CS PipeDocument2 pagesJRY 02CS Pipehanz bermejoNo ratings yet

- AWS Certified-Welder-Application (01-2023)Document2 pagesAWS Certified-Welder-Application (01-2023)hanz bermejoNo ratings yet

- Tutorial How To Change The Sleep Settings On Your Acer Laptop ScreenshotsDocument3 pagesTutorial How To Change The Sleep Settings On Your Acer Laptop Screenshotshanz bermejoNo ratings yet

- An Introduction To The Mechanics of Tensegrity StructuresDocument6 pagesAn Introduction To The Mechanics of Tensegrity StructuresAdministrasi sman1gampingdiyNo ratings yet

- Goa Board Physics 2018 June PaperDocument7 pagesGoa Board Physics 2018 June PaperSphoortiN XII B 927No ratings yet

- Maths Sample PaperDocument9 pagesMaths Sample PaperPonharish kumar.JNo ratings yet

- Wave On String - Exe With SolDocument76 pagesWave On String - Exe With SolArjun SabnisNo ratings yet

- Circuits - 1 - Lab - 6 - Charles Daryll ContridasDocument11 pagesCircuits - 1 - Lab - 6 - Charles Daryll ContridasCharles ContridasNo ratings yet

- MDD, Omc (VH) - GCSDocument4 pagesMDD, Omc (VH) - GCSDaniel KariukiNo ratings yet

- Physics Project: Topic: To Study Simple Harmonic MotionDocument7 pagesPhysics Project: Topic: To Study Simple Harmonic Motiongorilla soupNo ratings yet

- Welding Guide PDFDocument24 pagesWelding Guide PDFJán KožičkaNo ratings yet

- Valtek MaxFloDocument12 pagesValtek MaxFloAmanda RezendeNo ratings yet

- تحليل انظمه القوى شابتر رقم 1Document38 pagesتحليل انظمه القوى شابتر رقم 1Mohanad Al-tahrawiNo ratings yet

- Riser Stress CalculationsDocument9 pagesRiser Stress CalculationsJuan Roberto López BetanzosNo ratings yet

- N.R. Engineering: Chemical AnalysisDocument4 pagesN.R. Engineering: Chemical Analysisrajesh reddyNo ratings yet

- Fourier Series ThesisDocument7 pagesFourier Series Thesisgjcezfg9100% (2)

- Review of NCMA Segmental Retaining Wall Design Manual For Geosynthetic PDFDocument10 pagesReview of NCMA Segmental Retaining Wall Design Manual For Geosynthetic PDFJairoNo ratings yet

- DHR BrochureDocument23 pagesDHR BrochureDung ChuNo ratings yet

- An Experimental Study For In-Plane Cyclic Behavior of Low Aspect-Ratio Steel-Concrete Composite WallsDocument11 pagesAn Experimental Study For In-Plane Cyclic Behavior of Low Aspect-Ratio Steel-Concrete Composite Wallsci_balaNo ratings yet

- Kinematics Pose (Position and Orientation) of A Rigid Body: Introduction To RoboticsDocument35 pagesKinematics Pose (Position and Orientation) of A Rigid Body: Introduction To RoboticsFind UserNo ratings yet

- Schrödinger EquationDocument18 pagesSchrödinger EquationJuan Santiago Pineda Rodriguez PequeNo ratings yet

- Draft Syllabus: Engineering PhysicsDocument4 pagesDraft Syllabus: Engineering PhysicsMartin Luther JrNo ratings yet

- Billirurbim ErmaDocument3 pagesBillirurbim ErmaomarNo ratings yet

- Phy 119 General Physics Practical 20182019Document18 pagesPhy 119 General Physics Practical 20182019MaryjaneNo ratings yet

- Expt.6 BEEE101P TheveninsTinkerCADDocument6 pagesExpt.6 BEEE101P TheveninsTinkerCADBaba YagaNo ratings yet

- DeepFX LDocument1 pageDeepFX LSasha DimiciNo ratings yet

- Enhanced Photovoltaic Performances of Graphene-Si Solar Celle by Insertion of in Mos2 Thin FilmDocument102 pagesEnhanced Photovoltaic Performances of Graphene-Si Solar Celle by Insertion of in Mos2 Thin Filmouchene nedjm eddineNo ratings yet

- Din 2080-1-1978Document3 pagesDin 2080-1-1978tudorboulescuNo ratings yet

- 72 NBR 902-En - 1Document3 pages72 NBR 902-En - 1Pierre PescayNo ratings yet

- Thermal Conductivity Theory Properties and Applications Physics of Solids and LiquidsDocument306 pagesThermal Conductivity Theory Properties and Applications Physics of Solids and LiquidsArashSara BehrangHassanpourNo ratings yet

