Professional Documents

Culture Documents

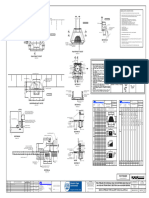

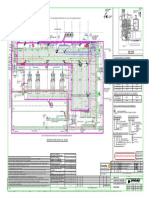

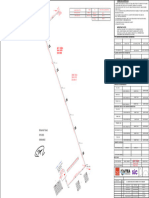

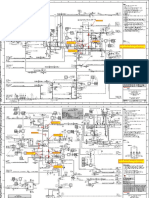

GD51 247 C1047.01 - 32 - 3 600mm PRECAST PIPE CULVERT WING WALL DETAILS

GD51 247 C1047.01 - 32 - 3 600mm PRECAST PIPE CULVERT WING WALL DETAILS

Uploaded by

Hudu JegaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GD51 247 C1047.01 - 32 - 3 600mm PRECAST PIPE CULVERT WING WALL DETAILS

GD51 247 C1047.01 - 32 - 3 600mm PRECAST PIPE CULVERT WING WALL DETAILS

Uploaded by

Hudu JegaCopyright:

Available Formats

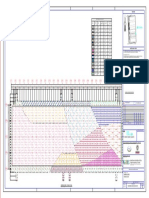

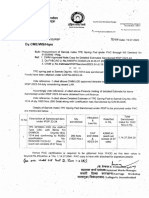

GD51/247 A

t t t t t t GENERAL INSITU CONCRETE NOTES:

1.1. CUT OFF WALLS TO BE CONSTRUCTED AT BOTH INLET AND OUTLET SIDES.

SHOULDER BREAK POINT

t 1.2. GABION SCOUR PROTECTION TO BE CONSTRUCTED AT OUTLET ONLY. EXTENT OF

INLET/OUTLET PROTECTION SPECIFIED ON DRAINAGE SCHEDULE.

100 100

85 2835 85 t = PIPE THICKNESS

2. MATERIAL SPECIFICATIONS

2.1. CONCRETE CLASS : 30/20 THROUGHOUT OR AS SPECIFIED

1420 1420

A03/ 5Y10 2.2. MINIMUM CEMENTITIOUS CONTENT : 300 kg/m3 THROUGHOUT.

75mm Ø WEEPHOLES

200 600Ø 600Ø 600Ø 200 2.3. GABIONS AND GEOTEXTILE : AS SHOWN.

PIPE WALL 2.4. STEEL REINFORCEMENT : HIGH TENSILE STEEL 450 MPa.

17

5

2.5. WELDED STEEL MESH : HIGH TENSILE STEEL 485 MPa.

B

150

A11/ Y10

17

5

2.6. WELDED STEEL MESH REINFORCEMENT TO CONFORM TO SANS 1024.

400

250

B03/ SMF 617 WELDED 3. CONCRETE FINISH

15

90

D D STEEL MESH IN 3.1. NON VISIBLE SURFACES F1

90

15

WINGWALL 3.2. VISIBLE SURFACES F2

13

30

t = PIPE THICKNESS 3.3. UNIFORM SURFACES U2

30

13

15

0 B 15

0

1400

A07/ Y10

20 4. ALL EXPOSED SHARP EDGES TO HAVE 20 x 20mm CHAMFERS.

1150

30° 0

0 30° 20

E E 200

5. MINIMUM CONCRETE COVER = 50mm.

13

30

30

13

6. REINFORCING LAP LENGTH = 45d.

175

100

6. HEADWALL TO BE 50mm ABOVE FILL SLOPE AND NOT MORE THAN 50mm ABOVE THE

SECTION G-G SHOULDER BREAK POINT.

Z1/ 9Y16-500

130 175 175 130 GALVANISED SCALE 1:10

7. THE NECESSITY AS WELL AS THE EXTENT OF GABION MATTRESS PROTECTION TO BE

ANCHORS

B01/ SMF 617 WELDED SPECIFIED BY THE ENGINEER.

