Professional Documents

Culture Documents

18W-118-134 Chrysler Jeep Land Rover 948te Reassembly Tips

18W-118-134 Chrysler Jeep Land Rover 948te Reassembly Tips

Uploaded by

สนั่น วิริยะเจริญกุลOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

18W-118-134 Chrysler Jeep Land Rover 948te Reassembly Tips

18W-118-134 Chrysler Jeep Land Rover 948te Reassembly Tips

Uploaded by

สนั่น วิริยะเจริญกุลCopyright:

Available Formats

118 "2018” SEMINAR INFORMATION

CHRYSLER/JEEP

948TE REASSEMBLY TIPS

The ZF9HP48 - 948TE automatic transmission is a 9 speed, electronically controlled unit manufactured by ZF.

The transmission represents the latest in automatic transmission technology for a transverse, AWD (all-wheel

drive) unit. ZF describes the ZF 9HP48 transmission as having the following features:

· Designed to be maintenance free

· Transmission fluid is fill for life

· The TCC strategy has a controlled slip feature with electronically regulated lock-up control on gears 1 to 9

· Planetary gearset with 9 speeds, 4 planetary geartrains and 6 shift elements

· Wide transmission ratio spread with small ratio steps

· The first-ever use of interlocking dog clutches in a passenger car automatic transmission

· Shift programs controlled by the TCM (transmission control module)

· TCM (transmission control module) has an adaptive capability to ensure efficient gear shift quality throughout

the service life of the transmission

· Diagnostics available from the TCM (transmission control module) via the high speed CAN (controller area

network) Powertrain systems bus

This transmission will be found in the following Global applications:

Acura TLX and MDX, Chrysler 200, Fiat Doblò, Fiat 500X, Honda CR-V, Jeep Cherokee (KL), Jeep Renegade,

Ram ProMaster City, Range Rover Evoque, Land Rover Discovery Sport.

Automatic Transmission Service Group

"2018” SEMINAR INFORMATION 119

CHRYSLER/JEEP

948TE REASSEMBLY TIPS

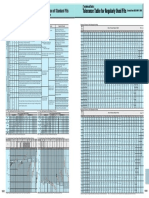

COMPONENT APPLICATION CHART

F

E

B

C

D

A Clutch B Clutch C Brake D Brake E Clutch F Clutch Ratio

(Dog)*** (Dog)***

P/N Open ON Closed

Reverse Open ON ON Closed 3.830

1st Gear Closed ON Closed 4.713

2nd Gear Closed ON Closed 2.842

3rd Gear* Closed ON Closed 1.909

4th Gear** Closed ON Closed 1.382

5th Gear Closed ON ON Open 1.000

6th Gear Closed ON ON Open 0.808

7th Gear Closed ON ON Open 0.699

8th Gear Open ON ON ON Open 0.580

9th Gear Open ON ON ON Open 0.479

* - Failsafe Gear according to Land Rover

** - Default Gear according to Dodge

*** - Dog Clutch shift transitions dependent upon proper engine and shaft speed Copyright © 2018 ATSG

Figure 1-A

Automatic Transmission Service Group

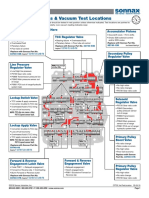

120 "2018” SEMINAR INFORMATION

948TE

SOLENOID IDENTIFICATION AND APPLICATION CHART

Magnetic System Pressure

Control Solenoid Solenoid

(Park-Lock Actuator)

Park Lock TCC

Solenoid Solenoid

C Brake B Clutch

D Brake F Dog Clutch A Dog Clutch E Clutch

Solenoid Solenoid

Solenoid Solenoid Solenoid Solenoid

A B C D E F TCC Press. Pk/Lk Pk/Lk

Sol. Sol. Sol. Sol. Sol. Sol. Sol. Sol. Act. Sol.

Park Mod.