- Standard Specifications: For Open Web Steel Joists, K-SeriesDocument11 pagesStandard Specifications: For Open Web Steel Joists, K-SeriesSalahuddin MNo ratings yet

WQT Form (ASME) 04-23

WQT Form (ASME) 04-23

Uploaded by

hanz bermejoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WQT Form (ASME) 04-23

WQT Form (ASME) 04-23

Uploaded by

hanz bermejoCopyright:

Available Formats

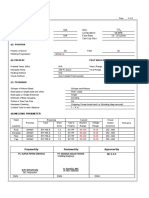

WELDER and WELDING OPERATOR PERFORMANCE

QUALIFICATION RECORD

Welder’s Name JOHNATAN L. MEDINA ATF No. 120101 Test No. B2.1

Welder’s SS No. SN-228 Date March 30, 2023 Reference WPS No: AWS B2.1-1-022-94R

VARIABLE QUALIFICATION TEST DETAIL QUALIFICATION RANGE*

Code or Specification Used: ASME IX

Welding Process and Type:

Manual Semiautomatic Manual Semiautomatic

SMAW ( MANUAL ) Mechanized Automatic Mechanized Automatic

Backing: (QW 402) Used Not Used Required if usedBacking

With or Without

Base Metal

Base Metal (QW 403) Spec/P or Mor-M Number

Spec/P - Number A106 Gr. B (P-1 to P-1) P-1 through P-15F, P-34, and P-41 through P-49

Plate / Plate

Pipe / Thickness – –Groove

Pipe Thickness Groove Plate Pipe Thick. 11 mm 5 mm to 22 mm Maximum Thickness

Plate Plate

/ Pipe/ Pipe

Thickness – –Fillet

Thickness Fillet Plate Pipe Thick. NA Unlimited

Pipe/Tubular

Pipe/Tubular OutsideOutside

Diameter – –Groove

Diameter Groove 6" OD (Schedule 80) 2-7/8" OD to Unlimited

Pipe/Tubular

Pipe/Tubular Outside Diameter

Outside – –Fillet

Diameter Fillet NA NA

FillerMetal

Filler Metal (QW 404) Specification

SpecificationNo.

No. SFA 5.1 SFA 5.1

Classification

Classification No.

No. E6010, E7018 E6010, E7018

FF No.

No. F3, F4 F1 to F3 w/ Backing, F3 w/o Backing, F4 w/ backing

Diameter

Diameter 3.2 mm As to WPS

Consumable

Consumable Insert

Insert Yes No Only Without Insert

Penetration

PenetrationEnhancing Flux

Enhancing Flux Yes No NA

DepositedWeld

Deposited WeldMetal

MetalThickness

Thickness(QW 404) 11 mm 22 mm

Current/Polarity

Current & Current

Type/Polarity (QW Range

409) Type/Polarity: DCEP [Reverse] for E6010; and Only DCEP [Reverse] for E6010; and

DCEP (Reverse) for E7018.

Range: Amperes

DCEP [Reverse] for E7018.

MetalTransfer

Metal Transfer Mode

Mode (GMAW

(GMAW or FCAW)

or FCAW) (QW 409) NA NA

TorchShielding

Torch ShieldingGas

Gas(QW-408) Type: NA Flow: NA

RootShielding

Root ShieldingGas

Gas (QW-408) NA Type: Flow: NA

Position(s) Test Position(s) (1G, 2G, etc.): Qualified Position(s) (F, H, V, O, or All)

Position(s) (QW 405)

6G All

VerticalProgression

Vertical Progression (QW-410) Uphill Downhill Uphill Downhill

*NOTE: Insert NA for Variables that are identified as Non-essential in the Code or Specification used for the Performance Qualification Test

MECHANICAL TEST RESULTS

Type And Figure No. Results Type And Figure No. Results

Side Bend Specimen, SB-89 No open defect was observed. Side Bend Specimen, SB-91 No open defect was observed.

Side Bend Specimen, SB-90 No open defect was observed. Side Bend Specimen, SB-92 No open defect was observed.

