Professional Documents

Culture Documents

Ats 639023900 001

Ats 639023900 001

Uploaded by

NombreuniversalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ats 639023900 001

Ats 639023900 001

Uploaded by

NombreuniversalCopyright:

Available Formats

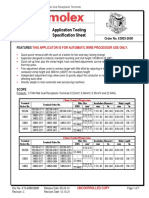

FineAdjust for Mini-Fit Crimp Terminals

FineAdjust

Applicator Application Tooling

Specification Sheet

Order No. 63902-3900

FEATURES

Quick punch removal with the push of a button for fast and easy tooling change

Applicator designed to industry standard mounting and shut height 135.80mm (5.346")

Quick set-up time; plus the crimp height, track and feed adjustments can be set without removing the applicator

from the press

Fine adjustment allows users to achieve target with little effort by adjusting in increments of .015mm (.0006") for

conductor crimp height and .063mm (.0025") for insulation height

Independent adjustment rings allow users to quickly adjust the conductor or insulation crimp height without

affecting each other

Directly adapts to most automatic wire processing machines

SCOPE

Products: Mini-Fit Jr. ™, Mini-Fit HCS™, and Mini-Fit Plus HCS™ Crimp Terminal 18-24 AWG with smaller

insulation OD’s.

Insulation Diameter

Terminal Wire Size Strip Length

Terminal Order No. IPC/WHMA-A620 (1) Terminal (2)

Series No.

AWG mm² mm In. mm In. mm In.

39-00-0038 39-00-0055

39-00-0059 39-00-0073

39-00-0108 39-00-0114

39-00-0153 39-00-0163

39-00-0169 39-00-0175

39-00-0181 39-00-0194

5556 18-24 0.80-0.20 1.40-1.70 .055-.067 1.30-3.10 .051-.122 3.00-3.50 .118-.138

39-00-0200 39-00-0207

39-00-0213 39-00-0405

39-00-0407 39-00-0410

39-00-0419 39-00-0425

39-00-0428 39-00-0436

39-00-0440 40-13-0851

39-00-0040 39-00-0053

39-00-0061 39-00-0075

39-00-0120 39-00-0121

39-00-0126 39-00-0219

5558 39-00-0411 39-00-0420 18-24 0.80-0.20 1.40-1.70 .055-.067 1.30-3.10 .051-.122 3.00-3.50 .118-.138

39-00-0426 39-00-0427

39-00-0430 39-00-0437

40-01-0853 40-13-0853

98-00-0174

30490-0002 30490-1002

30490 18-24 0.80-0.20 1.40-1.70 .055-.067 1.30-3.10 .051-.122 3.00-3.50 .118-.138

30490-2002

Doc No: ATS-639023900 Release Date: 04-13-11 UNCONTROLLED COPY Page 1 of 7

Revision: C Revision Date: 11-11-21

FineAdjust for Mini-Fit Crimp Terminals

Insulation Diameter

Terminal Wire Size Strip Length

Terminal Order No. IPC/WHMA-A620 (1) Terminal (2)

Series No.

AWG mm² mm In. mm In. mm In.

44476 44476-1111 44476-1211 18-20 0.80-0.50 1.40-1.70 .055-.067 1.30-3.10 .051-.122 3.00-3.50 .118-.138

44478 44478-1111 44478-1211 18-20 0.80-0.50 1.40-1.70 .055-.067 1.30-3.10 .051-.122 3.00-3.50 .118-.138

44485-1211 44485-1311

44485 18-24 0.80-0.20 1.40-1.70 .055-.067 1.30-3.10 .051-.122 3.00-3.50 .118-.138

44485-1411

45750 45750-1111 45750-1211 18-20 0.80-0.50 1.40-1.70 .055-.067 1.65-2.95 .065-.116 3.00-3.50 .118-.138

46012-1111 46012-1141

46012 46012-1211 46012-1241 18-20 0.80-0.50 1.40-1.70 .055-.067 1.65-2.95 .065-.116 3.00-3.50 .118-.138