305 665 1330 1330 665 305 STEEL MESH

8. CUT-OFF WALLS TO FORM AN INTEGRAL PART OF APRON OR BASE SLABS.

2420

A

PLAN OF INLET / OUTLET

F E

SCALE 1:25

A05/ 2Y10 EF

A10/ 1Y10 EF A10/ 1Y10 EF

A08/ 2Y10 A08/ 2Y10

A04

A04

A04

A04

A04

A04

A08 A05 A08

A08 A05 A08 A04/ 6Y10

A0

A0

9

9

9

A0

A06 A06

A0

A0

A0

A10

A10

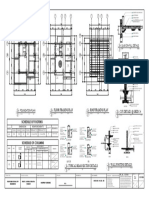

REINFORCEMENT NOTES SANS 282-2011: SHAPE CODES AND 99 CODES

9

A09/ Y10 EF

A06/ Y10 A06/ Y10

A07 A07

20 49 99K

A07/ Y10 G A07/ Y10 G 1. BEND TO 2d RADIUS FOR MILD STEEL BARS AND 3d RADIUS R = 2d FOR MILD STEEL B D

A06 A06 FOR HIGH TENSILE STEEL BARS UNLESS LARGER RADII ARE R = 3d FOR HIGH TENSIE STEEL

9

A0

A

A0

A0

9

A0

9

9

INDICATED FOR THE PARTICULAR SHAPE CODE.

A0

D

E

A0

9

9

B

A06/ Y10 A06/ Y10

A

A02a 2. STEEL SHALL COMPLY WITH THE LATEST VERSION OF SANS

(E)

A03/ 5Y10 A03/ 5Y10 C

A01

920.

A03

A03

SHOULDER BREAK POINT R R

A02b 3. MILD STEEL BARS SHALL BE PLAIN AND HIGH TENSILE STEEL C

A01/ 15Y10-250 BARS DEFORMED.

37 60 99AD

4. MILD STEEL BARS ARE IDENTIFIED BY A CAPITAL 'R' AND STANDARD HOOKS AND BENT ENDS

HIGH TENSILE STEEL BARS BY A CAPITAL 'Y' PREFIXED TO D

75mm Ø WEEPHOLES 3010 FLOOR SURFACE ON WHICH

A02b/ 4Y10-250 NF A02a/ 4Y10-250 FF THE DIAMETER IN mm.

A

WING WALLS ARE TO BE

C

B

ERECTED MUST FIRST BE 5. STANDARD SHAPE CODE BENDING DIMENSIONS SHALL BE IN

A

B

SCABBLED & CLEANED ACCORDANCE WITH SANS 282 AND 99 SHAPE CODE BENDING

F E A

200

B

DIMENSIONS AS SHOWN ON THIS SHEET. B

A

545

6. ALL BARS SHALL BE BENT COLD. A

7. WELDING SHALL NOT BE PERMITTED FOR STEEL BAR 38 62

845

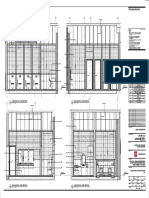

ELEVATION OF INLET / OUTLET

600Ø

600Ø

600Ø

REINFORCEMENT.

C

8. WELDING ON MILD STEEL BARS SHALL BE IN ACCORDANCE

200 300

CONSTRUCTION JOINT SCALE 1:25 MEASUREMENT OF OFFSETS AT FREE ENDS B

WITH SANS 044 AND BS 1856 OR BS 693.

B

9. ALL DIMENSIONS GIVEN FOR THE SHAPE CODES ARE EXTERNAL A A

UNLESS OTHERWISE INDICATED ON THE DRAWINGS OR BENDING C

SCHEDULE.

B

800

200 600Ø 600Ø 600Ø 200 B03/ SMF 617 WELDED B03/ SMF 617 WELDED 10. THE CUTTING LENGTH TOLERANCE IS TAKEN UP IN THE LAST

t = PIPE THICKNESS STEEL MESH STEEL MESH C

t t t t t t DIMENSION OR IN HOOKS OR BENT ENDS WHERE PRESENT.

B02/ SMF 617 WELDED B02/ SMF 617 WELDED

STEEL MESH STEEL MESH

(STARTERS) (STARTERS)

305 665 2665 665 305

ELEVATION OF INLET / OUTLET B01/ SMF 617 WELDED

STEEL MESH PROJECT

SHEET: 001 PROJECT No.: . SHEET: 001

SCALE 1:25 No.:

TITLE: TYPICAL PIPE HEADWALL DATE: 07/08/2020 TITLE: TYPICAL PIPE HEADWALL DATE:

SECTION D-D SNAVIA Building Tel : (012) 842-0000 P O BOX 72727 SNAVIA Building Tel : (012) 842-0000 P O BOX 72727

285 Albertus Street Fax : (012) 803-4429 Lynnwood Ridge

600Ø PIPE HEADWALL DRG REF: 285 Albertus Street Fax : (012) 803-4429 Lynnwood Ridge 3/600 DIA. PIPE ɑ = 0 DRG REF: .

