Professional Documents

Culture Documents

Pfeifer - Lifting Beam Rotor

Pfeifer - Lifting Beam Rotor

Uploaded by

Jonas PadillaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pfeifer - Lifting Beam Rotor

Pfeifer - Lifting Beam Rotor

Uploaded by

Jonas PadillaCopyright:

Available Formats

Prüflos Nr.

: 1961084 Seite : 1/57

Translation of the Original operating manual

no. 9981360

Spreader beam in special design

Table of Contents

1 PRODUCT DESCRIPTION ........................................................................................................................ 2

1.1 TECHNICAL SPECIFICATIONS ................................................................................................................2

1.2 AUTHORISED INTEND USE AND EQUIPMENT DESCRIPTION...................................................................3

1.3 USER GROUPS ......................................................................................................................................5

2 SAFETY PRECAUTIONS........................................................................................................................... 6

2.1 BASIC SAFETY PRECAUTIONS ..............................................................................................................6

2.2 DANGER SYMBOLS ...............................................................................................................................7

2.3 GENERAL SAFETY PRECAUTIONS ........................................................................................................8

3 SETTING TO OPERATION ....................................................................................................................... 9

3.1 ATTACHING AND LOCKING THE SPREADER BEAM IN THE CRANE HOOK ...............................................9

3.2 UNLOADING REQUIREMENTS / SETUP REQUIREMENTS ........................................................................9

3.3 STORAGE CONDITIONS / STORAGE WHEN NOT IN USE ......................................................................10

3.4 SETTING TO OPERATION .....................................................................................................................11

4 PICKING UP LOADS ................................................................................................................................ 12

4.1 POSITIONING THE SPREADER BEAM ...................................................................................................12

4.2 ATTACHING THE LOAD.........................................................................................................................12

4.3 LIFTING THE LOAD ...............................................................................................................................13

5 TRANSPORT OF LOADS ........................................................................................................................ 14

6 SETTING DOWN LOADS ........................................................................................................................ 14

7 SERVICE AND MAINTENANCE OF THE SPREADER BEAM .......................................................... 16

7.1 REGULAR INSPECTIONS......................................................................................................................16

7.2 IMPERATIVE INSPECTIONS ..................................................................................................................16

7.3 REPAIRS ..............................................................................................................................................16

8 WORKS CERTIFICATE ACCORDING TO EN 10 204-2.1 ................................................................. 17

9 KONFORMITÄTSERKLÄRUNG ............................................................................................................. 18

10 GLOSSARY ................................................................................................................................................ 19

11 INSPECTION RECORD ........................................................................................................................... 20

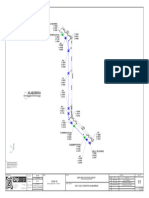

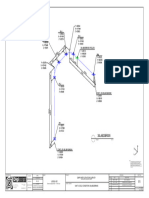

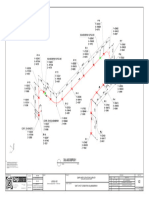

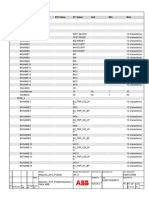

11.1 OVERVIEW DRAWING WITH PARTLIST.................................................................................................21

Siemens AG Görlitz Prudlo Torsten

Freigegeben QM1 reviewed

PG SU EIS DE P QM

2017.06.27 10:18:50 +02'00'

TYP / FABRIKNR.: 287765 / 9981360 1

Prüflos Nr. : 1961084 Seite : 2/57

1 Product Description

1.1 Technical Specifications

Manufacturer: PFEIFER Seil- und Hebetechnik GmbH

Dr. – Karl – Lenz Str. 66

87700 Memmingen

Item:: Spreader beam in special design

Fabrication number: 9981360

Type: 287765

Order no.: D45991

Year of construction: 2016

Capacity (SWL): 39.780 kg

Dead weight: 2.965 kg

Suspension of spreader beam: 2x Round slings ;

suitable for single hook and twin hook no. xx,

acc. to DIN 15401 and DIN 15402

Working length: 6.235 mm

Dist. lower edge spr. b.- rope sling: approx.± 200mm

Range of suspension adjustment: 8 x 200 mm

Design acc. to EN 13155

Copyright: © 2001 – 2014, PFEIFER Seil- und Hebetechnik GmbH.

Use, reprinting and copying of this document is only permitted with

the expressive authority of PFEIFER Seil- und Hebetechnik GmbH.

Each case of misuse is a punishable offence and may lead to the

offender having to pay compensation.

Version 5.1 – 02.01.2012 / date of issue 10.01.2017

.

TYP / FABRIKNR.: 287765 / 9981360 2

Prüflos Nr. : 1961084 Seite : 3/57

1.2 Authorised intend use and equipment description

1.1.1. Authorised intend use

The spreader beam is a lifting device that serves exclusively the lifting, transport and set-down of inherent,

rotationally symmetric loads with barycentric centre of gravity.

Description of load:

Turbine rotor

The load must be attached and transported by means of the two rope slings only. The load must be attached to

both rope slings!

The spreader beam will be lifted by a crane hook.

The spreader beam is intended for indoor and outdoor use with a crane.

The user must be convinced as to the proper state of the load condition. Only properly attached loads may be

lifted and transported!

Danger of accidents due to improper use!

In case of improper use, the spreader beam or the load can crash.

This can result in injury to persons and damage to the spreader beam or other

objects.

Only lift and transport loads as mentioned above!

DANGER!

Attache the load safely acc. to BGR 500! If necessary, attend a training for safe

attachment!

It is not allowed

to attach the load to fastenings such as binding wires, lashing belts etc.

to tear loads or break loads away.

to transport liquids or bulk cargo.

to transport of radioactive materials.

to lift or transport persons.

to use the spreader beam beyond the temperature range of -20 to +100 °C.

to use the spreader beam in flammable, explosion-prone areas or areas containing a lot of dust.

to use the spreader beam under chemical influences such as acids, alkaline solutions or fumes.

to use the spreader beam in the private sector.

The centre of gravity of the spreader beam is below the suspension. The tye plate is placed

at the side of the main beam. Mind the SWL of the spreader beam and the attachment

devices! The SWL given on the type plate is binding for the maximum weight to be lifted.

