Professional Documents

Culture Documents

SAIC-A-2005 Rev 8

SAIC-A-2005 Rev 8

Uploaded by

Syed ImranOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SAIC-A-2005 Rev 8

SAIC-A-2005 Rev 8

Uploaded by

Syed ImranCopyright:

Available Formats

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2014) Rev 8 30-Jun-14

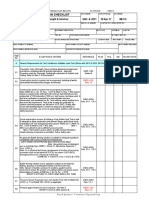

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Review of Leak Test Procedure (Bubble Test) SAIC-A-2005 31-Dec-14 MECH.

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A. General Requirements (See Notes in Remarks Section)

Procedure Definitions cover Leak Test applications :

A) Bubble Test - Direct Pressure Technique per ASME V, Article

10, App I, using pressure of 5-10 psi to identify any leaks See Note 1.

B) Hydrostatic Test-A pressure test conducted using water or other SAES-A-004,

approved liquid as the test medium. Section 4 /

A1

C) Pneumatic Test-A pressure test conducted using air or other ASME V Article

approved gas as the test medium or in conjunction with liquid. 10 Appendix 1

D) Pre Start-up Leak Test is "A pressure test to ensure tightness of

flanged and threaded joints at test pressure." (per SAES-A-004).

A pressure test procedure shall be prepared by the responsible

engineering group and made available to responsible inspection group SAES-A-004,

A2

prior to conducting the test. The test procedure shall be available on Para 5.6.1

site at all times.

The pressure test procedure shall include all required documentation SAES-A-004,

A3

specified in GI-0002.102, paragraph 5.1.2. Para 5.6.2

Code References for Leak Testing conducted in accordance with

SAES-A-004,

A4 applicable article of ASME V codes is listed in procedure reference

Para. 3.2

section.

B. Leak Test Procedural Requirements:

Bubble Leak Testing Procedure includes the nine (9) Attachment 1

ASME V Article

B1 procedural elements and soak time, pressure gages, test pressure (5-

10 Appendix 1

10 psi), and the acceptance criteria. See ATTACHMENT 1

Test Package is approved for system to be pneumatically tested SAEP-1160,

B2

(strength or service test) per SAIC-A-2003. Section 8

The pressure test procedure shall include all required documentation

specified in GI-0002.102, paragraph 5.2.1

A) Equipment and/or System Piping limits (applicable test manifold)

B) Test Pressure (5-10 psi during leak test) SAES-A-004,

B3 C) Test Temperature (usually ambient) Para. 5.6.2 and

D) Test GI-0002.102

Medium (Type of Air or Inert gas such as nitrogen, etc)

E) Safety requirements (G.I. - 2.102 Para. 5.2 bullet items

listed)

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2014) Rev 8 30-Jun-14

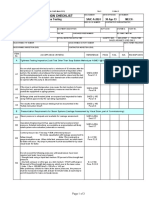

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Review of Leak Test Procedure (Bubble Test) SAIC-A-2005 31-Dec-14 MECH.

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

Procedures for both pre start-up leak tests and service tests

SAES-A-004,

B2 shall address, to the extent possible, the safety precautions

Para. 5.7.2.3

provided in GI-0002.102 "Pressure Testing Safely."

Test Records shall be recorded on Pressure Test Report Form SA-

SAES-A-004,

B3 2642-ENG and the applicable "Safety Instruction Sheet" per SAES-A-

Para. 9.3

005.

C. New System Pre Start-up Leak Test (Commissioning* Activity) Specific Applications:

The procedure contains/references applicable precommissioning*

C1 activities (Per GI-2.710 details & Precommissioning Plan). As referenced

See Notes 2 & 3.

REMARKS:

Notes:

Note 1: SAES-A-004 (January 2011 Edition, Para. 5.6.3) now requires ASME Code Leak Test (Direct Pressure Bubble Test) per ASME V, Article

10, Mandatory Appdix 1 "during" pneumatic strength tests. This also applies to service tests performed in lieu of pneumatic strength tests for Air

and Inert Gas Systems. Bubble tests at pressures higher than 5-10 psi are unreliable for leakage assessment as the solution can be immediately

"blown away". COMPANY now requires "BUBBLE TEST" evaluations at 5-10 psi per an approved LEAK TEST PROCEDURE to assure reliable

leakage assessment for new systems.

