Professional Documents

Culture Documents

Anhängerkupplung - Hayman Reese 03379RW Installationsanleitung 03379rw

Anhängerkupplung - Hayman Reese 03379RW Installationsanleitung 03379rw

Uploaded by

norbert xyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Anhängerkupplung - Hayman Reese 03379RW Installationsanleitung 03379rw

Anhängerkupplung - Hayman Reese 03379RW Installationsanleitung 03379rw

Uploaded by

norbert xyCopyright:

Available Formats

TOWBAR

INSTALLATION INSTRUCTIONS

PART NUMBER 03379RW

SSANGYONG MUSSO Q200/Q201 CL4

PRODUCT DETAILS:

Part Number: 03379RW Maximum Towing Braked: 3500 kg

ECU Number: 04835 Maximum Towing Unbraked: 750 kg

Tail Harness Length Required: 1200 mm Maximum Static Ball Load: 350 kg

TBM/Lug Part Number: 21342

Wiring Part Number: 102639-WL

FITTING DETAILS:

Towbar Installation Time: 60 Mins. Hayman Reese SmartCODE Solution Required: NO

Wiring Installation Time: 30 Mins. RPA Disable/Other: YES

Total Installation Time: 90 Mins.

Bumper Cut Required: Yes Note:

• When RPA is disabled there will be 3 Question

marks on the centre instrument cluster (This is not

a fault This is to indicate the rear parking sensors

are disabled).

49-75 Pacific Drive Keysborough, VIC 3173

Phone: 1800 812 017

Email: info@haymanreese.com.au

Rev: A Page 1 Issue Date: 10-08-2021

TOWBAR

INSTALLATION INSTRUCTIONS

PART NUMBER 03379RW

SSANGYONG MUSSO Q200/Q201 CL4

ENSURE THAT INSTRUCTIONS ARE UNDERSTOOD PRIOR TO FITMENT.

BEFORE YOU START:

1. Hayman Reese recommends that instructions are read completely prior to fitment.

2. Check all hardware items have been included refer to assembly diagram. CORRECT

3. Please ensure this towbar is only fitted to vehicle models as per Hayman Reese application guide

(www.haymanreese.com.au).

4. Bumper Cuts

5. Vehicle and bumper variations can and do occur during vehicle manufacture after initial towbar Figure 1

design. Fitment of towbar to vehicle and accuracy of bumper cut must be assessed prior to any INCORRECT

bumper modifications made. Incorrect bumper cuts are not covered under Hayman Reese warranty.

6. NOTE: Bumper cuts need to be approached with care, refer to notes below.

• Bumper centreline – where the centreline of the bumper needs to be determined, the installer

must assess centre point by measurement of bumper width or determining two symmetrical

reference points to give centreline.

• Bumper edge – To assist with accurate bumper cut measurement, reference to the start of the

bumper edge is now being commonly used.

o Measure from bottom edge along bumper and around corner to the 70 mm point Figure 2

(Figure 1).

o Do not measure from visible bumper front of corner, upwards (Figure 2).

7. Drilling

• For any required drilling during installation, ensure that the area is clear of fuel, electrical & other components that may be

damaged.

• All holes drilled into the body panels shall have all burrs & swarf removed then coated with a suitable rust preventative paint.

8. Bolts/Fasteners

• Ensure that all hardware is fastened to correct torque as specified in this fitting instruction.

• All fasteners supplied with this product are used to achieve a specified clamp loading. If replacement is required ensure that

fasteners of the same grade and class are used.

9.

10. NOTE: Achieving correct torque is critical to proper installation and responsibility of the installer. Towbar failures attributed to

tension issues from over tightening or under tightening are not covered by Hayman Reese warranty.

11.

12. Product Labels

a. Towbar load rating sticker provided with this product shall be conspicuously located on inside rear end of the driver’s door.

b. Powertrain Control Module (PCM)/Body Control Module (BCM) upgrade warning label will be provided in towbar kit for

vehicles as required. Affix warning label in door and owner’s handbook.

