Professional Documents

Culture Documents

Pmi Procedure

Pmi Procedure

Uploaded by

Ketan GavadeCopyright:

Available Formats

You might also like

- Hhmi Cell Cycle and Cancer - CompletedDocument3 pagesHhmi Cell Cycle and Cancer - CompletedAbel89% (9)

- Operating QualificationDocument6 pagesOperating QualificationEnko Šatrović75% (4)

- Positive Material Identification Procedure: IndexDocument8 pagesPositive Material Identification Procedure: Indexselvakumar100% (1)

- Pip Vespmi01-2019Document11 pagesPip Vespmi01-2019d-fbuser-93320248100% (2)

- Engineering Spec For Positive Material IdentificationDocument8 pagesEngineering Spec For Positive Material Identificationcancerian86100% (1)

- T41. GIS - Refractory Inspection - GIS 72-004Document8 pagesT41. GIS - Refractory Inspection - GIS 72-004Hung LuongNo ratings yet

- Tandard Perating Rocedure: TitleDocument5 pagesTandard Perating Rocedure: TitlevishalstjsNo ratings yet

- Calibration Procedure.Document7 pagesCalibration Procedure.Mohammed Kamal78% (9)

- 8.pmi ProcedureDocument9 pages8.pmi ProceduremadanbhopeNo ratings yet

- PMI Report May 2019Document19 pagesPMI Report May 2019RifanjshshNo ratings yet

- C075 Aq SPC 0006 - 3Document12 pagesC075 Aq SPC 0006 - 3Mingyu SongNo ratings yet

- PMI TestingDocument3 pagesPMI TestinghungNo ratings yet

- TTA-NDT-PMI-001 Rev.00 PDFDocument8 pagesTTA-NDT-PMI-001 Rev.00 PDFTrịnh Quốc TuyếnNo ratings yet

- Proceduer of Pmi - Rev - 03 Dec 25-2019Document14 pagesProceduer of Pmi - Rev - 03 Dec 25-2019Rajat TiwariNo ratings yet

- FAD 1.0 v2 - IsO-IEC 17025 GAC Field Application DocumentDocument6 pagesFAD 1.0 v2 - IsO-IEC 17025 GAC Field Application DocumenteducobainNo ratings yet

- Material Inspection Procedure-General Requirement-Combined (30-P01-00)Document8 pagesMaterial Inspection Procedure-General Requirement-Combined (30-P01-00)Samira MahmoodiNo ratings yet

- Nabl 126Document31 pagesNabl 126Gazal GuptaNo ratings yet

- Calibration Procedure PMIDocument8 pagesCalibration Procedure PMIbmkale100% (1)

- Supplier Quality Manual PDFDocument13 pagesSupplier Quality Manual PDFSAMPATHU100% (1)

- PMI ProcedureDocument7 pagesPMI ProcedureRoberto Carlos Arana ChumpitazNo ratings yet

- Positive Material Identification Procedure: IndexDocument8 pagesPositive Material Identification Procedure: Indexrame63No ratings yet

- 1.validation Protocol For Foil SealerDocument6 pages1.validation Protocol For Foil SealervishwahlifestyleNo ratings yet

- Nabl 142 PDFDocument6 pagesNabl 142 PDFavmrNo ratings yet

- Carry Out A Direct Current Voltage Gradient (DCVG) Survey in The Gas Transmission IndustryDocument4 pagesCarry Out A Direct Current Voltage Gradient (DCVG) Survey in The Gas Transmission IndustryMuhammad Nasir SiddiqueNo ratings yet

- 207H210856890 Certificado Fusionadora NMDocument1 page207H210856890 Certificado Fusionadora NMyiseth amayaNo ratings yet

- Positive Material Identification Procedure (PMI)Document13 pagesPositive Material Identification Procedure (PMI)SANUNo ratings yet

- PmiDocument10 pagesPmiparaneetharanNo ratings yet

- Monitoring and Measurement of Product and ProcessesDocument8 pagesMonitoring and Measurement of Product and ProcessestriveshNo ratings yet

- DKD-R 8-1 Englisch NeuDocument32 pagesDKD-R 8-1 Englisch Neugsv988No ratings yet

- Validation of Special ProcessesDocument3 pagesValidation of Special ProcessesJeyakumarNo ratings yet

- TUV SUD - MT Procedure Rev.05Document11 pagesTUV SUD - MT Procedure Rev.05HassanNo ratings yet