Reverse X X X Mod. X X

Neutral X Mod. X X

1st Gear X X X Mod. Mod. X X

2nd Gear X X X Mod. Mod. X X

3rd Gear X X X Mod. Mod. X X

4th Gear X X X Mod. Mod. X X

5th Gear X X X Mod. Mod. X X

6th Gear X X X Mod. Mod. X X

7th Gear X X X Mod. Mod. X X

8th Gear X X X Mod. Mod. X X

9th Gear X X X Mod. Mod. X X

Copyright © 2018 ATSG

Figure 1-B

Automatic Transmission Service Group

"2018” SEMINAR INFORMATION 121

948TE REASSEMBLY TIPS

Figure 1 on the previous page along with figures 2

thru 6 on this page serve as an orientation to "D" Brake

component identification and location.

When the case halves are split, Dog Clutch F (figure

2) and the E Clutch (figure 3) are located in the

converter housing half.

The D Brake (figure 4), Dog Clutch A and the B

Clutch (figure 5), along with the C Brake (figure 6)

are all located in the main case housing.

Disassembling this transmission is not difficult and

can be done quite easily. The reassembly process can

be tougher unless you know a couple of tips and Figure 4

acquire one reasonably priced special tool.

Dog Clutch "F" "B" Clutch

Dog

Clutch "A"

Figure 2 Figure 5

"E" Clutch "C" Brake

Figure 3 Figure 6

Automatic Transmission Service Group

122 "2018” SEMINAR INFORMATION

948TE REASSEMBLY TIPS

The recommended special tool that will greatly assist

in the disassembly and reassembly process of this

transmission is the compressor plate for the belleville

spring inside the C-brake piston (figure 7). This can

be found online at www.moparessentialtools.com

under tool number 10504. It currently lists for

approximately $64.00 US dollars.

This custom fit plate (figures 8 and 9) compresses the

belleville spring making it easier to remove a lip type

snap ring (figure 10). It also makes installing this

special snap ring (lip down) much easier as well. DO

NOT install the snap ring as seen in figure 11. It has

been known to pop out of its groove. It may even be

Figure 7 the reason it in your shop for repairs. Install it the way

it is seen in figure 9.

Figure 8 Figure 10

Figure 9 Figure 11

Automatic Transmission Service Group

"2018” SEMINAR INFORMATION 123

948TE REASSEMBLY TIPS

Do not forget the input shaft selective washer (figure

12) that must go on top of the B-clutch/Dog clutch-A

hub followed by the thrust needle bearing (figure 13).

Once the C-brake assembly has been installed, the

reaction plate with raised bosses that face upwards,

has one longer notch as seen in figure 14.

Figure 15 shows the factory location of this longer

notch while figure 16 shows the 1.75 mm (0.069 in)

thick retaining snap ring installed.

The D-brake assembly can now be installed

beginning with the reaction plate which will sit on the

lugs above the C-brake assembly. Figure 14

Figure 12 Figure 15

Figure 13 Figure 16

Automatic Transmission Service Group

124 "2018” SEMINAR INFORMATION

948TE REASSEMBLY TIPS

The reaction plate is the first to go down on the B

Clutch hub followed by friction and steel plates. A

wave plate sits on top of the last steel plate. The

belleville spring then sits inside the hub with the inner

fingers facing upward as seen in figure 17.

The B-clutch piston is then fitted on top of the

belleville spring (figure 18) followed by the shim

support piston (figure 19).

The assembly can be compressed to install the

retaining snap ring (figure 20). Once in place, the

input shaft can be inserted into the drum and secured

by its snap ring (figure 21).

Figure 17

Figure 18 Figure 20

Figure 19 Figure 21

Automatic Transmission Service Group

"2018” SEMINAR INFORMATION 125

948TE REASSEMBLY TIPS

The B-clutch drum and input shaft can be set in place

(figure 22).

The C and D brake hub and planetary assembly can be

installed into the friction plates with a rotating motion

of both the annulus gear and sun gear (figures 23 and

24).

Install a new o-ring into the D-brake piston retainer

and then two new lip seals into the D-brake piston and

lubricate with jell (figure 25).