REPORT NO.: BT-23-03/SB-15

GuidedMechanical

Guided mechanicalTesting Conducted

Testing Conducted By:

By: G. SHERRY QW-160, QW-163, Fig.'s.QW-462.2 / QW-463.2 (e) Date: March 31, 2023 Angle of Bend: 180 Degrees

NONDESTRUCTIVE EXAMINATION RESULTS

RadiographicResults

Radiographic Results:

: Report No. :

RadiographicTesting

Radiographic TestingConducted

ConductedBy:By: Company:

WeldingWitnessed

Welding Witnessed By: Nevoe M. Bermejo

By: Haron Visual Inspection: (QW-302.4)Pass Fail (reason)

We certify that the statements in this record are correct and the test welds were prepared, welded and tested in accordance with

the requirements of: ASME AWS D1.1 ed.)- AWS B2.1 -

IX (2019 Other:

Date Qualified: March 31, 2023 ATF Name and Number: SUBNET SERVICES LTD. ATF No.: 120101

Signed By: HARON NEVOE M. BERMEJO CWI No. : 09051491

ATF WPQR Blank Form 2010-04-15 Rev. 1

ATF WPQR Blank Form 2010-04-15

You might also like

- Welding Procedure Specification FormatDocument3 pagesWelding Procedure Specification FormatAnonymous 4e7GNjzGW100% (1)

- AWS Maintenance-of-Welder-Certification-Form (01-2023)Document1 pageAWS Maintenance-of-Welder-Certification-Form (01-2023)hanz bermejoNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- PQR Is7307Document1 pagePQR Is7307Tridib Dey100% (1)

- WPS and PQRDocument4 pagesWPS and PQRdandiar1No ratings yet

- A Seminar Report On Rover Mission .1Document23 pagesA Seminar Report On Rover Mission .1monster gaming100% (1)

- I-Ready Multiply Whole NumbersDocument6 pagesI-Ready Multiply Whole Numbersapi-28514220150% (4)

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaNo ratings yet

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- P91 ProfileDocument6 pagesP91 ProfilesrinivasanNo ratings yet

- Radiographic Testing: Inspection ReportDocument2 pagesRadiographic Testing: Inspection Reportsuria qaqcNo ratings yet

- Birla Copper WPS For Tube To Tubesheet Welding MOC - CSDocument2 pagesBirla Copper WPS For Tube To Tubesheet Welding MOC - CSJitu Padhiyar PadhiyarNo ratings yet

- Indt QCP RT HJ 05NDocument14 pagesIndt QCP RT HJ 05NAsad Bin Ala QatariNo ratings yet

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- Preliminary Welding Procedure Specification (PWPS)Document1 pagePreliminary Welding Procedure Specification (PWPS)AzriNo ratings yet

- WPS SampleDocument182 pagesWPS Sampleaymenfr23No ratings yet

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDocument2 pagesASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaNo ratings yet

- PQR TipsDocument4 pagesPQR TipsWaqas WaqasNo ratings yet

- Juta Bumi Kapital Sdn. BHD: Doc. No. Revision NoDocument2 pagesJuta Bumi Kapital Sdn. BHD: Doc. No. Revision NoSong Kiet ChooNo ratings yet

- Welding Procedure Specification For GTAW & GMAWDocument4 pagesWelding Procedure Specification For GTAW & GMAWanh thoNo ratings yet

- WPS Qualify To DNV-OS-C401 - SampleDocument12 pagesWPS Qualify To DNV-OS-C401 - SampleBien NguyenDuyNo ratings yet

- WPQT FormatDocument176 pagesWPQT FormatRafiqKu50% (2)

- Dimension Check & Fit Up Inspection Report (Piping)Document1 pageDimension Check & Fit Up Inspection Report (Piping)ZaidiNo ratings yet

- Dokumen - Tips Wqt-FormatDocument2 pagesDokumen - Tips Wqt-FormatMr Pie100% (1)

- PQR - PipeDocument3 pagesPQR - PipeAdvanced Quality Centre AQC100% (1)

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium WeldingMohammed MusaNo ratings yet

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- Welding Electrode Selection Table - Piping StudyDocument1 pageWelding Electrode Selection Table - Piping StudySujay AsukarNo ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad Pathan100% (1)

- WPS ListDocument2 pagesWPS ListAdeel OmerNo ratings yet

- QW 483Document2 pagesQW 483delta lab sangliNo ratings yet

- Wps For Smaw06-001 (Pipe 6g CS)Document10 pagesWps For Smaw06-001 (Pipe 6g CS)walitedisonNo ratings yet

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 pagesCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNo ratings yet

- ASME 9 - CalculatorDocument2 pagesASME 9 - CalculatorEmel Besir100% (1)

- Asme Ix 2013 PTDocument1 pageAsme Ix 2013 PTRonel John Rodriguez CustodioNo ratings yet