SCALE 1:25 La Montagne e-mail : pta@sna.co.za 0040 La Montagne e-mail : pta@sna.co.za 0040

0184 Web : www.sna.co.za MESH SCHEDULE REV No.: 0184 Web : www.sna.co.za

. REV No.: .

TOTAL AREA

No. MATS TOTAL BARS TOTAL CUT

200 BAR No. PER

AREA MASS BAR TYPE No. OF

LENGTH

SHAPE A B C D E/R

MEMBER SMF OF PER UNIT BENDING DIMENSIONS PER MAT MEMBER PER No. OF

MARK OF MARK DIA UNITS CODE (mm) (mm) (mm) (mm) (mm)

UNITS UNIT (m2) (kg) UNIT BARS (mm)

MATS (m2)

GEOTEXTILE GRADE 1 BONDED TO A04/ 2Y10 A05/ 4Y10

B01 617 2 1 2 5.5 11.0 68 600 DIA. A01 Y10 2 15 30 2100 60 670 300

WALL USING BITUMINOUS ADHESIVE 4460

OR SIMILAR APPROVED PRODUCT PIPE A02a Y10 2 4 8 2950 20 2950

755 2950 755

HEADWALL A02b Y10 2 4 8 3300 20 3300

FROM 300 TO 845

A03 Y10 2 10 20 1450 37 1300 (150)

200

A04 Y10 2 6 12 700 60 120 150

APRON SLAB

1305

1305

1450

1450

75mm Ø WEEPHOLES B01/ SMF 617 WELDED A05 Y10 2 4 8 2800 20 2800

230x100x500mm LONG PRECAST 'NO FINES' STEEL MESH A06 Y10 2 4 8 1100 99AD 150 350 165 70

75 CONCRETE BLOCKS CONTINUOUSLY PLACED

A07 Y10 2 2 4 900 99AD 150 250 165 70

A02b/ 4Y10-250

A02a/ 4Y10-250

WITH GEOTEXTILE GRADE 1 AS SHOWN

145

145

Z1/ Y16-500 A08 Y10 2 4 8 1200 99K 500 215 165 215 (500)

1:10 GALVANISED 250 250

3960 A09 Y10 2 24 48 750 49 200 200 (350) 140 140

CONCRETE SCREED ANCHORS

100

4460

57

A10 Y10 2 4 8 1450 37 1300 (150)

CONSTRUCTION JOINT B04/ SMF 617 A11 Y10 2 6 12 800 62 200 175 (600)

55 WELDED STEEL MESH

B02 617 2 2 4 1.1 4.4 27.2

WINGWALL STARTERS

1280

200

SHOULDER BREAK POINT 500

A01/ Y10-250

GALV. Z1 Y16 2 9 18 1600 20 1600

500 380

SLOPE FILL AS APPLICABLE

380

SECTION E-E FOLD

880

ANCHORS

1400 500

SCALE 1:25

1150 250

SECTION B-B 100 B03 617 2 2 4 0.8 3.2 19.7

SCALE 1:10

50

A08/ 2Y10

200

1280

t

WINGWALL

545

6.0m x 2.0m x 0.3m GABION A11/ 3Y10-250

355 525

845

MATTRESSES IF REQUIRED

880

600Ø

(VOIDS FILLED WITH 1:3 CEMENT /

150

SAND MORTAR) 800 A06/ Y10

300

C.J.

t

A07/ Y10

200

300

A11

B01/ SMF 617 WELDED A06/ Y10 B04 617 2 1 2 4.5 9.0 55.5

800

STEEL MESH 3890

A03/ Y10

500

500

A02b/ 4Y10-250

A02a/ 4Y10-250

DROP WALL

GEOTEXTILE GRADE 1 75mm

650 500

CONCRETE Z1/ Y16-500 FOLD

1150

650

SCREED GALVANISED

ANCHORS

250 900 400 CLASS 'A' OR 'C'

