Professional Documents

Culture Documents

Process Audit Checklist

Process Audit Checklist

Uploaded by

arun pandiyanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Audit Checklist

Process Audit Checklist

Uploaded by

arun pandiyanCopyright:

Available Formats

FORM NO: PH/QA/R/10

POLYHOSE ENTERPRISE LLP REV. NO: 01

MANUFACTURING PROCESS AUDIT CHECKLIST REV DATE: 02/11/2019

PROCESS FLOW CHART NO: Part No: Audited by :

CONTROL PLAN NO: Part description: Audit date :

PFMEA No: Auditee: Audit type Surveillance

S.No Check points Characteristics Spec Actual C NC Observation

Incoming inspection is carried out -

Sampling inspection done based on standards/

Self approved

Incoming

For raw material TC are crossed verified by testing

1

in outside lab

Identification of rejected material are stored

seperately stored

Are equipments used of inspection is calibrated

Shearing Machine

A

PH/WI/06

Plasma PH/PDR/D/02-B

B

Laser PH/PDR/D/02-A

C

Bandsaw cutting PH/WI/04

Machining

Iron worker PH/WI/05

E

Bending

F

PH/WI/02

Page 1 Process audit

S.No Check points Characteristics Spec Actual C NC Observation

Incoming inspection is carried out

Drilling PH/WI/03

G

Rolling PH/WI/01

H

Incoming

1 Availabilityof flow meter and gauges

Wire diameter 1.2mm

Protective sheilding on welding area -

Welding

3 Welding Amp Volt Gas flow

150 - 180

3 to 5mm 20 - 22 V 10-15 lpm

A

Welding parameters

180 - 220

5 to 8 mm 22 - 24 V 10-15 lpm

A

220 - 240

More than 8mm 22 - 24 V 10-15 lpm

A

Shot blasting

Steel grit G-18

Shot blasting

4 Shot blasting parameters Steel shot S- 330

Mixing ratio

1:1

(Grit : Shot)

Current 16-19 Amps

Page 2 Process audit

S.No Check points Characteristics Spec Actual C NC Observation

Incoming inspection is carried out Primer Painting

Apply viscosity 20-22 sec

Pressure 3.5 - 4.5 bar

Painting

Incoming

5

1 Painting parameters

Finish Painting

Apply viscosity 18-22 sec

Pressure 4 - 6 bar

Is the FMEA available and is it reviewed & updated

6

following quality concerns?

Does the FMEA adhere to the process flow and is it

7

linked to the processing sequence numbers?

Are there corrective actions against high risk-priority-

8

numbers?

9 Are control plans are recorded, updated and verified?

Does the control plan adhere to the process flow and to

10 PFMEA and is it linked to the processing sequence

numbers?

Is the Control Plan reviewed and updated following

11

quality concerns?

Are appropriate sampling and control methods

12 identified, including the application of SPC where

required?

Is appropriate inspection, measuring and test

13

equipment identified?

Page 3 Process audit

S.No Check points Characteristics Spec Actual C NC Observation

Incoming

Does the reaction plan inspection is carriedresponses

define appropriate out in

14 the event of out of control, non-capable, and/or

nonconforming conditions?

Incoming

15 Do Cp, Cpk, values meet requirements?

1

16 Is SPC data analyzed for continuous improvement?

Are in process inspections conducted per the control

17 plan and/or other documents and do records

demonstrate conformity to requirements?

Are final inspections conducted per the control plan

18 and do records demonstrate conformity to

requirements?

Is all MME necessary for process controls are available,

19 adequate, calibrated and working in good operating

condition?

Does the Control Plan address all "special" product

20 - - - -

characteristics & process parameters?

Is there a calibration system available for both company

21 - - - -

owned & personal gauges & is calibration up to date?

Are Measurement System Analyses conducted on

22 special characteristics' measurement systems? Do the - - - -

results satisfy the acceptance criteria?

Is first piece inspection required and do records

23 - - - -

demonstrate conformity to requirements?

Are in process/sampling inspections conducted as per

24 - - - -

the control plan?