TYP / FABRIKNR.: 287765 / 9981360 3

Prüflos Nr. : 1961084 Seite : 4/57

1.1.2. Product description

Type of spreader beam

The spreader beam consists of an IBP girder with plates welded at the fronts.

As suspension for the spreader beam, there are two round slings with 1 leg each with a hook.

The load is attached with two rope slings.

At the two rope slings there are lashing systems for the exact positioning of the load. The lashing

systems are suitable for all points.

Rope- Chainsling with

Spreader Beam

Ratchet load tesioner P2

suspension Counterweight

and P4

Rope- Chainsling with

Ratchet load tesioner P1

TYP / FABRIKNR.: 287765 / 9981360 4

Prüflos Nr. : 1961084 Seite : 5/57

1.3 User groups

The following user groups may carry out the respective task referenced:

User Groups Task Qualification

Commissioning, Skilled metalworker, machine fitter, industrial mechanic

Specialist personnel operation, maintenance / or similar person (trained by the operating company

wear inspection based on the Operating Manual, prior to commissioning!)

Trained person (and Operation, visual Trained by the operating company based on the

apprentices) inspection Operating Manual (prior to commissioning!)

Definitions of user groups:

A person is considered to be a specialist, who, based of his technical training, knowledge and

experience, as well as his knowledge of applicable regulations, is able to appraise the assigned work task

and recognise potential hazards.

A person is considered to be trained, who has received instruction on the assigned tasks and potential

hazards associated with improper behaviour, and has been briefed as necessary on the required safety

equipment and protective measures.

A layperson is considered to be anyone not qualified as a specialist or trained person.

Danger of accidents due to insufficiently qualified users and/or incorrect

operation of the spreader beam!

The lack of knowledge about proper usage can result in damage to the spreader

beam and represents a risk to the user.

This can lead to deformation or to a crash or toppling of the load.

The spreader beam must be operated and maintained only by

sufficiently qualified personnel!

WARNING Laypersons must not operate the spreader beam!

Conduct regular personnel training!

Regularly check the work tasks from a safety perspective!

TYP / FABRIKNR.: 287765 / 9981360 5

Prüflos Nr. : 1961084 Seite : 6/57

2 Safety Precautions

2.1 Basic Safety Precautions

1.1.3. The following operating manual describes the spreader beam listed therein as well as their operation.

Should there be any unanswered questions, please contact PFEIFER Seil- und Hebetechnik GmbH in

Memmingen/Germany. We will be glad to assist you.

1.1.4. This operating manual incorporates the internationally recognised SI units of measurement.

1.1.5. It is essential that the operating manual is read and fully understood before initial use of the

corresponding spreader beam. The owner must ensure that all users have read and understood the

operating instructions.

1.1.6. The operating manual is designed for sufficiently trained and qualified personnel to carry out correct

operation, maintenance and repair of the spreader beam. It is therefore imperative that only sufficiently

qualified personnel (see item 1.3 “User Groups”) operate, maintain and repair the spreader beams.

PFEIFER Seil- und Hebetechnik GmbH will not accept any liability for maintenance and repair work that

has been carried out incorrectly.

1.1.7. The spreader beam may only be used for operation and / or transport of corresponding loads (“see item

1.2 “Authorised intend use”). Any dangers to the life and limb of the user or others must be avoided.

Every other use is unauthorised and relieves PFEIFER of any liability and guarantee obligation. .

1.1.8. The operator of the spreader beam is obliged to strictly adhere to and record all maintenance and

servicing schedules specified in this operating manual.

1.1.9. This Operating Manual must be available to operating, service and maintenance personnel during the

entire time the lifting device is being used or worked on (obligation to preserve records!). If the lifting

device changes hands, this Operating Manual must be transferred to the new operating company.

1.1.10. Unauthorised modifications (grinding, welding, attaching parts etc.) are prohibited. Modifications to the

spreader beam must be carried out only by PFEIFER Seil- und Hebetechnik GmbH.

1.1.11. Personal protective equipment must be used according to workplace risk analysis (also refer to the

German BGR 500)! We recommend using a hardhat, safety shoes and gloves!

1.1.12. PFEIFER Seil- und Hebetechnik GmbH retain the copyright of all these technical documents and the

operating manual must not be made available to third parties or competitors of PFEIFER Seil- und

Hebetechnik GmbH .

1.1.13. We retain the right to make changes. All specifications and details were prepared in accordance with the

best knowledge of the originator and the company, and the originator cannot be held responsible in any

way for discrepancie.

TYP / FABRIKNR.: 287765 / 9981360 6

Prüflos Nr. : 1961084 Seite : 7/57

2.2 Danger Symbols

Each start, operation, maintenance and servicing action of the spreader beam may only be

carried out with due consideration to the operating instructions specified in this operating

manual.

It is therefore imperative that you carefully read and understand the instructions in this operating manual before

commissioning the spreader beam. The specially marked safety precautions must be strictly adhered to!

Important instructions, especially technical safety instructions, are identified by respective

symbols (pictographs), the meaning of which is described in the following text. Observe these

instructions to prevent any physical injuries and/or material damage.

.

Consequence

Danger symbol Meaning in case of

disregard

Resulting in

Immediate danger death or

serious injury

DANGER

Possibly Resulting in

immediate death or

danger. serious injury.

WARNING

Can result in

Possibly

slight injuries

immediate

or material

danger.

damage.

CAUTION

Information

relating to safety

and protection of

property.

NOTE

TYP / FABRIKNR.: 287765 / 9981360 7

Prüflos Nr. : 1961084 Seite : 8/57

2.3 General Safety Precautions

1.1.14. Hanging the crane hook into the suspension of the spreader beam.

Danger of accident due to oscillating spreader beam!

When hanging the crane hook into the suspension, the spreader beam

may oscillate.

An oscillating spreader beam can damage machines and equipments or

injure persons standing nearby.

Danger of accident due to crashing spreader beam!

The spreader beam can crash if the crane hook is not locked and falls out

of the suspension during the crane drive accidentally.

DANGER

This can cause death or severe injuries.

Only lift the spreader beam with a suitable and locked crane hook!

When using chain slings or round slings, the chains or round slings

must not be twisted!

Danger of crushing fingers!

When the fingers are between crane hook and suspension during

attaching and lifting, there is the danger of crushing fingers or graze of

skin.