6.0m x 1.0m x 0.5m

BEDDING B04/ SMF 617

GABION BOXES IF 1550

REQUIRED WELDED STEEL MESH

500 REINFORCEMENT MASSES (kg) DETAILED BY: REINFORCEMENT MASSES (kg) DETAILED BY:

A01/ Y10-250

Y16-500 GALVANISED ANCHORS FOR DIAMETER 193 245 311 500 617 746 TOTAL AREA (m2) TOTAL MASS (kg) M Christodoulou DIAMETER 6 8 10 12 16 20 25 32 40 TOTAL M Joannou

GABION MATTRESSES 1.6m LONG AREA 27.6 CHECKED BY: MILD STEEL . CHECKED BY:

SECTION F-F MASS 170.4

28 171

M Joannou H.T. STEEL 162.7 45.4 208 M Christodoulou

SECTION A-A SCALE 1:25

SCALE 1:25

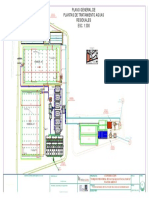

FOR TENDER 0m 50 m 100 m

(FOR TENDER PURPOSES ONLY)

1 cm = 10 m for A0 size

APPROVED APPROVED P.R.E's FILE NO. SCALE

No. DATE ADDITIONS AND AMENDMENTS DESIGNED BY: M.CHRISTODOULOU

V1 15/07/2020 ORIGINAL VERSION

CONS. ENG.

KM

PRE CIVIL AND STRUCTURAL ENGINEERS (PTY) LTD.

_ _ _ _ _ _ _ _ _ _

THIS APPROVAL IS FOR PROCEDURAL AND

ADMINISTRATIVE REVIEW PURPOSES

ONLY AND DOES NOT ATTRACT LEGAL

THE UPGRADE OF DIVISIONAL ROAD 1618 BETWEEN MAIN ROAD 347 TPW16/6/4/1/5-DR01618-C1047.01 AS SHOWN

CHECKED BY: K.MALCOMSON TEL : 021-930 8971

FAX : 088 021-930 7298

Reg. No. 2005/006128/07

CONSULTING ENGINEERS

LIABILITY OF ANY KIND FROM

WHATSOEVER OR HOWEVER ARISING

(km 0.00) AND TRUNK ROAD 2 SECTION 9 (km 4.44) NEAR GEORGE CONTRACT NO. WCG STRUCTURE PLAN

E-mail : capetown@sna.co.za C1047.01 -

DRAWN BY: M.JOANNOU GROUND FLOOR P.O. BOX 15287 _ _ _ _ _ _ _ _ _ _ _ _

PLATTEKLOOF OFFICE PARK PANORAMA

DATE: _ _ _ _ _ _ _

PROVINCIAL ROADS ENGINEER CONSULTANTS DWG NO. WCG INDEX NO. VER

CHECKED BY: K.MALCOMSON

BLOULELIE STREET

PLATTEKLOOF

PAROW

7506

DATE: _ _ _ _ _ _ _ _

3/600mm Ø PRECAST PIPE CULVERT WING WALL DETAILS SNA/C1047.01/32 GD51/247 V1

You might also like

- General Design Specification: 076971C 0000 JSD 1700 01 B 1/59Document59 pagesGeneral Design Specification: 076971C 0000 JSD 1700 01 B 1/59aegean227No ratings yet

- Column Shop DrawingDocument1 pageColumn Shop DrawingdantevariasNo ratings yet

- Audit Checklist - Material ControlDocument4 pagesAudit Checklist - Material ControlAngel Angeleye100% (2)

- GD51 245 C1047.01 - 30 - 600mm PRECAST PIPE CULVERT WING WALL DETAILSDocument1 pageGD51 245 C1047.01 - 30 - 600mm PRECAST PIPE CULVERT WING WALL DETAILSClement TakavarashaNo ratings yet

- ST NDDocument11 pagesST NDAbe babooNo ratings yet

- YMM800005Document12 pagesYMM800005Vinicius NevesNo ratings yet

- 1 - Colonne - 101C100: e D B CDocument1 page1 - Colonne - 101C100: e D B CGleyner JulioNo ratings yet

- SS-1 Deep Well Earth PitDocument1 pageSS-1 Deep Well Earth PitM&N ProjectsNo ratings yet