Note 2: ALL LEAKS FOUND during Bubble leak tests shall be identified for follow-up repair and documented on QC Construction records for

specific systems. Inspection shall not accept or certify systems requiring leak test as "Construction Complete" until leak testing is accepted.

Additionally, the appropriate threaded joint repair measures (SAIC-L-2015 & SAIC-W-2037) shall be addressed. In no case, shall a system be

accepted prior to determining whether threaded joints are acceptable (DO NOT LEAK).

Note 3: Other systems (steam, etc) are "checked for leakage" after strength tests. This is primarily a gage test just prior to start-up and requires

simple visual examination at threaded & flanged connections to assure system tightness. These are precommissioning or commissioning

activities to be agreed upon and they are not covered by this checklist.

REFERENCE DOCUMENTS:

1. SAES-A-004, General Requirements for Pressure Testing, (30 January, 2011)

2. ASME Section V (2010 Edition, Nov 2011 Addenda)

3. Saudi Aramco General Instruction, G.I.-2.102, Pressure Testing Safely, (28 Oct 2008)

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection:

T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved:

Name, Organization, T&I Witnessed QC Record Reviewed Work Verified

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2014) Rev 8 30-Jun-14

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Review of Leak Test Procedure (Bubble Test) SAIC-A-2005 31-Dec-14 MECH.

Attachment 1 -- BUBBLE LEAK TEST PROCEDURE REQMTS

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2014) Rev 8 30-Jun-14

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Review of Leak Test Procedure (Bubble Test) SAIC-A-2005 31-Dec-14 MECH.

Saudi Aramco: Company General Use

You might also like

- Grand Coulee Dam 70 Years Later What Can We LearnDocument19 pagesGrand Coulee Dam 70 Years Later What Can We LearnGhulam MustafaNo ratings yet

- IEE Earthing & Bonding TutorialDocument51 pagesIEE Earthing & Bonding Tutorialtgkenny873492% (37)

- Quality Control Handbook Street LightingDocument36 pagesQuality Control Handbook Street LightingbalaafconsNo ratings yet

- Manual SonicLockDocument5 pagesManual SonicLockToine ZxyNo ratings yet

- Load Cell Simulator v2Document1 pageLoad Cell Simulator v2Ivica LukicNo ratings yet

- SAIC-A-2005 Rev 5 Leak TestDocument4 pagesSAIC-A-2005 Rev 5 Leak Testpookkoya thangalNo ratings yet

- Saic A 2005Document10 pagesSaic A 2005Ansar Ali VemmullyNo ratings yet

- Saic A 2005Document10 pagesSaic A 2005karthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Reqmts Are Listed in Attachment 1Document6 pagesSaudi Aramco Inspection Checklist: Reqmts Are Listed in Attachment 1sureshNo ratings yet

- SAIC-A-2021 Rev 6 Pnematic Test - 3Document4 pagesSAIC-A-2021 Rev 6 Pnematic Test - 3pookkoya thangalNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 30-Apr-17 MechDocument4 pagesSaudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 30-Apr-17 Mechkarthi51289No ratings yet

- SAIC-A-2020 Rev 6 Pnematic Test PessureDocument5 pagesSAIC-A-2020 Rev 6 Pnematic Test Pessurepookkoya thangalNo ratings yet

- Saudi Aramco Inspection Checklist: 1-Dec-06 Mech. Review of Leak Test Procedure (Bubble Test) SAIC-A-2005Document3 pagesSaudi Aramco Inspection Checklist: 1-Dec-06 Mech. Review of Leak Test Procedure (Bubble Test) SAIC-A-2005ரமேஷ் பாலக்காடுNo ratings yet

- Saudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 30-Apr-17 MechDocument5 pagesSaudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 30-Apr-17 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 31-Dec-14 MechDocument4 pagesSaudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 31-Dec-14 MechpravinNo ratings yet