46012-1261

46018 46018-1541 18-20 0.80-0.50 1.40-1.70 .055-.067 1.65-2.95 .065-.116 3.00-3.50 .118-.138

46083-1111 46083-1121

46083 18-20 0.80-0.50 1.40-1.70 .055-.067 1.65-2.95 .065-.116 3.00-3.50 .118-.138

46083-1211 46083-1221

46098 46098-1541 18-20 0.80-0.50 1.40-1.70 .055-.067 1.65-2.95 .065-.116 3.00-3.50 .118-.138

46134-1111 46134-1121

46134 18-20 0.80-0.50 1.40-1.70 .055-.067 1.65-2.95 .065-.116 3.00-3.50 .118-.138

46134-1211 46134-1221

(1) To achieve optimum IPC-A620 insulation crimps, use this insulation OD range.

(2) Overall insulation OD specification for terminal.

Applicator 63900-2600 should be used for insulation OD 2.50-2.95mm (example UL1015).

Applicator 63900-2900 should be used for insulation OD 1.65-2.05mm (example UL1007).

Applicator 63901-5600 should be used for insulation OD 1.90-2.30mm.

Applicator 63902-4900 should be used for insulation OD 2.30-2.60mm.

DEFINITION OF TERMS

BEND UP

ROLLING

BELL SEAM

BRUSH CONDUCTOR

MOUTH

CRIMP

INSULATION

CRIMP

TWISTING

STRIP

LENGTH BEND

DOWN

CUT-OFF

TAB CRIMP HEIGHT

The above terminal drawing is a generic terminal representation. It is not an image of a terminal listed in the

scope.

Doc No: ATS-639023900 Release Date: 04-13-11 UNCONTROLLED COPY Page 2 of 7

Revision: C Revision Date: 11-11-21

FineAdjust for Mini-Fit Crimp Terminals

CRIMP SPECIFICATION

Bell mouth Cut-off Tab Maximum Conductor Brush

Terminal Series No.

mm In. mm In. mm In.

5556 0.20-0.50 .008-.020 0.30 .012 0.00-1.00 .000-.039

5558 0.20-0.50 .008-.020 0.30 .012 0.00-1.00 .000-.039

30490 0.20-0.50 .008-.020 0.30 .012 0.00-1.00 .000-.039

44476 0.20-0.50 .008-.020 0.30 .012 0.00-1.00 .000-.039

44478 0.20-0.50 .008-.020 0.30 .012 0.00-1.00 .000-.039

44485 0.20-0.50 .008-.020 0.30 .012 0.00-1.00 .000-.039

45750 0.20-0.50 .008-.020 0.30 .012 0.00-1.00 .000-.039

46012 0.20-0.50 .008-.020 0.30 .012 0.00-1.00 .000-.039

46018 0.20-0.50 .008-.020 0.30 .012 0.00-1.00 .000-.039

46083 0.20-0.50 .008-.020 0.30 .012 0.00-1.00 .000-.039

46098 0.20-0.50 .008-.020 0.30 .012 0.00-1.00 .000-.039

46134 0.20-0.50 .008-.020 0.30 .012 0.00-1.00 .000-.039

Punch Width (Ref)

Bend up Bend down Twist Roll

Terminal Series No. Conductor Insulation

Degree Degree mm In. mm In.

5556 and 5558 5 2 5 15 1.60 .063 2.00 .079 Seam

30490 5 2 5 15 1.60 .063 2.00 .079

44476, 44478 and 44485 5 2 5 15 1.60 .063 2.00 .079 Seam shall not be open

45750 5 2 5 15 1.60 .063 2.00 .079 And no wire allowed out

46012 and 46018 5 2 5 15 1.60 .063 2.00 .079 of the crimping area

46083 5 2 5 15 1.60 .063 2.00 .079

46098 5 2 5 15 1.60 .063 2.00 .079

46134 5 2 5 15 1.60 .063 2.00 .079

After crimping, the crimp profiles should measure the following:

Conductor

Wire Size Pull Force Minimum

Terminal Series No. Crimp Height Crimp Width (Ref)

AWG mm2 mm In. mm In. N Lb.