- A1.22 - ROOF PLAN - BUILDING TYPE B Rev.1 MarkupDocument1 pageA1.22 - ROOF PLAN - BUILDING TYPE B Rev.1 MarkupjhamiralexNo ratings yet

- 01 - Amort. Pulsação - 1# Sucção - LP-1Document1 page01 - Amort. Pulsação - 1# Sucção - LP-1joaofbragasNo ratings yet

- Preliminary: Drawings NotesDocument1 pagePreliminary: Drawings Notesbatopotcholo03No ratings yet

- Red-Line Ne 2311000024 - FiberDocument1 pageRed-Line Ne 2311000024 - FiberMohamed F. AbdullahNo ratings yet

- Ohtl Route and Profile. Rev.0 - Part-3-1Document1 pageOhtl Route and Profile. Rev.0 - Part-3-1Hassan H AlshokyNo ratings yet

- C3349 DWG 1043 CaeDocument1 pageC3349 DWG 1043 Caeganesh kumarNo ratings yet

- EGMOND - II Corno in FaDocument2 pagesEGMOND - II Corno in FaGabriele BaiNo ratings yet

- Isolation Package For 25-T-01: Remove SpoolDocument2 pagesIsolation Package For 25-T-01: Remove SpoolAdel Moustafa NafrawyNo ratings yet

- Ea-0685780.0000.0 1Document1 pageEa-0685780.0000.0 1vs6jghbngzNo ratings yet

- PEDWPRTS771025A1 - Main Compressor B Train 1 - 5Document1 pagePEDWPRTS771025A1 - Main Compressor B Train 1 - 5macielNo ratings yet

- GF GCOT B 14 4002 - 1 SignedDocument2 pagesGF GCOT B 14 4002 - 1 SignedYuan DiNo ratings yet

- ZX230 270 Eng e PDFDocument1 pageZX230 270 Eng e PDFIksan RadenNo ratings yet

- 1 J I:'a L / Gi: I I I I I I I I IDocument1 page1 J I:'a L / Gi: I I I I I I I I IShivendra KumarNo ratings yet

- Gad LusDocument1 pageGad LusArun K RajNo ratings yet

- City Place Dania - Linear Interior Walls (Inside Units Only)Document7 pagesCity Place Dania - Linear Interior Walls (Inside Units Only)James RecañaNo ratings yet

- Road "B" Road "B": Thai Oil Public Company LimitedDocument1 pageRoad "B" Road "B": Thai Oil Public Company LimitedRachane NuanyaiNo ratings yet

- Foundation Plan and Anchor Locations: Section CDocument1 pageFoundation Plan and Anchor Locations: Section CJavier Guerra TriviñoNo ratings yet

- Drawing 3.Document1 pageDrawing 3.tiyaniNo ratings yet

- MFE Shell Plan - Signed OffDocument2 pagesMFE Shell Plan - Signed OffJuly FermiaNo ratings yet

- B737NG-v1 3Document1 pageB737NG-v1 3Akshay KharatNo ratings yet

- CAI - DWG-S-DD-S-W2-1001 Piling Plan - r1Document1 pageCAI - DWG-S-DD-S-W2-1001 Piling Plan - r1Ikade SuartanaNo ratings yet

- Amphi TheatreDocument1 pageAmphi TheatreanzaniNo ratings yet

- PB01B-CCW-001 Closed Cooling Water Distribution SystemDocument1 pagePB01B-CCW-001 Closed Cooling Water Distribution SystemzhangNo ratings yet

- PB02-HRH-001 Hot Reheat Steam SystemDocument1 pagePB02-HRH-001 Hot Reheat Steam SystemzhangNo ratings yet

- General Drawing Exchanger N°1Document1 pageGeneral Drawing Exchanger N°1calinvasco190670No ratings yet

- FLR A9sn Ep 3810 PD Is 5605 03Document1 pageFLR A9sn Ep 3810 PD Is 5605 03Brandon C LoyolaNo ratings yet

- Tilal Mall and Hotel Sharjah, UAE: Detail 1Document22 pagesTilal Mall and Hotel Sharjah, UAE: Detail 1Michael Camit Eso100% (1)

- GODFREY QUIERREZ-ModelDocument1 pageGODFREY QUIERREZ-Modelmarinel martinNo ratings yet