Page 4 Process audit

S.No Check points Characteristics Spec Actual C NC Observation

25 Incoming

Where applicable, areinspection is carried out

effective Poke-Yokes utilized? - - - -

26 Are there appropriately marked places for scrap? - - - -

Incoming

1

27 Is internal scrap & rework monitored? - - - -

Are SOP's available at all

28 - - - -

operations?

29 Are the SOP's followed by the operators? - - - -

Do the SOP's reference the part

30 - - - -

name, part number, and part revision?

31 Is there a complaint log?

32 Is a disciplined problem solving method used (8D/JDI)

Manufacturing process including the appropriate

33

sampling of the shift handover?

34 Ensure PFMEA covers all rework process?

35 Ensure PFMEA addressed all continual improvements?

36 Ensure fixture verificaton & validation?

37 Ensure FMEA ranking as per requirement.

Auditor signature: Auditee signature :

Page 5 Process audit

You might also like

- Manufacturer Data RecordDocument29 pagesManufacturer Data RecordAdd Gar80% (10)

- 8 Week Muscle Building Blueprint For Mma 8 Week Muscle Building Blueprint ForDocument30 pages8 Week Muscle Building Blueprint For Mma 8 Week Muscle Building Blueprint Forcavaleramax100% (1)

- Ir - L1904-32 17apr19-Mt (Sfjt-E)Document5 pagesIr - L1904-32 17apr19-Mt (Sfjt-E)Alleyson Akin100% (1)

- Jonathan Spence InterviewDocument22 pagesJonathan Spence InterviewJustin LokeNo ratings yet

- Drilling Fluids ManualDocument486 pagesDrilling Fluids ManualParaZzzit100% (12)

- FFT Aura Fence Installation Manual v1.1.2Document104 pagesFFT Aura Fence Installation Manual v1.1.2Usman Zouque100% (2)

- Pre Shortening Insert QAPDocument1 pagePre Shortening Insert QAPtibindas2463No ratings yet

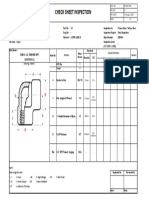

- Check Sheet Inspection: Pt. DffiDocument2 pagesCheck Sheet Inspection: Pt. DffiJovianto PrisilaNo ratings yet

- Milton Roy Job N°: 14006006 Client Contract N°: PTV5015/01Document2 pagesMilton Roy Job N°: 14006006 Client Contract N°: PTV5015/01quangNo ratings yet

- WPS - 0601 00112 01 PDFDocument1 pageWPS - 0601 00112 01 PDFAnonymous zzMwR2aNNo ratings yet

- FRM-Welder Performance Qualification RecordDocument1 pageFRM-Welder Performance Qualification RecordraofrhanNo ratings yet

- Datasheet & Specification For Deluge ValveDocument2 pagesDatasheet & Specification For Deluge ValvechintanNo ratings yet

- 3010-PS003 - 3 Valve ScheduleDocument61 pages3010-PS003 - 3 Valve ScheduleMichael adu-boahenNo ratings yet

- Itp For Tank Fabrication Installation Work1 Rev02 PDFDocument22 pagesItp For Tank Fabrication Installation Work1 Rev02 PDFMichelNo ratings yet

- Position Actual Dimension Remark Drawing / Sketch:: Pt. DffiDocument1 pagePosition Actual Dimension Remark Drawing / Sketch:: Pt. DffiJovianto PrisilaNo ratings yet

- MDR C40 Pt. DmiDocument14 pagesMDR C40 Pt. DmiwidiNo ratings yet

- Cable Trays (ITP E 0002)Document1 pageCable Trays (ITP E 0002)Avishek ChowdhuryNo ratings yet

- Check Sheet Inspection: Pt. DffiDocument2 pagesCheck Sheet Inspection: Pt. DffiJovianto PrisilaNo ratings yet

- Pemex Exploracion Y Produccion Level Instruments (Discplacer or Float) Akal B5-BDocument1 pagePemex Exploracion Y Produccion Level Instruments (Discplacer or Float) Akal B5-BIgnacia Ramon JaimeNo ratings yet

