Professional Documents

Culture Documents

TSDS38vsNC38 Table 2011 11 03 US

TSDS38vsNC38 Table 2011 11 03 US

Uploaded by

Jcchcc JcchccOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TSDS38vsNC38 Table 2011 11 03 US

TSDS38vsNC38 Table 2011 11 03 US

Uploaded by

Jcchcc JcchccCopyright:

Available Formats

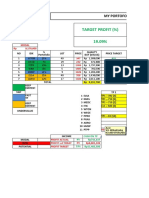

Texas

Steel Conversion TSDS 38 comparison with API NC 38

Box Pin Make‐Up Torsional Pin Connection

OD ID Torque Yield Tensile Yield Size and Style

RSC Type

(in) (in) (ft‐lbs) (ft‐lbs) (lbs)

Values in green indicate the improved performance of TSDS over API

20,110 + 75% 33,520 b + 75% 947,700 + 13% TSDS 38

2 1/8

11,504 19,174 b 842,400 API NC 38

17,900 + 56% 29,840 b + 56% 796,500 + 13% TSDS 38

4 3/4 2 7/16

11,504 19,174 b 708,000 API NC 38

16,900 + 47% 28,170 b + 47% 730,300 + 13% TSDS 38

2 9/16

11,504 19,174 b 649,100 API NC 38

22,630 + 65% 37,720 b + 65% 947,700 + 13% TSDS 38

2 1/8

13,745 22,908 b 842,400 API NC 38

19,830 + 50% 33,060 + 50% 796,500 + 13% TSDS 38

4 7/8 2 7/16

13,221 22,035 708,000 API NC 38

17,520 + 45% 29,200 + 45% 730,300 + 13% TSDS 38

2 9/16

12,057 20,095 649,100 API NC 38

25,060 + 58% 41,770 + 58% 947,700 + 13% TSDS 38

2 1/8

15,902 26,503 842,400 API NC 38

19,830 + 50% 33,060 + 50% 796,500 + 13% TSDS 38

5 2 7/16

13,221 22,035 708,000 API NC 38

17,520 + 45% 29,200 + 45% 730,300 + 13% TSDS 38

2 9/16

12,057 20,095 649,100 API NC 38

b ‐ Torsional yield values shown in yellow indicate the connection is box weak in torsion.

TSDS Values based on 135Ksi Material Yield Strength. API NC Values based on 120Ksi Material Yield Strength.

Torsional values are based on using a thread compound with a 1.0 API friction factor.

Pin tensile yield values are based on tensile loading conditions only, and do not include the combined effect of torsional and tensile loading.

You might also like

- Mutu Beton Keras MoeDocument11 pagesMutu Beton Keras MoeYusufIPNo ratings yet

- Pfi Es-49 PDFDocument8 pagesPfi Es-49 PDFjxsnyderNo ratings yet

- 1 - Grinding Media Catalogue PDFDocument14 pages1 - Grinding Media Catalogue PDFmahreza189No ratings yet

- AOR Contrete WorksDocument1 pageAOR Contrete WorksAVINASH SAININo ratings yet

- TSDS46vsNC46 Table 2011 11 03 USDocument1 pageTSDS46vsNC46 Table 2011 11 03 USJcchcc JcchccNo ratings yet

- Practice Problems 2Document9 pagesPractice Problems 2Divyam GargNo ratings yet

- Cout Du Capital: BFR 0 23958333,33 31145833,33 35817708,33 CH VAR Unitaire 385 365,75 347,4625Document9 pagesCout Du Capital: BFR 0 23958333,33 31145833,33 35817708,33 CH VAR Unitaire 385 365,75 347,4625joNo ratings yet

- 31 - 10 - Seguimiento Semanal - Apertura - Canal - Apertura - CEDocument33 pages31 - 10 - Seguimiento Semanal - Apertura - Canal - Apertura - CELILIANA MARINNo ratings yet

- TSDS50vsNC50 Table 2011 11 03 USDocument1 pageTSDS50vsNC50 Table 2011 11 03 USJcchcc JcchccNo ratings yet