CAUTION Wear safety gloves!

1.1.15. Taking up the load.

Danger of crushing hands or fingers!

While the load is being taken up, there is the danger of crushing

fingers or graze of skin.

CAUTION Wear safety gloves and keep a safety distance!

1.1.16. Crane Movement and Transport

Danger of accident due to oscillating spreader beam and / or crash of

load!

Due to jerky driving and braking the crane and / or lifting and lowering the

crane hook, the spreader beam may oscillate. Oscillating loads or loads

hitting obstacles, can damage machines and equipments or injure persons

standing nearby. In worst case, the load can crash.

This can cause death or severe injuries.

DANGER

Always handle the load slowly and without oscillation!

Do not drive the crane during lifting!

Never unload, lift, transport and set down overhastily, do not stay in the danger zone. Never unload and

transport the loads over persons or safety areas.

Danger of accident due to falling or oscillating load!

In case of overhasty unloading, lifting, transporting or settind down,

dynamic forces can lead to the load fall out or oscillate.

This can cause death or severe injuries.

DANGER Never stand or go under pending loads!

TYP / FABRIKNR.: 287765 / 9981360 8

Prüflos Nr. : 1961084 Seite : 9/57

3 Setting to Operation

3.1 Attaching and locking the spreader beam in the crane hook

1.1.17. The crane hook must be equipped with a functional safety catch.

1.1.18. Hang the suspension of the spreader beam into a suitable crane hook and lock it (close safety catch!). In

case of too big crane hooks, attach the spreader beam by a suitable transition sling to the suspension.

1.1.19. In case of twin hooks, both round slings must be hung into the crane hook and be locked. The crane

hook must be suitable for the round slings.

Danger of accident due to crash of the spreader beam!

When the load is only hung into the crane hook by one round sling, the

load can crash. Consequently, persons can be severely injured or

machines can be severely damaged.

This can lead to death or severe injuries.

DANGER Hang both round slings into the twin hook! There must be one round

sling in each hook ground!

1.1.20. The suspension and the round slings must be freely moveable in the crane hook and the shackles.

Danger of accident due to inclined position or crash of the load!

When the shackles or the hooks of the round slings are jammed in the

crane hook, there may be an inclined position or sudden crash of the load.

This can lead to death or severe injuries.

Take the suspensions out of the crane hook when it is relieved and

DANGER shake it until the shackles / suspension / hooks are freely moveable

again!

3.2 Unloading requirements / Setup requirements

1.1.21. Unload the spreader beam which is lying on a pallet by means of a fork lifter. Safeguard that protruding

parts of the spreader beam do not touch or hit persons or objects. After unloading, remove packing

materials. Attach a round sling in the suspension of the lying spreader beam and erect it by means of the

crane hook or a fork lifter. Lift the spreader beam with a crane and remove the pallet.

Danger of crushing!

When there are protruding parts of the spreader beam, there is the danger

of crushing fingers or graze of skin.

Wear safety gloves!

CAUTION

1.1.22. Unload the spreader beam standing on a transport vehicle. Attach a round sling in the suspension of the

lying spreader beam and erect it by means of the crane hook or a fork lifter. Mind the SWL of the

attachment device / crane hook! Finally, remove the round sling.

1.1.23. Keep at a safety distance of at least 2 mts. during the unloading operation.

TYP / FABRIKNR.: 287765 / 9981360 9

Prüflos Nr. : 1961084 Seite : 10/57

1.1.24. Do not set down the spreader beam at objects nearby.

Danger of damage to the spreader beam!

When the spreader beam is set down on objects, the spreader beam can

fall down or be damaged.

This can lead to injuries (danger of crushing!) or damage to objects.

CAUTION Set down the spreader beam horizontally on a free space!

1.1.25. Never open the safety catch at the crane hook as long as the spreader beam is still in the air.

Danger of accident due to crash of the spreader beam!

When the safety catch is opened before the spreader beam is set down,

the spreader beam can fall down.

This can lead to severe injuries or damage to objects.

WARNING Only open the safety catch of the crane hook when the spreader beam

is fully set down and the crane hook is relieved!

1.1.26. Set the spreader beam down on its stocking feet or a stand. See chapter stocking conditions.

3.3 Storage conditions / Storage when not in use

1.1.27. The storage or parking location should feature a level surface while being dry and free from coarse dirt

or grime (low degree of contamination).

1.1.28. Never put the spreader beam down or stock it in the outside.

Possible damage to the spreader beam!

Putting the spreader beam down in the outside can lead to damage at the

spreader beam and screws or similar parts can corrode.

Always stock the spreader beam in the hall!

NOTE

1.1.29. When the spreader beam is not in use or being stored, it should be set down on a stand. Ensure the

safe position of the stand..

Possible damage to the spreader beam!

If the stand or the spreader beam is not in a stable position but at an

inclination, the spreader beam can fall and injure persons or damage

objects.

Always position the stand safely and plan and fix it with screws in the

CAUTION

ground if necessary!

TYP / FABRIKNR.: 287765 / 9981360 10

Prüflos Nr. : 1961084 Seite : 11/57

3.4 Setting to operation

The spreader beam should be set down onto the stocking feet or on a stand during setting to operation.

1.1.30. Before setting to operation, it must be ensured that the user has been outfitted with the prescribed

personal protective equipment according to the workplace risk analysis (also refer to the German DGUV

Regel 100-500

1.1.31. Note the lifting capacity of the spreader beam (shown on the type plate). Never overload the spreader

beam. If the type plate is lost or illegible, stop using the spreader beam until it has been identified or

labelled again.

1.1.32. Always check the spreader beam for functional capability, damage and wear before every use. Never

use overloaded, damaged or worn spreader beams. Check free movement and sufficient fastening of

moveable parts (connection links, shackles, long hooks etc.)!

Danger of accident by crash of load and / or the load!

A spreader beam which is no longer operational can lead to failure,

slipping, tilting or crash of the load.

This can lead to death or severe injuries.

Moveable parts must be smoothly running and be fastened sufficiently!

DANGER

Exchange immediately damaged or worn parts by original spare parts!

1.1.33. Never exceed the admissible date of 34.200 kg referring to the SWL on the type plate. The load weight

must correspond at the maximum to the admissible carrying capacity (SWL) of the spreader beam.