Place Load Rating

sticker inside driver’s

door here

Place Vehicle PCM/ BCM upgrade

warning label in door AND on front

cover of owner’s service handbook

WARNING:

1. 2. Do not, drill, cut, weld or otherwise modify the towbar.

3. FOR TOWING PURPOSES ONLY - This towbar is designed and tested by Hayman Reese to adhere to ADR 62/02 which provides

only for the expected load demands of towing.

49-75 Pacific Drive Keysborough, VIC 3173

Phone: 1800 812 017

Email: info@haymanreese.com.au

Rev: A Page 2 Issue Date: 10-08-2021

TOWBAR

INSTALLATION INSTRUCTIONS

PART NUMBER 03379RW

SSANGYONG MUSSO Q200/Q201 CL4

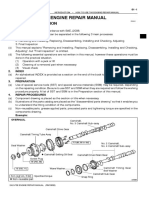

TOWBAR ASSEMBLY DIAGRAM

ITEM DESCRIPTION QTY ITEM DESCRIPTION QTY

1 SSANGYONG MUSSO WELD ASSEMBLY 1 11 CHASSIS SHIM PLATE 2

2 TRAILER BALL MOUNT 1 12 TOWBALL 50mm 1

3 UNIVERSAL PLUG BRACKET KIT 1 13 "D" SHACKLE 10mm 2

4 BOLT HEX HD M14x190x2.0P 4 14 SMART PIN GOLD 1

5 NUT HEX HD M14x2.0P 4 15 HAYMAN REESE LOGO STICKER 1

6 WASHER PLAIN M14x28x3 10 16 HITCH BOX COLLAR COVER 1

7 CRUSH TUBE 2 17 COMPLIANCE LABEL 1

8 BOLT HEX HD M14x130x2.0P 2 18 DOOR RATING LABEL 1

9 NUT PLATE 2 19 WIRE LOOM 1

10 CHASSIS SHIM PLATE 6MM 4

49-75 Pacific Drive Keysborough, VIC 3173

Phone: 1800 812 017

Email: info@haymanreese.com.au

Rev: A Page 3 Issue Date: 10-08-2021

TOWBAR

INSTALLATION INSTRUCTIONS

PART NUMBER 03379RW

SSANGYONG MUSSO Q200/Q201 CL4

1. Using the wheel tool kit and lower the spare

wheel.

Unclip the harness wire from the chassis

2. Remove the rubber muffler isolator for easy

access.

3. Fit the tow bar between the chassis and loosely

secure with 1x bolt, 2 washers and 1x nut.

Repeat for the other side

49-75 Pacific Drive Keysborough, VIC 3173

Phone: 1800 812 017

Email: info@haymanreese.com.au

Rev: A Page 4 Issue Date: 10-08-2021

TOWBAR

INSTALLATION INSTRUCTIONS

PART NUMBER 03379RW

SSANGYONG MUSSO Q200/Q201 CL4

4. Fit 2x spacers under the chassis.

Loosely secure 1x M14 bolt, 1x washer and 1x nut

plate.

Repeat for the other side

SPACERS

5. Fit the crush tube into the chassis and slide 1x CRUSH

M14 bolt and 1x washer halfway in. TUBE

Repeat for the other side

6. Fit 1x spacer on the side of the chassis, push the SPACER

M14 bolt through the spacer, 1x washer and

secure with 1x M14 nut.

Repeat for the other side.

Torque fasteners as follows:

M14 x 2.0P = 124 Nm

49-75 Pacific Drive Keysborough, VIC 3173

Phone: 1800 812 017

Email: info@haymanreese.com.au

Rev: A Page 5 Issue Date: 10-08-2021

TOWBAR

INSTALLATION INSTRUCTIONS

PART NUMBER 03379RW

SSANGYONG MUSSO Q200/Q201 CL4

7. Fit the plug bracket on the dropper and secure

with 2x screws, 4x washer and 2x nuts.

Fit the TBM face up as shown.

8. In the Engine Bay, disconnect the vehicle battery

negative terminal (1).

9. Remove the cover off the fuse block (2).

10. Under the vehicle left hand side, connect the vehicle

pre-wire connector (1) to the mating connector on

the trailer patch (102639-WL).