- E&FB ABP HandoutsDocument10 pagesE&FB ABP HandoutsAishwarya HetawalNo ratings yet

- Investasi YukksDocument79 pagesInvestasi YukkspascalNo ratings yet

- UPS QuotationsDocument6 pagesUPS QuotationsAshish MahapatraNo ratings yet

- Alp, Tech. Mayhs e - BookDocument79 pagesAlp, Tech. Mayhs e - BookDigital WorldNo ratings yet

- Exam Gestion Financier Ratt 2018 Prof MESK - Faculté HASSAN 2 CASABLANCADocument1 pageExam Gestion Financier Ratt 2018 Prof MESK - Faculté HASSAN 2 CASABLANCAAbdoNo ratings yet

- CDS BrochureDocument2 pagesCDS Brochure11tkt11No ratings yet

- Partnership ActivityDocument6 pagesPartnership ActivityKenneth Christian WilburNo ratings yet

- Plantilla DimensionamientoDocument243 pagesPlantilla Dimensionamientolaura DuranNo ratings yet

- Net Drum With Installation For 1 Netdrum (Karnafully)Document5 pagesNet Drum With Installation For 1 Netdrum (Karnafully)M Jobayer AzadNo ratings yet

- GPM (Sales) Total AmountDocument13 pagesGPM (Sales) Total AmountMarvin CaliwaganNo ratings yet

- Constable Police Employee Payslip - IFMISDocument1 pageConstable Police Employee Payslip - IFMISpraveen kumarNo ratings yet

- Sarvajal - Estados Financieros 211028-PDF-ENG-19Document1 pageSarvajal - Estados Financieros 211028-PDF-ENG-19Santiago et AlejandraNo ratings yet

- Process CostingDocument4 pagesProcess CostingDanilynNo ratings yet

- Capital Investment Break-Up: Marketing and PromotionDocument7 pagesCapital Investment Break-Up: Marketing and PromotionDeepak RamamoorthyNo ratings yet

- (Latest) Edc Ffa Long QuestionDocument11 pages(Latest) Edc Ffa Long QuestionputeriNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Wanda Firdiana Agustin - Paralel ADocument19 pagesWanda Firdiana Agustin - Paralel AintanNo ratings yet

- Rama Raju Final Workings 30.08.2020Document2 pagesRama Raju Final Workings 30.08.2020Varma RebalNo ratings yet

- Apr-20 May-20 Jun-20 1st QTR Jul-20 Aug-20 Sep-20 2nd QTR Oct-20 Nov-20Document22 pagesApr-20 May-20 Jun-20 1st QTR Jul-20 Aug-20 Sep-20 2nd QTR Oct-20 Nov-20Manash HazarikaNo ratings yet

- Green and Renewable BiofuelDocument10 pagesGreen and Renewable BiofuelMokhsein AbdullahNo ratings yet

- Departmentalization Problem Key UeDocument2 pagesDepartmentalization Problem Key Ueedrianclyde100% (1)

- Chart Title: 25,000 F (X) 2474.76518677286 LN (X) + 17857.0134206001 R 0.958813908236723Document6 pagesChart Title: 25,000 F (X) 2474.76518677286 LN (X) + 17857.0134206001 R 0.958813908236723Frank PeraltaNo ratings yet

- Ekonomi Hans DadiDocument279 pagesEkonomi Hans DadiHans DadiNo ratings yet

- HDFC MAYDocument1 pageHDFC MAYpraveen kumarNo ratings yet

- Gathara Ecc 502 CatDocument7 pagesGathara Ecc 502 CatJohn Wafula wekesaNo ratings yet

- Insitu California Bearing Ratio (CBR) Test With Dynamic Cone Penetrometer (DCP)Document1 pageInsitu California Bearing Ratio (CBR) Test With Dynamic Cone Penetrometer (DCP)salman al-fariziNo ratings yet