- SJV-EP-IA-011-VP-003 - DATA SHEET - 190117 - 최종Document15 pagesSJV-EP-IA-011-VP-003 - DATA SHEET - 190117 - 최종Jahangir AlamNo ratings yet

- Van Stone Thermowells: Data SheetDocument3 pagesVan Stone Thermowells: Data Sheetjittshong8072No ratings yet

- Qaqc-015 Weld History SheetDocument12 pagesQaqc-015 Weld History SheetUmair KhanNo ratings yet

- Check Sheet Inspection: Pt. DffiDocument2 pagesCheck Sheet Inspection: Pt. DffiJovianto PrisilaNo ratings yet

- Padle Blank 16-900 RTJDocument1 pagePadle Blank 16-900 RTJJovianto PrisilaNo ratings yet

- Process Flow Diagram: Avon Tubetech Pvt. Limited, FaridabadDocument4 pagesProcess Flow Diagram: Avon Tubetech Pvt. Limited, FaridabadHimanshu GaurNo ratings yet

- Computer Engineering, Inc.: WPQ D1.1 - C - 5.2.0 Form 2000 Rev. 0Document1 pageComputer Engineering, Inc.: WPQ D1.1 - C - 5.2.0 Form 2000 Rev. 0Erick GoyesNo ratings yet

- Fit - Up and Visual Examination Report: Attachment Drawing Joint DetailDocument1 pageFit - Up and Visual Examination Report: Attachment Drawing Joint DetailMuhammad Fitransyah Syamsuar Putra100% (1)

- WPQ Process As Per ISO-9606-1 2013Document4 pagesWPQ Process As Per ISO-9606-1 2013Md Anamul Hoque0% (1)

- Inspection and Test Plan: Migas Certification 1 Unit Crawler Crane Lattice BoomDocument4 pagesInspection and Test Plan: Migas Certification 1 Unit Crawler Crane Lattice Boomrizal mubarokNo ratings yet

- Checklist Fire StopDocument9 pagesChecklist Fire StopAnonymous DMdGdsOENo ratings yet

- Quality Assurance PlanDocument8 pagesQuality Assurance Plankamlesh vaishnavNo ratings yet

- Check Sheet Inspection: Position Actual Dimension Remark Drawing / SketchDocument1 pageCheck Sheet Inspection: Position Actual Dimension Remark Drawing / SketchJovianto PrisilaNo ratings yet

- Inspection Test Plan PV Nozzle Modification/AlterationDocument4 pagesInspection Test Plan PV Nozzle Modification/AlterationMohd Shafuaaz KassimNo ratings yet

- 2005 S003 NBPG Rfi 04435Document1 page2005 S003 NBPG Rfi 04435RPDeshNo ratings yet

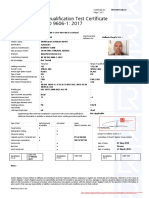

- Welder Qualification Test Certificate BS EN ISO 9606-1: 2017Document2 pagesWelder Qualification Test Certificate BS EN ISO 9606-1: 2017idthdrayahbdnhauniNo ratings yet

- WQTDocument1 pageWQTRamkunwar YadavNo ratings yet

- Check Sheet Inspection: Pt. DffiDocument2 pagesCheck Sheet Inspection: Pt. DffiJovianto PrisilaNo ratings yet

- Position Actual Dimension Remark Drawing / Sketch:: Pt. DffiDocument1 pagePosition Actual Dimension Remark Drawing / Sketch:: Pt. DffiJovianto PrisilaNo ratings yet

- Inspeksi - Steel StructureDocument9 pagesInspeksi - Steel StructureyuwantoniNo ratings yet

- Wqt-Visual-Mag - BS 2Document24 pagesWqt-Visual-Mag - BS 2KyNo ratings yet

- Hex Bushing 0,75 X 0,5Document1 pageHex Bushing 0,75 X 0,5Jovianto PrisilaNo ratings yet