11. Connect the waterproof ECU (04835) to the ECU

connector on the trailer wiring harness.

12. Secure the ECU to the chassis rail (2).

Note: Ensure the module connector is pointing

downwards.

49-75 Pacific Drive Keysborough, VIC 3173

Phone: 1800 812 017

Email: info@haymanreese.com.au

Rev: A Page 6 Issue Date: 10-08-2021

TOWBAR

INSTALLATION INSTRUCTIONS

PART NUMBER 03379RW

SSANGYONG MUSSO Q200/Q201 CL4

13. For vehicles with reverse sensors, under the vehicle

left hand side behind the rear left wheel, locate the

vehicle bumper connector (1) attached to the chassis.

14. On the vehicle side, cut the RPA ground (Black) wire

(2) and strip, crimp, splice and seal the grey and grey

black wires to each side of the black wire.

Note: The wire is thin Black.

15. Route the power and ground wires along the chassis

rail towards the front of the vehicle.

16. Secure the harness to the vehicle chassis rail.

NB: Keep harness routing clear of all sharp edges,

moving parts and places of extreme heat.

17. In the engine bay, connect the M6 ground wire ring

terminal to the vehicle earthing point (1) on the

firewall.

18. Connect the M6 orange fused ring terminal to the

fuse box positive stud (2).

19. Reconnect the vehicle negative battery terminal.

20. Tie up any excess lengths as required.

49-75 Pacific Drive Keysborough, VIC 3173

Phone: 1800 812 017

Email: info@haymanreese.com.au

Rev: A Page 7 Issue Date: 10-08-2021

TOWBAR

INSTALLATION INSTRUCTIONS

PART NUMBER 03379RW

SSANGYONG MUSSO Q200/Q201 CL4

21. At the rear of the vehicle LHS, connect the tail

harness (tail length 1200mm) 8-way connector (1) to

the trailer patch mating 8-way connector (2).

22. Cut-off, crimp the tail harness GREY and GREY/BLACK

wires (3) to the trailer patch matching GREY and

GREY/BLACK wires (4).

23. Test the trailer patch function using a light board or

multi-meter.

24. Secure all harness using cable ties (not supplied).

25. Re-fit all removed parts and secure all fasteners,

ensuring there are no squeaks or rattles.

26. Place the fitting instructions in the glove box after

fitment.

49-75 Pacific Drive Keysborough, VIC 3173

Phone: 1800 812 017

Email: info@haymanreese.com.au

Rev: A Page 8 Issue Date: 10-08-2021

CUSTOMER INFORMATION

PLACE THESE INSTRUCTIONS IN THE

VEHICLE’S GLOVEBOX AFTER INSTALLATION

THANK YOU FOR PURCHASING HAYMAN REESE.

WITH CORRECT MAINTENANCE AND CARE THIS PRODUCT WILL PROVIDE A

LIFETIME OF TROUBLE-FREE OPERATION.

TOWBAR MAINTENANCE AND CARE:

1. Hayman Reese recommend that the towbar LUG or TBM (tow ball Mount) Pull Pin and R-clip are removed

and stored when not in use. Removal of LUG or TBM (tow ball mount) is advisable when not in use to

assist with any of the following.

• Ensure rear number plate is not obscured.

• Allow maximum available departure angle and prevent any potential interference.

• Prevent possible interference with vehicles reverse sensors or camera detecting a tow ball mount

as an obstruction during reversing.

• Removes towball mount as an obstruction for when moving around the rear of the vehicle.

2. Hayman Reese recommends routine inspection of your towbar to ensure trouble free towing.

• Bolt security and tension should be regularly inspected and checked for correct tension. Replace

any worn or defective parts with suitable grade & class fasteners. Inspection should be requested

to coincide with vehicle major services.

3. It is the owner’s responsibility to ensure towing and down ball weight capacities of the towing vehicle are

not exceeded.

• Towing and down ball weights allowable may differ according to model variations. Please refer to

owner’s manual or vehicle dealer to confirm exact rating for your vehicle model variant.

• It is not uncommon for the vehicle tow rating to differ from the towbar rating. When this occurs,

the lesser rating must be adhered to.