Thus, the crane capacity must be higher than the load weight and the dead weight of the spreader beam

together (39.780 kg + 2.965 kg = 35.230 kg).

Danger of accident due to crash of the spreader beam and / or the

load!

Never use the spreader beam with a work load that exceeds the maximum

permissible work load limit together with the dead weight of the beam. This

could cause the spreader beam and or/its components to deform and

release the spreader beam and the load. The load can tip over or fall off.

This can lead to death or severe injuries.

DANGER Ensure before each operaton that the load weight does not exceed the

admissible carrying capacity (SWL) of the spreader beam!

In case of uncertainty, determin the weight of the load (by means of

crane scales etc.)!

TYP / FABRIKNR.: 287765 / 9981360 11

Prüflos Nr. : 1961084 Seite : 12/57

4 Picking up loads

4.1 Positioning the spreader beam

1.1.34. Pick up the spreader beam by means of the crane hook.

1.1.35. The suspension of the spreader beam and the crane hook must be positioned vertically above the load

centre of gravity.

1.1.36. The adjustable ropes with ratches must only be adjusted without load. Danger of finger crushing!

Danger of accident due to crash of load!

If the ropes or the ratchets are not correctly adjusted, this can lead to

sliding and finally crashing of the load.

This can lead to death or severe injuries.

DANGER Ensure the longhooks always to be positioned in their adjustment

strap!

Danger of crushing fingers!

If the fingers are between the spreader beam and the load while the ropes

are adjusted, there is the danger of finger crushing.

Wear safety gloves!

CAUTION

4.2 Attaching the load

1.1.37. Select the appropriate method of fastening, attachment devices and attaching points. Check the

attachment devices and attaching points on the load for damage or wear (also refer to BGI 556 and BGR

500 in Germany). Sufficiently dimension the attaching points.

1.1.38. Attach the load (arbors etc.) to the rope slings with positive locking. The load must be positioned at the

lowest point of the ropes and be completely gripped under by both ropes.

Danger of accident due to crash of the load!

If the load is attached to only one rope, the load can fall out.

Thus, persons can be severely injured or machines can be severely

damaged.

Always hang the load in both ropes!

DANGER

1.1.39. Only lift the loads separately. The load must not slide or fall out.

1.1.40. Mind the vertical centre of gravity of the load.

The load is stable if:

the load centre of gravity (LSP) is lower than the attachment points of the load (see sketch).

TYP / FABRIKNR.: 287765 / 9981360 12

Prüflos Nr. : 1961084 Seite : 13/57

the spreader beam has a high construction height (A > D). This can be achieved by suspension by a

chain sling for example.

A = construction height of the spreader beam (see glossary)

Danger of accident due to tilting / crash of the load!

Due to an unstable load, there can be uncontrollable forces which can

release the load and hit persons or objects, or the load can be damaged.

This can lead to death or severe injuries.

DANGER As described in the sketch, A must be > D, i. e. D < 400 mm.

4.3 Lifting the load

Spreader beam with suitable crane hook. Lock safety catch of the crane hook!

1.1.41. Always lift the load horizontally and above all without oscillation. Avoid inclination. In case of inclination,

lower the crane hook, relieve it and attache the load anew.

Danger of accident due to crash of the load!

In case of inclination, the arising forces can be so large, that the spreader

beam fails and the load crashes.

This can lead to death or severe injuries.

DANGER Always lift the load vertically, horizontally and without oscillation!

1.1.42. Avoid oscillation, jerky lifting and lowering as well as hitting the load to obstacles.

1.1.43. When lifting and during transport always ensure sufficent free space to surrounding obstacles. During

lifting do not drive the crane at the same time. After lifting, drive evenly.

1.1.44. The ropes must only be charged vertically.

TYP / FABRIKNR.: 287765 / 9981360 13

Prüflos Nr. : 1961084 Seite : 14/57

Danger of accident due to crash of the load!

If the ropes have an inclination of more than 6°, this can lead to

deformation of the load and to damage of the parts.

This can lead to death or severe injuries.

In case of too much inclination lower the crane hook, relieve it and

attach the load anew!

DANGER

1.1.45. Keep sufficient safety distance (at least 2 mts) during the lifting process.

5 Transport of Loads

1.1.46. The load must not be transported in jerks, as this can also lead to inadmissible oscillation. Moreover, the

spreader beam can be inadmissibly overloaded in case the dynamic charge due to jerky transport. Avoid

oscillating and hitting the load to obstacles.

1.1.47. Always ensure sufficient free space to surrounding obstacles during trasnport! Do not drive the crane

when lifting the crane hook at the same time. After lifting, drive the crane evenly.

6 Setting down Loads

1.1.48. Set the load down at its point of destination without oscillating. When setting the load down, do not hit

surrounding objects, in order to avoid an inclination of the load.

Danger of accident due to inclination!

When the load is set down at an inclination, the load can crash or be

damaged.

This can lead to severe injuries or damage to material.

WARNING Ensure sufficient free space before setting down the load!

1.1.49. Keep sufficient safety distance (at least 2mts) during setting the load down.

1.1.50. Never open the safety catch of the crane hook or at the included load hooks as long as the spreader

beam is still in the air. Only open the safety catches after the load has been completely set down / has

been in a stable stand and relief of the crane hook!

TYP / FABRIKNR.: 287765 / 9981360 14

Prüflos Nr. : 1961084 Seite : 15/57

Danger of accident due to too early opening of the safety catches!

If the safety catches are opened before the load has been completely set

down / the load has been in a stable position and before relief of the crane

hook, the load or the spreader beam can accidently hang off and possibly

crash.

This can lead to severe injuries or damage to material.

WARNING

Set the spreader beam down in a stable position. Open the safety

catches only then!

1.1.51. Ensure safe position / stand of the spreader beam (see also chapter storage conditions).

Danger due to inclination!

If ths spreader beam is not in a stable positon but at an inclinatin, it can tilt

over and hurt persons or damage objects.

This can lead to injuries or damage to material.

CAUTION Set the spreader beam down in a stable position, if necessary put it on

a storage stand!

1.1.52. Lift the spreader beam vertically in unloaded position and prepare for the next attachment of load. When

lifting, ensure that the spreader beam does not hit obstacles or at the load edges.