- HPS 1401HDocument1 pageHPS 1401Hapi-3826086No ratings yet

- Circuit Diagram Ultima CoupleDocument4 pagesCircuit Diagram Ultima CouplehoriNo ratings yet

- 21BP002-351-DD0-1GR020 - R0 - GirderDocument1 page21BP002-351-DD0-1GR020 - R0 - GirderDang TranNo ratings yet

- Floor Pattern Layout 1: Masterpiece Asia Properties IncDocument7 pagesFloor Pattern Layout 1: Masterpiece Asia Properties Incerwin leeNo ratings yet

- (Steps Going To Deck Roof) : LegendDocument1 page(Steps Going To Deck Roof) : LegendLowie Torres TonioNo ratings yet

- Saudi Arabian Oil Company: 282 A BA-274759 006 0B2Document1 pageSaudi Arabian Oil Company: 282 A BA-274759 006 0B2Mohamed Wasim ShaikhNo ratings yet

- NCGM XX XX D Aec DR 930 1103Document1 pageNCGM XX XX D Aec DR 930 1103yusufuNo ratings yet

- NCGM XX XX D Aec DR 930 1103Document1 pageNCGM XX XX D Aec DR 930 1103yusufuNo ratings yet

- 1-MEPs-ELECT-LTG-B4&7-0001 (SH 1-1) - R-2 (FND Reviewed) - LTG-B4-0001Document1 page1-MEPs-ELECT-LTG-B4&7-0001 (SH 1-1) - R-2 (FND Reviewed) - LTG-B4-0001muzeek306No ratings yet

- Drawing 4.Document1 pageDrawing 4.tiyaniNo ratings yet

- JB MC STR CA 202 r2Document1 pageJB MC STR CA 202 r2Fatih ArıkanNo ratings yet

- ZX110to130LCN CIRCUITDocument17 pagesZX110to130LCN CIRCUITSaul Baquero Quevedo100% (2)

- Plano General de Plantas de Tratamiento-Planta de Tratamiento GeneralDocument1 pagePlano General de Plantas de Tratamiento-Planta de Tratamiento GeneralarmandoteranbNo ratings yet

- High Level Canopy Plan: Baseplate 'Type 1'Document1 pageHigh Level Canopy Plan: Baseplate 'Type 1'kameshNo ratings yet

- Title NO. Material Q'Ty Sgrface Treatment Remark 1 - Heat TreatmentDocument1 pageTitle NO. Material Q'Ty Sgrface Treatment Remark 1 - Heat TreatmentHà Văn TúNo ratings yet

- Wh-1088pe DrawingDocument1 pageWh-1088pe Drawingom sai quality developmentNo ratings yet

- Nc0-Ep-710-2303 (A) - Diesel Pump Controller: 46b 6b 26b 88n 85n 87n J6Document4 pagesNc0-Ep-710-2303 (A) - Diesel Pump Controller: 46b 6b 26b 88n 85n 87n J6KechaouNo ratings yet

- Isometric View Lifting Detail: NotesDocument2 pagesIsometric View Lifting Detail: NotesRajveer SinghNo ratings yet

- A-609-Ladies Ablution & Toilet Detail's (Sheet 22)Document1 pageA-609-Ladies Ablution & Toilet Detail's (Sheet 22)Emmanuel InfanteNo ratings yet

- Fatehpur Slab Detail GF PDFDocument1 pageFatehpur Slab Detail GF PDFmohan890No ratings yet

- Focus: All Devices and Components To Match Base Built System Make and ModelDocument1 pageFocus: All Devices and Components To Match Base Built System Make and ModelArun UdayabhanuNo ratings yet

- Milliken's Complete Book of Instant Activities - Grade 4: Over 110 Reproducibles for Today's Differentiated ClassroomFrom EverandMilliken's Complete Book of Instant Activities - Grade 4: Over 110 Reproducibles for Today's Differentiated ClassroomNo ratings yet

- Instant Assessments for Data Tracking, Grade 1: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 1: Language ArtsNo ratings yet

- MRPMEPDocument26 pagesMRPMEPRajyalakshmiNo ratings yet

- F-Class: Four Bearing Vibrating ScreenDocument23 pagesF-Class: Four Bearing Vibrating ScreenkosmcNo ratings yet