18 0.80 0.97-1.07 .038-.042 1.68 .066 88.0 19.8

20 0.50 0.95-1.04 .037-.041 1.66 .065 58.7 13.2

5556

22 0.35 0.85-0.94 .033-.037 1.65 .065 39.1 8.8

24 0.20 0.79-0.87 .031-.034 1.63 .064 29.3 6.6

18 0.80 0.97-1.07 .038-.042 1.68 .066 88.0 19.8

20 0.50 0.95-1.04 .037-.041 1.66 .065 58.7 13.2

5558

22 0.35 0.85-0.94 .033-.037 1.65 .065 39.1 8.8

24 0.20 0.79-0.87 .031-.034 1.63 .064 29.3 6.6

18 0.80 0.97-1.07 .038-.042 1.68 .066 88.0 19.8

20 0.50 0.95-1.04 .037-.041 1.66 .065 58.7 13.2

30490

22 0.35 0.85-0.94 .033-.037 1.65 .065 39.1 8.8

24 0.20 0.79-0.87 .031-.034 1.63 .064 29.3 6.6

18 0.80 0.97-1.07 .038-.042 1.68 .066 68.4 15.4

44476

20 0.50 0.95-1.04 .037-.041 1.66 .065 58.7 13.2

18 0.80 0.97-1.07 .038-.042 1.68 .066 68.4 15.4

44478

20 0.50 0.95-1.04 .037-.041 1.66 .065 58.7 13.2

18 0.80 0.97-1.07 .038-.042 1.68 .066 88.0 19.8

20 0.50 0.95-1.04 .037-.041 1.66 .065 58.7 13.2

44485

22 0.35 0.85-0.94 .033-.037 1.65 .065 39.1 8.8

24 0.20 0.79-0.87 .031-.034 1.63 .064 29.3 6.6

Doc No: ATS-639023900 Release Date: 04-13-11 UNCONTROLLED COPY Page 3 of 7

Revision: C Revision Date: 11-11-21

FineAdjust for Mini-Fit Crimp Terminals

Conductor

Wire Size Pull Force Minimum

Terminal Series No. Crimp Height Crimp Width (Ref)

AWG mm2 mm In. mm In. N Lb.

18 0.80 0.97-1.07 .038-.042 1.68 .066 68.4 15.4

45750

20 0.50 0.84-0.94 .033-.037 1.66 .065 58.7 13.2

18 0.80 0.97-1.07 .038-.042 1.68 .066 68.4 15.4

46012

20 0.50 0.84-0.94 .033-.037 1.66 .065 58.7 13.2

18 0.80 0.97-1.07 .038-.042 1.68 .066 68.4 15.4

46018

20 0.50 0.84-0.94 .033-.037 1.66 .065 58.7 13.2

18 0.80 0.97-1.07 .038-.042 1.68 .066 68.4 15.4

46083

20 0.50 0.84-0.94 .033-.037 1.66 .065 58.7 13.2

18 0.80 0.97-1.07 .038-.042 1.68 .066 68.4 15.4

46098

20 0.50 0.84-0.94 .033-.037 1.66 .065 58.7 13.2

18 0.80 0.97-1.07 .038-.042 1.68 .066 68.4 15.4

46134

20 0.50 0.84-0.94 .033-.037 1.66 .065 58.7 13.2

Tool Qualification Notes:

1. Pull Force should be measured with no influence from the insulation crimp.

2. The above specifications are guidelines to an optimum crimp.

Doc No: ATS-639023900 Release Date: 04-13-11 UNCONTROLLED COPY Page 4 of 7

Revision: C Revision Date: 11-11-21

FineAdjust for Mini-Fit Crimp Terminals

PARTS LIST

FineAdjust Applicator 63902-3900

Item Order No Engineering No. Description Quantity

Perishable Tooling

63902-3970 63902-3970 Tool Kit (All “Y” Items) REF

1 63444-1609 63444-1609 Conductor Punch 1Y

2 63445-1646 63445-1646 Conductor Anvil 1Y

3 63446-1815 63446-1815 Insulation Punch 1Y

4 63445-1819 63445-1819 Insulation Anvil 1Y

5 63443-0002 63443-0002 Front Cut-Off Plunger 1Y

6 63443-0012 63443-0012 Front Plunger Retainer 1Y

Other Components

7 11-18-4083 60707-8 Feed Guide 1

8 11-24-1067 4996-4 Cut-Off Plunger Spring 1

9 63443-0009 63443-0009 Front Scrap Chute 1

10 63443-0024 63443-0024 Key 1

11 63443-0090 63443-0090 Wire Stop 1

12 63443-1717 63443-1717 Height Spacer 1

13 63443-2216 63443-2216 Coarse Spacer (16.00mm) 1

14 63443-2302 63443-2302 Fine Spacer (3.10mm) 1

15 63443-2802 63443-2802 Plunger Striker 1

16 63443-2908 63443-2908 Wire Hold Down Plunger 1

17 63443-6111 63443-6111 Rear Cover 1

18 63600-1057 63600-1057 Compression Spring 1

Frame

19 63800-4901 63800-4901 Top 1

20 63801-3281 63801-3281 Base 1

21 63801-4650 63801-4650 Track 1

Hardware

22 N/A N/A M3 by 6 Long SHCS 2**

23 N/A N/A M3 by 6 Long FHCS 1**

24 N/A N/A M4 by 6 Long SHCS 2**

25 N/A N/A M4 by 12 Long BHCS 2**

26 N/A N/A M4 by 50 Long SHCS 2**

27 N/A N/A M5 by 12 Long SHCS 1**

28 N/A N/A #10-32 by 3/8”Long Flat Point SSS 1**

29 N/A N/A #10-32 Hex Jam Nut 1**

** Available from an industrial supply company such as MSC (1-800-645-7270).

Doc No: ATS-639023900 Release Date: 04-13-11 UNCONTROLLED COPY Page 5 of 7

Revision: C Revision Date: 11-11-21

FineAdjust for Mini-Fit Crimp Terminals

Assembly Drawing

19

28

29

18

15

25 (2)

16

17

19

21

22 20

(2) 11

7

27

14

5 24

2

4

8

13

6 11

12

10

Figure 1

23

(2)

9

26 24

Doc No: ATS-639023900 Release Date: 04-13-11 UNCONTROLLED COPY Page 6 of 7

Revision: C Revision Date: 11-11-21

FineAdjust for Mini-Fit Crimp Terminals

NOTES

1. Molex recommends an extra perishable tooling kit be maintained at your facility.

2. Verify tooling alignment by manually cycling the press and Applicator before crimping under power. Check that

all screws are tight.

3. Slugs, Terminals, Dirt and Oil should be kept clear of work area.

4. Wear safety glasses at all times.

5. For recommended maintenance refer to the FineAdjust Manual.

CAUTION: This applicator should only be used in a press with a shut height of 135.80 mm (5.346”). Tooling

damage could result at a lower setting.

CAUTION: To prevent injury never operate this Applicator without the guards supplied with the press or wire-

processing machine in place. Reference the press or wire processing manufacturer’s instruction manual.

CAUTION: Molex crimp specifications are valid only when used with Molex terminals, applicators and tooling.

Application Tooling Support

Phone: (402) 458-TOOL (8665)

E-Mail: toolingsupport@molex.com

Website: www.molex.com/applicationtooling

Molex is a registered trademark of Molex, LLC in the United States of America and may be registered in other countries; all other trademarks

listed herein belong to their respective owners.