- SAIC-L-2042 Rev 6 Field Hydrostatic Testing of Isolation ValvesDocument6 pagesSAIC-L-2042 Rev 6 Field Hydrostatic Testing of Isolation ValvesAhdal NoushadNo ratings yet

- SAIC-A-2009 Rev 6 Test EquipmentDocument5 pagesSAIC-A-2009 Rev 6 Test Equipmentpookkoya thangalNo ratings yet

- SAIC-A-2009 Rev 7Document4 pagesSAIC-A-2009 Rev 7sajidazmi.amuNo ratings yet

- Saudi Aramco Inspection Checklist: Pressurization of Pneumatic Test (Strength & Service) SAIC-A-2020 30-Apr-17 MechDocument5 pagesSaudi Aramco Inspection Checklist: Pressurization of Pneumatic Test (Strength & Service) SAIC-A-2020 30-Apr-17 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 15-Dec-09 MechDocument6 pagesSaudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 15-Dec-09 MechEagle SpiritNo ratings yet

- Saudi Aramco Inspection Checklist: Pressurization of Pneumatic Test (Strength & Service) SAIC-A-2020 3-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Pressurization of Pneumatic Test (Strength & Service) SAIC-A-2020 3-Jul-18 Mechkarthi51289No ratings yet

- SAIC-A-2024 Rev 6 Leakness Tightness TestDocument3 pagesSAIC-A-2024 Rev 6 Leakness Tightness Testpookkoya thangalNo ratings yet

- Saic-A-2001 Rev 62Document21 pagesSaic-A-2001 Rev 62pradeepthalava97No ratings yet

- SAIC-A-2020 Rev 2Document3 pagesSAIC-A-2020 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 3-Jul-18 Mechkarthi51289No ratings yet

- SAIC-L-2095 Rev 7Document6 pagesSAIC-L-2095 Rev 7Jaseel KanhirathingalNo ratings yet

- SAIC-A-2001 - Review Procedure - Pressure Testing (All Applications)Document13 pagesSAIC-A-2001 - Review Procedure - Pressure Testing (All Applications)walidNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydro Test) SAIC-A-2013 31-Dec-14Document10 pagesSaudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydro Test) SAIC-A-2013 31-Dec-14pravinNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydro Test) SAIC-A-2013 3-Jul-18Document5 pagesSaudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydro Test) SAIC-A-2013 3-Jul-18karthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Leaks For Tightness Testing SAIC-A-2024 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: Inspection of Leaks For Tightness Testing SAIC-A-2024 3-Jul-18 Mechkarthi51289100% (1)

- Hydrotest ChecklistDocument12 pagesHydrotest ChecklistSami UllahNo ratings yet

- SAIC-A-2013 Rev 6 Hydro PipeDocument6 pagesSAIC-A-2013 Rev 6 Hydro Pipepookkoya thangalNo ratings yet

- Saudi Aramco Inspection Checklist Visual Inspection at Test PressureDocument8 pagesSaudi Aramco Inspection Checklist Visual Inspection at Test Pressurekarthi51289No ratings yet

- Saudi Aramco Inspection Checklist Visual Inspection at Test PressureDocument8 pagesSaudi Aramco Inspection Checklist Visual Inspection at Test Pressurekarthi51289No ratings yet

- 26 Saic A 2009Document5 pages26 Saic A 2009Naveed ShahNo ratings yet

- Saudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechDocument3 pagesSaudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechHamidNo ratings yet

- Saic A 2001Document21 pagesSaic A 2001GanesanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 3-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 3-Jul-18 Mechkarthi51289No ratings yet

- SAIC-A-2023 Rev 6 Prssure Test Air GasDocument5 pagesSAIC-A-2023 Rev 6 Prssure Test Air Gaspookkoya thangalNo ratings yet

- Saudi Aramco Inspection Checklist: Review Procedure - Pressure Testing (All Applications) SAIC-A-2001 15-Nov-17 MechDocument27 pagesSaudi Aramco Inspection Checklist: Review Procedure - Pressure Testing (All Applications) SAIC-A-2001 15-Nov-17 MechNaushad AlamNo ratings yet

- Saic A 2011Document8 pagesSaic A 2011jerinNo ratings yet

- Saic A 2013Document6 pagesSaic A 2013jerinNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistDilshad AhemadNo ratings yet