• For vehicles fitted with enhanced vehicle functions that may be altered/changed when towing i.e

Trailer sway mitigation, blind spot detection, adaptive cruise control etc. Please consult owner’s

manual to understand changes enabled when towing and after towing.

WARRANTY INFORMATION:

Hayman Reese Towbars are covered by a Lifetime Warranty.

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are

entitled to a replacement or refund for a major failure and for compensation for any other reasonably

foreseeable loss or damage. You are also entitled to have the goods repaired or replaced if the goods fail to

be of acceptable quality and the failure does not amount to a major failure.

For further details please visit www.haymanreese.com.au/warranty or contact customer service on

1800 812 017 or info@haymanreese.com.au.

49-75 Pacific Drive Keysborough, VIC 3173

Phone: 1800 812 017

Email: info@haymanreese.com.au

Rev: A Page 9 Issue Date: 10-08-2021

CUSTOMER INFORMATION

PLACE THESE INSTRUCTIONS IN THE

VEHICLE’S GLOVEBOX AFTER INSTALLATION

HAYMAN REESE SMART PIN

Your Hayman Reese towbar is equipped with Smart Pin technology to help reduce towbar tongue rattle in most

driving conditions. Please ensure below instructions are understood and routine maintenance is carried out to

ensure best towing experience.

Regularly inspect for wear and check the tightness of the Smart Pin Nut. Follow instructions below to re-

tighten the nut as necessary when movement and noise in the tow ball mount is noted.

• Before towing, ensure R-Clip is properly installed and Smart pin nut is installed and tensioned.

Replacement parts are available from your Hayman Reese Distributor.

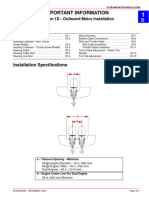

TOWBALL MOUNT REMOVAL/INSTALLATION

HITCHBOX (b)

STEP 1

Insert Trailer Ball Mount (TBM) (a) into towbar

hitchbox (b), aligning hole in TBM shank (c) with

hole in hitchbox (d) (Fig. 1) TRAILER BALL

MOUNT (a)

STEP 2

(d)

Insert Smart Pin (e) through hole in hitchbox and

hole in TBM shank (g); ensure the locators are (c)

Fig. 1

inserted into the notches in the hitchbox (Fig. 2)

STEP 3

(g) SMART PIN NUT (f)

Screw Smart Pin Nut (f) onto Smart Pin (g); tighten

Smart Pin Nut until finger tight, ensuring TBM is

restrained from up and down movement. SMART PIN (e)

STEP 4

R-CLIP

Tighten Smart Pin Nut by turning nut a further

1/8th of a turn in the clockwise direction using a Fig. 2 Fig. 3

24mm spanner (Fig. 4).

STEP 5

Install Smart Pin R-Clip through the hole that

provides best clearance or easiest access. (Fig. 5)

Fig. 5

STEP 6

Install towball onto TBM and tighten to 350 Nm

using a calibrated torque wrench (Fig. 6). Fig. 4

Fig. 6

49-75 Pacific Drive Keysborough, VIC 3173

Phone: 1800 812 017

Email: info@haymanreese.com.au

Rev: A Page 10 Issue Date: 10-08-2021

You might also like

- SM350D en 20180207Document204 pagesSM350D en 20180207Mokim Performance100% (1)

- Tarex Jaw Crusher Part Manual PDFDocument333 pagesTarex Jaw Crusher Part Manual PDFKAMAL SINGH100% (3)

- 9852 1007 01j Maintenance Instructions COP 1840,1840EXDocument32 pages9852 1007 01j Maintenance Instructions COP 1840,1840EXrolandNo ratings yet

- 2004 Liberty Service Manual (Inc.)Document131 pages2004 Liberty Service Manual (Inc.)Terrance Vinson MooreNo ratings yet

- WB97R KomatsuDocument478 pagesWB97R Komatsufernando7jose7alcant100% (6)

- 15F2284 Manual A320 v2016 (Vigente)Document23 pages15F2284 Manual A320 v2016 (Vigente)Joe ReyNo ratings yet