Install the D-brake piston into the retainer followed

by the belleville spring as seen in figure 26.

Figure 24

Figure 22 Figure 25

Figure 23 Figure 26

Automatic Transmission Service Group

126 "2018” SEMINAR INFORMATION

948TE REASSEMBLY TIPS

Carefully install the D-brake piston assembly into the

transmission. Utilizing an appropriate press,

compress the assembly and install the 28.24 mm

(1.112 in) thick retaining snap ring (figure 27).

Insert a new o-ring into the carrier (figure 28) and

lubricate the annulus gear with gel (figure 29). Install

the gear into the carrier along with the retaining snap

ring. One side of the annulus gear will press down into

the o-ring allowing one end of the snap ring to get

inserted. Place a flat blade screw driver between the

gear and carrier on the opposite side (figure 30). Lean

the screwdriver towards the center to set the annulus

gear into the o-ring. The snap ring should pop into

Figure 27 place. Then place the assembly into the transmission

(figure 31).

Figure 28 Figure 30

Figure 29 Figure 31

Automatic Transmission Service Group

"2018” SEMINAR INFORMATION 127

948TE REASSEMBLY TIPS

With the thrust bearing in position under the annulus

gear 1 planetary hub (figure 32), install the gear into

the transmission (figure 33).

Place another thrust bearing on the annulus gear as

seen in figure 34.

Install the annulus gear 4 and carrier assembly into

annulus gear 3 (figure 35).

Install a new thrust spacer on the underside of the gear

4 planetary pinion carrier (figure 36) and place the

carrier into annulus gear 4.

Figure 34

Figure 32 Figure 35

Figure 33 Figure 36

Automatic Transmission Service Group

128 "2018” SEMINAR INFORMATION

948TE REASSEMBLY TIPS

Removing the transfer gear bearing cone is not

required unless it needs to be replaced. If it was

removed, place the shim onto the transmission

housing and use special tool 6888 and C-4171

(handle) or equivalent and install the gear bearing

cone onto the housing. It will sit slightly below flush

(figure 37).

Pin the park rod in the "out of park" position (figure

38) and install the transfer gear and differential

assembly (figure 39).

Install the sun gear 3 and 4 and Dog clutch-F in the

gear 4 planetary pinion carrier (figure 40) and its

Figure 37 roller type thrust bearing (figure 41).

Figure 38 Figure 40

Figure 39 Figure 41

Automatic Transmission Service Group

"2018” SEMINAR INFORMATION 129

948TE REASSEMBLY TIPS

Install the output gear support into the gear 4

planetary pinion carrier as shown in figures 42 and 43.

Install a new tube style seal into the case in the

location shown in figure 44.

Install the E-clutch hub and shaft in the output gear

support (figure 45) followed by the E-clutch drum

(figure 46).

Figure 44

Figure 42 Figure 45

Figure 43 Figure 46

Automatic Transmission Service Group

130 "2018” SEMINAR INFORMATION

948TE REASSEMBLY TIPS

The oil pump sits inside the intermediate support and

is held into place with a stout snap ring. The pump

provides a slight amount of spring tension against the

snap ring. By carefully introducing a slight

compression on the pump it will make it easier to pop

the snap ring free. Once free, release the tension and

remove the pump assembly from the intermediate

support (figures 47 and 48).

Flip the pump over and remove the e-clip (figure 49)

followed by two tension discs, a support brace and a

centering washer (figures 50 and 51).

Figure 47

Figure 48 Figure 50

Figure 49 Figure 51

Automatic Transmission Service Group

"2018” SEMINAR INFORMATION 131

948TE REASSEMBLY TIPS

The pressure plate cover contains a small center o-

ring and a large outer o-ring (figure 52).

When the pressure plate cover is lifted off of the pump

assembly, it will be seen that one of the two locating

pins for the cam extends into the cover (figure 53).

To ensure proper alignment of parts, a dimple is

placed into the cam next to the locating pin that

extends into the cover (figure 54).