- Bearings 1Document6 pagesBearings 1Rodil ManaloNo ratings yet

- August 15-September 7Document7 pagesAugust 15-September 7April NNo ratings yet

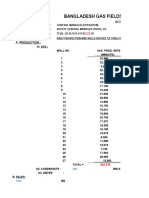

- Bangladesh Gas Fields Company Limited: A. ProductionDocument4 pagesBangladesh Gas Fields Company Limited: A. ProductionAbdullah Al MamunNo ratings yet

- Supply of Power CableDocument7 pagesSupply of Power CableArshad Ali AnjumNo ratings yet

- Diagrama TransiciónDocument4 pagesDiagrama TransiciónNicolás JaimesNo ratings yet

- BOK ValuationDocument7 pagesBOK ValuationsuryagcNo ratings yet

- Forecasting Example Set 2Document16 pagesForecasting Example Set 2abhijeet091993No ratings yet

- 43-Utm Load Cell Tensile Calibration CartificateDocument1 page43-Utm Load Cell Tensile Calibration CartificateCustomer SupportNo ratings yet

- Misc Matters - May'24 - PAN India - Excluding - West & KeralaDocument3 pagesMisc Matters - May'24 - PAN India - Excluding - West & Keralabarsha2011No ratings yet

- Section-4 Pkg-II-1Document13 pagesSection-4 Pkg-II-1Yasir HameedNo ratings yet

- Pengajuan Alat ElindDocument2 pagesPengajuan Alat ElindAbdul RokibNo ratings yet

- ESP Excel PAD Rev01 - 5628121 - 01Document37 pagesESP Excel PAD Rev01 - 5628121 - 01Geraldo Soemaschris SoewarnoNo ratings yet

- Market Report - 05 June 2024Document3 pagesMarket Report - 05 June 2024Habakuki HussenNo ratings yet

- Market Report_20 June 2024Document3 pagesMarket Report_20 June 2024Habakuki HussenNo ratings yet

- Sahianwala Project - Waqar SBDocument4 pagesSahianwala Project - Waqar SBRana Ahmad AamirNo ratings yet

- F5 CRQ PracticeDocument11 pagesF5 CRQ Practiceprabhakaran arumugamNo ratings yet

- Connection Fees Tables: Table 1Document6 pagesConnection Fees Tables: Table 1SteveNo ratings yet

- Mining Production & Cost ALEDocument33 pagesMining Production & Cost ALEyunediNo ratings yet

- RCC13 Punching ShearDocument10 pagesRCC13 Punching Shearelser yuber sanches condorNo ratings yet

- Market Report - 16 January 2024Document3 pagesMarket Report - 16 January 2024Habakuki HussenNo ratings yet

- Kourba Costing Sheet - Q4 - 301119Document15 pagesKourba Costing Sheet - Q4 - 301119Haneen JosephNo ratings yet

- So LLLLLDocument12 pagesSo LLLLLYeiko YamocaNo ratings yet

- Tax inDocument1 pageTax ina KhanNo ratings yet

- Ballada Book Practice SetsDocument38 pagesBallada Book Practice SetskikoNo ratings yet

- Pay Slip APRILDocument1 pagePay Slip APRILpraveen kumarNo ratings yet

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to LSIFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to LSINo ratings yet

- TSDS50vsNC50 Table 2011 11 03 USDocument1 pageTSDS50vsNC50 Table 2011 11 03 USJcchcc JcchccNo ratings yet

- TSDS40vsNC40 Table 2011 11 03 USDocument1 pageTSDS40vsNC40 Table 2011 11 03 USJcchcc JcchccNo ratings yet

- 3-1/2'', 13.30#, 0.368'', S135, EU, R2: NC38 (3-1/2"IF) - 4.875'' X 2.563''Document3 pages3-1/2'', 13.30#, 0.368'', S135, EU, R2: NC38 (3-1/2"IF) - 4.875'' X 2.563''Jcchcc JcchccNo ratings yet

- 3-1/2'', 13.30#, 0.368'', S135, EU, R2: Delta377 - 4.750'' X 2.563''Document5 pages3-1/2'', 13.30#, 0.368'', S135, EU, R2: Delta377 - 4.750'' X 2.563''Jcchcc JcchccNo ratings yet