TYP / FABRIKNR.: 287765 / 9981360 15

Prüflos Nr. : 1961084 Seite : 16/57

7 Service and Maintenance of the Spreader Beam

7.1 Regular Inspections

The regular inspections must be carried out by the operating company.

1.1.53. The spreader beams must be inspected by an expert at intervals of one year at the most. In case of high

demand, an expert must assess the inspections at shorter intervals. Inspection or maintenance of the

spreader beam is to be executed by an expert at your premises or in our production plant.

Only the use of original spare parts will guarantee the functionality of the spreader beams. If there are questions

on the wear of attachment devices, please contact an expert.

1.1.1. Prior to every lifting operation, the spreader beam, its components and the attachment devices must be

checked for damage and wear (visual check!). This applies in particular to the suspension of the

spreader beam, the built in load hooks, shackles and links. Damaged or worn components must be

replaced immediately with original spare parts of the manufacturer

The wear criteria for attachment devices (ropes, shackles etc.) can be learned from the BGI 556.

If the suspension eyes or the ropes at the spreader beam are enlarged by more than 2%, only use the

spreader beam after discussion and advice by the manufacturer.

1.1.2. Only spare parts of the manufacturer may be used.

1.1.3. Defects in paint work must always be touched up in order to prevent corrosion.

1.1.4. The spreader beam must be cleaned when heavy accumulations of dirt or grime are present.

7.2 Imperative Inspections

1.1.5. Operation must be in accordance with BGR 500 "Operation of Equipment", with particular reference to

chapter 2.8. The owner must procure this standard and make it available to the operators and

maintenance personnel.

1.1.6. See also the accident prevention regulations "Load hoisting equipment in hoisting operations" (VBG

9a). This now represents the "state of the art" and remains valid.

1.1.7. Further regulations issued by the competent local authorities may also apply. This is the responsibility of

the owner.

7.3 Repairs

Repairs must only be executed by the manufacturer or after approval by the manufacturer.

TYP / FABRIKNR.: 287765 / 9981360 16

Prüflos Nr. : 1961084 Seite : 17/57

8 Works Certificate according to EN 10 204-2.1

Your purchase order: 7000562992

We herby confirm the device supplied by us to correspond to the requirements in your order.

Certificate no.: 9981360

Item: PFEIFER- Spreader beam in special design

Quantity: 1 pc

Type and fabrication no.: 287765 / 9981360

Year of construction: 2016

Carrying capacity (SWL): 39.780.000 kg

Dead weight: 2.965 kg

i.A. Klaus Fischer

Project manager

TYP / FABRIKNR.: 287765 / 9981360 17

Prüflos Nr. : 1961084 Seite : 18/57

9 Konformitätserklärung

EG - Konformitätserklärung

im Sinne der EG – Maschinenrichtlinie 2006 / 42 / EG

Hiermit erklären wir, dass die nachfolgend bezeichnete Maschine/Ausrüstung aufgrund ihrer Konzipierung und Bauart, sowie in der von uns in den

Verkehr gebrachten Ausführung den einschlägigen grundlegenden Sicherheits- und Gesundheitsanforderungen der oben aufgeführten EG-Richtlinie

entspricht. Bei einer nicht mit uns abgestimmten Änderung der Maschine/Ausrüstung verliert diese Erklärung ihre Gültigkeit.

Produktbezeichnung: Sondertraverse

Typ- bzw. Fabrik-Nr.: 287765 / 9981360

Einschlägige EG – Richtlinie:

EG – Maschinenrichtlinie 2006 / 42 / EG

Weitere angewandte harmonisierte Normen:

DIN EN 13155 – 08/2009 – „Krane-Sicherheit-Lose Lastaufnahmemittel“

Declaration of Conformity with EC Requirements

pertaining to the EC Machine Directive 2006 / 42 / EC

We hereby declare that the machinery/equipment designated below complies in its conception and construction and in the designs we bring into

circulation with the relevant basic safety and health requirements of the associated EC Directives. This declaration shall void if modifications are

made to the machinery/equipment without our approval.

Item: Special Spreader Beam

Type / Fabrication No.: 287765 / 9981360

Relevant EC Directives:

EC Machine Directive 2006 / 42 / EC

Following harmonised standard was applied:

DIN EN 13155 – 08/2009 – „Cranes – Safety – Non-fixed load lifting attachments“

Bevollmächtigter für die Zusammenstellung der technischen Unterlagen:

Authorised person for the completion of the technical documents:

PFEIFER Seil und Hebetechnik GmbH, Dr.-Karl-Lenz Str. 66, 87700 Memmingen

Diese EG-Konformitätserklärung wurde ausgestellt:

This declaration of conformity was made out:

Memmingen, den 10.01.2017 ppa. Siegmund Erhard (Bereichsleitung Hebetechnik)

(Ort, Datum / Place, Date) (Angaben zum Unterzeichner / Identification of signor)

TYP / FABRIKNR.: 287765 / 9981360 18

Prüflos Nr. : 1961084 Seite : 19/57

10 Glossary

Attachment device is equipment not integral to the hoisting gear, yet which provides a connection between

the load-bearing element and the load or, as the case may be, the load-bearing element

and the load suspension device. [DGUV Regel 100-500]

Suspensin flame-cut suspension eye, suspension ring, sliding bolt, welded bolt

Construction height is the dimension from the lower edge of the suspension for the

crane hook to the attachment point of the attachment devices

(dimension A)

Inclination angle is the angle between vertical (plumb-line) and a shank of the attachment

device.

Load suspension device is equipment not integral to the hoisting gear, yet which can be connected for take-up of

the load by the load-bearing element of the hoisting gear. [DGUV Regel 100-500]

Technical expert is a person who, based on his technical training and experience, has sufficient

knowledge of the field of load suspension devices and is familiar with the applicable

national occupational health and safety regulations, accident prevention regulations and

the generally accepted technical rules (e.g. BG rules, DIN standards, VDE directives, the

technical rules of other member states of the European Union or other states, which are

parties to the Agreement on the European Economic Area) to a level that he is able to

appraise the operationally safe condition of the load suspension devices. [BGR 500]

Sharp edge exists when the edge radius (R) on the load is smaller than the diameter (D) of the cable

or the thickness of the sling band.