- John Crane StrategiesDocument17 pagesJohn Crane StrategiesNitin PathaniaNo ratings yet

- MD ST C - 28420101020en00010047Document47 pagesMD ST C - 28420101020en00010047Armin-NerminMujanovicNo ratings yet

- Crane Lift RAMsDocument18 pagesCrane Lift RAMsKaren Olivier100% (1)

- United States Patent: (10) Patent No.: (45) Date of PatentDocument20 pagesUnited States Patent: (10) Patent No.: (45) Date of Patentbonny mistryNo ratings yet

- ENVIROCRON Powder Coat PCTA89105 RAL 9010 Pure White UD PolyesterDocument1 pageENVIROCRON Powder Coat PCTA89105 RAL 9010 Pure White UD Polyesterlong chanNo ratings yet

- Mahesh SugumarDocument3 pagesMahesh Sugumarmaheshece28No ratings yet

- Task Flash Sale Api PDFDocument2 pagesTask Flash Sale Api PDFpriyank tripathiNo ratings yet

- Holcim Awards For Sustainable ConstructionDocument4 pagesHolcim Awards For Sustainable ConstructionpeperiverosNo ratings yet

- CB Timing Tester SMC Manual - EngineeringDocument356 pagesCB Timing Tester SMC Manual - Engineeringsmi1989No ratings yet

- Bombardier Aerospace The CSeries DilemmaDocument26 pagesBombardier Aerospace The CSeries DilemmakevinNo ratings yet

- Diagrama TTT e Jominy Teórico: PL22, PL30, PL33, PL41, 4140 e 5135Document18 pagesDiagrama TTT e Jominy Teórico: PL22, PL30, PL33, PL41, 4140 e 5135DanielNo ratings yet

- Linear Programming TheoryDocument104 pagesLinear Programming Theorykostas_ntougias5453No ratings yet

- R 10433 1690351714362Document23 pagesR 10433 1690351714362SSE BOGIE STORESNo ratings yet

- Adeor Velocity Brochure Lores PDFDocument16 pagesAdeor Velocity Brochure Lores PDFrelinNo ratings yet

- Chapter-11:-SHE Pillar Activities: DateDocument9 pagesChapter-11:-SHE Pillar Activities: Datesamkaria rajeshNo ratings yet

- SAEP-1150 Inspection Coverage On ProjectsDocument50 pagesSAEP-1150 Inspection Coverage On ProjectsSergey KichenkoNo ratings yet

- Davis Controls Ltd. TC Klinger Steam Level GaugesDocument6 pagesDavis Controls Ltd. TC Klinger Steam Level GaugesDavis Controls Ltd.No ratings yet

- Lobe Blower TheoryDocument6 pagesLobe Blower TheoryAnonymous CMS3dL1TNo ratings yet

- Sample MCQ - Facility Location and LayoutDocument3 pagesSample MCQ - Facility Location and Layoutpartha sarathiNo ratings yet

- Kutni I Ostali ProfiliDocument2 pagesKutni I Ostali ProfiliMarjan FaberNo ratings yet

- Planning: Processes and TechniquesDocument18 pagesPlanning: Processes and TechniquesSunil JoshiNo ratings yet

- S Banerjee Thermal Power Plant Performance Improvement Using Quality InitiativesDocument39 pagesS Banerjee Thermal Power Plant Performance Improvement Using Quality InitiativesSantosh Kumar EturiNo ratings yet

- Managing Software Process Evolution: Marco Kuhrmann Jürgen Münch Ita Richardson Andreas Rausch He Zhang EditorsDocument345 pagesManaging Software Process Evolution: Marco Kuhrmann Jürgen Münch Ita Richardson Andreas Rausch He Zhang EditorsYanNo ratings yet

- of SCTPLDocument23 pagesof SCTPLDebashish SahuNo ratings yet

- Google Doc WBS Template 02 - 43 - Company Project WBS Levels ExampleDocument2 pagesGoogle Doc WBS Template 02 - 43 - Company Project WBS Levels ExampleJaouad IDBOUBKERNo ratings yet

- Actuator BrochureDocument6 pagesActuator BrochureCarlos Ramirez100% (1)

- Unit - 1: Switches and FusesDocument3 pagesUnit - 1: Switches and FusesRoopa ReddyNo ratings yet