Doc No: ATS-639023900 Release Date: 04-13-11 UNCONTROLLED COPY Page 7 of 7

Revision: C Revision Date: 11-11-21

You might also like

- YHD-1100DW 2D Wireless Barcode Scanner Manual GuideDocument27 pagesYHD-1100DW 2D Wireless Barcode Scanner Manual GuideAnonymous kkAd5v3xNo ratings yet

- Art - Scribble Art Lesson PlanDocument3 pagesArt - Scribble Art Lesson Planapi-534995697No ratings yet

- NEMA IEC Body Phantom SetDocument1 pageNEMA IEC Body Phantom SetdridiNo ratings yet

- Fineadjust Applicator Specification Sheet Order No. 63900-0100Document5 pagesFineadjust Applicator Specification Sheet Order No. 63900-0100Amine MaaouiNo ratings yet

- 5556 Series Approval SpecificationDocument8 pages5556 Series Approval SpecificationEnzo AscañoNo ratings yet

- Hand Crimp Tool Specification Sheet: Order No. 63811-5200Document6 pagesHand Crimp Tool Specification Sheet: Order No. 63811-5200AbhinavNo ratings yet

- Crimp Tool For King InstallsDocument6 pagesCrimp Tool For King InstallssafariNo ratings yet

- App 2037023000Document6 pagesApp 2037023000danielNo ratings yet

- Application Tooling Specification Sheet: Fineadjust Applicator Order No. 63903-2600 FeaturesDocument7 pagesApplication Tooling Specification Sheet: Fineadjust Applicator Order No. 63903-2600 FeaturesAmine MaaouiNo ratings yet

- Molex Maquina Terminales 2002181900-000Document8 pagesMolex Maquina Terminales 2002181900-000FransoloNo ratings yet

- Features: Hand Crimp Tool Specification Sheet Order No. 63819-1300Document9 pagesFeatures: Hand Crimp Tool Specification Sheet Order No. 63819-1300Jose Antonio Huitron NuñezNo ratings yet

- Aiwa CX Nv700lh NSX v700Document34 pagesAiwa CX Nv700lh NSX v700Iva Ne100% (1)

- Brosur Breaker SOOSAN SB Series (New)Document8 pagesBrosur Breaker SOOSAN SB Series (New)HidayatNo ratings yet

- Sirius 3rfDocument201 pagesSirius 3rfRaul E. SoliNo ratings yet

- Harfon Sensor 01Document56 pagesHarfon Sensor 01Martha RuizNo ratings yet

- Manual Instalación Radar Furuno 1622iDocument24 pagesManual Instalación Radar Furuno 1622ipevalpevalNo ratings yet

- Turbine Flow MeterDocument33 pagesTurbine Flow MeterPandeyNo ratings yet

- Bergeon ScrewdriverDocument4 pagesBergeon ScrewdriverGene4MoNo ratings yet

- CMMT-As EMMT-As Preferred Combinations en 202308Document5 pagesCMMT-As EMMT-As Preferred Combinations en 202308rwnl2003No ratings yet

- Medidores Rotativos Série FMRDocument3 pagesMedidores Rotativos Série FMRmateuNo ratings yet

- Warning: Installation Instructions - 14 Gauge C-Track SystemDocument4 pagesWarning: Installation Instructions - 14 Gauge C-Track SystemjorafestNo ratings yet

- Thread Pitch ChartDocument2 pagesThread Pitch ChartGeorgeMtyNo ratings yet

- Antigo LMR400Document4 pagesAntigo LMR400Joao CarameloNo ratings yet

- 24V - D3427 and 5V D3423Document14 pages24V - D3427 and 5V D3423Pradeeban NNo ratings yet

- Bar L/H KW: High-Pressure Washers - Cold WaterDocument2 pagesBar L/H KW: High-Pressure Washers - Cold WaterMhel TagalagNo ratings yet

- AD Drilling Manual 600 Series 2018pangeaDocument20 pagesAD Drilling Manual 600 Series 2018pangearoberto funezNo ratings yet

- Type 680 Hydraulic Stage CollarDocument6 pagesType 680 Hydraulic Stage Collar唐辉No ratings yet

- LC0406FC3.3C LC0406FC36C: ApplicationsDocument6 pagesLC0406FC3.3C LC0406FC36C: ApplicationsselocaNo ratings yet