Load-bearing element is the equipment continuously connected hoisting gear for take-up of the load

suspension devices, slinging equipment or loads. [DGUV Regel 100-500

TYP / FABRIKNR.: 287765 / 9981360 19

Prüflos Nr. : 1961084 Seite : 20/57

11 Inspection Record

The recurring inspection is performed in The recurring inspection is performed in

accordance with EN 13155 and DGUV Regel accordance with EN 13155 and DGUV Regel

100-500. 100-500.

No deficiencies have been detected. No deficiencies have been detected.

The following deficiencies have been The following deficiencies have been

detected: detected:

_____________________________________ _____________________________________

Date and signature of the technical expert Date and signature of the technical expert

The recurring inspection is performed in The recurring inspection is performed in

accordance with EN 13155 and DGUV Regel accordance with EN 13155 and DGUV Regel

100-500. 100-500.

No deficiencies have been detected.

No deficiencies have been detected.

The following deficiencies have been

detected: The following deficiencies have been

detected:

_____________________________________ _____________________________________

Date and signature of the technical expert Date and signature of the technical expert

The recurring inspection is performed in The recurring inspection is performed in

accordance with EN 13155 and DGUV Regel accordance with EN 13155 and DGUV Regel

100-500. 100-500.

No deficiencies have been detected.

No deficiencies have been detected.

The following deficiencies have been

detected: The following deficiencies have been

detected:

_____________________________________ _____________________________________

Date and signature of the technical expert Date and signature of the technical expert

TYP / FABRIKNR.: 287765 / 9981360 20

Prüflos Nr. : 1961084 Seite : 21/57

11.1 Overview drawing with partlist

TYP / FABRIKNR.: 287765 / 9981360 21

You might also like

- MRCS Part A Essential Revision Notes Part 1 PDFDocument1,627 pagesMRCS Part A Essential Revision Notes Part 1 PDFfiansis89% (37)

- 068 - Att. 4 - Operating Instruction Hoisting Gear ELK-8000kg-ABUSDocument297 pages068 - Att. 4 - Operating Instruction Hoisting Gear ELK-8000kg-ABUSBoodseiker33% (3)

- Lemken EuroDrill 300-25, Instruction Book & Parts List (ENG) .BeeLinedDocument102 pagesLemken EuroDrill 300-25, Instruction Book & Parts List (ENG) .BeeLinedSiniša Keco100% (2)

- 9853 1124 01 Overhauling Instructions COP2160-2560-2160EX-2560EX PDFDocument68 pages9853 1124 01 Overhauling Instructions COP2160-2560-2160EX-2560EX PDFcoelhoclaudios100% (2)

- Operating - Instructions SD20 - SD185 - enDocument6 pagesOperating - Instructions SD20 - SD185 - enAswin AntonyNo ratings yet

- The Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsFrom EverandThe Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsNo ratings yet

- Bromma Telescopic Spreader EH5U PDFDocument418 pagesBromma Telescopic Spreader EH5U PDFsubhan.ubaedillah100% (3)

- Bill Nye Motion Video QuestionsDocument2 pagesBill Nye Motion Video Questionsapi-29309281025% (4)

- Technische Dokumentation Technical Documentation: Fallreepanlage Accommodation Ladder SystemDocument23 pagesTechnische Dokumentation Technical Documentation: Fallreepanlage Accommodation Ladder SystemGogaNo ratings yet

- PQ-Sample TwoDocument11 pagesPQ-Sample Twocpkakope100% (6)

- M32-W o IncineratorDocument137 pagesM32-W o IncineratorAlex100% (1)

- WP320L WP460LDocument59 pagesWP320L WP460Ljohn smithNo ratings yet

- Perc Om enDocument14 pagesPerc Om engibyjohnNo ratings yet

- FH 5432 GBDocument16 pagesFH 5432 GBMuhsin Abdul AzizNo ratings yet

- Owner's ManualDocument31 pagesOwner's ManualNestor MarriagaNo ratings yet

- SBKJ - Spiral Tubeformer 1602 Decoiler DVC1000Document18 pagesSBKJ - Spiral Tubeformer 1602 Decoiler DVC1000rinconvega0% (1)

- Manual: Toku Pneumatic Co.,LtdDocument54 pagesManual: Toku Pneumatic Co.,LtdKadir Koray BozyelNo ratings yet

- COUPLING (PTOMMEE) VULASTIK L 845kW 955 RPMDocument10 pagesCOUPLING (PTOMMEE) VULASTIK L 845kW 955 RPMtm5u2r100% (1)

- ATIB 474.170 Pallet Clamp User ManualDocument44 pagesATIB 474.170 Pallet Clamp User ManualDuncan ReedNo ratings yet

- BVH2021 GBDocument32 pagesBVH2021 GBsamer salamehNo ratings yet

- t3.Kcd - XV.X Speed Blade Auia.167 OmDocument29 pagest3.Kcd - XV.X Speed Blade Auia.167 OmDaniel RegoNo ratings yet

- CD160-1400 Open Frame MAY 2021Document52 pagesCD160-1400 Open Frame MAY 2021Madel D.No ratings yet

- Safety Principles, Operation and Maintenance Manual: BRANO A.s, 747 41 Hradec Nad Moravicí The Czech RepublicDocument14 pagesSafety Principles, Operation and Maintenance Manual: BRANO A.s, 747 41 Hradec Nad Moravicí The Czech RepublicRingo StarrNo ratings yet

- Duo Cone SealDocument15 pagesDuo Cone SealM Ferry AnwarNo ratings yet

- Operating Instruction - CRUDE FIBRE and HYDROLYSIS APPARATUS - 05.2017 - EnglishDocument8 pagesOperating Instruction - CRUDE FIBRE and HYDROLYSIS APPARATUS - 05.2017 - EnglishseringwelskiNo ratings yet

- GA Fluxi 2000 TZ InstructionManual 652 099 2025 - TZ - 09 10 2014Document56 pagesGA Fluxi 2000 TZ InstructionManual 652 099 2025 - TZ - 09 10 2014Muhammad Darussalam HerdaniNo ratings yet

- 06.08.02.S4 A320DL SLIDE RAFT-SpecificationDocument10 pages06.08.02.S4 A320DL SLIDE RAFT-SpecificationFly WingsNo ratings yet