- Specific Criteria For Calibration of Medical DevicesDocument31 pagesSpecific Criteria For Calibration of Medical DevicesaymanNo ratings yet

- PMI ProcedureDocument7 pagesPMI Procedureosito1214100% (1)

- MS For Welding Consumable ControlDocument10 pagesMS For Welding Consumable Controlmansih457100% (1)

- Nabl 122 09 PDFDocument19 pagesNabl 122 09 PDFmaheshNo ratings yet

- Quality Reqs For Basic Process Measurement Instruments S 718Qv2022 09Document11 pagesQuality Reqs For Basic Process Measurement Instruments S 718Qv2022 09Osas AsemotaNo ratings yet

- TUV SUD - PT Procedure Rev.05Document13 pagesTUV SUD - PT Procedure Rev.05HassanNo ratings yet

- Nabl 122-08 Push Pull Gauge WebDocument16 pagesNabl 122-08 Push Pull Gauge Webprasadjoshi781429No ratings yet

- MNT-INTG-2007OP - Maintenance Welding InspectionDocument43 pagesMNT-INTG-2007OP - Maintenance Welding InspectionNatarajan MurugesanNo ratings yet

- Ur w35 PDFDocument5 pagesUr w35 PDFBala MuruganNo ratings yet

- Qad Sop 129Document4 pagesQad Sop 129Hemendra DaveNo ratings yet

- Calibaration Procedure Rev3Document4 pagesCalibaration Procedure Rev3Zubair Ahmed KhaskheliNo ratings yet

- Schneider LV Switchboard Inspection GuideDocument59 pagesSchneider LV Switchboard Inspection GuideAlp Arslan Ok100% (2)

- Nabl 122 13 PDFDocument20 pagesNabl 122 13 PDFmahesh100% (1)

- Carry Out Cathodic Protection System Troubleshooting Survey in The Gas Transmission IndustryDocument4 pagesCarry Out Cathodic Protection System Troubleshooting Survey in The Gas Transmission IndustryImam BuchairiNo ratings yet

- 002 Pressure Calibration, Master Gauges and Pressure Indicator PDFDocument9 pages002 Pressure Calibration, Master Gauges and Pressure Indicator PDFManzoor AhmadNo ratings yet

- KSA-POP-010-General Guidelines For Sampling For Laboratory TestingDocument7 pagesKSA-POP-010-General Guidelines For Sampling For Laboratory TestingASHJANNo ratings yet

- Irndt Central Certification Program For NDT PersonnelDocument31 pagesIrndt Central Certification Program For NDT PersonnelAhmed GomaaNo ratings yet

- PTS-021 Final Report Calibration of Digital Thermometer-Amd-01Document17 pagesPTS-021 Final Report Calibration of Digital Thermometer-Amd-01icivenggNo ratings yet

- Quality Requirements For Field Instruments - Electronic Transmitters - Pressure, Differential Pressure and TemperatureDocument12 pagesQuality Requirements For Field Instruments - Electronic Transmitters - Pressure, Differential Pressure and TemperaturekochicommNo ratings yet

- Nabl 122 11 PDFDocument17 pagesNabl 122 11 PDFmahesh100% (1)

- Type Approval ProgramDocument4 pagesType Approval ProgramaksjaalNo ratings yet

- Nabl 122 12 PDFDocument21 pagesNabl 122 12 PDFmaheshNo ratings yet

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- Safety Analysis and Licensing Documentation for Nuclear Fuel Cycle FacilitiesFrom EverandSafety Analysis and Licensing Documentation for Nuclear Fuel Cycle FacilitiesNo ratings yet

- Total Quality Process Control for Injection MoldingFrom EverandTotal Quality Process Control for Injection MoldingRating: 5 out of 5 stars5/5 (1)

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1From EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Rating: 4.5 out of 5 stars4.5/5 (2)

- Computer Modeling for Injection Molding: Simulation, Optimization, and ControlFrom EverandComputer Modeling for Injection Molding: Simulation, Optimization, and ControlHuamin ZhouNo ratings yet

- Establishing A CGMP Laboratory Audit System: A Practical GuideFrom EverandEstablishing A CGMP Laboratory Audit System: A Practical GuideNo ratings yet

- Ensuring Quality to Gain Access to Global Markets: A Reform ToolkitFrom EverandEnsuring Quality to Gain Access to Global Markets: A Reform ToolkitNo ratings yet