A small c-clip retains the pump's drive shaft to the

rotor. When this is removed (figure 55), all the pump

parts can be separated for inspection (figure 56). The

main pump cover consists of a large outer o-ring in Figure 54

addition to the pump drive shaft seal.

Figure 52 Figure 55

Figure 53 Figure 56

Automatic Transmission Service Group

132 "2018” SEMINAR INFORMATION

948TE REASSEMBLY TIPS

The pump can be easily mis-assembeld by simply

placing the support bracket in-between its seat or

ledge as shown in figure 57. This will cause the two

tension discs to be installed upside down. When the

centering washer is put in place, it will sit far below

the groove for the e-clip retainer (figure 58).

Figure 59 shows the correct image of the support

brace being placed on its ledge. This allows for the

proper positioning of the two tension discs (figure

60).

When the centering washer is installed, it will now

require a slight compression to install the e-clip

Figure 57 retainer (figure 61).

Figure 58 Figure 60

Figure 59 Figure 61

Automatic Transmission Service Group

"2018” SEMINAR INFORMATION 133

948TE REASSEMBLY TIPS

With new seals and o-rings lubricated with gel, the oil

pump can be installed into the intermediate support

(figure 62). It will be necessary to provide a slight

compression on the pump to ensure that the retaining

snap ring is fully seated (figure 63).

The fluid temperature sensor can be installed now as

seen in figure 64 or before mounting the support to the

converter housing.

Carefully install the reaction shaft, washer, drive gear

and chain into the intermediate support and driven

gear as seen in figure 65.

Using caution, lay the entire support assembly onto Figure 64

the converter housing (figure 66).

Figure 62 Figure 65

Figure 63 Figure 66

Automatic Transmission Service Group

134 "2018” SEMINAR INFORMATION

948TE REASSEMBLY TIPS

Install the bolts to hold the reaction shaft to the

intermediate support plate and tighten to 10 Nm/88 in

lbs (figure 67). Then install a new filter and attaching

bolt using the same torque specifications (figure 68).

Install the feed pipe that runs along the filter as seen in

figure 2 on page 121.

With a new gasket on the main case, carefully place

the converter housing onto the main case and finger

tighten all the perimeter bolts (figure 69). Then install

8 long and one short converter housing to output gear

support attaching bolts with new washers finger

tighten (figure 70). Tighten all bolts to 25 Nm/18 ft

lbs.

Figure 67 The transmission is now prepared to receive the valve

body assembly (figure 71).

Figure 68 Figure 70

Figure 69 Figure 71

Automatic Transmission Service Group

You might also like

- ZF 9 HP 48 ValvebodyDocument26 pagesZF 9 HP 48 Valvebodyสนั่น วิริยะเจริญกุล88% (8)

- ZF 9 HP 48 ValvebodyDocument26 pagesZF 9 HP 48 Valvebodyสนั่น วิริยะเจริญกุล88% (8)

- ZF6HP28 TG PDFDocument94 pagesZF6HP28 TG PDFИгорь Наумов100% (9)

- Proof of Insurance Cards PDFDocument4 pagesProof of Insurance Cards PDFTricey Moore0% (1)

- GM 6T70/75 and Ford 6F50/55: 2007 6T70 (MH2) FWD 2007 6T75 (MY9) FWD/ (MH6) AWD Six Speed Automatic TransaxleDocument60 pagesGM 6T70/75 and Ford 6F50/55: 2007 6T70 (MH2) FWD 2007 6T75 (MY9) FWD/ (MH6) AWD Six Speed Automatic TransaxleRepuestos Maceira100% (5)

- TBR at Aw03-72leDocument19 pagesTBR at Aw03-72lehayyeuanh_duchimotla84% (19)

- 20r-22-68 GM 9t50 Non-Etrs Models Preliminary InformationDocument37 pages20r-22-68 GM 9t50 Non-Etrs Models Preliminary InformationVIDAL ALEJANDRO GARCIAVARGAS100% (5)