- 2az Fse Engine Repair Manual (Rm1083e)Document120 pages2az Fse Engine Repair Manual (Rm1083e)Osvaldo Chimbas100% (2)

- MALIBU 2010 Brake Light TSBDocument19 pagesMALIBU 2010 Brake Light TSBRenato M FariaNo ratings yet

- Flexi Coil 340 Chisel Plow PDFDocument172 pagesFlexi Coil 340 Chisel Plow PDFАнатолій Гуменюк0% (1)

- 2RZ 3RZ SC PDFDocument21 pages2RZ 3RZ SC PDFUliAlejandroRodriguezCoriangaNo ratings yet

- 00602-89661-001 Electronic Boost ControlDocument11 pages00602-89661-001 Electronic Boost ControlSupaTouring0% (1)

- D 1761 - 88 R00 - Rde3njeDocument13 pagesD 1761 - 88 R00 - Rde3njeAnonymous 6SHxUn1xd10% (1)

- Workshop Manual Volvo TWD1240Document76 pagesWorkshop Manual Volvo TWD1240DeMen Nguyen89% (19)

- 03002RWDocument13 pages03002RWIsmail AmreNo ratings yet

- Vr40 #7 Compressor Conversion Kit Renault / Opel / NissanDocument12 pagesVr40 #7 Compressor Conversion Kit Renault / Opel / NissanDaniel EMNo ratings yet

- NTB04 065bDocument5 pagesNTB04 065bSr. PolestarNo ratings yet

- Street Series: CBR-1000RRDocument3 pagesStreet Series: CBR-1000RR김재치No ratings yet

- 250 1836 2009 2013tacomaDocument12 pages250 1836 2009 2013tacomaedgargtzNo ratings yet

- LTB00079 NAS2 ParkbrakeDocument6 pagesLTB00079 NAS2 Parkbrakeserdar akmanNo ratings yet

- FD202LDocument7 pagesFD202LGrzegorz samuraiNo ratings yet

- Euro III BH117L Service Manual 1st January 2006 PDFDocument329 pagesEuro III BH117L Service Manual 1st January 2006 PDFKhom JeknokNo ratings yet

- Rod BearingsDocument29 pagesRod BearingsDaniel SarmientoNo ratings yet

- Bolt Torque Sequence PDFDocument2 pagesBolt Torque Sequence PDFmil100% (1)

- Daewoo Bus Chassis Service ManualDocument20 pagesDaewoo Bus Chassis Service Manualdortha100% (62)

- Paracaídas Instantáneo Dynatech/ Parachute Instantane DynatechDocument9 pagesParacaídas Instantáneo Dynatech/ Parachute Instantane DynatechJuan IribarrenNo ratings yet

- Precision Sport ShifterDocument9 pagesPrecision Sport ShifterBuda BudaNo ratings yet

- Important Information: Section 1D - Outboard Motor InstallationDocument13 pagesImportant Information: Section 1D - Outboard Motor InstallationDr. Centelha Mecânica NaúticaNo ratings yet

- Installation, Maintenance and Service Manual: Winch DivisionDocument27 pagesInstallation, Maintenance and Service Manual: Winch DivisionWesly ChavezNo ratings yet

- Installation LGDocument26 pagesInstallation LGkhantoNo ratings yet

- Pro Comp Suspension: PN# 62170 1998-2010 Ford Ranger 4wd & Edge 2wd/4wd Torsion Bar Key KitDocument8 pagesPro Comp Suspension: PN# 62170 1998-2010 Ford Ranger 4wd & Edge 2wd/4wd Torsion Bar Key KitomarNo ratings yet

- Manual Adaptar 5.2 v8 A WranglerDocument2 pagesManual Adaptar 5.2 v8 A WranglerOscar GutierrezNo ratings yet

- A A 11090Document4 pagesA A 11090Raúl Rosalino Pérez GómezNo ratings yet

- AB ShaftSealKitsDocument8 pagesAB ShaftSealKitsCarlos PNo ratings yet

- 7821 - 316 - 2 DECK BM&M Manual PDFDocument35 pages7821 - 316 - 2 DECK BM&M Manual PDFPRASHANTHNo ratings yet