- What Hartmann'S Solution Is and What It Is Used For?Document4 pagesWhat Hartmann'S Solution Is and What It Is Used For?YudhaNo ratings yet

- Blood of YahwehDocument22 pagesBlood of YahwehwilliamstewardNo ratings yet

- Martha RogersDocument2 pagesMartha RogersMary Angel VelascoNo ratings yet

- Notice: Buy America Waivers: Mars Electronics International Et Al.Document2 pagesNotice: Buy America Waivers: Mars Electronics International Et Al.Justia.comNo ratings yet

- Pronoun Reference - Exercise 5: Correction Should Sound Natural and Be LogicalDocument4 pagesPronoun Reference - Exercise 5: Correction Should Sound Natural and Be LogicalPreecha ChanlaNo ratings yet

- ISO 00426-1-1983 ScanDocument5 pagesISO 00426-1-1983 ScanthangNo ratings yet

- Extreme Cold Weather (ECW) ClothingDocument7 pagesExtreme Cold Weather (ECW) ClothingSnowshadowNo ratings yet

- Global Warming (Word Formation)Document2 pagesGlobal Warming (Word Formation)EvaNo ratings yet

- Computational Methods: Test Program For Chasing Method Developed in MatlabDocument6 pagesComputational Methods: Test Program For Chasing Method Developed in MatlabMujtaba MujahidNo ratings yet

- Marc AisenDocument33 pagesMarc AisenjeremyreedsNo ratings yet

- Electrical Transmission and DistributionDocument31 pagesElectrical Transmission and DistributionPutri Hanifah SNo ratings yet

- Servicio y Reparación GenieDocument268 pagesServicio y Reparación Geniejonny david martinez perezNo ratings yet

- torque sensor |Unipulse CorporationDocument6 pagestorque sensor |Unipulse CorporationVerdy A. KoehuanNo ratings yet

- Gramatica LB EnglezeDocument85 pagesGramatica LB Englezemitiloi100% (1)

- 10 Traditional Chilean Desserts - Insanely Good PDFDocument1 page10 Traditional Chilean Desserts - Insanely Good PDFMarilynn SpringerNo ratings yet

- Conduit Trunking Capacity Chart RM TechnicalDocument1 pageConduit Trunking Capacity Chart RM TechnicalPrabir BhowmikNo ratings yet

- ESP Front Page Idea Aravinth 2Document10 pagesESP Front Page Idea Aravinth 2adcreation3696No ratings yet

- Vanilla Icebox CookiesDocument2 pagesVanilla Icebox CookiesmadduxdavidNo ratings yet

- Replica Metallography and Penetrant TestingDocument14 pagesReplica Metallography and Penetrant TestingBala Singam100% (1)

- Important Questions 2016Document57 pagesImportant Questions 2016Anonymous t9LFhvF100% (1)

- Review of Solar Energy Measurement SystemDocument4 pagesReview of Solar Energy Measurement SystemEditor IJRITCC100% (1)

- MP900 and MP9000 Series Kool-Pak Power Film Resistors: TO-126, TO-220 and TO-247 StyleDocument3 pagesMP900 and MP9000 Series Kool-Pak Power Film Resistors: TO-126, TO-220 and TO-247 StyleManoel HenriqueNo ratings yet

- MCO 3 (30/3-3/4/2020) Reinforcement Chapter 2 Part A: Objective QuestionsDocument5 pagesMCO 3 (30/3-3/4/2020) Reinforcement Chapter 2 Part A: Objective QuestionsZalini AbdullahNo ratings yet

- Jean AttachmentDocument17 pagesJean AttachmentReena VermaNo ratings yet

- Astm D2563-94Document24 pagesAstm D2563-94Santiago AngelNo ratings yet

- 1.introduction To HydraulicsDocument32 pages1.introduction To HydraulicsJet Espejon JavierNo ratings yet

- Bba 400 Module Revised 2017 April To DsvolDocument68 pagesBba 400 Module Revised 2017 April To DsvolKafonyi JohnNo ratings yet

- Type 4536 Oscillator-Divider ICDocument13 pagesType 4536 Oscillator-Divider ICRoscoeDog718No ratings yet

Pmi Procedure

Pmi Procedure

Uploaded by

Ketan GavadeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pmi Procedure

Pmi Procedure

Uploaded by

Ketan GavadeCopyright:

Available Formats

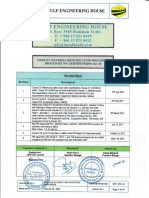

POSITIVE MATERIAL IDENTIFICATION PROCEDURE

( PMI )

Document Type SOP No.:- FSPL/PMI/01

Standard Operating Procedure REV. NO.:- 00

Document Revisions Signature

00 20/07/2022 Issued for information

Rev. Date Description Prepared by Approved by

Page 1 of 6 DOC. NO.:- FSPL/PMI/01 Rev. No.:- 00 DATE:- 20/07/2022

POSITIVE MATERIAL IDENTIFICATION PROCEDURE

( PMI )

1.0 SCOPE

Positive Material Identification (PMI) also called Alloy Verification (AV), is

an exercise in alloy verification and semi–quantitative analysis.

The following procedure identifies the test method and traceability of this

technique.

2.0 BACKGROUND

PMI testing should be carried out to supplement the mill certificate where this

is available .Tests are performed in accordance with the chemical requirements

as per applicable ASTM standard but do not replace the BS EN 10204 type 3.1,

3.2 certification. Additional test methods may be performed on the same

samples and the results shall be reported along with PMI results on the same

inspection certificate.

3.0 TEST METHOD

The test method used should be suitable for the analytical information required.

Special attention should be given to ensure that the technique used is suitable to

identify the important elements in the material. Example: where a material mix

up is identified or where low wavelength elements are important.

Accuracy is ±10 percent of the given result.

3.1 ACCEPTANCE CRITERIA

Material test results shall match with the respective ASME section II A

standard, with ±10 percent variation is acceptable.

Page 2 of 6 DOC. NO.:- FSPL/PMI/01 Rev. No.:- 00 DATE:- 20/07/2022

POSITIVE MATERIAL IDENTIFICATION PROCEDURE

( PMI )

4.0 ENVIRONMENT

Instruments are manufactured to operate on or off site in dry conditions,

acceptable temperature range is 0-35 degree Celsius.

5.0 HEALTH AND SAFETY

It is the operator’s responsibility to ensure that the correct health and safety

legislation is strictly adhered to; When working on site , liaise with the

customer representative for local directives. Also that a risk assessment has

been carried out and IRR 99 regulations are met.

6.0 EQUIPMENT

6.1 Equipment Details

XMET 8000 TYPE S.NO.814086 has been manufactured by M/s Hitachi

High-tech.

6.2 Mode of Operation

1. Switch on the instrument and log in with password.

2. Perform the system check of instrument to ensure its working condition.

3. Select the general metal mode for verification.

4. Analyze the CRM sample for correct PMI identification and values shall be

compared and ensured with standard chart.

Page 3 of 6 DOC. NO.:- FSPL/PMI/01 Rev. No.:- 00 DATE:- 20/07/2022

POSITIVE MATERIAL IDENTIFICATION PROCEDURE

( PMI )

7.0 PRIMARY CALIBRATION

Primary calibration is to be carried out by the manufacturer of the instrument

taking due care over power settings and inter-element effects for each program.

Adjustments to these programs should only be carried out by approved

personnel.

8.0 CALIBRATION PROCEDURE

As a minimum the instrument shall be calibrated at the beginning of the test

period and at the end of each period and after an interval of 50 analysis.

Calibration shall be performed strictly using certified standards. Calibration of

the instrument used should be carried out to the manufacturer’s instructions and

calibrated by an approved engineer on a yearly basis.

A selection of material test samples are available to the operator.

9.0 ANALYTICAL PROCEDURE

The instruments are used for identifying the material by quantitative

measurement of the alloying elements. Additional tests such as chemical

analysis may also be carried out, which is conducted by a third party

organization.

Areas of contamination of loss scale, paint etc. shall be avoided.

Test areas may be welds or parent materials.

Single or multi analysis may be taken in one or more locations.

Page 4 of 6 DOC. NO.:- FSPL/PMI/01 Rev. No.:- 00 DATE:- 20/07/2022

POSITIVE MATERIAL IDENTIFICATION PROCEDURE

( PMI )

10.0 STANDARD REFERENCES

The procedure meets the requirements of ASTM Designation: E 1476-97

11.0 OPERATOR QUALIFICATION

The P.M.I. will be carried out by operators who have completed a training

course.