- Satr K 4003Document3 pagesSatr K 4003Bander Al–kouhlaniNo ratings yet

- SAIC-A-2001 Rev 6 Review Procedure - Pressure Testing (All Applications)Document23 pagesSAIC-A-2001 Rev 6 Review Procedure - Pressure Testing (All Applications)pookkoya thangalNo ratings yet

- SAIC-A-2016 Pneumatic Test of Reinf Pad, Weld+EndsDocument2 pagesSAIC-A-2016 Pneumatic Test of Reinf Pad, Weld+EndsAnonymous S9qBDVkyNo ratings yet

- SAIC-A-2001 Rev 7Document23 pagesSAIC-A-2001 Rev 7shemeemtkmNo ratings yet

- Saudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 30-Apr-13 PipingDocument15 pagesSaudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 30-Apr-13 Pipingpookkoya thangalNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingDocument12 pagesSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingAnonymous 4e7GNjzGWNo ratings yet

- Saic A 2025Document3 pagesSaic A 2025usmanNo ratings yet

- SAIC-A-2025 Rev 6 Pre Test Pressure VesselDocument4 pagesSAIC-A-2025 Rev 6 Pre Test Pressure Vesselpookkoya thangal100% (1)

- SAIC-A-2009 - Verify Test Equipment (Safety Assessment)Document4 pagesSAIC-A-2009 - Verify Test Equipment (Safety Assessment)walidNo ratings yet

- SAIC-A-2006 Rev 6Document16 pagesSAIC-A-2006 Rev 6biplabpal2009No ratings yet

- Saudi Aramco Inspection Checklist Visual Inspection at Test PressureDocument7 pagesSaudi Aramco Inspection Checklist Visual Inspection at Test Pressurepookkoya thangalNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydrotest) SAIC-A-2013 15-Dec-09 MechDocument5 pagesSaudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydrotest) SAIC-A-2013 15-Dec-09 MechEagle SpiritNo ratings yet

- SAIC-A-2023 Rev 0Document2 pagesSAIC-A-2023 Rev 0philipyapNo ratings yet

- Saudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 31-Dec-14 PipingDocument5 pagesSaudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 31-Dec-14 PipingpravinNo ratings yet

- Saic e 2010Document3 pagesSaic e 2010sureshNo ratings yet

- Saic A 2011Document5 pagesSaic A 2011Anonymous 4e7GNjzGWNo ratings yet

- SAIC-A-2026 Rev 6 Pre Test API TankDocument6 pagesSAIC-A-2026 Rev 6 Pre Test API Tankpookkoya thangalNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 30-Apr-17 MechDocument18 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 30-Apr-17 Mechkarthi51289No ratings yet

- SAIC-A-2006 Rev 7Document5 pagesSAIC-A-2006 Rev 7Shyam Sundar GayenNo ratings yet

- Airman Certification Standards: Remote Pilot - Small Unmanned Aircraft Systems (2024): FAA-S-ACS-10BFrom EverandAirman Certification Standards: Remote Pilot - Small Unmanned Aircraft Systems (2024): FAA-S-ACS-10BNo ratings yet

- Saep 38Document23 pagesSaep 38Syed ImranNo ratings yet

- Saep 12Document41 pagesSaep 12Syed ImranNo ratings yet

- 012-Procedure For Vacuum Box TestingDocument9 pages012-Procedure For Vacuum Box TestingSyed ImranNo ratings yet

- SAIC-D-2005 Rev 8Document6 pagesSAIC-D-2005 Rev 8Syed ImranNo ratings yet

- SAIC-D-2004 Rev 8Document3 pagesSAIC-D-2004 Rev 8Syed ImranNo ratings yet

- SAIC-D-2002 Rev 8Document5 pagesSAIC-D-2002 Rev 8Syed ImranNo ratings yet

- SAIC-A-2010 Rev 8Document13 pagesSAIC-A-2010 Rev 8Syed ImranNo ratings yet

- SAIC-H-2010 Rev 8Document2 pagesSAIC-H-2010 Rev 8Syed ImranNo ratings yet

- Heat and Mass Transfer: Haramay University Haramaya Institute of TechnologyDocument50 pagesHeat and Mass Transfer: Haramay University Haramaya Institute of TechnologyworkisaNo ratings yet