- YoshimuraDocument7 pagesYoshimuraNguon MadolyNo ratings yet

- Motor B411 Turbo MitsubishiDocument1 pageMotor B411 Turbo MitsubishiCarlos Alberto Lau SosaNo ratings yet

- Toyota Tundra TRD Brake Kit Installation InstructionsDocument10 pagesToyota Tundra TRD Brake Kit Installation InstructionsJason LancasterNo ratings yet

- SRV-TSB-23-003 CR246 Spring Installation For Fuel Tank Breather HoseDocument7 pagesSRV-TSB-23-003 CR246 Spring Installation For Fuel Tank Breather Hosecarlos antonio gonzalez abregoNo ratings yet

- SM-BB80: General Safety InformationDocument1 pageSM-BB80: General Safety InformationVIRAL WORLD IDNo ratings yet

- Important Information: Section 1D - Outboard InstallationDocument16 pagesImportant Information: Section 1D - Outboard Installationibrahimvisham99No ratings yet

- INS T032 1998 2002 Toyota Land Cruiser 100 2.5 Rear ShocksDocument5 pagesINS T032 1998 2002 Toyota Land Cruiser 100 2.5 Rear ShocksHuzaifa AhmedNo ratings yet

- Duratec 16v tTI-VCTDocument40 pagesDuratec 16v tTI-VCTStarsky UrblejoNo ratings yet

- Manual - Ace CraneDocument60 pagesManual - Ace CraneManoj SinghNo ratings yet

- Tomei Manual EnglishDocument5 pagesTomei Manual EnglishMuaiyad AL-baluchi100% (1)

- Technical Service Information: DescriptionDocument7 pagesTechnical Service Information: DescriptionMohamed HassanNo ratings yet

- Thruster 140-300TT - B500100 Iss 6Document28 pagesThruster 140-300TT - B500100 Iss 6Heriberto TorresNo ratings yet

- Screenshot 2023-01-14 at 10.13.00 AmDocument30 pagesScreenshot 2023-01-14 at 10.13.00 AmCraig MalthouseNo ratings yet

- StopTech High Performance Brake SystemsDocument2 pagesStopTech High Performance Brake SystemsAnonymous Wyb8Y1No ratings yet

- Manual Generador KatoDocument160 pagesManual Generador Katomass72100% (4)

- CT6073Document3 pagesCT6073Philipus MNo ratings yet

- Toyota Tundra Skid Plate Installation InstructionsDocument5 pagesToyota Tundra Skid Plate Installation InstructionsJason LancasterNo ratings yet

- SB 10083664 6903Document9 pagesSB 10083664 6903J.T. NoneyaNo ratings yet

- 2009-20 RAM 1500 5.7L Hemi Engine: RemovalDocument2 pages2009-20 RAM 1500 5.7L Hemi Engine: RemovalMAKSIDOM InternetNo ratings yet

- 2021 Integration Manual: Tested - Proven - TrustedDocument28 pages2021 Integration Manual: Tested - Proven - TrustedSENTHIL NATHANNo ratings yet

- Instrucciones de Instalación CHX8200Document16 pagesInstrucciones de Instalación CHX8200teopol2No ratings yet

- Motor & Brake Operating Instructions 09 793 77 USDocument6 pagesMotor & Brake Operating Instructions 09 793 77 USArnold StevenNo ratings yet

- AA02193C STRG Pin Wear Checks and SizesDocument8 pagesAA02193C STRG Pin Wear Checks and SizesSebastiao DuarteNo ratings yet

- Sunchaser 827XXXX InstallationDocument7 pagesSunchaser 827XXXX InstallationTCHOMEBUILDNo ratings yet

- InstructionsDocument14 pagesInstructionsALEXNo ratings yet

- TJ Full Cage Kit Install: Parts ListDocument7 pagesTJ Full Cage Kit Install: Parts ListMark BarberaNo ratings yet

- Mechanical Seal Installation InstructionDocument4 pagesMechanical Seal Installation InstructionSandi AslanNo ratings yet

- Ajin SMT - Operating Manual-1Document38 pagesAjin SMT - Operating Manual-1henry vegaNo ratings yet