Page 5 of 6 DOC. NO.:- FSPL/PMI/01 Rev. No.:- 00 DATE:- 20/07/2022

POSITIVE MATERIAL IDENTIFICATION PROCEDURE

( PMI )

12.0 REPORTING:

Reports of P.M.I. test shall be submitted stating as a minimum:

Item identity

Job Number (If applicable).

Date of test

Instrument make

Analysis results

Name of Operator

Date of Calibration

Page 6 of 6 DOC. NO.:- FSPL/PMI/01 Rev. No.:- 00 DATE:- 20/07/2022

You might also like

- Hhmi Cell Cycle and Cancer - CompletedDocument3 pagesHhmi Cell Cycle and Cancer - CompletedAbel89% (9)

- Operating QualificationDocument6 pagesOperating QualificationEnko Šatrović75% (4)

- Positive Material Identification Procedure: IndexDocument8 pagesPositive Material Identification Procedure: Indexselvakumar100% (1)

- Pip Vespmi01-2019Document11 pagesPip Vespmi01-2019d-fbuser-93320248100% (2)

- Engineering Spec For Positive Material IdentificationDocument8 pagesEngineering Spec For Positive Material Identificationcancerian86100% (1)

- T41. GIS - Refractory Inspection - GIS 72-004Document8 pagesT41. GIS - Refractory Inspection - GIS 72-004Hung LuongNo ratings yet

- Tandard Perating Rocedure: TitleDocument5 pagesTandard Perating Rocedure: TitlevishalstjsNo ratings yet

- Calibration Procedure.Document7 pagesCalibration Procedure.Mohammed Kamal78% (9)

- 8.pmi ProcedureDocument9 pages8.pmi ProceduremadanbhopeNo ratings yet

- PMI Report May 2019Document19 pagesPMI Report May 2019RifanjshshNo ratings yet

- C075 Aq SPC 0006 - 3Document12 pagesC075 Aq SPC 0006 - 3Mingyu SongNo ratings yet

- PMI TestingDocument3 pagesPMI TestinghungNo ratings yet

- TTA-NDT-PMI-001 Rev.00 PDFDocument8 pagesTTA-NDT-PMI-001 Rev.00 PDFTrịnh Quốc TuyếnNo ratings yet

- Proceduer of Pmi - Rev - 03 Dec 25-2019Document14 pagesProceduer of Pmi - Rev - 03 Dec 25-2019Rajat TiwariNo ratings yet

- FAD 1.0 v2 - IsO-IEC 17025 GAC Field Application DocumentDocument6 pagesFAD 1.0 v2 - IsO-IEC 17025 GAC Field Application DocumenteducobainNo ratings yet

- Material Inspection Procedure-General Requirement-Combined (30-P01-00)Document8 pagesMaterial Inspection Procedure-General Requirement-Combined (30-P01-00)Samira MahmoodiNo ratings yet

- Nabl 126Document31 pagesNabl 126Gazal GuptaNo ratings yet

- Calibration Procedure PMIDocument8 pagesCalibration Procedure PMIbmkale100% (1)

- Supplier Quality Manual PDFDocument13 pagesSupplier Quality Manual PDFSAMPATHU100% (1)

- PMI ProcedureDocument7 pagesPMI ProcedureRoberto Carlos Arana ChumpitazNo ratings yet

- Positive Material Identification Procedure: IndexDocument8 pagesPositive Material Identification Procedure: Indexrame63No ratings yet

- 1.validation Protocol For Foil SealerDocument6 pages1.validation Protocol For Foil SealervishwahlifestyleNo ratings yet

- Nabl 142 PDFDocument6 pagesNabl 142 PDFavmrNo ratings yet

- Carry Out A Direct Current Voltage Gradient (DCVG) Survey in The Gas Transmission IndustryDocument4 pagesCarry Out A Direct Current Voltage Gradient (DCVG) Survey in The Gas Transmission IndustryMuhammad Nasir SiddiqueNo ratings yet

- 207H210856890 Certificado Fusionadora NMDocument1 page207H210856890 Certificado Fusionadora NMyiseth amayaNo ratings yet

- Positive Material Identification Procedure (PMI)Document13 pagesPositive Material Identification Procedure (PMI)SANUNo ratings yet

- PmiDocument10 pagesPmiparaneetharanNo ratings yet

- Monitoring and Measurement of Product and ProcessesDocument8 pagesMonitoring and Measurement of Product and ProcessestriveshNo ratings yet

- DKD-R 8-1 Englisch NeuDocument32 pagesDKD-R 8-1 Englisch Neugsv988No ratings yet