- AOA Instruction ManualDocument9 pagesAOA Instruction ManualDave ElrickNo ratings yet

- ReservoirsDocument2 pagesReservoirsJay R SVNo ratings yet

- Assistant Professor Mechanical Department: Mr. G. Aravind ReddyDocument67 pagesAssistant Professor Mechanical Department: Mr. G. Aravind ReddySai RamNo ratings yet

- Draft Report SRIKAR LABS Annual Safety Review & Safety AuditDocument16 pagesDraft Report SRIKAR LABS Annual Safety Review & Safety AuditL JayanthiNo ratings yet

- Foam Water-and-Wet-ChemicalDocument2 pagesFoam Water-and-Wet-ChemicalMD AbdullahNo ratings yet

- Processes and Printers 3DDocument6 pagesProcesses and Printers 3DFresnel FisicoNo ratings yet

- Iso 5178 (2019)Document9 pagesIso 5178 (2019)Fadi SetiawanNo ratings yet

- Broch Delta2FlySeries2WayControlValves 420C en 20200806Document24 pagesBroch Delta2FlySeries2WayControlValves 420C en 20200806Ahmed Al-JewariNo ratings yet

- Anotec Product Catalogue GeneralDocument16 pagesAnotec Product Catalogue GeneralAnotec Pty Ltd100% (1)

- Shade Card Cement PaintDocument2 pagesShade Card Cement PaintNARAYANSINGH RAJPUTNo ratings yet

- Battery White PaperDocument27 pagesBattery White PaperSohail AliNo ratings yet

- Welding TechDocument348 pagesWelding Techniteenkardi100% (2)

- SOLIDWORKS Simulation ProfessionalDocument1 pageSOLIDWORKS Simulation ProfessionalpinguituxNo ratings yet

- Memristor My PresentationDocument23 pagesMemristor My PresentationPrateek AgrawalNo ratings yet

- Sylvania Twist-Pak Post Top Refractor Models Spec SheetDocument2 pagesSylvania Twist-Pak Post Top Refractor Models Spec SheetAlan MastersNo ratings yet

- 1506a-E88tag2 Electropak Pn3087Document2 pages1506a-E88tag2 Electropak Pn3087Md ShNo ratings yet

- EIBACHDocument24 pagesEIBACHfranpardalvagNo ratings yet

- Barangay Ordinance SWMDocument5 pagesBarangay Ordinance SWMNixon A. Baban100% (4)

- WPS 1-1-GT-SM-6 Rev. 0Document8 pagesWPS 1-1-GT-SM-6 Rev. 0Melby de la rosaNo ratings yet

- 310 Drum Lifting Jacks, Shafts, Loading TraversesDocument14 pages310 Drum Lifting Jacks, Shafts, Loading TraversesKlanac BrčkoNo ratings yet

- Volumetric Cup Filler: Models Vc-2 and VC-SV SeriesDocument2 pagesVolumetric Cup Filler: Models Vc-2 and VC-SV SeriesAmilcar Huayhua MontevillaNo ratings yet

- Acknowledgement and IndexDocument8 pagesAcknowledgement and Indexpatel ketanNo ratings yet

- 66 Bridge Maintenance Safety Management Health Monitoring and Informatics KohDocument780 pages66 Bridge Maintenance Safety Management Health Monitoring and Informatics Kohjamniczu100% (1)

- Chandrahash Sahoo ResumeDocument4 pagesChandrahash Sahoo Resumec_h_sahooNo ratings yet

- Schedule Maintenance Preventive 2023 (Major)Document1 pageSchedule Maintenance Preventive 2023 (Major)BennyNo ratings yet

- OA 3961 Zinc Phosphate Primer Product Data: (Exterior / Interior)Document1 pageOA 3961 Zinc Phosphate Primer Product Data: (Exterior / Interior)tshawkyNo ratings yet

- Final Chemazing RaceDocument9 pagesFinal Chemazing RaceRobiños AngeloNo ratings yet

- Pipe Rack Sizing and Loading DataDocument6 pagesPipe Rack Sizing and Loading DataapirakqNo ratings yet