- RC 750Document7 pagesRC 750ahmetNo ratings yet

- 650 01 GB 0111 01Document12 pages650 01 GB 0111 01Phan HaiNo ratings yet

- Rigid Flexible Waveguide ComponentsDocument10 pagesRigid Flexible Waveguide Componentsapi-30606527No ratings yet

- Libro 7 1Document38 pagesLibro 7 1romanNo ratings yet

- Sistema Surface Scanning Probe Series For Opcs - Product CatalogueDocument6 pagesSistema Surface Scanning Probe Series For Opcs - Product CatalogueLinh NgoNo ratings yet

- 31a10 PSV 001Document3 pages31a10 PSV 001JITHIN VIJAYANNo ratings yet

- En DocksDocument2 pagesEn DocksArmando SantiagoNo ratings yet

- Brochures - Bucking Unit+Power StationDocument9 pagesBrochures - Bucking Unit+Power StationWei ShangNo ratings yet

- Cable Gland Types E1W, E2W, E1X, E2X, E1U & E2UDocument2 pagesCable Gland Types E1W, E2W, E1X, E2X, E1U & E2UWidhi ImranovichNo ratings yet

- New Products Mets 2019Document38 pagesNew Products Mets 2019Sh LzNo ratings yet

- Hoyt AMMETERDocument3 pagesHoyt AMMETERDayanna MorenoNo ratings yet

- Antenna&MillimeterDocument60 pagesAntenna&MillimeterShaina SharmaNo ratings yet

- 8017031Document4 pages8017031alisuseNo ratings yet

- Price List Fortindo 2021 Fortindo IdDocument143 pagesPrice List Fortindo 2021 Fortindo IdRijal Al KautsarNo ratings yet

- Krausz Spesifications Hymax-Flensemuffe enDocument4 pagesKrausz Spesifications Hymax-Flensemuffe enibrahimNo ratings yet

- CTX 400Document5 pagesCTX 400Brzata PticaNo ratings yet

- fwmpc.18 PXT-K InstallDocument15 pagesfwmpc.18 PXT-K Installozeias.rosaNo ratings yet

- Fineadjust Applicator Applicator Tooling Specification Order No. 63901-7400Document5 pagesFineadjust Applicator Applicator Tooling Specification Order No. 63901-7400Ernesto VelásquezNo ratings yet

- Zenith Technical Data Sheet - 30 To 120 Liters - SignedDocument1 pageZenith Technical Data Sheet - 30 To 120 Liters - Signedusama arainNo ratings yet

- 106 CmasDocument2 pages106 CmasPablo DpNo ratings yet

- Sony hcd-fc8, fc9 PDFDocument140 pagesSony hcd-fc8, fc9 PDFRaymundo Moran LopezNo ratings yet

- Spares Estimation Elect Line1Document10 pagesSpares Estimation Elect Line1Muhammad NabeelNo ratings yet

- LMR 600Document4 pagesLMR 600Edytryk MghbjNo ratings yet

- 000-I-Ts-102 - DS - 2 PitDocument42 pages000-I-Ts-102 - DS - 2 PitCristian RománNo ratings yet

- Natraj Pricelist 17 PDFDocument8 pagesNatraj Pricelist 17 PDFlkchoudhuryNo ratings yet

- External Threads For Machine Screws and SEMSDocument2 pagesExternal Threads For Machine Screws and SEMSez1010No ratings yet

- Lifetime Warranty - Patent Number 4716989Document1 pageLifetime Warranty - Patent Number 4716989dgn tkyaNo ratings yet

- Archt 33 AssignmentDocument4 pagesArcht 33 AssignmentKean Matthew SantiagoNo ratings yet

- Press DetailsDocument36 pagesPress Detailssateesh_tpNo ratings yet

- AM3KA539 Combined Depth/Tension Measurement Device: With Low Voltage Tension AmplifierDocument27 pagesAM3KA539 Combined Depth/Tension Measurement Device: With Low Voltage Tension AmplifierDiego CorderoNo ratings yet

- Service Manual: 20J-S100/S100S CJ20S10 21MJ50Document30 pagesService Manual: 20J-S100/S100S CJ20S10 21MJ50Francisco BandresNo ratings yet