- Alarm Installation V3Document18 pagesAlarm Installation V3Momik BahmansonNo ratings yet

- Rear SealDocument9 pagesRear SealHammad Uddin JamilyNo ratings yet

- Bolted Connexion SheetDocument48 pagesBolted Connexion SheethalackNo ratings yet

- Analysis of Bolted-Flange Joint Using Finite Element MethodDocument12 pagesAnalysis of Bolted-Flange Joint Using Finite Element MethodTJPRC PublicationsNo ratings yet

- Ns 18 Steel DesignDocument50 pagesNs 18 Steel DesignproahyNo ratings yet

- Modes of Failure in Tension Members.Document2 pagesModes of Failure in Tension Members.Sajjad BalochNo ratings yet

- Hydrogen Compressor Flange Bolts FailureDocument8 pagesHydrogen Compressor Flange Bolts FailurePablo ScottNo ratings yet

- Filedate - 858download Ebook Shigleys Mechanical Engineering Design 11Th Ed PDF Full Chapter PDFDocument67 pagesFiledate - 858download Ebook Shigleys Mechanical Engineering Design 11Th Ed PDF Full Chapter PDFjeremy.collins128100% (34)

- SpaceBolt ESA EvaluationDocument4 pagesSpaceBolt ESA EvaluationFrancisco PolanoNo ratings yet

- Wa0030.Document3 pagesWa0030.Muhammad Shihabudin AhmedNo ratings yet

- Casafont - 1Document15 pagesCasafont - 1ma.shaheNo ratings yet

- 1 Lindapter Maggio 2023Document84 pages1 Lindapter Maggio 2023CALGERINo ratings yet

- Maryland Metrics - Fastener Technical DataDocument92 pagesMaryland Metrics - Fastener Technical Dataserzo75100% (1)

- Design of Steel StructuresDocument2,529 pagesDesign of Steel StructuresStructural Spreadsheets67% (9)

- DURLON RR TANKCAR February 2015Document16 pagesDURLON RR TANKCAR February 2015Hugh Manta100% (1)

- Bolted Connection FatigueDocument12 pagesBolted Connection FatigueMahfuzur Rahman100% (1)

- Bolt Loosening Transverse Vibration Test RigDocument2 pagesBolt Loosening Transverse Vibration Test RigSubhasis MallikNo ratings yet

- TKB 00804-203 13 202308Document30 pagesTKB 00804-203 13 202308Ronaldo Bandeira RodriguesNo ratings yet

- Connections of Steel Member by Rivet and BoltDocument13 pagesConnections of Steel Member by Rivet and BoltRaju SharmaNo ratings yet

- BearingsDocument10 pagesBearingsafif atmaja100% (1)

- Machine Elements Life and Design: Boris M. Klebanov David M. Barlam Frederic E. NystromDocument5 pagesMachine Elements Life and Design: Boris M. Klebanov David M. Barlam Frederic E. NystromRachu Raj100% (1)

- 5-TRAFFIC-ENGINEERING and Assignment of BaDocument28 pages5-TRAFFIC-ENGINEERING and Assignment of BaCity GuideNo ratings yet

- Workshop Manual - D16 - 7746647Document237 pagesWorkshop Manual - D16 - 7746647thaynaNo ratings yet

- Marc Mentat FEM PDFDocument19 pagesMarc Mentat FEM PDFMahmud Kori EffendiNo ratings yet

- Nycotte StandardeDocument4 pagesNycotte StandardezzzaNo ratings yet

- J. Y. Richard Liew, Yuichi Nishida - Design Guide For Semi-Rigid Composite Joints and beams-SSSS (Singapore Structural Steel Society) (2021)Document136 pagesJ. Y. Richard Liew, Yuichi Nishida - Design Guide For Semi-Rigid Composite Joints and beams-SSSS (Singapore Structural Steel Society) (2021)tmaNo ratings yet

- Review of The Application of Design Guideline Vdi 2230: Using Sr1 For PcsDocument16 pagesReview of The Application of Design Guideline Vdi 2230: Using Sr1 For PcsCunha Projetos de Cilindros HidráulicosNo ratings yet