- 06e Inspeksi Pipa BajaDocument5 pages06e Inspeksi Pipa BajaSatria 'igin' Girindra NugrahaNo ratings yet

- PQR - PipeDocument3 pagesPQR - PipeAdvanced Quality Centre AQC100% (1)

- Check Sheet Inspection: Pt. DffiDocument2 pagesCheck Sheet Inspection: Pt. DffiJovianto PrisilaNo ratings yet

- 34222-4010 Itp Rev 0Document2 pages34222-4010 Itp Rev 0anwar sadatNo ratings yet

- Qap - Kongsberg - NabDocument4 pagesQap - Kongsberg - NabDeepak DasNo ratings yet

- Hoja de Datos - RascadorDocument19 pagesHoja de Datos - RascadorCarlos Felipe Reyes MartínezNo ratings yet

- PQR Acero Al CarbonoDocument2 pagesPQR Acero Al CarbonoROBERTO QUESADANo ratings yet

- Inspection and Test Program: Fabrication / In-Process InspectionDocument4 pagesInspection and Test Program: Fabrication / In-Process InspectionGLEDSONNo ratings yet

- Check Sheet Inspection: Position Actual Dimension Remark Drawing / SketchDocument1 pageCheck Sheet Inspection: Position Actual Dimension Remark Drawing / SketchJovianto PrisilaNo ratings yet

- Inspection and Testing Plan (Itp) Item: Instruments Air PipingDocument9 pagesInspection and Testing Plan (Itp) Item: Instruments Air PipingNguyen DienNo ratings yet

- Burckhardt Compression (India) PVT - LTD.: 1.0 MaterialsDocument2 pagesBurckhardt Compression (India) PVT - LTD.: 1.0 MaterialsYOGESHNo ratings yet

- Welder Qualification Test RecordDocument75 pagesWelder Qualification Test RecordVenkatesh Sundarrajan100% (1)

- Inspection Report: 1 - Reference SectionDocument2 pagesInspection Report: 1 - Reference SectionMahesh RINANo ratings yet

- ITP No. 0762022 - GRE - RFIP MRB SA Rev. 0Document4 pagesITP No. 0762022 - GRE - RFIP MRB SA Rev. 0AhmedNo ratings yet

- NDT Request Form - 19Document3 pagesNDT Request Form - 19Firas AlbaweiNo ratings yet

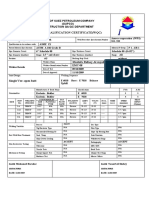

- Welder Qualification Certificate (WQC) : Gulf of Suez Petroleum Company (Gupco) Construction Qa/Qc DepartmentDocument1 pageWelder Qualification Certificate (WQC) : Gulf of Suez Petroleum Company (Gupco) Construction Qa/Qc DepartmentMohamad ShafeyNo ratings yet

- REPORT-MT 21.10.2022 (Test)Document2 pagesREPORT-MT 21.10.2022 (Test)Nhien ManNo ratings yet

- REPORT-MT 21.10.2022 (Test)Document2 pagesREPORT-MT 21.10.2022 (Test)Nhien ManNo ratings yet

- Position Actual Dimension Remark Drawing / Sketch:: Pt. DffiDocument1 pagePosition Actual Dimension Remark Drawing / Sketch:: Pt. DffiJovianto PrisilaNo ratings yet

- 18558-1002 A Quality ITP PDFDocument8 pages18558-1002 A Quality ITP PDFBRENNo ratings yet

- Summary Daily ReportDocument10 pagesSummary Daily Reportdidi sudiNo ratings yet

- Elbow 0,5-3000 NPT - OKDocument1 pageElbow 0,5-3000 NPT - OKJovianto PrisilaNo ratings yet

- AuditDocument1 pageAuditarun pandiyanNo ratings yet

- Inspection ReportDocument4 pagesInspection Reportarun pandiyanNo ratings yet

- Redbus Ticket - DownDocument2 pagesRedbus Ticket - Downarun pandiyanNo ratings yet

- Process Change NotesDocument1 pageProcess Change Notesarun pandiyanNo ratings yet