- AWF-21 / TF-81SC General Reference Data: Clutch / Band / Solenoid Application Chart Trans Basic OperationDocument1 pageAWF-21 / TF-81SC General Reference Data: Clutch / Band / Solenoid Application Chart Trans Basic OperationautomaticosbrasilNo ratings yet

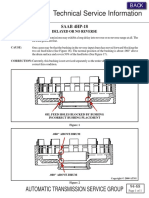

- Technical Service Information: Audi/Porche/Saab/Volvo/VwDocument9 pagesTechnical Service Information: Audi/Porche/Saab/Volvo/VwCiner FarukNo ratings yet

- CVT Transmission Parts k313 Automatic Transmission Valve BodyDocument5 pagesCVT Transmission Parts k313 Automatic Transmission Valve BodyRepuestos Maceira50% (2)

- A 442FDocument142 pagesA 442FJan Eklund100% (3)

- JF015E Valve Body DiagnosticDocument2 pagesJF015E Valve Body Diagnosticสนั่น วิริยะเจริญกุล100% (2)

- Optra 1.6 WiringDocument188 pagesOptra 1.6 Wiringสนั่น วิริยะเจริญกุล100% (2)

- 2013 Ducati Streetfighter 848 Owner's ManualDocument151 pages2013 Ducati Streetfighter 848 Owner's Manualสนั่น วิริยะเจริญกุลNo ratings yet

- Jf506e PDFDocument6 pagesJf506e PDFAdrian Phillips100% (1)

- 1.users Manual Dipstick Mercedes 722.6 722.7 722.8 Professional ToolsDocument2 pages1.users Manual Dipstick Mercedes 722.6 722.7 722.8 Professional ToolsLeonardo SouttoNo ratings yet

- 6HP21 SP52Document1 page6HP21 SP52Tom TomNo ratings yet

- ZF Vt1f MiniDocument31 pagesZF Vt1f Minibaccara180% (5)

- Jf404e VW PoloDocument8 pagesJf404e VW Polofulltransmission100% (2)

- 94 A 541 eDocument15 pages94 A 541 eEli Mires100% (1)

- 5L40E VacTestGuide PDFDocument7 pages5L40E VacTestGuide PDFbelchior100% (2)

- DP0, Al4Document2 pagesDP0, Al4Marcelo Nascimento100% (1)

- The 8-Speed Automatic Transmission 0C8 Design and Function: Self Study Program 850103Document48 pagesThe 8-Speed Automatic Transmission 0C8 Design and Function: Self Study Program 850103jorge Angel Lope75% (4)

- 09g SolenoidDocument3 pages09g SolenoidKarim AbbasNo ratings yet

- AB60E Transmission OperationDocument1 pageAB60E Transmission OperationЙордан ВасилевNo ratings yet

- Apu Comparison in Igo Fleet PDFDocument19 pagesApu Comparison in Igo Fleet PDFRahul Unnikrishnan100% (1)

- 948te Zf9hp48 Zip inDocument12 pages948te Zf9hp48 Zip inRonald100% (1)

- Af-40 VB DiagDocument4 pagesAf-40 VB Diagsanya72100% (2)

- AISIN Introducing The AW 6 SpeedDocument5 pagesAISIN Introducing The AW 6 SpeedhaddadiNo ratings yet

- Front Wheel Drive Automatic Transmission VT2Document6 pagesFront Wheel Drive Automatic Transmission VT2Erin Lam100% (2)

- Re5r05a 2Document18 pagesRe5r05a 2Denis KonovalovNo ratings yet

- 10R80 Adaptive Learning Drive CycleDocument1 page10R80 Adaptive Learning Drive CyclemedicaluvNo ratings yet

- A 6 LF 1Document2 pagesA 6 LF 1Mansor Alqaaf100% (1)

- 6DCT450, MPS6, 6DCT470: Technical Bulletin #1944Document1 page6DCT450, MPS6, 6DCT470: Technical Bulletin #1944Semen Alexandrov100% (2)