- Validation of Special ProcessesDocument3 pagesValidation of Special ProcessesJeyakumarNo ratings yet

- TUV SUD - MT Procedure Rev.05Document11 pagesTUV SUD - MT Procedure Rev.05HassanNo ratings yet

- Specific Criteria For Calibration of Medical DevicesDocument31 pagesSpecific Criteria For Calibration of Medical DevicesaymanNo ratings yet

- PMI ProcedureDocument7 pagesPMI Procedureosito1214100% (1)

- MS For Welding Consumable ControlDocument10 pagesMS For Welding Consumable Controlmansih457100% (1)

- Nabl 122 09 PDFDocument19 pagesNabl 122 09 PDFmaheshNo ratings yet

- Quality Reqs For Basic Process Measurement Instruments S 718Qv2022 09Document11 pagesQuality Reqs For Basic Process Measurement Instruments S 718Qv2022 09Osas AsemotaNo ratings yet

- TUV SUD - PT Procedure Rev.05Document13 pagesTUV SUD - PT Procedure Rev.05HassanNo ratings yet

- Nabl 122-08 Push Pull Gauge WebDocument16 pagesNabl 122-08 Push Pull Gauge Webprasadjoshi781429No ratings yet

- MNT-INTG-2007OP - Maintenance Welding InspectionDocument43 pagesMNT-INTG-2007OP - Maintenance Welding InspectionNatarajan MurugesanNo ratings yet

- Ur w35 PDFDocument5 pagesUr w35 PDFBala MuruganNo ratings yet

- Qad Sop 129Document4 pagesQad Sop 129Hemendra DaveNo ratings yet

- Calibaration Procedure Rev3Document4 pagesCalibaration Procedure Rev3Zubair Ahmed KhaskheliNo ratings yet

- Schneider LV Switchboard Inspection GuideDocument59 pagesSchneider LV Switchboard Inspection GuideAlp Arslan Ok100% (2)

- Nabl 122 13 PDFDocument20 pagesNabl 122 13 PDFmahesh100% (1)

- Carry Out Cathodic Protection System Troubleshooting Survey in The Gas Transmission IndustryDocument4 pagesCarry Out Cathodic Protection System Troubleshooting Survey in The Gas Transmission IndustryImam BuchairiNo ratings yet

- 002 Pressure Calibration, Master Gauges and Pressure Indicator PDFDocument9 pages002 Pressure Calibration, Master Gauges and Pressure Indicator PDFManzoor AhmadNo ratings yet

- KSA-POP-010-General Guidelines For Sampling For Laboratory TestingDocument7 pagesKSA-POP-010-General Guidelines For Sampling For Laboratory TestingASHJANNo ratings yet

- Irndt Central Certification Program For NDT PersonnelDocument31 pagesIrndt Central Certification Program For NDT PersonnelAhmed GomaaNo ratings yet

- PTS-021 Final Report Calibration of Digital Thermometer-Amd-01Document17 pagesPTS-021 Final Report Calibration of Digital Thermometer-Amd-01icivenggNo ratings yet

- Quality Requirements For Field Instruments - Electronic Transmitters - Pressure, Differential Pressure and TemperatureDocument12 pagesQuality Requirements For Field Instruments - Electronic Transmitters - Pressure, Differential Pressure and TemperaturekochicommNo ratings yet

- Nabl 122 11 PDFDocument17 pagesNabl 122 11 PDFmahesh100% (1)

- Type Approval ProgramDocument4 pagesType Approval ProgramaksjaalNo ratings yet

- Nabl 122 12 PDFDocument21 pagesNabl 122 12 PDFmaheshNo ratings yet

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- Safety Analysis and Licensing Documentation for Nuclear Fuel Cycle FacilitiesFrom EverandSafety Analysis and Licensing Documentation for Nuclear Fuel Cycle FacilitiesNo ratings yet

- Total Quality Process Control for Injection MoldingFrom EverandTotal Quality Process Control for Injection MoldingRating: 5 out of 5 stars5/5 (1)

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1From EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Rating: 4.5 out of 5 stars4.5/5 (2)

- Computer Modeling for Injection Molding: Simulation, Optimization, and ControlFrom EverandComputer Modeling for Injection Molding: Simulation, Optimization, and ControlHuamin ZhouNo ratings yet

- Establishing A CGMP Laboratory Audit System: A Practical GuideFrom EverandEstablishing A CGMP Laboratory Audit System: A Practical GuideNo ratings yet