- Bulkline 650 & 1000 Installation, Operating & Maintenance InstructionsDocument22 pagesBulkline 650 & 1000 Installation, Operating & Maintenance InstructionsNelson KardozoNo ratings yet

- Drive Shaft-Ex: Operating Instructions BA 276/02Document12 pagesDrive Shaft-Ex: Operating Instructions BA 276/02Daisy ChanNo ratings yet

- Titan DieselDocument120 pagesTitan DieselCarlos Eduardo Cardenas SochaNo ratings yet

- Z 300 K / July 2000Document22 pagesZ 300 K / July 2000samityNo ratings yet

- Titan PowrLiner 850Document84 pagesTitan PowrLiner 850Juan GonzalezNo ratings yet

- Ce125-2500 Open FrameDocument48 pagesCe125-2500 Open FrameRomão OliveiraNo ratings yet

- Operating Instructions: VKS 80 Pneumatic DrifterDocument15 pagesOperating Instructions: VKS 80 Pneumatic DrifterДмитрий ОвчинниковNo ratings yet

- Operation Manual Safety Principles, Operation and MaintenanceDocument12 pagesOperation Manual Safety Principles, Operation and MaintenanceMuhammad UmairNo ratings yet

- Manual Performance 850eDocument52 pagesManual Performance 850eRAUL CAVITANo ratings yet

- DCC Operating Manual 210924Document14 pagesDCC Operating Manual 210924santhosh shettyNo ratings yet

- Pioneer Deh-X1950ubDocument64 pagesPioneer Deh-X1950ubmeahdiNo ratings yet

- PMT Hps Installation Manual Pressure Transmitters pl3700x Series Mi5098e Rev3Document34 pagesPMT Hps Installation Manual Pressure Transmitters pl3700x Series Mi5098e Rev3Control Cia LtdaNo ratings yet

- 01 - Operating InstructionsDocument74 pages01 - Operating InstructionsАндрей100% (1)

- TRB Installation PDFDocument64 pagesTRB Installation PDFPatNo ratings yet

- Bourbon Astyanax 120 MT BP dp1Document2 pagesBourbon Astyanax 120 MT BP dp1Erwin Paulian SihombingNo ratings yet

- Drifter Yh70 e Yh70rpDocument68 pagesDrifter Yh70 e Yh70rpDipper Tellez100% (1)

- TM 5-4310-275-14 Compressor Stewart-Warner MDL 43040-301-01 NSN 4310-00-878-7969Document128 pagesTM 5-4310-275-14 Compressor Stewart-Warner MDL 43040-301-01 NSN 4310-00-878-7969Advocate100% (1)

- Ahts Bourbon TeguhDocument2 pagesAhts Bourbon TeguhErwin Paulian SihombingNo ratings yet

- 444-001-M - 0 HP Cleaner - Duo Boosters BasicDocument85 pages444-001-M - 0 HP Cleaner - Duo Boosters BasicDaniel OMNo ratings yet

- Props and Tresteled Towers Alu-Up2: Read This Manual Carefully Before Using The ProductsDocument38 pagesProps and Tresteled Towers Alu-Up2: Read This Manual Carefully Before Using The ProductsSnezana RaicevicNo ratings yet

- Service: ManualDocument46 pagesService: Manualcarolina PortocarreroNo ratings yet

- Ro-1 PDFDocument93 pagesRo-1 PDFMihai AndreiNo ratings yet

- ABB GOB InstalacionDocument20 pagesABB GOB InstalacionOsmar Marca CondoriNo ratings yet

- Intruction Manual Unique Single Seat Valve - Atex Standard - Ese00674Document48 pagesIntruction Manual Unique Single Seat Valve - Atex Standard - Ese00674pxpingenieriaNo ratings yet

- Machine LLOVERAS U3000Document72 pagesMachine LLOVERAS U3000bayuNo ratings yet

- Kit de Serie D A Serie PDDocument15 pagesKit de Serie D A Serie PDCinthya CollaguazoNo ratings yet

- Den-Jet Ce20-500 - Super Slim Manual - Jul 2015Document31 pagesDen-Jet Ce20-500 - Super Slim Manual - Jul 2015First LastNo ratings yet

- Itron TZ en ManualDocument47 pagesItron TZ en Manualdilor19No ratings yet

- VortexDocument16 pagesVortexMitch GagnonNo ratings yet

- PHB1500 Rotopercutor HR RO BG ELDocument54 pagesPHB1500 Rotopercutor HR RO BG ELlin2m3No ratings yet

- Operating Instructions: N - R 468 en 02.11Document41 pagesOperating Instructions: N - R 468 en 02.11mhafizanNo ratings yet

- Technical Data Sheet: Rothe Erde Large Diameter Slewing BearingDocument19 pagesTechnical Data Sheet: Rothe Erde Large Diameter Slewing BearingAkash RockNo ratings yet

- Skid E Mit AGB PDFDocument37 pagesSkid E Mit AGB PDFForum PompieriiNo ratings yet

- Instruction Manual: Heto Gel Dryer GD-2Document16 pagesInstruction Manual: Heto Gel Dryer GD-2Eclecticindia EclecticindiaNo ratings yet

- Warranty Terms & Conditions / Instruction Manual: Idlers, Idler Installations, and Idler GarlandsDocument9 pagesWarranty Terms & Conditions / Instruction Manual: Idlers, Idler Installations, and Idler Garlandshenry201No ratings yet

- 2.2 Unit 3 Cold Condition 30lab20br003 Rev-2Document1 page2.2 Unit 3 Cold Condition 30lab20br003 Rev-2Jonas PadillaNo ratings yet

- 2.2 Unit 3 Cold Condition 30lab20br004 Rev-2Document1 page2.2 Unit 3 Cold Condition 30lab20br004 Rev-2Jonas PadillaNo ratings yet

- 138SiemensE02+R11F877 - 7UT612Short LinePDocument5 pages138SiemensE02+R11F877 - 7UT612Short LinePJonas PadillaNo ratings yet

- 2.2 Unit 3 Cold Condition 30lab20br005 Rev-2Document1 page2.2 Unit 3 Cold Condition 30lab20br005 Rev-2Jonas PadillaNo ratings yet

- 2.2 Unit 3 Hot Condition 30lab33br001.1 Rev - 2Document1 page2.2 Unit 3 Hot Condition 30lab33br001.1 Rev - 2Jonas PadillaNo ratings yet