- 0b5 TransmisionDocument6 pages0b5 TransmisionAnonymous NzJUyHq4100% (4)

- Critical Wear Areas & Vacuum Test Locations: Valve & Pump BodiesDocument2 pagesCritical Wear Areas & Vacuum Test Locations: Valve & Pump BodiesAnderson0% (1)

- 9HP48 Parts PDFDocument4 pages9HP48 Parts PDFCatalin Belea100% (2)

- ZF 7DT-45HL,: Rear Engine 2WD Dual Clutch Transmission (Porsche PDK, 911 2WD 2009-)Document4 pagesZF 7DT-45HL,: Rear Engine 2WD Dual Clutch Transmission (Porsche PDK, 911 2WD 2009-)jaciel leonNo ratings yet

- U151E U250E VacTestDocument5 pagesU151E U250E VacTestbyungchul kimNo ratings yet

- ZF8 Zip inDocument10 pagesZF8 Zip inEdgar BolañosNo ratings yet

- 2013-2017 ALTIMA AND 2014-2017 ROGUE 4 CYLINDER WITH DTC P17F0, P17F1, P0776, P2813, P1715, AND/OR P0841 StoredDocument103 pages2013-2017 ALTIMA AND 2014-2017 ROGUE 4 CYLINDER WITH DTC P17F0, P17F1, P0776, P2813, P1715, AND/OR P0841 StoredCristian Jaramillo100% (2)

- 09D-TG AtsgDocument75 pages09D-TG AtsgValdir Gomiero100% (3)

- 16K in PDFDocument2 pages16K in PDFossoskiNo ratings yet

- Pdf35 Aw Tf80sc PDFDocument5 pagesPdf35 Aw Tf80sc PDFAlfredoNo ratings yet

- CFT30 VacTestDocument7 pagesCFT30 VacTestOscar SerranoNo ratings yet

- jf011 F1cja W1cjaDocument61 pagesjf011 F1cja W1cjaValentin Ivanov100% (5)

- 01m Erro 1 E2Document7 pages01m Erro 1 E2choco84No ratings yet

- Transmission Control Module (TCM) Adaptation - 8HP45 / 845RE / 8HP50 / 8HP70 / 8HP75 / 8HP90Document6 pagesTransmission Control Module (TCM) Adaptation - 8HP45 / 845RE / 8HP50 / 8HP70 / 8HP75 / 8HP90jorge almaraz0% (1)

- Atb1758 U341E TOYOTA NO FORWARD AFTER VALVE BODY WORKDocument2 pagesAtb1758 U341E TOYOTA NO FORWARD AFTER VALVE BODY WORKAleNo ratings yet

- Re5r05a Catalogo Peçs PDFDocument4 pagesRe5r05a Catalogo Peçs PDFNayara Alcântara Lima SilvaNo ratings yet

- Af21 IntroductionDocument27 pagesAf21 IntroductionHuỳnh Minh ĐứcNo ratings yet

- AW55-50SN, AW55-51SN, AF23/33, RE5F22A Zip Kit: Installation DiagramDocument10 pagesAW55-50SN, AW55-51SN, AF23/33, RE5F22A Zip Kit: Installation DiagramKalinin Pineda100% (1)

- Transmission Filters Catalog 20181202 PDFDocument75 pagesTransmission Filters Catalog 20181202 PDFssinokrot100% (2)

- A43 PDFDocument126 pagesA43 PDFyermain100% (1)

- Dsi 6 Speed Auto TransaxleDocument24 pagesDsi 6 Speed Auto TransaxleKada Ben youcefNo ratings yet

- Ford Rep Matrix 7-5-06Document41 pagesFord Rep Matrix 7-5-06rodrigo michelNo ratings yet

- Installation Manual: Canopy Ford Ranger PXDocument13 pagesInstallation Manual: Canopy Ford Ranger PXhehetuibuon13No ratings yet