- PQR Asme Template EDITABLEDocument6 pagesPQR Asme Template EDITABLErcpretoriusNo ratings yet

- Reports - QAQC - R0Document10 pagesReports - QAQC - R0talupurumNo ratings yet

- Welding Procedure Specification (WPS) : N.A N.ADocument1 pageWelding Procedure Specification (WPS) : N.A N.AMajdi Jerbi100% (1)

- PQR - 152Document3 pagesPQR - 152MAT-LIONNo ratings yet

- Electrode Backing RegisterDocument4 pagesElectrode Backing RegisterSimbu Arasan100% (1)

- Welding Procedure Specification (WPS) : Asme Boiler and Pressure Vessel Code - Section Ix - Qw-482Document2 pagesWelding Procedure Specification (WPS) : Asme Boiler and Pressure Vessel Code - Section Ix - Qw-482Edwin Romero100% (2)

- FM-IN-02 Monorail CHECKLISTDocument3 pagesFM-IN-02 Monorail CHECKLISTishfaq100% (1)

- wps63 PDFDocument4 pageswps63 PDFErick HoganNo ratings yet

- QA-R-04 - Visual Inspection ReportDocument1 pageQA-R-04 - Visual Inspection ReportvinothNo ratings yet

- Technofibre International SDN BHD: Welder Qualification Test Reord (WQT)Document1 pageTechnofibre International SDN BHD: Welder Qualification Test Reord (WQT)dandiar1100% (1)

- EFR-190719-PQR-01 - Shell Vertical-Horizontal PDFDocument11 pagesEFR-190719-PQR-01 - Shell Vertical-Horizontal PDFIonut FloricaNo ratings yet

- QW-483 BlankDocument2 pagesQW-483 BlankCraftyBob100% (1)

- WPS E6013+e7018Document2 pagesWPS E6013+e7018Anvesh Vaddi100% (1)

- Wps Aws d1.1 Ss400 To Ss400 Gmaw-RevDocument2 pagesWps Aws d1.1 Ss400 To Ss400 Gmaw-RevAnonymous zfC1zo9C100% (2)

- WPS Pipe 08'' SHD 40 SMAW REV02Document2 pagesWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejNo ratings yet

- QW-484A (WPQ) GTAW 4MM FilletDocument2 pagesQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- Welding Proposed Pwps For Our Jubail WorkDocument2 pagesWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- 57 PQRDocument13 pages57 PQRAbdul Tri Hamdani Hamdani100% (1)

- WPS002 312Document2 pagesWPS002 312proxywarNo ratings yet

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- ASME IX Sample WPS GTAW SMAWDocument1 pageASME IX Sample WPS GTAW SMAWDeepak ShrivastavNo ratings yet

- WQT Form (AWS D1.1) 04-23Document1 pageWQT Form (AWS D1.1) 04-23hanz bermejoNo ratings yet

- 6gr Smaw WQTR - F. Edilo (Sn-189)Document1 page6gr Smaw WQTR - F. Edilo (Sn-189)hanz bermejoNo ratings yet

- Toaz - Info Welding Procedure Specification Format PRDocument3 pagesToaz - Info Welding Procedure Specification Format PRKarim ZahranNo ratings yet

- Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001Document2 pagesWelding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001neerajNo ratings yet

- Welding-Joining-InstructionsDocument1 pageWelding-Joining-Instructionshanz bermejoNo ratings yet

- Son WPS 262 WQTDocument1 pageSon WPS 262 WQThanz bermejoNo ratings yet

- N-7018-2.5mm-64210048 (F18)Document1 pageN-7018-2.5mm-64210048 (F18)hanz bermejoNo ratings yet

- SR Al WPS 011 BWDocument2 pagesSR Al WPS 011 BWhanz bermejoNo ratings yet

- PWPS Image 1 1024x1024Document1 pagePWPS Image 1 1024x1024hanz bermejoNo ratings yet

- C. 6GR Test Schedule (Mar. 13, 2023)Document1 pageC. 6GR Test Schedule (Mar. 13, 2023)hanz bermejoNo ratings yet

- JRY 02CS PipeDocument2 pagesJRY 02CS Pipehanz bermejoNo ratings yet

- AWS Certified-Welder-Application (01-2023)Document2 pagesAWS Certified-Welder-Application (01-2023)hanz bermejoNo ratings yet

- Tutorial How To Change The Sleep Settings On Your Acer Laptop ScreenshotsDocument3 pagesTutorial How To Change The Sleep Settings On Your Acer Laptop Screenshotshanz bermejoNo ratings yet