- Grade 11 Chemistry - SCH 3U1Document19 pagesGrade 11 Chemistry - SCH 3U1Sasha Kheyson100% (6)

- Edc DiodeDocument11 pagesEdc DiodeAnonymous JnvCyu85No ratings yet

- Ohms LawDocument98 pagesOhms LawIshma BendiolaNo ratings yet

- FINAL Libya ReportDocument111 pagesFINAL Libya Reportadrian armanuNo ratings yet

- GS2011Document29 pagesGS2011Priya MehtaNo ratings yet

- Open Circuit in An Electromechanical CableDocument3 pagesOpen Circuit in An Electromechanical CablefelipeNo ratings yet

- Indonesia RTGC Retrifit 22 Unit - NewDocument189 pagesIndonesia RTGC Retrifit 22 Unit - NewMechatronic EngineeringNo ratings yet

- Maintenance Manual 1400 HP DEMUsDocument556 pagesMaintenance Manual 1400 HP DEMUsKaushal Shrivastava100% (1)

- Shunt Capacitor Bank Fundamentals and ProtectionDocument18 pagesShunt Capacitor Bank Fundamentals and ProtectionDavid MorenoNo ratings yet

- A Review: Mesoporous Santa Barbara Amorphous-15, Types, Synthesis and Its Applications Towards Biorefinery ProductionDocument8 pagesA Review: Mesoporous Santa Barbara Amorphous-15, Types, Synthesis and Its Applications Towards Biorefinery ProductionbenahmedNo ratings yet

- Stirling EngineDocument4 pagesStirling Engineanon-124856100% (7)

- Low Capacitance TVS For LVDS Interfaces: Protection Products - Railclamp Description FeaturesDocument7 pagesLow Capacitance TVS For LVDS Interfaces: Protection Products - Railclamp Description FeaturesFakhri AliNo ratings yet

- RES Unit 3 PPT-converted FinalDocument55 pagesRES Unit 3 PPT-converted Finallingam kavyaNo ratings yet

- Brochure Tecnimont Rev15 Web Con SegnalibroDocument13 pagesBrochure Tecnimont Rev15 Web Con Segnalibroabhinav7373No ratings yet

- 18037959Document5 pages18037959Gathy BrayohNo ratings yet

- Hipot Cable TestingDocument13 pagesHipot Cable Testingsofyan_shah100% (4)

- User's Manual Glow-Wire Tester: (ZRS-3H)Document11 pagesUser's Manual Glow-Wire Tester: (ZRS-3H)FranciscoNo ratings yet

- LECTURE 1 Behaviour of Sound in Enclosed SpacesDocument13 pagesLECTURE 1 Behaviour of Sound in Enclosed Spaces622 MANSI TANJILANo ratings yet

- High-Efficiency, 2A, 16V, 500Khz Synchronous, Step-Down Converter in A 6-Pin Tsot 23 Description FeaturesDocument17 pagesHigh-Efficiency, 2A, 16V, 500Khz Synchronous, Step-Down Converter in A 6-Pin Tsot 23 Description FeaturesAnonymous qpnZNmchFdNo ratings yet

- Selection Table For Residual Current DeviceDocument71 pagesSelection Table For Residual Current DeviceSathiyanathan ManiNo ratings yet

- En 600ugStepUpSine 1Document35 pagesEn 600ugStepUpSine 1cristian mauricio calderon escobarNo ratings yet

- RMIT University Vietnam Busm 4692 - Mibr: Subject CodeDocument12 pagesRMIT University Vietnam Busm 4692 - Mibr: Subject CodePhạmVũĐứcAnhNo ratings yet

- 3Document8 pages3luketsghghNo ratings yet

- Manual-Book-Kijang-Inova-Diesel (Google Tranlated Indonesian To English)Document508 pagesManual-Book-Kijang-Inova-Diesel (Google Tranlated Indonesian To English)Orly Palomar Jr.100% (5)