- Escalade Escalade ESV Suburban Tahoe Yukon Yukon XL Electrical Body Builders Manual Service Manual 2017 en US 1Document1,719 pagesEscalade Escalade ESV Suburban Tahoe Yukon Yukon XL Electrical Body Builders Manual Service Manual 2017 en US 1Octavian GrecuNo ratings yet

- ControllerDocument132 pagesControllermohanamarasingheNo ratings yet

- Owner'S Manual Supplement 600 RMK and 700 RMK PN 9914864: 700 RMK 700 RMK Opt A 600 RMK 600 RMK Opt ADocument5 pagesOwner'S Manual Supplement 600 RMK and 700 RMK PN 9914864: 700 RMK 700 RMK Opt A 600 RMK 600 RMK Opt AhundredprestonNo ratings yet

- Rendezvous - 2005-2007 PDFDocument8,854 pagesRendezvous - 2005-2007 PDFKirk1978No ratings yet

- Item-Ancillary 20240412144020-L3EgodvFd7 DS03028 SK045-2 LP-01994 20240321 SK045-2 LP-01994 enDocument1 pageItem-Ancillary 20240412144020-L3EgodvFd7 DS03028 SK045-2 LP-01994 20240321 SK045-2 LP-01994 enhungthienphu999No ratings yet

- Manual Transmision Automatica 6r80 Ford F150 2011-2014Document701 pagesManual Transmision Automatica 6r80 Ford F150 2011-2014Jose Carlos Ochoa lugoNo ratings yet

- MGB Workshop ManualDocument417 pagesMGB Workshop ManualjailemeilleurfrereaumondeNo ratings yet

- Landini Rex4 Cab F-S-V-GT 80 90 100 110 120Document4 pagesLandini Rex4 Cab F-S-V-GT 80 90 100 110 120gennaro mongiardoNo ratings yet

- 02 atDocument13 pages02 atjoseNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- 6r80 Oil ChangeDocument13 pages6r80 Oil Changeสนั่น วิริยะเจริญกุลNo ratings yet

- Power Source Air Conditioner Air ConditionerDocument1 pagePower Source Air Conditioner Air Conditionerสนั่น วิริยะเจริญกุล100% (3)

- Multiplex Beam WishDocument1 pageMultiplex Beam Wishสนั่น วิริยะเจริญกุลNo ratings yet

- Wiring Altis 121.122Document1 pageWiring Altis 121.122สนั่น วิริยะเจริญกุลNo ratings yet

- Abs Altis 2549Document1 pageAbs Altis 2549สนั่น วิริยะเจริญกุลNo ratings yet

- 2009 Ducati Superbike SBK 848 Owner's ManualDocument126 pages2009 Ducati Superbike SBK 848 Owner's Manualสนั่น วิริยะเจริญกุลNo ratings yet

- Technical Service Information: Automatic Transmission Service GroupDocument2 pagesTechnical Service Information: Automatic Transmission Service Groupสนั่น วิริยะเจริญกุลNo ratings yet

- Technical Service Information: Automatic Transmission Service GroupDocument1 pageTechnical Service Information: Automatic Transmission Service Groupสนั่น วิริยะเจริญกุลNo ratings yet

- Technical Service Information: Automatic Transmission Service GroupDocument1 pageTechnical Service Information: Automatic Transmission Service Groupสนั่น วิริยะเจริญกุลNo ratings yet

- MPYADocument112 pagesMPYAสนั่น วิริยะเจริญกุลNo ratings yet

- PL5X L5Document112 pagesPL5X L5สนั่น วิริยะเจริญกุลNo ratings yet

- Rolls-Royce 30 P1!4!86 P01-4 Controllable Pitch Propellers Installations Manual 15S000553Document398 pagesRolls-Royce 30 P1!4!86 P01-4 Controllable Pitch Propellers Installations Manual 15S000553rusbellopez150No ratings yet

- Meritor Wabco Operación de La Válvula de Suspensión InglésDocument1 pageMeritor Wabco Operación de La Válvula de Suspensión InglésrichieNo ratings yet