- Ensuring Quality to Gain Access to Global Markets: A Reform ToolkitFrom EverandEnsuring Quality to Gain Access to Global Markets: A Reform ToolkitNo ratings yet

- What Hartmann'S Solution Is and What It Is Used For?Document4 pagesWhat Hartmann'S Solution Is and What It Is Used For?YudhaNo ratings yet

- Blood of YahwehDocument22 pagesBlood of YahwehwilliamstewardNo ratings yet

- Martha RogersDocument2 pagesMartha RogersMary Angel VelascoNo ratings yet

- Notice: Buy America Waivers: Mars Electronics International Et Al.Document2 pagesNotice: Buy America Waivers: Mars Electronics International Et Al.Justia.comNo ratings yet

- Pronoun Reference - Exercise 5: Correction Should Sound Natural and Be LogicalDocument4 pagesPronoun Reference - Exercise 5: Correction Should Sound Natural and Be LogicalPreecha ChanlaNo ratings yet

- ISO 00426-1-1983 ScanDocument5 pagesISO 00426-1-1983 ScanthangNo ratings yet

- Extreme Cold Weather (ECW) ClothingDocument7 pagesExtreme Cold Weather (ECW) ClothingSnowshadowNo ratings yet

- Global Warming (Word Formation)Document2 pagesGlobal Warming (Word Formation)EvaNo ratings yet

- Computational Methods: Test Program For Chasing Method Developed in MatlabDocument6 pagesComputational Methods: Test Program For Chasing Method Developed in MatlabMujtaba MujahidNo ratings yet

- Marc AisenDocument33 pagesMarc AisenjeremyreedsNo ratings yet

- Electrical Transmission and DistributionDocument31 pagesElectrical Transmission and DistributionPutri Hanifah SNo ratings yet

- Servicio y Reparación GenieDocument268 pagesServicio y Reparación Geniejonny david martinez perezNo ratings yet

- torque sensor |Unipulse CorporationDocument6 pagestorque sensor |Unipulse CorporationVerdy A. KoehuanNo ratings yet

- Gramatica LB EnglezeDocument85 pagesGramatica LB Englezemitiloi100% (1)

- 10 Traditional Chilean Desserts - Insanely Good PDFDocument1 page10 Traditional Chilean Desserts - Insanely Good PDFMarilynn SpringerNo ratings yet

- Conduit Trunking Capacity Chart RM TechnicalDocument1 pageConduit Trunking Capacity Chart RM TechnicalPrabir BhowmikNo ratings yet

- ESP Front Page Idea Aravinth 2Document10 pagesESP Front Page Idea Aravinth 2adcreation3696No ratings yet

- Vanilla Icebox CookiesDocument2 pagesVanilla Icebox CookiesmadduxdavidNo ratings yet

- Replica Metallography and Penetrant TestingDocument14 pagesReplica Metallography and Penetrant TestingBala Singam100% (1)

- Important Questions 2016Document57 pagesImportant Questions 2016Anonymous t9LFhvF100% (1)

- Review of Solar Energy Measurement SystemDocument4 pagesReview of Solar Energy Measurement SystemEditor IJRITCC100% (1)

- MP900 and MP9000 Series Kool-Pak Power Film Resistors: TO-126, TO-220 and TO-247 StyleDocument3 pagesMP900 and MP9000 Series Kool-Pak Power Film Resistors: TO-126, TO-220 and TO-247 StyleManoel HenriqueNo ratings yet

- MCO 3 (30/3-3/4/2020) Reinforcement Chapter 2 Part A: Objective QuestionsDocument5 pagesMCO 3 (30/3-3/4/2020) Reinforcement Chapter 2 Part A: Objective QuestionsZalini AbdullahNo ratings yet

- Jean AttachmentDocument17 pagesJean AttachmentReena VermaNo ratings yet

- Astm D2563-94Document24 pagesAstm D2563-94Santiago AngelNo ratings yet

- 1.introduction To HydraulicsDocument32 pages1.introduction To HydraulicsJet Espejon JavierNo ratings yet

- Bba 400 Module Revised 2017 April To DsvolDocument68 pagesBba 400 Module Revised 2017 April To DsvolKafonyi JohnNo ratings yet

- Type 4536 Oscillator-Divider ICDocument13 pagesType 4536 Oscillator-Divider ICRoscoeDog718No ratings yet