- 2.2 UNIT 3 HOT CONDITION 30LAB24BR002 REV-3-Layout1Document1 page2.2 UNIT 3 HOT CONDITION 30LAB24BR002 REV-3-Layout1Jonas PadillaNo ratings yet

- 138ABB-E00R12-REB670Bus DP─╕▓εDocument50 pages138ABB-E00R12-REB670Bus DP─╕▓εJonas PadillaNo ratings yet

- 138Siemens7SS85 - BBIBus DP─╕▓εDocument7 pages138Siemens7SS85 - BBIBus DP─╕▓εJonas PadillaNo ratings yet

- Oisd 118Document35 pagesOisd 118Jonas PadillaNo ratings yet

- STD 124 Predictive MaintenanceDocument22 pagesSTD 124 Predictive MaintenanceJonas PadillaNo ratings yet

- Std-122 - INSPECTION OF FANS, BLOWERS, AGITATORSDocument14 pagesStd-122 - INSPECTION OF FANS, BLOWERS, AGITATORSJonas PadillaNo ratings yet

- Std-210 - STORAGE, HANDLING & REFUELINGDocument42 pagesStd-210 - STORAGE, HANDLING & REFUELINGJonas PadillaNo ratings yet

- Std-125 - INSPECTION OF MECHANICAL SEALSDocument15 pagesStd-125 - INSPECTION OF MECHANICAL SEALSJonas PadillaNo ratings yet

- Std-121 - INSPECTION OF TURBINES AND DIESEL ENGINESDocument21 pagesStd-121 - INSPECTION OF TURBINES AND DIESEL ENGINESJonas PadillaNo ratings yet

- ID: ID Name: Name Rev: Rev Author: CN CD Reviewer: RN RD Approver: AN ADDocument1 pageID: ID Name: Name Rev: Rev Author: CN CD Reviewer: RN RD Approver: AN ADJonas PadillaNo ratings yet

- Onboarding ChecklistDocument3 pagesOnboarding ChecklistJonas PadillaNo ratings yet

- Twist of FaithonesheetDocument1 pageTwist of FaithonesheetpepperbashamNo ratings yet

- Theory of Evolution by Natural SelectionDocument15 pagesTheory of Evolution by Natural Selectionpaula nicolle mostoles100% (1)

- PMS07K 60Hz AC Wiring DiagramDocument5 pagesPMS07K 60Hz AC Wiring DiagramuserfileNo ratings yet

- Eden - Atlantis ProjectDocument25 pagesEden - Atlantis ProjectLeomar MartínezNo ratings yet

- Research Paper 2Document6 pagesResearch Paper 2Avanti ThorveNo ratings yet

- Saifee Golden Jubilee English Public School: 3rd Term (2019 - 2020) Progress Report ForDocument1 pageSaifee Golden Jubilee English Public School: 3rd Term (2019 - 2020) Progress Report ForFaizan IqbalNo ratings yet

- Zhang, Qin - Basics of Hydraulic Systems PDFDocument339 pagesZhang, Qin - Basics of Hydraulic Systems PDFNeha Gupta100% (2)

- Tata MotorsDocument20 pagesTata MotorsABHISHEK SHARMANo ratings yet

- Session 23 Local Climate Change Expenditure TaggingDocument72 pagesSession 23 Local Climate Change Expenditure TaggingMDRRMC Response1855No ratings yet

- Jahanzeb Mirza - LomDocument2 pagesJahanzeb Mirza - LomZain HaiderNo ratings yet

- No 5Document10 pagesNo 5nguyennguyennduNo ratings yet

- TechWeb E DL SiDocument92 pagesTechWeb E DL Si徐偉豪No ratings yet

- Earth As A Shithole Planet - From A Universal Perspective? Understanding Why There Are No Extraterrestrial VisitorsDocument17 pagesEarth As A Shithole Planet - From A Universal Perspective? Understanding Why There Are No Extraterrestrial VisitorsAnthony JudgeNo ratings yet

- Site Organisation in Construction: Samson Adesope & YaredDocument18 pagesSite Organisation in Construction: Samson Adesope & YaredSHRADDHA GHUGENo ratings yet

- 01.03 ABG (Arterial Blood Gas) Interpretation-ROME - NRSNG Nursing CoursesDocument3 pages01.03 ABG (Arterial Blood Gas) Interpretation-ROME - NRSNG Nursing CoursesTurkleNo ratings yet

- Exit Strategy Report Tiger Revised26Nov2021 1Document52 pagesExit Strategy Report Tiger Revised26Nov2021 1Nwabisa NjizaneNo ratings yet

- IGBC Green Factory Buildings - Addenda - August 2011Document2 pagesIGBC Green Factory Buildings - Addenda - August 2011chakka nagendra subrahmanyamNo ratings yet

- Third - Year - Automobile - (BE Sem-V and VI) - Teaching Scheme and Course ContentDocument71 pagesThird - Year - Automobile - (BE Sem-V and VI) - Teaching Scheme and Course Contentshaikh javedNo ratings yet

- Learning Guide 10: Animal Health Care Service NTQF Level-IVDocument14 pagesLearning Guide 10: Animal Health Care Service NTQF Level-IVRafez JoneNo ratings yet

- Lesson PlanDocument3 pagesLesson Planapi-644493680No ratings yet

- NAME: DATE: CLASS: Review Unit 3,4,5Document4 pagesNAME: DATE: CLASS: Review Unit 3,4,5Hạnh NguyễnNo ratings yet

- 7 Mudas LeanDocument5 pages7 Mudas Leanharry.hopps1992No ratings yet

- Practice Problems On Descriptive StatisticsDocument4 pagesPractice Problems On Descriptive StatisticsprofharishNo ratings yet

- Loctite Ablestik 8290: Technical Data SheetDocument2 pagesLoctite Ablestik 8290: Technical Data SheetAl Haba Ahmad Zaki Abdul HamidNo ratings yet

- Industrialization in IndiaDocument5 pagesIndustrialization in Indiasimran khiroriaNo ratings yet

- Alphabet Infographic: A B C D EDocument20 pagesAlphabet Infographic: A B C D ETulia Concepcion PerezNo ratings yet

- Future MagickDocument284 pagesFuture MagickAnonymous Hero83% (6)