- FSG23 AS Beginners Guide v1.1Document16 pagesFSG23 AS Beginners Guide v1.1Hao Ming TengNo ratings yet

- Piston Pump - High Pressure Stall - Steering 950 GC Wheel Loader M5K00001-UP (MACHINE) POWERED BY C7.1 Engine (SEBP6716 - 29) - DocumentaciónDocument5 pagesPiston Pump - High Pressure Stall - Steering 950 GC Wheel Loader M5K00001-UP (MACHINE) POWERED BY C7.1 Engine (SEBP6716 - 29) - DocumentaciónPablo Cesar Poma ArrateaNo ratings yet

- Hitachi Ex150 1 Spare PartsDocument9 pagesHitachi Ex150 1 Spare Partsfred100% (52)

- CM 7.5 - Stronger S Tine (65376)Document88 pagesCM 7.5 - Stronger S Tine (65376)Дмитрий ЧернеевNo ratings yet

- Honda - Prelude - Wiring Diagram - 1994 - 1994Document8,924 pagesHonda - Prelude - Wiring Diagram - 1994 - 1994Kristen Phillips100% (1)

- Dod Pest Management Material ListDocument12 pagesDod Pest Management Material ListBatanNo ratings yet

- Gear Train PDFDocument18 pagesGear Train PDFamanuelfitsum589No ratings yet

- Polaris LRDocument11 pagesPolaris LRDavid Lionel Fernandez ValdiviaNo ratings yet

- Manual Shoprider Streamer Sport PDFDocument24 pagesManual Shoprider Streamer Sport PDFFreddy JironNo ratings yet

- Tabel Tolerante Arbori Si AlezajeDocument1 pageTabel Tolerante Arbori Si AlezajeCosmin RobuNo ratings yet

- 1964 Gibson Firebird IIIDocument5 pages1964 Gibson Firebird IIIBeto RodriguesNo ratings yet

- Armoured Patrol CarDocument24 pagesArmoured Patrol CarRanjith SriNo ratings yet

- Maintenance - Schedule Evinrude E25Document1 pageMaintenance - Schedule Evinrude E25Cesar GamezNo ratings yet

- Research Article / Research Project / Literature ReviewDocument15 pagesResearch Article / Research Project / Literature ReviewMohamed IbrahemNo ratings yet

- Transfer System LC200Document32 pagesTransfer System LC200Yannick de WalqueNo ratings yet

- Perspective Paper On Present & Future TechnologiesDocument11 pagesPerspective Paper On Present & Future Technologiesapi-360683034No ratings yet

- Asas ONLINE JuniDocument90 pagesAsas ONLINE Junirina meilaniNo ratings yet

- PMP GG OilDocument19 pagesPMP GG OilmasdikaNo ratings yet

- Smart #1 FULL USP HighlightsDocument65 pagesSmart #1 FULL USP Highlightscheongmw78No ratings yet

- How Electric Cars WorkDocument4 pagesHow Electric Cars WorkCarla LoiaconoNo ratings yet

- Name: Email-ID: Smart Task No.: Project TopicDocument8 pagesName: Email-ID: Smart Task No.: Project TopicPrakhar SinghNo ratings yet

- Othello Essay IntroductionDocument3 pagesOthello Essay Introductionxqqryvwhd100% (2)

- Profile: Name:Ariston, Rudolf Dee P. Grade and Section:G7-Mencius (SPFL)Document1 pageProfile: Name:Ariston, Rudolf Dee P. Grade and Section:G7-Mencius (SPFL)rudy aristonNo ratings yet

- Olp4181 - TW-1-24 Fa LRDocument24 pagesOlp4181 - TW-1-24 Fa LRMelita ArifiNo ratings yet

- C8 - Volkswagen and Tata Motors - A Strategic Alliance in IndiaDocument12 pagesC8 - Volkswagen and Tata Motors - A Strategic Alliance in Indiaaswin.v25exNo ratings yet