- Tourism Management: Emily Ma, Huijun Yang, Yao-Chin Wang, Hanqun SongDocument13 pagesTourism Management: Emily Ma, Huijun Yang, Yao-Chin Wang, Hanqun Song韩意颜No ratings yet

- Assignment Rubric Template 8.17.21Document3 pagesAssignment Rubric Template 8.17.21Aris Kendell BungabongNo ratings yet

- Payton Tackett Resume 7 13 22Document2 pagesPayton Tackett Resume 7 13 22api-624729128No ratings yet

- PV Inverter: SUNNY MINI CENTRAL 9000TL / 10000TL / 11000TL With Reactive Power ControlDocument96 pagesPV Inverter: SUNNY MINI CENTRAL 9000TL / 10000TL / 11000TL With Reactive Power ControlIonut Robert BalasoiuNo ratings yet

- Annual Procurement Plan-AppDocument6 pagesAnnual Procurement Plan-AppJonas MapacpacNo ratings yet

- Double Wedding Ring Size Fabric Requirements EditedDocument3 pagesDouble Wedding Ring Size Fabric Requirements EditedfrapatchNo ratings yet

- SCADA System PDFDocument420 pagesSCADA System PDFbambang_gastomoNo ratings yet

- Uterine Fibroids: By: DR Dolapo AduDocument35 pagesUterine Fibroids: By: DR Dolapo AduAdu DolapoNo ratings yet

- Book Review of I Love You Since 1892Document2 pagesBook Review of I Love You Since 1892hannah100% (1)

- Amos PMS GuideDocument26 pagesAmos PMS Guidevuhoan84No ratings yet

- Choosing The Right Home Furniture For Your Own Home Some Advicedcvsx PDFDocument2 pagesChoosing The Right Home Furniture For Your Own Home Some Advicedcvsx PDFVinsonLaw13No ratings yet

- II. DragonsDocument44 pagesII. DragonsKlamMakerNo ratings yet

- District CalendarDocument1 pageDistrict Calendarapi-271737972No ratings yet

- Democratization of Secondary School in MalaysiaDocument12 pagesDemocratization of Secondary School in MalaysiaKavinesh Kaneson100% (1)

- Aols Group 1Document8 pagesAols Group 1Marta SaragihNo ratings yet

- To Biochemistry: Murang'a University of TechnologyDocument6 pagesTo Biochemistry: Murang'a University of TechnologyJoseph NyabugaNo ratings yet

- CNS Depressants TametaDocument29 pagesCNS Depressants TametaJhareinne GardeNo ratings yet

- Co-Designing Machine Learning Apps in K-12 With Primary School ChildrenDocument3 pagesCo-Designing Machine Learning Apps in K-12 With Primary School ChildrenLucas FiordelisiNo ratings yet

- MA Thesis The Role of The Ombudsman in I PDFDocument159 pagesMA Thesis The Role of The Ombudsman in I PDFSweta ToppoNo ratings yet

- Designing English Learning Materials For Tourism Police OfficerDocument3 pagesDesigning English Learning Materials For Tourism Police OfficerArga AnggaraNo ratings yet

- CAPNOGRAPHYDocument10 pagesCAPNOGRAPHYJessica GuzmanNo ratings yet

- BM 1020 - Revision PaperDocument5 pagesBM 1020 - Revision PaperShenali NupehewaNo ratings yet

- A6 Standard Lift Assembly m3 CAN Plasma System: Instruction ManualDocument79 pagesA6 Standard Lift Assembly m3 CAN Plasma System: Instruction ManualJulio De la RosaNo ratings yet

- KWL Comprehension Strategy Handout Copy 2 0 PDFDocument20 pagesKWL Comprehension Strategy Handout Copy 2 0 PDFMuhammad FauziNo ratings yet

- Presented by Aliza Zaina: Usman Rafique PHD (Education) 03007573057Document31 pagesPresented by Aliza Zaina: Usman Rafique PHD (Education) 03007573057Islam Din RahimoonNo ratings yet

- Indriver CloneDocument31 pagesIndriver Clonenetwork.oyelabsNo ratings yet