- An Introduction To The Mechanics of Tensegrity StructuresDocument6 pagesAn Introduction To The Mechanics of Tensegrity StructuresAdministrasi sman1gampingdiyNo ratings yet

- Goa Board Physics 2018 June PaperDocument7 pagesGoa Board Physics 2018 June PaperSphoortiN XII B 927No ratings yet

- Maths Sample PaperDocument9 pagesMaths Sample PaperPonharish kumar.JNo ratings yet

- Wave On String - Exe With SolDocument76 pagesWave On String - Exe With SolArjun SabnisNo ratings yet

- Circuits - 1 - Lab - 6 - Charles Daryll ContridasDocument11 pagesCircuits - 1 - Lab - 6 - Charles Daryll ContridasCharles ContridasNo ratings yet

- MDD, Omc (VH) - GCSDocument4 pagesMDD, Omc (VH) - GCSDaniel KariukiNo ratings yet

- Physics Project: Topic: To Study Simple Harmonic MotionDocument7 pagesPhysics Project: Topic: To Study Simple Harmonic Motiongorilla soupNo ratings yet

- Welding Guide PDFDocument24 pagesWelding Guide PDFJán KožičkaNo ratings yet

- Valtek MaxFloDocument12 pagesValtek MaxFloAmanda RezendeNo ratings yet

- تحليل انظمه القوى شابتر رقم 1Document38 pagesتحليل انظمه القوى شابتر رقم 1Mohanad Al-tahrawiNo ratings yet

- Riser Stress CalculationsDocument9 pagesRiser Stress CalculationsJuan Roberto López BetanzosNo ratings yet

- N.R. Engineering: Chemical AnalysisDocument4 pagesN.R. Engineering: Chemical Analysisrajesh reddyNo ratings yet

- Fourier Series ThesisDocument7 pagesFourier Series Thesisgjcezfg9100% (2)

- Review of NCMA Segmental Retaining Wall Design Manual For Geosynthetic PDFDocument10 pagesReview of NCMA Segmental Retaining Wall Design Manual For Geosynthetic PDFJairoNo ratings yet

- DHR BrochureDocument23 pagesDHR BrochureDung ChuNo ratings yet

- An Experimental Study For In-Plane Cyclic Behavior of Low Aspect-Ratio Steel-Concrete Composite WallsDocument11 pagesAn Experimental Study For In-Plane Cyclic Behavior of Low Aspect-Ratio Steel-Concrete Composite Wallsci_balaNo ratings yet

- Kinematics Pose (Position and Orientation) of A Rigid Body: Introduction To RoboticsDocument35 pagesKinematics Pose (Position and Orientation) of A Rigid Body: Introduction To RoboticsFind UserNo ratings yet

- Schrödinger EquationDocument18 pagesSchrödinger EquationJuan Santiago Pineda Rodriguez PequeNo ratings yet

- Draft Syllabus: Engineering PhysicsDocument4 pagesDraft Syllabus: Engineering PhysicsMartin Luther JrNo ratings yet

- Billirurbim ErmaDocument3 pagesBillirurbim ErmaomarNo ratings yet

- Phy 119 General Physics Practical 20182019Document18 pagesPhy 119 General Physics Practical 20182019MaryjaneNo ratings yet

- Expt.6 BEEE101P TheveninsTinkerCADDocument6 pagesExpt.6 BEEE101P TheveninsTinkerCADBaba YagaNo ratings yet

- DeepFX LDocument1 pageDeepFX LSasha DimiciNo ratings yet

- Enhanced Photovoltaic Performances of Graphene-Si Solar Celle by Insertion of in Mos2 Thin FilmDocument102 pagesEnhanced Photovoltaic Performances of Graphene-Si Solar Celle by Insertion of in Mos2 Thin Filmouchene nedjm eddineNo ratings yet

- Din 2080-1-1978Document3 pagesDin 2080-1-1978tudorboulescuNo ratings yet

- 72 NBR 902-En - 1Document3 pages72 NBR 902-En - 1Pierre PescayNo ratings yet

- Thermal Conductivity Theory Properties and Applications Physics of Solids and LiquidsDocument306 pagesThermal Conductivity Theory Properties and Applications Physics of Solids and LiquidsArashSara BehrangHassanpourNo ratings yet

- Standard Specifications: For Open Web Steel Joists, K-SeriesDocument11 pagesStandard Specifications: For Open Web Steel Joists, K-SeriesSalahuddin MNo ratings yet