- En Pulsor170assemblyDocument2 pagesEn Pulsor170assemblysoorajssNo ratings yet

- Assembly and Torque Procedures For V-Band CouplingsDocument3 pagesAssembly and Torque Procedures For V-Band CouplingsFranco BasualdoNo ratings yet

- Evaluating Your ContentDocument4 pagesEvaluating Your ContentSalman TahirNo ratings yet

- Research and Policy FellowDocument1 pageResearch and Policy FellowConnCANNo ratings yet

- Cognitive Behavioral TheoryDocument28 pagesCognitive Behavioral TheoryAngela CabasNo ratings yet

- College Students' Need For Cognition, Academic Motivation, Performance, and Well-Being 2012Document19 pagesCollege Students' Need For Cognition, Academic Motivation, Performance, and Well-Being 2012Vania RamirezNo ratings yet

- Atlas Copco PDFDocument6 pagesAtlas Copco PDFPRASHANT KANTENo ratings yet

- 4a.plant LayoutDocument31 pages4a.plant LayoutSagar PhullNo ratings yet

- Clinical InvestigationsDocument152 pagesClinical InvestigationsDev MartelNo ratings yet

- Bullying Risk Factors and Prevention MethodsDocument11 pagesBullying Risk Factors and Prevention MethodsIsa RianoNo ratings yet

- Job Description-Demand PlanningDocument4 pagesJob Description-Demand PlanningTushit NathNo ratings yet

- Collection Indesign - 1 To 15Document15 pagesCollection Indesign - 1 To 15Nulled ByteNo ratings yet

- Focus 4 Unit 2 PersonalityDocument2 pagesFocus 4 Unit 2 Personalityk.nowakNo ratings yet

- Crest Audio 6 - 11-25-97Document2 pagesCrest Audio 6 - 11-25-97Justin WilliamsNo ratings yet

- Fluent-Intro 15.0 WS08b Vortex SheddingDocument39 pagesFluent-Intro 15.0 WS08b Vortex Sheddingmatteo_1234No ratings yet

- Generator Technical Submittal - Ac820-6Document128 pagesGenerator Technical Submittal - Ac820-6ahmed saadNo ratings yet

- Organic Cotton Yarn QualityDocument87 pagesOrganic Cotton Yarn QualityMuhammad Qamar TusiefNo ratings yet

- Research and TheoryDocument6 pagesResearch and TheoryWahengbam Rorrkychand100% (1)

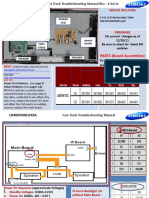

- Samsung LN46D550K1FXZA Fast Track Guide (SM)Document4 pagesSamsung LN46D550K1FXZA Fast Track Guide (SM)Carlos OdilonNo ratings yet

- PDF Note - Doors and WindowsDocument10 pagesPDF Note - Doors and WindowsAbhayNo ratings yet

- La Calidad Cambia Al Mundo SANY Heavy Industry Co., LTDDocument34 pagesLa Calidad Cambia Al Mundo SANY Heavy Industry Co., LTDEvert Vargas Torrez100% (1)

- Quality Control & Quality AssuranceDocument75 pagesQuality Control & Quality Assurancemuhammad omerNo ratings yet

- Figure M 39 Ethanol Water MixtureDocument10 pagesFigure M 39 Ethanol Water MixturediegoNo ratings yet

- Development of TherapistDocument15 pagesDevelopment of TherapistChetna DuggalNo ratings yet

- Nitocote CM210 PDFDocument4 pagesNitocote CM210 PDFAnggieta AyuNo ratings yet

- 74756562Document29 pages74756562Jose Graca Vieira AndradeNo ratings yet

- 2022-12-15 StrategiesDocument1 page2022-12-15 StrategiesquemilangaNo ratings yet

- An Expansion For XDocument2 pagesAn Expansion For XErivelton VitorNo ratings yet

- Lesson Plan Sept 21 and 22Document3 pagesLesson Plan Sept 21 and 22api-532275056No ratings yet